Professional Documents

Culture Documents

10 MLD Desalination Plant at Ttps Prefeasibility Report

Uploaded by

adalcayde2514Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 MLD Desalination Plant at Ttps Prefeasibility Report

Uploaded by

adalcayde2514Copyright:

Available Formats

TAMIL NADU GENERATION AND DISTRIBUTION CORPORATION LIMITED

10 MLD

Desalination

plant at

10 MLD

Desalination plant

TTPS

at

Tuticorin Thermal Power Station

Prefeasibility Report

September 2014

TTPS Desalination plant

List of contents

S.No

1.0

1.1

1.2

1.3

1.4

1.5

2.0

2.1

2.2

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

10.1

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

11.0

11.1

11.2

12.0

13.0

14.0

15.0

Description

Introduction

Location

Nature of the project

Project Proponent

Need for the Project

Project Description Site data

About Existing Thermal Power Station

Installed Capacity

Land

Present status of Raw Water drawal

Water requirement for the power plant

Location of Desalination Plant

Intake location of sea water

Outfall location of Brine

Mode of conveyance of sea water and brine

General details of proposed desalination plant

Treatment scheme and operation data

Water treatment plant

Operating data of pre treatment system

Filtration system

Operating data for filters

Operating data ultra filtration

Desalination system

Operating data for plant

Tanks and building involved

Equipment and pumps involved

System Description

Section 1 Pre treatment system

Section II SWRO

Equipments involved in desalination plant

Cost of the project

Financial Analysis

Conclusion

Page

No

1

1

1

1

1

3

3

4

4

4

5

6

6

6

6

7

8

8

8

9

9

9

10

10

11

11

12

12

14

18

20

22

22

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

1.0. INTRODUCTION

Tamil Nadu Generation and Distribution corporation Limited (TNEB Ltd,) has proposed to

construct and operate one Desalination Plant of capacity 10 MLD at Tuticorin Thermal Power

Station campus to meet the Raw water requirement of its 5 x 210 MW capacity Thermal

Power Station.

The project falls in the vicinity of Coastal Regulation Zone (CRZ) of Mullakkadu Village. The

site area has flat topography with Gulf of Mannar on the north, east and south and

Korapallam creek in the west. The area around the site is fully developed and well

connected with national highways and ports.

1.1. LOCATION

The Desalination Plant will be located inside Tuticorin Thermal Power Station campus which

is 20 Km from Tuticorin Airport. Tuticorin is located about 600 Km South of Chennai city.

1.2. NATURE OF THE PROJECT

It is a sea water desalination plant with two pass Reverse Osmosis process, of capacity

10 MLD.

1.3 PROJECT PROPONENT

The project proponent is TANGEDCO (Tamil Nadu Generation and Distribution

Corporation Limited) for the proposed project of 10 MLD desalination plant.

1.4 NEED FOR THE PROJECT

It is proposed to meet the raw water requirement of Tuticorin Thermal Power Plant.

Presently, the main source of raw water for Tuticorin Thermal Power Station is

Papanasam Dam. Now, year by year the rainfall quantum has reduced gradually in the

catchment area of Papanasam dam and the dam does not fill to its full capacity. During

the recent past years, water shortage has been faced regularly during the summer

months. Last year sufficient quantity of rainfall was not received during south west

monsoon. North east monsoon also failed last year.

_____________________________________________________________________________________________

Page 1 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

In the future years TTPS may have to face the increasing supply - demand gap and the

generation of 5 x 210 MW from TTPS may become critical.

Further the Tuticorin District Collector convened a meeting on 21.06.2012 in which all

the beneficiaries of 20 MGD closed conduit scheme along with PWD & TWAD board

officials participated. In the meeting the District Collector informed that the water of the

River Tambiraparani supplied by TWAD board through 20 MGD closed conduit scheme

to various beneficiaries would be restricted for supplying the entire water to the public

and for Agriculture in the District. The administration is facing public / Agriculturist

protests and agitations in the District often.

Further instructed that the beneficiaries including TTPS may have to arrange their own

source of Raw water by establishing Desalination plant at their cost individually or in

connection with the TWAD board.

_____________________________________________________________________________________________

Page 2 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

PROJECT DESCRIPTION

1.5. SITE DATA

The proposed power plant site is situated inside the existing Tuticorin Thermal Power

Station complex Tuticorin, Tamil Nadu.

1.5.1. Meteorological data

Maximum Dry Bulb temperature :

38.5 0C

Minimum Dry Bulb Temperature :

21.3 0C

1.5.2. Humidity

Maximum humidity

85%

Minimum humidity

70%

Maximum

100 km/hr

Minimum

78 km/hr

1.5.3. Wind Velocity

1.5.4. Rainfall

Maximum average rainfall :

1111.1 mm

Minimum average rainfall :

450.5 mm

1.5.5. Access to site

By Road

: National Highway (NH) 7A, 4 km from the site

By Sea

: Tuticorin Harbour 6 km from site

By Air

: Tuticorin Airport 24 km from site

1.5.6. Railway siding

: Available within 3 km from the site.

2.0. ABOUT EXISTING THERMAL POWER STATION (5 x 210MW):

Tuticorin Thermal Power Station is located at about 8 K.M. from Tuticorin Town. The basic

requirements for running a Thermal Power Station are easily met at Tuticorin. The raw

water for the Power Station is obtained from Thamiraparani river, Coal from Bengal-Bihar

coal mines by ship, and the cooling water from the Tuticorin harbour basin. The project was

_____________________________________________________________________________________________

Page 3 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

cleared in 1973 and the work at site commenced in January 1976. The area for the Power

House, about 160 Hectares (395 acres) was taken on lease from the Port Authorities. The

Project was erected in three stages. The first stage comprising of 2 x 210 MW Units, the

second stage 1 x 210 MW Unit and third stage 2 x 210 MW Units. Now the total installed

capacity is 1050 MW. The estimated cost of the station is Rs. 1,071 Crores. (approx).

2.1. INSTALLED CAPACITY

I

II

III

Stage

Stage

Stage

2 x 210 M.W.

1 x 210 M.W.

2 x 210 M.W.

The full generating capacity of 1050 MW was achieved on 07-01-1994.

2.2. LAND

2.2.1. Power House Area:

2.2.2

Soil:

0 3.75 m

3.75 4.50 m

4.50 6.00 m

Below 6.00 m

Water table

Chemical properties

About 160 hectares (395 acres)

Fine Sand

Soft to medium stiff clay

Dense to very dense sand mixed with

Rock and Gravel

Coral sand stone

About 1.1 m below G.L.

Presence of sulphates harmful for foundation

3.0. PRESENT STATUS OF RAW WATER DRAWAL:

At present the raw water requirement of TTPS is being met out from the water supply

by TWAD board through 20 MGD scheme from Tamiraparani river basin.

TWAD board has allotted 3.5MGD (million gallons per day) i.e., 15.89 MLD of water

from their source from Tamirabarani at Manjaneerkayal under 20 MGD scheme to TTPS.

Now TTPS utilizes about 1.75 MGD of water for D.M. plant, other service purposes and

Township usage. TWAD Board receives

water from Tambiraparani

River

at

Srivaikundam Dam through closed conduit pipes to Manjaneerkayal which is 20 km

away from TTPS and after filtration the clear water is pumped from Manjaneerkayal

Head works through 20 MGD lines to Tuticorin Industrial complex.

_____________________________________________________________________________________________

Page 4 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

Since Tuticorin Thermal Power Station is located at the tail end of the 20 MGD line, one

booster pump house was provided, near SPIC to supply the required quantity of water

to Power Station. There are four ground level reservoirs at the Power Station.

GLR 1 : capacity 5 MG [22.7 Million Litre]

GLR 2 : capacity 5 MG [22.7 Million Litre]

GLR 3 : capacity 10 MG [45.4 Million Litre]

GLR 4 : capacity 20 MG [90.8 Million Litre]

There are two over head tanks of 0.6 Million Litres capacity each. The ground

level reservoirs can meet the requirements of the power station for about one week.

The water system of the Power Station consists of three grades.

One is DM water used for Boiler and Generator Stator cooling. The other is

filtered water used for Auxiliary cooling water system. The third is service water used

for various purposes like Seal water, Coal wetting, Dust suppression, etc.

4.0. WATER REQUIREMENT FOR THE POWER PLANT:

The water requirement for TTPS is as follows.

D.M. Plant I & II (Boiler)

: 100 KL / Hour

Potable water

5 KL / Hour

Auxiliary CWPH

25 KL / Hour

Regeneration

20 KL / Hour

Service water

: 180 KL / Hour

Township:

Camp I

Camp II

:

:

35KL / Hour

35KL / Hour

Total : 400KL / Hour

Total water required per day 24 Hours x 400KL = 9600KL

_____________________________________________________________________________________________

Page 5 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

5.0. LOCATION OF DESALINATION PLANT:

The Proposed Desalination Plant will be located within CRZ (Costal Regulation Zone).

An area of 30,400 Sqm is available in eastern side of Cooling water pump house in

between cooling water channel for unit 1,2 & 3 and northern compound wall. This area

is sufficient for the proposed Desalination plant.

The following are the Latitude and longitude of the four corners of the proposed

location.

Latitude

Longitude

North West Corner:

80 45 56.3 N

780 10 50.9 E

North East Corner :

80 45 52.4 N

780 11 02.0 E

South East Corner:

80 45 50.5 N

780 11 01.9 E

South West Corner:

80 45 52.3 N

780 10 50.1 E

6.0 INTAKE LOCATION OF SEA WATER:

It is proposed to draw sea water for this Desalination Plant from cooling water pump

house-I. Sufficient sea water is available at CWPH-I in addition to the requirement for

unit I, II and III.

The inflow at CWPH-I is about 1, 25,000 m3 per hour

Water used for cooling purpose for unit I, II and III is about 94,500 m3 per hour.

Water requirement for this Desalination Plant is about 1,250 m3 per hour.

7.0 OUTFALL LOCATION OF BRINE

It is proposed to dispose the brines at outfall arrangements for unit I, II & III. About

90,000 m3 per hour of sea water is being let-out from unit I, II & III through the outfall

structure. The brines disposal from this Desalination Plant is about 833.33 m3 per hour.

8.0 MODE OF CONVEYENCE OF SEA WATER AND BRINE

It is proposed to convey the sea water from cooling water pump house-I to this

Desalination Plant by buried pipe line. The pipe line may be HDPE pipe of size 630mm

outer dia. The brine disposal will also through buried pipe line of size 450mm outer dia

HDPE pipe. For conveying raw water produced from this Desalination Plant to GLRs, it is

proposed use 300mm dia MS ERW pipe.

_____________________________________________________________________________________________

Page 6 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

9.0 GENERAL DETAILS OF PROPOSED DESALINATION PLANT:

9.1 BASIS OF DESIGN AND TREATMENT SCHEME:

To meet the water requirement of 5 x 210 MW coal based power plant at TTPS

TANGEDCO intends to set up a sea water reverse osmosis based desalination plant of

capacity 10 MLD.

9.2 SEA WATER ANALYSIS:

The following are the typical sea water parameter for basis of design system.

01.

pH

8.5 8.8

02.

Conductivity

86000 micro-mhos / cm

03.

Turbidity

5 NTU

04.

Total Dissolved Solids

05.

COD

150 ppm

06.

Chloride as CI

19896 ppm

07.

Oil and Grease

2 mg / litre

08.

Density

1.02 gm / cc

46000 ppm

Cations, Anions, Heavy metal, Suspended Particle size range and Colloidal particle size

range could not be analyzed with existing available infrastructure facility.

9.3 REQUIRED QUALITY OF TREATED WATER:

Ref: Ion Exchange (India) Manual Raw water quality for DM Plant

01.

M. Alkalinity as CaCO3

156 mg / litre

02.

Chloride as CaCO3

03.

Sulphate as CaCO3

04.

Total Hardness as CaCO3

05.

Calcium Hardness as CaCO3

06.

Magnesium Hardness as CaCO3 _

07.

Silica as SiO2

08.

Sodium as CaCO3

09.

Conductivity

99 mg / litre

72 mg / litre

_ 130 mg / litre

_

40 mg / litre

_

90 mg / litre

30 mg / litre

197 mg / litre

600 micro mhos / cm

_____________________________________________________________________________________________

Page 7 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

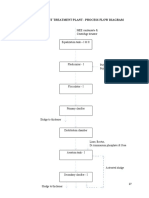

10.0 TREATMENT SCHEME AND OPERATION DATA:

10.1 WATER TREATMENT PLANT:

PRE TREATMENT FOR DESALINATION PLANT:

The sea water shall be treated through the following Treatment Stages.

S.No

Description

1.

Flow Control Station

2.

Stilling chamber NaOCl dosage from ECP to remove Algae.

3.

Flash mixer Fecl3 coagulant dosage to remove turbidity.

4.

Floccullatorcoagulant aidpoly electrolyte dosage to remove colloidal silica

5.

Clarifier

6.

Pressure sand filter.

7.

Filter water storage.

8.

Electro chlorination

9.

Hypo Degassing

10.

Ultra filtration skid (UF)

11.

UF permeate cum back wash

12.

First pass R.O

13.

Potable water storage

10.2 OPERATING DATA OF PRE TREATMENT SYSTEM:

S.No

Description

Unit

1.

Nos. of units offered

2 Nos

2.

Output Capacity of each unit

580 m3 / hour

3.

Operating Hours

24 Hrs3

_____________________________________________________________________________________________

Page 8 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

10.3 FILTRATION SYSTEM:

The clarified water from clarified water storage tank shall be treated through the

following treatment Stages.

S.No

Particulars

1.

Pressure Sand Filter

2.

Backwash pump for Filter Unit

3.

Filter Air Blower

4.

Ultra filtration

5.

CEB backwash pump

6.

CEB backwash chemical dosing system

7.

UF product water tank

10.4 OPERATING DATA FOR FILTER:

S.No

Description

Unit

1.

Nos. of Streams offered

6 Nos

2.

Feed flow rate per stream

290 m3 /hr

3.

Operating Hours

24 Hrs

4.

Mode of Operation

Semi Automatic

10.5 OPERATING DATA ULTRA FILTRATION:

S.No

Description

Unit

1.

Nos. of Streams offered

3 Nos

2.

Feed flow rate per stream

387 m3 /hr

3.

Product flow rate per stream

347 m3 /hr

4.

Recovery

90%

3.

Operating Hours

24 Hrs

4.

Mode of Operation

Automatic

_____________________________________________________________________________________________

Page 9 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

10.6 DESALINATION SYSTEM:

The UF treated water from UF product water tank shall be treated through the

following treatment Stages.

S.No

Particulars

1.

MCF Feed Pumps

2.

Micron Cartridge Filter

3.

Anti scalant Dosing System

4.

SMBS Dosing System

5.

Acid dosing system

6.

High pressure pump with ERD (Turbocharger) system for RO unit

7.

Sea water Reverse Osmosis unit

8.

Chemical cleaning system

9.

Flushing System

10.

Desalinated water storage Tank

10.7 OPERATING DATA FOR PLANT:

S.No

Description

Unit

1.

Nos. of Streams offered

2 Nos

2.

Feed flow rate per stream

522 m3 /hr

3.

Product flow rate per stream

209 m3 /hr

4.

Recovery

40%

3.

Operating Hours

24 Hrs

4.

Mode of Operation

_____________________________________________________________________________________________

Page 10 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

10.8 TANKS & BUILDING INVOLVED:

Tanks & Building involved

1) Stilling chamber

2) Flash mixer (RCC)

3) Flocculation chamber (RCC)

4) Clarifier (RCC)

5) Valve pit (RCC)

6) Sludge tank (RCC)

7) Gravity sand filter (RCC)

8) Filter water storage tank

9) Electro chlorination building

: 10) Pre treatment chemical house

: 11) Pre treatment pump house (RCC)

: 12) Reject tank (RCC)

: 13) UF cum back wash storage tank (RCC)

: 14) Electrical building (RCC)

: 15) AC plant and ventilation room

: 16) UF and R.O. building

: 17) Potable water tank

10.9 EQUIPMENT & PUMPS INVOLVED:

Equipments and pumps involved

1) Sludge Dosage and Recycle pump

2) Gravity filter back wash pump

3) Ultra Filtration (UF) feed pump

4) UF cleaning pump

5) UF back wash pump

6) 1st pass R.O. Cartridge filter feed pump

7) 1st pass R.O. High pressure pump

8) Booster pump

9) Service water pump

: 10) Feed pump for service water

_____________________________________________________________________________________________

Page 11 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

: 11) Potable water pump for plant

: 12) Potable water pump for camp

: 13) Regeneration pump

: 14) Continuous Dosing pump for pre treatment

plant

: 15) Continuous Dosing pump for post

treatment plant

: 16) Continuous Dosing pump for CW

: 17) Shock Dosing pump for CW

: 18) Shock Dosing pump for UF cleaning

: 19) Reject Disposal pump

: 20) Alkali unloading and transfer pump

: 21) Acid unloading and transfer pump

: 22) Coagulant unloading transfer pump

: 23) Electro chlorination feed pump

: 24) 1st pass R.O. cleaning pump

: 25) 1st pass Alkali Dosing pump

: 26) 1st pass R.O. acid Dosing pump

: 27) 1st pass R.O. Antioxidant Dosing pump

: 28) 1st pass R.O. Anti sealant Dosing pump

: 29) Coagulant acid Dosing pump

: 30) Coagulant Dosing pump

11.0 SYSTEM DESCRIPTION:

11.1 SECTION I: PRE-TREATMENT SYSTEM:

Incoming Sea water is first treated by this Pre-treated system to produce filtered

water suitable for further treatment by desalination plant for production of Desalinated

water. A brief description of Pre-tr

eatment plant is as below.

11.1.1 STILLING CHAMBER:

Seawater shall be first passed through a Stilling chamber where turbulence of water

will be dampened out. Stilling chamber shall be in a RCC construction with suitable

detention time.

_____________________________________________________________________________________________

Page 12 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

11.1.2 FLASH MIXER:

Flash mixers are specially designed for the process requirement in the water and

wastewater treatment.

The mixer design ensures efficient, minimum energy

consumption and long life. This equipment blends coagulants and other chemicals with

water / wastewater prior to flocculation.

The aggressive agitation results in

instantaneous and effective mixing of chemicals. This unit is also useful for general

mixing.

11.1.3 DUAL MEDIA SAND FILTERS:

Filtered water from clarifier shall be further filtered by dual media sand filter unit in

order to remove suspended matters of turbidity present in water.

11.1.4. FILTER BACHWASH SYSTEM:

The water required for backwashing of Pressure Sand Filter is supplied from RO

reject water tank.

11.1.5 AIR SCOURING BLOWER FOR FILTERS:

Low pressure high flow air is supplied to media filter (PSF) with the help of this

filter air blower for loosening of filter bed during backwashing. Each blower is fitted with

suction air filter, discharge pipe work, Non return valve, isolation valves & Pressure

gauge at discharge.

11.1.6 SLUDGE PIT:

Sludge generated by clarifier is collected in the sludge pit which shall be then

transferred to ash pond through sludge disposal pumps.

11.1.7 ULTRA FILRATION:

Ultra filtration (UF) is a variety of membrane filtration in which hydrostatic

pressure forces a liquid against a semi permeable membrane. Suspended solids and

solutes of high molecular weight are retained, while water and low molecular weight

_____________________________________________________________________________________________

Page 13 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

solutes pass through the membrane. Feed water shall enter from bottom and treated

water shall be collected from another end. Reject water shall be collected from top and

shall be drained on constant basis part of UF permeate will be used for backwashing.

11.1.8 CHEMICAL ENHANCING BACKWASH OF UF SYSTEM:

After some cycles of operation of UF system chemical enhance backwash is

required. For this purpose hydrochloric acid, Caustic and sodium hypo chlorite solutions

are used.

These solutions are prepared in right concentration in different tank of

suitable material. Metering type pumps are used for this purpose. These chemicals are

dosed in the backwash line. Pumps of suitable capacity & suitable head are provided

for the backwash of UF unit.

11.1.9 UF PRODUCT WATER STORAGE TANK:

UF product water then shall be transferred to UF permeate water tank. It is of

RCC construction with suitable lining.

11.2 SECTION-II SWRO:

11.2.1 SMBS DOSING SYSTEM:

Pre-treated feed may contain some residual chlorine based on the chlorine

consumed in the system. Since free chlorine is dangerous for RO membranes, it needs

to be neutralized before the water enters RO block.

For preventing chlorine from entering into RO system, a de-chlorination agent in

terms of sodium Meta Bi-Sulphite is dosed in specific proportion. SMBS is dosed with

the help of dosing pump in line and solution preparation tank.

_____________________________________________________________________________________________

Page 14 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

11.2.2 ANTI-SCALANT DOSING SYSTEM:

During Reverse Osmosis process, dissolved salts are concentrated reject side as

permeate water is being drawn at a specific recovery. As a result of this, dissolved salts

concentration increases on reject end and may precipitate if saturation limit exceeds.

As a resultant effect of salt concentration, scaling (deposition) occurs on membrane

surface which results in reduced flow rate and increased pressure requirement in RO

system.

For prevention of scaling and anti scalent formulation is closed in specific

proportion. For anti scalent closing purpose closing pumps and solution preparation

tanks are provides.

11.2.3 ACID DOSING SYSTEM:

Since raw water analysis indicates wide range for pH, provision for acid dosing

system has been provided as an additional safety for prevention of scale formation on

RO membranes.

For acid dosing purpose dosing pumps and solution preparation tanks are

provided.

11.2.4 MICRON CARTRIDGE FILTER:

After chemical dosing, RO feed water may get contaminated with very fine

suspended matters.

To supply highly filtered water micron cartridge filter units are

provided in parallel operation. Each MCF unit is a vertical pressure vessel. Internally it

is fitted with PP wound depth type micron cartridge filter element. Water to be filtered

passed though this cartridge element to produce highly filtered RO feed water.

11.2.5 HIGH PRESSURE PUMP (WITH ENERGY RECOVERY DEVICE): Multi stage

Horizontal centrifugal type of High pressure pump with energy recovery device shall be

provided for supply of high pressure filtered water to RO system.

_____________________________________________________________________________________________

Page 15 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

Each pump shall be fitted with super duplex piping (high pressure side) and same

material of construction for pump.

Necessary instruments & isolation valves are

provided for necessary control of system. An energy recovery device (Turbocharger) is

used to recover significant energy available in RO brine stream there by reducing the

pumping cost.

11.2.6 ENERGY RECOVERY DEVICE:

Turbocharger is a unique energy recovery turbo pump designed specifically for

reverse osmosis service. The Turbo provides a direct pressure boost to the RO feed

stream from energy recovered from the brine stream.

This pressure transfer is

accomplished in a single casing design utilizing a rotor on which turbine and pump

impellers are mounted on the same shaft.

High-pressure brine from the RO membranes enters the turbine volute

tangentially through a titanium nozzle where the brine pressure energy is partially

converted to a high velocity flow. This flow then enters a Francis type reaction turbine

where additional fluid energy is converted to shaft work. The mechanical shaft energy

produced by the turbine is converted back to pressure energy by the pump impeller.

11.2.7 REVERSE OSMOSIS SYSTEM:

Sea water RO system is provided for removal of salinity from feed sea water. RO

system comprises of spirally wound Seawater RO membranes, housed in FRP Pressure

tubes.

RO pressure tubes shall be mounted horizontally on Mild Steel Structural

fabricated/Epoxy painted RO Skid. For each stream, a feed, product and reject header

with End ports connection and victaulic coupling are provided for easy maintenance.

For monitoring of various parameters like pressure, flow, & conductivity,

respective field mounted indicators/micro processors based analyzing instruments are

_____________________________________________________________________________________________

Page 16 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

provided at required location. An electrical & instrumentation panel with PLC control is

provided for semi automatic operation of RO system.

Product water from each RO

system is finally collected & stored in permeate water storage tank.

11.2.8 SUCK BACK TANK:

Each RO skid is provide with suck back tank arrangement.

The main motive

behind providing this provision is to ensure that RO system is protected from any back

pressure, deposition of salinity during the shutdown of the RO system.

11.2.9 DESALINATED WATER STORAGE TANK:

Permeate water is stored in a permeate water storage tank.

11.2.10 CHEMICAL CLEANING SYSTEM & RO FLUSHING SYSTEM:

This system comprises of a Chemical solution preparation tank, a micron cartridge filter

unit chemical cleaning pump & flexible hoses Cleaning of membrane is carried out at a

regular duration for removal of any deposition of organic salts, suspended matters,

Microbiological impurities on membrane surface over a continuous period of usage. The

Cleaning chemical is passed in the same direction as that of feed water flow in order to

remove the deposition from membranes.

Prescribed chemical solution of required

concentration is prepared in tank. It is re-circulated with the help of chemical cleaning

pump and micron cartridge filter through RO system at specified flow rate and pressure

after primary flushing with permeate water. After cleaning, permeate shall be used for

RO system flushing and final cleaning.

11.2.11 BRINE WATER TANK AND TRANSFER PUMPS:

Reject from PSF backwash water and UF reject water and from SWRO system

shall be collected in this tank. This will be disposed off to the sea in the cooling water

outfall of units I,II and III.

_____________________________________________________________________________________________

Page 17 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

12.0 EQUIPMENTS INVOLVED IN DESALINATION PLANT:

S.No

Description

Quantity

1.

Flow control station

1 No

2.

Electro chlorination system

1 No

3.

Stilling chamber (1 min retention time)

1 No

4.

Coagulant dosing arrangement

2 Nos.

5.

Flash mixer (1min retention time)

2 Nos.

6.

Agitator for flash mixer

2 Nos.

7.

Flocculator (1min retention time)

2 Nos.

8.

Agitator for Flocculator

4 Nos.

9.

Clarifier

2 Nos.

10.

Media for Clarifier

2 Nos.

11.

Isolation gates for Pre-treatment system

4 Nos.

12.

Sludge pit (4 hours retention)

13.

Sludge disposal pump

2 Nos. (1W +1S)

14.

Air blower for sludge pit

2 Nos. (1W + 1S)

15.

Air grid arrangement for sludge pit

1 Lot

16.

Fecl3 bulk storage tank

2 Nos.

17.

Fecl3 unloading pump

2 Nos. (1W + 1S)

18.

Fecl3 dosing tank

2 Nos.

19.

Agitator for Fecl3 dosing tank

2 Nos.

20.

Fecl3 dosing pump

21.

PE dosing tank

2Nos.

22.

Agitator for PE dosing tank

2 Nos.

23.

PE dosing pump

24.

PT service water preparation tank

1 No

25.

PT chemical storage building (2 storeyed)

1 No

1 No

4 Nos. (2W + 2S)

4 Nos. (2W + 2S)

_____________________________________________________________________________________________

Page 18 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

26.

Electrical hoist for chemical building

1 No

27.

Weighing scale for chemical building

1 No

28.

Clarified water storage tank-2 compartment

1 No

(4 hrs retention)

29.

Filter feed pump

5 Nos. (4W + 1S)

30.

Pressure sand filter

5 Nos. (4W + 1S)

31.

Media for PSF

32.

Filter backwash pump

2 Nos. (1W +1S)

33.

Air blower for filter backwash pump

2 Nos. (1W +1S)

34.

Basket strainer for UF

3 Nos.

35.

UF skid

3 Nos.

36.

UF membranes

1 Lot

37.

UF backwash pump

38.

Acid dosing tank for CEB

2 Nos.

39.

Acid dosing pump

2 Nos.

40.

Alkali dosing tank for CEB

2 Nos.

41.

Alkali dosing pump

2 Nos.

42.

NaoCl dosing tank for CEB

2 Nos.

43.

NaoCl dosing pump

2 Nos.

44.

UF product cum backwash water storage tank

45.

SWRO feed pump

3 Nos. (2W +1S)

46.

Acid dosing tank

4 Nos.

47.

Acid dosing pump

3 Nos. (2W +1S)

48.

Antiscalant dosing tank

4 Nos.

49.

Agitator for antiscalant dosing tank

4 Nos.

50.

Antiscalant dosing pump

51.

SMBS dosing tank

1 Lot

3 Nos. (2W +1S)

1 No

3 Nos. (2W +1S)

4 Nos.

_____________________________________________________________________________________________

Page 19 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

52.

Agitator for SMBS dosing tank

4 Nos.

53.

SMBS dosing pump

3 Nos. (2W +1S)

54.

Micron cartridge filter

3 Nos. (2W +1S)

55.

Cartridges for MCF

56.

SWRO high pressure pumps (Turbocharger)

57.

Turbocharger

58.

SWRO skids

2 Nos.

59.

SWRO membranes

1 Lot

60.

SWRO pressure tubes

1 Lot

61.

Suck back tank

2 Nos.

62.

Desalinated water cum fire water storage tank

1 No

63.

RO CIP tank

1 No

64.

RO CIP pump

2 Nos. (1W +1S)

65.

Cartridge filter for RO CIP

66.

SWRO flushing pump

67.

Reject / Brine water tank

68.

Miscellaneous

69.

Safety shower

1 Lot

70.

Dissolving basket

1 Lot

71.

Interconnecting piping

1 Lot

72.

Access ladder, walkway and handrials

1 Lot

1 Lot

3 Nos. (2W +1Store)

2 Nos. (2W +0S)

1 No

2 Nos. (1W +1S)

1 No

13.0. COST OF THE PROJECT

The project cost for the proposed Desalination plant of capacity 10 MLD is arrived at

based on the estimated unit cost which includes all machineries, erection charges, civil

works etc., and includes the cost towards interest during construction. A brief summary

is given below

_____________________________________________________________________________________________

Page 20 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

13.1. CAPITAL COST

Sl.No Particulars

Amount

1

Land lease rent & development

1,09,44,000

30400 sq.m x 36.00x10

2

Environment Impact Assessment study, Environment

Management plan, DPR, Obtaining mandatory

50,00,000

clearances etc.,

3

Design, Engineering, supply of equipments and

components for SWRO plant, erection and

51,10,00,000

commissioning

4

Approximate cost for spares for 2 years

3,14,00,000

4

Cost for Intake and Brine disposal system

17,44,00,000

5

Interest during construction

16,12,03,680

73,27,44,000 x 22/100

Total project cost

89,39,47,680

13.2. WORKING CAPITAL (FOR 5 YEARS)

Description

Operation and Maintenance cost

Value (Rs.)

19,66,00,000

Cost of consumables and chemicals

7,50,00,000

Cost of consumption of O&M power

16,50,00,000

Total

43,66,00,000

13.3. TOTAL CAPITAL INVESTMENT

Fixed Capital

Working Capital per year = 43,66,00,000/5

Total

89,39,47,680

8,73,20,000

98,12,67,680

_____________________________________________________________________________________________

Page 21 of 22

Prefeasibility Report for Desalination plant at TTPS

Establishing a Desalination Plant of Capacity 10 MLD at TTPS

Pre Feasibility Report

_______________________________________________________________________________________

14. FINANCIAL ANALYSIS

14.1. COST OF PRODUCTION (PER YEAR)

Cost of Production (per year)

(Rs.)

Total Recurring Cost

8,73,20,000

Interest on Total Capital Investment @ 22%

(98,12,67,680 x 22/100)

21,58,78,889.6

Total

30,31,98,889.6

14.2. TURNOVER (FOR 1 YEAR)

Qty per year

Cost per KL

3650000 KL water

30,31,98,889.6/3650000 = 83.06

15. Conclusion

The proposed desalination plant will cater the raw water requirement of TTPS. The

present requirement of 10 MLD water is supplied by the TWAD Board.

By establishing the new Desalination plant, the water supplied by the civic body could

well be utilized for the domestic usage.

_____________________________________________________________________________________________

Page 22 of 22

Prefeasibility Report for Desalination plant at TTPS

You might also like

- Degremont - Desalination (Eng)Document6 pagesDegremont - Desalination (Eng)Juanmiguel1968No ratings yet

- Doosan Heavy Industries & Construction - Global Leader in Water SolutionsDocument20 pagesDoosan Heavy Industries & Construction - Global Leader in Water Solutionsvasilev_darkoNo ratings yet

- Multi Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingDocument8 pagesMulti Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingMuhammadEhtishamSiddiquiNo ratings yet

- BAB 5 Seawater DesalinationDocument75 pagesBAB 5 Seawater DesalinationShanna Sinaga100% (1)

- SWRO Design and OptimizationDocument27 pagesSWRO Design and OptimizationJames N Velinsky100% (1)

- Methodology, O&M PhylosophyDocument11 pagesMethodology, O&M PhylosophyVuthpalachaitanya KrishnaNo ratings yet

- Reverse OsmosisDocument11 pagesReverse Osmosisindry100% (1)

- Bap - Bwro SystemDocument55 pagesBap - Bwro SystemGloria HamiltonNo ratings yet

- Desalination Plant at Bhgavnagar Mundra in Gujarat On PPPDocument17 pagesDesalination Plant at Bhgavnagar Mundra in Gujarat On PPPJay TailorNo ratings yet

- Groundwater Management Plan for Iloilo CityDocument92 pagesGroundwater Management Plan for Iloilo CityMae Ann GonzalesNo ratings yet

- Tor Indonesia PDFDocument44 pagesTor Indonesia PDFzulkifliharahapNo ratings yet

- Desalination, The Sustainable AlternativeDocument12 pagesDesalination, The Sustainable AlternativeIhsan SalimNo ratings yet

- Prensentation Slides For Industry BriefingDocument40 pagesPrensentation Slides For Industry BriefingkunalkhubaniNo ratings yet

- AdvancedWatertek BrochureDocument5 pagesAdvancedWatertek BrochureAnonymous whI91WzNo ratings yet

- Project Execution PlanDocument20 pagesProject Execution Planprabhu rajendranNo ratings yet

- Site Water Balance: MAC-ENC-PRO-059Document21 pagesSite Water Balance: MAC-ENC-PRO-059Yazid Eriansyah PradantaNo ratings yet

- Main Report Hapur STPDocument121 pagesMain Report Hapur STPManoj PatneNo ratings yet

- The Universal Traveler Don Koberg Jim Bagnall PDFDocument12 pagesThe Universal Traveler Don Koberg Jim Bagnall PDFRevathi Hariharan0% (1)

- RO System Quotation 20m3/h 73% RecoveryDocument6 pagesRO System Quotation 20m3/h 73% Recoverytata_77No ratings yet

- Desalination and Water TreatmentDocument10 pagesDesalination and Water Treatmentl209No ratings yet

- Voutchkov (2010) CoinsiderationdForSelectionOfSeawaterFiltrationPretrementSystem Desalination (261 354-364Document12 pagesVoutchkov (2010) CoinsiderationdForSelectionOfSeawaterFiltrationPretrementSystem Desalination (261 354-364Shamma DamaniNo ratings yet

- Operating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryDocument12 pagesOperating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryJoshua OmolewaNo ratings yet

- Two Pass SWRO Tender Technical SpecificationDocument369 pagesTwo Pass SWRO Tender Technical Specificationmarksion exchangeNo ratings yet

- Journal of Water Process Engineering: SciencedirectDocument8 pagesJournal of Water Process Engineering: SciencedirectOmar GameelNo ratings yet

- Economic and Technical Analysis of Reverse OsmosisDocument13 pagesEconomic and Technical Analysis of Reverse OsmosisYoussefNo ratings yet

- Desalination Plant PDR3Document66 pagesDesalination Plant PDR3jpv90No ratings yet

- LPH RO ManualDocument28 pagesLPH RO ManualAnil UnechaNo ratings yet

- Estimating Reservoir Capacity Loss From Sedimentation With TablesDocument17 pagesEstimating Reservoir Capacity Loss From Sedimentation With TablesDC MarvelNo ratings yet

- DowDocument8 pagesDowrammu2001No ratings yet

- ECE4453 Physical Chemical Treatment I Week 4Document113 pagesECE4453 Physical Chemical Treatment I Week 4Mohsen Mohammad0% (1)

- 2010 SMR ClarifierDocument60 pages2010 SMR ClarifierRohan KakdeNo ratings yet

- Effluent Treatment Plant (ETP) - Process Flow DiagramDocument4 pagesEffluent Treatment Plant (ETP) - Process Flow DiagramshimanthNo ratings yet

- Mobile Desalinators Reverse Osmosis PlantsDocument4 pagesMobile Desalinators Reverse Osmosis PlantslabeauNo ratings yet

- 02 Water Supply Engineering-Lecture 2-Quantity of Water 2019-2020 PDFDocument14 pages02 Water Supply Engineering-Lecture 2-Quantity of Water 2019-2020 PDFSeashells Do ImpossibleNo ratings yet

- LTE V/S RO-MEE ZLD ComparisonDocument28 pagesLTE V/S RO-MEE ZLD ComparisonKapa Kamalakar100% (1)

- EFFECT OF SILICA ON CELLULOSE ACETATE/PEG MEMBRANES FOR REVERSE OSMOSISDocument15 pagesEFFECT OF SILICA ON CELLULOSE ACETATE/PEG MEMBRANES FOR REVERSE OSMOSISPendi Adi MertaNo ratings yet

- Technical Spectification For 2 Pass SWRODocument241 pagesTechnical Spectification For 2 Pass SWROAhmed AnsariNo ratings yet

- Operation and Control of STPDocument11 pagesOperation and Control of STPHari Krishna.MNo ratings yet

- Treating Water for SafetyDocument17 pagesTreating Water for Safetyayesha zahraNo ratings yet

- Design Elements For Sedimentation Tank Construction With CalculationsDocument2 pagesDesign Elements For Sedimentation Tank Construction With CalculationsAravindanNo ratings yet

- Effluent Treatment Plant - Process Flow DiagramDocument45 pagesEffluent Treatment Plant - Process Flow DiagramAmarnath PNo ratings yet

- Compact Water TreatmentDocument22 pagesCompact Water TreatmentCHEMSTRONG100% (1)

- Desalination Plant of TobrukDocument21 pagesDesalination Plant of TobrukMotaz ZgogoNo ratings yet

- Rock Catchment Dam With Self-Closing WatertapDocument90 pagesRock Catchment Dam With Self-Closing WatertapGreen Action Sustainable Technology GroupNo ratings yet

- Integration of MembraneDocument316 pagesIntegration of MembraneKhuram MaqsoodNo ratings yet

- Yanbu WWTW Process Group PresentationDocument52 pagesYanbu WWTW Process Group Presentationyxp2237No ratings yet

- De Jager - D - DTech Thesis 2013 FINALDocument247 pagesDe Jager - D - DTech Thesis 2013 FINALbobbymayaaNo ratings yet

- Treatment Dissolved Air Flotation Feb14 v2Document13 pagesTreatment Dissolved Air Flotation Feb14 v2Arpit RanderiaNo ratings yet

- Cost Estimating of SWRO Desalination Plants: Estimating Indirect and Total Capital CostsDocument33 pagesCost Estimating of SWRO Desalination Plants: Estimating Indirect and Total Capital CostsYhuaman2No ratings yet

- WatergenDocument4 pagesWatergenParthiban BalakrishnanNo ratings yet

- Sanitation Module - IndiaDocument48 pagesSanitation Module - IndiaHarish BabuNo ratings yet

- Desalination EngineeringDocument8 pagesDesalination EngineeringShafayet A SiddiqueNo ratings yet

- DESSOL - Desalination With Photo Voltaic Solar EnergyDocument11 pagesDESSOL - Desalination With Photo Voltaic Solar EnergyCognosfera100% (1)

- Aerated BiofiltersDocument18 pagesAerated BiofiltersNataliaKNo ratings yet

- GVT-ODIS-SWRO For PBMC PDFDocument35 pagesGVT-ODIS-SWRO For PBMC PDFSwati BhattacharyyaNo ratings yet

- Membrane Drinking Water TreatmentDocument16 pagesMembrane Drinking Water TreatmentRamesh SoniNo ratings yet

- Water Engineering BooksDocument10 pagesWater Engineering BooksdandewjangerNo ratings yet

- Plant Water SystemDocument13 pagesPlant Water SystemPrasanna kumar subudhi100% (1)

- Reduction in Power Plant Specific Water Consumption: February 2016Document9 pagesReduction in Power Plant Specific Water Consumption: February 2016aedi0611No ratings yet

- Mega DaltanDocument1 pageMega Daltanadalcayde2514No ratings yet

- "Quality Comes First Before Our Name Goes Out.": Motech MindanaoDocument15 pages"Quality Comes First Before Our Name Goes Out.": Motech Mindanaoadalcayde2514No ratings yet

- Semi-Universal 0-18kg Child Car Seat ManualDocument36 pagesSemi-Universal 0-18kg Child Car Seat Manualadalcayde2514No ratings yet

- Environmental Issues in Seawater Reverse Osmosis Desalination: Intakes and OutfallsDocument18 pagesEnvironmental Issues in Seawater Reverse Osmosis Desalination: Intakes and OutfallsEnrique MartinezNo ratings yet

- Hydrotest FormulaDocument17 pagesHydrotest FormulaEarnest007100% (2)

- D&C PGA EMP Att B - Project ComponentsDocument9 pagesD&C PGA EMP Att B - Project Componentsadalcayde2514No ratings yet

- D&C PGA EMP Att B - Project ComponentsDocument9 pagesD&C PGA EMP Att B - Project Componentsadalcayde2514No ratings yet

- Api Oil Water Separators 2013Document6 pagesApi Oil Water Separators 2013adalcayde2514No ratings yet

- Construction Method StatementDocument9 pagesConstruction Method Statementadalcayde2514100% (2)

- Construction Plume Impacts from Port Bonython Desalination PlantDocument104 pagesConstruction Plume Impacts from Port Bonython Desalination Plantadalcayde2514No ratings yet

- Industrial Water Treatment Plant for Umm Wu'al Phosphate Fertilizer ProjectDocument2 pagesIndustrial Water Treatment Plant for Umm Wu'al Phosphate Fertilizer Projectadalcayde2514No ratings yet

- MICROTUNNELING AND PIPE JACKING CONSTRUCTION SPECIFICATIONDocument16 pagesMICROTUNNELING AND PIPE JACKING CONSTRUCTION SPECIFICATIONadalcayde2514No ratings yet

- Escalante Water District: 2 Escalante City, Negros Occidental Telefax (034) 454-0563Document4 pagesEscalante Water District: 2 Escalante City, Negros Occidental Telefax (034) 454-0563adalcayde2514No ratings yet

- Bulk Water Supply CodeDocument38 pagesBulk Water Supply Codeadalcayde2514No ratings yet

- 比较SBMBR与CMBR在不同COD/TN比下的污水处理效果Document9 pages比较SBMBR与CMBR在不同COD/TN比下的污水处理效果adalcayde2514No ratings yet

- Tornado - FLuence - AeromixDocument2 pagesTornado - FLuence - Aeromixadalcayde2514No ratings yet

- Deq WB Dwehs Gwwfwim Section7 - 183032 - 7 PDFDocument20 pagesDeq WB Dwehs Gwwfwim Section7 - 183032 - 7 PDFHari RamNo ratings yet

- Product Water CostsDocument26 pagesProduct Water Costsadalcayde2514No ratings yet

- DR900 Multiparameter Portable Colorimeter: Fastest and Simplest Water Testing For The Most Demanding Field EnvironmentsDocument2 pagesDR900 Multiparameter Portable Colorimeter: Fastest and Simplest Water Testing For The Most Demanding Field Environmentsadalcayde2514No ratings yet

- 1Document43 pages1Tariq WahidNo ratings yet

- Water Meter Sizing FormDocument3 pagesWater Meter Sizing Formadalcayde2514No ratings yet

- Produced Water Costs PDFDocument40 pagesProduced Water Costs PDFcmegmhiNo ratings yet

- Meter ClassDocument4 pagesMeter Classadalcayde2514No ratings yet

- Taco Pump - VT Series - Vertical Turbine PumpsDocument8 pagesTaco Pump - VT Series - Vertical Turbine Pumpsadalcayde2514No ratings yet

- 75525OP8136 - Trade Waste PolicyDocument4 pages75525OP8136 - Trade Waste Policyadalcayde2514No ratings yet

- 13Document6 pages13adalcayde2514No ratings yet

- Eaton Eaton Basket Screen DataDocument2 pagesEaton Eaton Basket Screen Dataadalcayde2514No ratings yet

- Calculation of Design Exa of HDPE PenstockDocument29 pagesCalculation of Design Exa of HDPE PenstockZainNo ratings yet

- Pumps 2Document2 pagesPumps 2Meetoo SharvamNo ratings yet

- Maximum Dissolved Oxygen Concentration Saturation TableDocument3 pagesMaximum Dissolved Oxygen Concentration Saturation Tableadalcayde2514No ratings yet

- Fluid Mech PaperDocument23 pagesFluid Mech Papertech2lifeNo ratings yet

- Bore Water 12 Pump System - Assesment ReportDocument6 pagesBore Water 12 Pump System - Assesment ReportKrishna JashaNo ratings yet

- Applying CFD To Study Boundary Layer FlowDocument12 pagesApplying CFD To Study Boundary Layer Flowudhaya kumarNo ratings yet

- Penstock Presentation - PpsDocument42 pagesPenstock Presentation - PpsGourav KhudasiaNo ratings yet

- Experiment 5 OrificeDocument8 pagesExperiment 5 OrificeRazahamid904No ratings yet

- Fundamentals of Industrial Instrumentation Process Control Chapter 5Document6 pagesFundamentals of Industrial Instrumentation Process Control Chapter 5Marco Maca0% (1)

- International Journal of Modern Trends in Engineering and ResearchDocument15 pagesInternational Journal of Modern Trends in Engineering and ResearchIJMTERNo ratings yet

- GasDynamics SampleFinalDocument2 pagesGasDynamics SampleFinalMd.tanvir Ibny GiasNo ratings yet

- eCOMPRESSOR OIL PDFDocument1 pageeCOMPRESSOR OIL PDFKeshav Shrivastava KSNo ratings yet

- Flow Sheet Eh-500fk 1000-030-9846Document1 pageFlow Sheet Eh-500fk 1000-030-9846thanh thien nguyenNo ratings yet

- Lecture 2 Fluid Statics PressuresDocument35 pagesLecture 2 Fluid Statics PressuresJuan MarcosNo ratings yet

- Analytical modelling of groundwater wells and well systemsDocument40 pagesAnalytical modelling of groundwater wells and well systemsMagdy BakryNo ratings yet

- Red Blood Cells FactsDocument462 pagesRed Blood Cells FactsDas- DigitalNo ratings yet

- Reynolds equation in one dimension (RE1DDocument3 pagesReynolds equation in one dimension (RE1DRio DermawanNo ratings yet

- Operation and Maintenance of Sewage Treatment PlantsDocument30 pagesOperation and Maintenance of Sewage Treatment PlantsSarangNo ratings yet

- GW Flow & Well HydraulicsDocument23 pagesGW Flow & Well HydraulicsEyuelAdamNo ratings yet

- Es Oftwh ResDocument2 pagesEs Oftwh ResWattsNo ratings yet

- Problem SetDocument4 pagesProblem SetblueberrytimeNo ratings yet

- Colfax Americas / Imo PumpDocument8 pagesColfax Americas / Imo PumprajeegargNo ratings yet

- Bingham Fluid Flow in A Plane Narrow SlabDocument6 pagesBingham Fluid Flow in A Plane Narrow Slabrachma tiaNo ratings yet

- PHED Criteria (Latest)Document129 pagesPHED Criteria (Latest)MuhammadUsman90% (10)

- Tech Data: Turboflo™ R&O T /C ODocument4 pagesTech Data: Turboflo™ R&O T /C OJeremias UtreraNo ratings yet

- V. Bernoulli EquationDocument31 pagesV. Bernoulli EquationNugraha RizkiNo ratings yet

- Pietro Fiorentini FB - Pe2.2psiDocument4 pagesPietro Fiorentini FB - Pe2.2psiHelton De AlbaNo ratings yet

- Chevron Line Sizing GuidelinesDocument6 pagesChevron Line Sizing GuidelinesWayne Monnery0% (1)

- 15-Daf Recycle PumpDocument1 page15-Daf Recycle Pumpbalaji krishnanNo ratings yet

- Water Feature 1,2,3Document15 pagesWater Feature 1,2,3Anonymous 6HjnToW6No ratings yet

- WATER SUPPLY CALCULATIONSDocument23 pagesWATER SUPPLY CALCULATIONSSabu Joseph100% (2)

- Fluids Mechanics - Topic 4 - Tutorial-5Document14 pagesFluids Mechanics - Topic 4 - Tutorial-5vaniya hameedNo ratings yet

- Lec - 1 - Introduction & Fluid PropertiesDocument24 pagesLec - 1 - Introduction & Fluid PropertiesShehroz JavedNo ratings yet