Professional Documents

Culture Documents

Construccion Con Barro

Uploaded by

Benito Rubio FrancoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construccion Con Barro

Uploaded by

Benito Rubio FrancoCopyright:

Available Formats

Adv. Studies Theor. Phys., Vol. 7, 2013, no.

1, 25 - 56

HIKARI Ltd, www.m-hikari.com

SANSWALL: Sandblasted Armed

Non-Stabilized Wall of Rammed Earth

M. A. El Azreq

Mohamed Vth University, Agdal, FSR

Rabat, Morocco

hirch_med@hotmail.com

A. El Hammoumi

Mohamed Vth University, Agdal, FSR

Rabat, Morocco

A. Iben Brahim

National Center for Scientific and Technical Research, Morocco

M. Kerroum

Mohamed Vth University, Agdal, FSR

Rabat, Morocco

K. Gueraoui

University Mohammed Vth Rabat-Agdal, LPT

URAC 13, Rabat, Morocco

kgueraoui@yahoo.fr

A. El Mouraouah

National Center for Scientific and Technical Research, Morocco

A. Lbadaoui

Mohamed Vth University, Agdal, FSR

Rabat, Morocco

26

M. A. El Azreq et al.

M. Kasmi

National Center for Scientific and Technical Research, Morocco.

A. Birouk

National Center for Scientific and Technical Research, Morocco.

K. El Harrouni

Ecole Nationale dArchitecture, Rabat, Morocco

Abstract

The earthen building construction is an ancient technique that is experiencing

resurgence in the world today thanks to the energy performance of this material

throughout the life cycle of building phases of construction, occupancy and

demolition. This strength allows us to consider the earth as a promising material

in the construction sector in the context of sustainable development. Yet, there

remain problems of quantification of the mechanical performance that prevent

people to use this material. This paper is devoted to the study of these problems.

Through numerical modeling of a wall of mud, I propose to optimize the

composition to increase its resistance; the optimization also affects its size. A

nonlinear dynamic behavior of the wall allowed us to study the conditions of its

stability. Reinforcement techniques to improve the seismic capacity of the mud

walls were also discussed.

All these parameters characterize what we have agreed to call a mud wall SANS

(sandblasted, armed, non-stabilized).

Keywords: Sustainable development, mud wall, durability, strength, earthquake,

nonlinear dynamics, numerical modeling

1 Introduction

Non-industrial materials used in civil engineering materials are manufactured and

installed by craftsmen in short production runs. This is typically local materials,

earth, stone, plant fiber with binder etc.. Found on site or near the construction site.

their study and their use has become very promising in the industrialized and the

developing countries for the cause of sustainable development, the second point is

that the structures in non-industrial materials are still very several around the

SANSWALL

27

world and the third reason is will strengthen the fight against natural hazards

including earthquakes.

As an example of scientific approach adapted to non-industrial materials, we

choose to study in this paper a structural element, namely a structural wall made

from clay.

The approach is to quantify the behavior of this material through experimental

tests, and use the results to develop a reliable numerical model representing a wall

of mud.

Therefore, optimizations in the composition of the mud and the geometry of the

wall will be proposed through a static analysis and nonlinear dynamic analysis.

Finally, techniques for building the wall to improve its seismic resistance will be

suggested.

All these improvements will transform a wall of traditional mud in a SANS wall

(sandblasted, armed, non-stabilized).

2 Optimal composition of SANS wall mud

In a modern project of earthen construction in Marrakech (Morocco) [Figure

1], a sample was taken on the land used in the manufacture of adobe. The

superposition of experimental tests with the results of fractal modeling of soil,

will allow us to propose an optimal composition of the mud.

Figure1. Main Facade of earthen construction

2-1 Tests on earthen material:

a Particle size :

This test is to determine the respective quantities of the various grain constituents

28

M. A. El Azreq et al.

earth according to their sizes. It is measured by particle size analysis by sieving

[Figure 2] for coarse grains with a diameter greater than 80 to determine the

grading curve characteristic soil studied [Figure 3].

Figure2. Screening Test

Figure3. Grading curve

b Limit of consistency

Soil can have three states of consistency. It can be solid, liquid or plastic.

The plasticity analysis is done on the fine granular fraction, called fine "mortar"

and to determine the change in consistency and its cohesion. The plasticity of a

kind of earth is evaluated by calculating three quantities called Atterberg limits,

which are: the plastic limit wp, the liquid limit wL and the plasticity index Ip.

SANSWALL

29

The results of these parameters related to the studied earth are summarized in

Table 1.

Number of strokes

number tare

Dry total weight g

wet weight total

g

tare weight g

weight water g

Dry soil weight g

Water content W

TABLE1

liquid limit

WL= 56%

18

21

26

T7

T8

T5

28

27

17

21

20

14

34

T25

15

13

T1

10 ,539

10,19

T14

10,758

10,34

8

7

12

58

7

2

5

54

9,031

0,349

1,15

30,1

8,96

0,418

1,38

30,3

9

6

11

57

8

3

5

55

plastic limit

WP= 30,2%

So we deduce from Table plasticity index:

IP=25,8

The water content of the sample: W=2,4%

LCPC classification of the sample gives:

silty sand (SL)

By projecting the plasticity index and liquid limit of the diagram Cohesion found

that the earth is considered highly cohesive.

2-2 Fractal optimization of particle size by addition of sand:

The concept of soil structure is closely related to the aggregate of which the

creation or destruction can be explained by several physicochemical factors.

The observation of the studied soil structure shows that the schematic

representations are most appropriate for the aggregates are: (fig4,5)

Figure 4

30

M. A. El Azreq et al.

Figure 5: schematic representation of aggregates

Therefore we will adopt a polygonal surface to represent the solid parts of the sample.

The constructed models of soil are defined by a partition of the exact space into a set of

solid elements and individual pores. for this purpose, a polygonal area of any plane Zo

representing a simulated soil sample is first fragmented into sub-areas polygon disjoint.

For each model the percentage distribution of the surfaces of solids is calculated

according to the sizes of grains linear: figure 6. [1]

Figure 6 a,b,c : numerical fragmentations of soil

SANSWALL

31

By transforming the grading curve of the sample, in a distribution of the

percentages of surfaces, depending on the linear sizes of particles, we find: figure

7

Figure 7: distribution of the percentages of surfaces.

Comparing this distribution with the models presented, the model shows that the

closest is the last one : figure 6 c).

This model is simulated with a fractal structure parameters of production: number

of fragmentation, number of germs and homothetic ratio denoted

(n ; N ; k) = (5 ; 7 ; 0,96) [1]

The porosity of this model is calculated by the formula [1]:

1 k 2 n (1)

We find :

33%

And therefore the compactness

67%

(2)

Which is a very satisfactory value.

Thus, to transform our land into a natural structure similar to the model studied,

we will use sand mined in the region whose surface distribution (Figure 9) derived

from the grading curve (figure 8) is as follows:

Figure 8: grading curve of sand

32

M. A. El Azreq et al.

Figure 9: distribution of surfaces of sand

Inspired by the fineness modulus Mf, we propose the following module:

Ms

1

%area size linear 8;16;31,5;63;125; 250;310 (3)

100

And so if :

Ms1 : modulus of the natural earth = 2,55;

Ms2 : correction module sand = 6,09;

Ms : module of the numerical model fractal = 3,74;

Knowing that: Ms1< Ms< Ms2

The proportion in % of the natural soil used in the mud will be:

S1

M s M s2

100 (4)

M s1 M s 2

So 66,2% of natural earth.

And the proportion in% of correction sand to add is:

S2

M s M s1

100 (5)

M s1 M s 2

So 33,8% of correction sand.

With : S1+S2=100% (6)

Increasing the amount of sand may decrease the cohesion of the mixture, to

overcome this difficulty, additives are used, on the other hand, land is considered

highly cohesive from the previous chapter.

Moreover, the size distribution curve obtained must fall within the spindle

proposed by CRATerre : figure 10 [2]

SANSWALL

33

Figure 10 spindle curves CRATerre

2-3 Optimization of dry density of the earth:

The parameters that influence the dry density and will be treated in this paragraph

are: water content, compaction energy and thickness of layers.

Indeed, not only at the microscopic scale of a few micrometers to a few

millimeters, but also to a few centimeters wide, the mud is still a heterogeneous

material. The heterogeneity of the mud comes primarily from the composition of

the constituent material (earth rammed in the case of non-stabilized) as for other

geomaterials. [2]

The heterogeneity of the mud comes next method of manufacture of this material.

First, the clay material is the stack of layers of rammed earth (figure11), therefore,

the adhesion between the layers of earth is not perfect. Second, during compaction

in earth, the upper part of a layer being in contact directly with the hammer is

denser while the lower part is less dense. Third, the heterogeneity is still some

friction with the formwork during compaction. The part of the mud in contact is

less compacted because compaction of the'' energy was dissipated by friction with

the wall forms. [2]

Figure 11: layers of an mud wall

34

M. A. El Azreq et al.

According to the study made by [2], plus the thickness of the compacted layers is

smaller, the compressive strength actually increases on samples subjected to a

force uniaxial, a decrease of the thickness of layers about 19% increases the

compressive strength of 60%. However, the time of implementation is increased

and this does not seem preferable compared to budget constraints during

construction on site. [2]

Another important parameter of the material earth is dry density. The compressive

strength of the material earth is proportional to its dry density as shown in Figure

12 below:[2]

Figure 12: compressive strength

On the other hand, the dry density of the material earth in general and the mud

necessarily depend in particular the water content of manufacturing and energy

production Figure13, a method for determining the optimum water content is

testing with a modified Proctor compaction energy of about 2.71KJ/dm3 against

(1.9 KJ/dm3) in case the mud is compacted on site with a dam tire.

The water content of the clay should vary between: 7%<w<12%

Saturation

Figure 13: optimum

Waterproctor

content

curve

SANSWALL

35

2-4 Using additives to the earth: [3]

The physical quality of the earth is its total recyclability. End of life of a building,

it can be crushed and mixed again with water to produce a new material, either

return to earth without a trace. Another of its qualities is its thermal inertia, which

comes from the water trapped between clays. As in the day, transfers

evaporation-condensation corresponds to heat exchange. The earth follows the

same principle as transpiration, which helps us keep a constant temperature when

the outside increases. The variations are clipped. Neither fired brick nor concrete

does possess this quality. Finally, land is a phase change material (PCM) natural!

For PCM manufacturers, paraffin balls are injected: when this wax melts between 23 and 26 C -, the heat exchange increases the overall thermal inertia.

In the case of earth, water naturally contained in the mass evaporates or condenses,

then changes phase, depending on temperature variations, for all these reasons we

propose to add additives in inorganic forms, organic derivatives natural sources or

mineral origin and avoid the addition of cement and lime. This is actually a work

on natural adhesives to replace the water with another "binder", consisting of very

large molecules that can connect several clay particles together, a technique called

bypass. These "spaghetti" microscopic particles bind to several at a time and

adhere more strongly.

The objective is to consolidate the material earth in two steps. Upon

implementation, the clays are dispersed as possible to avoid the formation of

aggregates and porosity that limit the mechanical strength, and to obtain a spatial

organization of clays which maximizes the contact surfaces. Cohesion of the

resulting structure can then be improved by various methods.

Inorganic stabilization (mineral) :

CSH (Calcium silicate hydrates):

The CSH (Calcium silicate hydrates): main hydrates and true (glue) cement are

particularly close to smectiles (swelling clays): nanometer-thick slices with

negative charges in the interlayer space attracting cations.

The pozzolanic reaction, to produce HSCS can be triggered by putting

diatomaceous earth in the presence of lime, it should be noted that this land is

abundant in the Melilla-Nador area and Al Hoceima in Morocco.

Ashes:

Ashes often contain calcium carbonate and may have stabilizing properties. The

ash can be used are produced by burning coal but woody plant materials not

because the ashes of the latter contain too much carbon. However, the ash of

certain plant residues such as rice grains which are high concentrations of silica

can be used.

The ash is normally added in proportions of between 5 and 10% and often allows

improvements in the compressive strength dry, while having less effect on water

resistance, but it can also reduce shrinkage and swelling. The ash can be a little

pozzolanic, so when combined with lime, further improvements are possible. The

36

M. A. El Azreq et al.

ash, when added to soils, is also known to act as a repellent against termites.

organic stabilizing:

The problem of this stabilization can be decomposed into three parts: [10] (figure

14)

release and disperse organic matter: The use of excrement, dung, urine and

manure as organic stabilizers can be explained by the fact that the body of the

animal itself accomplishes a significant degradation of organic matter ingested.

disperse clays: use of cellulose derivatives, lignin, starch, or organic acids,

tannins and humic acids.

Tannins

Tannins often act to disperse clay particles so that they coat sand grains in the soil

more evenly and, also help to break up clay lumps during compaction as well as

reducing permeability of the soil and improving water resistance.

organize and link the clay and organic matter: The large family of

polysaccharides such as cellulose, starch, pectins, mucilages, gums, or algae, as

well as the large family of proteins such as casein, collagen or gelatin, which have

the ability to form gels in water, and also known as thickening agents and / or

gelling agents, are specifically adapted to enhance the cohesion of earth material.

Figure 14[11]: behavior of the clay according to the acidity of the water

Casein: The (ENTPE Lyon) has conducted spectacular tests studying casein

mixed in a land of the Rhone-Alpes: adding only 1 to 2% casein, she got a

resistance of 10 MPa.

Hydrophobantes molecules (albumin, a glycoprotein present in blood, egg white,

milk) can protect the earth material from the water: they are amphiphilic

molecules, in other words they have a hydrophilic part and a hydrophobic part.

The hydrophilic parts are adsorbed on the clay particles, on contact with water,

while the hydrophobic portions remain on the surface of the material, in contact

with air, and form a surface film which prevents water from entering the earth.

SANSWALL

37

Vegetable oils and fats:

The best additives of this type are those which dry, thereby harden, quickly and

are insoluble in water. Such additives include coconut, cotton and linseed oil as

well as castor oil which is very expensive. Kapok, palmitic oil and shea butter

have also been tried, but with variable results, so local trials are recommended.

Shea butter can repel termites, and an addition of around 3% is recommended,

although it can also be painted or sprayed on surfaces.

Gum Arabic

This is a product obtained from the acacia tree. It acts primarily as a flocculant,

that is it helps to form flocs of clay particles within the soil which help to increase

dry compressive strength and slow down water absorption, hence reducing

shrinkage. However, it is soluble in water and so offers little protection to

long-term moisture exposure. It is best used inside a building, added at 5 to 10%

proportions.

Palmo copal

Copal is a resin obtained from certain tropical trees. It is usually added at 3 to 8%

concentration to sandy soils. One variety, manilla copal, has waterproofing

qualities..

Sap and latex

The latex of certain trees, such as euphorbia, hevea rubber and concentrated sisal

juice, reduces permeability slightly and improves cohesion. Proportions between 3

and 15% are normally used and best results are achieved with neutral rather than

acidic soils. The juice squeezed from banana leaves, which is subsequently

precipitated by mixing with lime to clean it, is another material which has similar

properties.

molasses

Dehydrated sugar molasses contain aldehydes which can be converted into

polymers at high temperatures with the aid of phenolic catalysts. The resinous

material obtained is similar to asphalt and other resins in its effects. It improves

the strength and reduces permeability. Normally a proportion of about 5% is used.

2-5 Arming the earth:

Arming the earth fiber aims to limit the cracking by dispersing the constraints, and

increase the tensile strength of the material. Another advantage is that it greatly

eases the earth, and makes it more thermally insulating and hasten drying.

The fibers vary in fome, size, strength, elasticity and adhesion to the land, the

improvements vary with different types of fibers, as the quantity of a particular

fiber required. The usual proportions are between 1 and 4% by weight, which is a

bulk volume which can be as high as the volume of soil. [4]

The fibers most commonly used include straw, for example from wheat, rice or

barley. The chaff or pods of these crops can also be used. Other suitable vegetable

38

M. A. El Azreq et al.

fibers include hay, hemp and millet, sisal, casuarinas needles, and elephant grass.

The camel dung was also used as additives, as it contains short fibers that make

the soil workable for plastering and rendering. Synthetic fibers such as rosin, steel

or glass wool found very limited application. The best results are obtained with

reinforcing fibers if the wet mixture is prepared several days before use.

A disadvantage of vegetable fiber is variable durability. The dry fibers usually last

a very long time, but when wet they may rot. In addition, some are attacked by

insects, especially termites, but others are not and often local knowledge exist to

identify the most resistant types. [4]

Note that the straw is the most used of all, because it significantly improves the

properties of the earth at low cost. However the use of other plant fibers and

practice is perfectly justified, according to local productions. Animal fibers, such

as pet hair, or synthetic fibers can also be used. Good results are obtained from an

assay to 4% by volume, and amounts of 20 to 30 kg per cubic meter are common.

Studies have also shown that best results are obtained by cutting the straw into

segments of 4 to 6 cm. This technique is mainly used in the manufacture of adobe

and mud, but also suitable for the lair and techniques of compressed earth (or mud

blocks).

It has been demonstrated by the experience:

Jute and straw are effective in improving the ductility of adobe blocks, while

hemp is not. Jute is more effective in improving the ductility and stiffness of

adobe blocks.

Shrinkage cracks in the unreinforced mortar are the main causes of poor seismic

performance. Jute is effective in preventing shrinkage cracks and Figure 15, and it

improves the strength of the mortar and increases bonding. [3]

Figure 15: use of straw to arm the cob

3 Optimization of the dimensions of the wall

To determine the optimal dimensions of a mud wall, two approaches are

adopted:

SANSWALL

39

The first, based on the calculation of applied forces, is a quasi-static analysis of

the behavior of the wall of mud. The second, based on the calculation of wall

displacements under the effect of seismic action, is a nonlinear dynamic analysis,

for which we will use computer software (ANSYS).

We will finally compare the results with the codes of different countries.

3-1 Optimization of the dimensions by calculating forces

In this chapter we begin by calculating the ratio of wall dimensions deduced from

equilibrium equations of the applied forces.

According to the Moroccan RPCT, pending approval: [5]

- Ultimate stress applied N should check the condition of resistance following:

N 0, 6K. c .A (7)

A : wall section

c : compressive strength of the earth wall

K : coefficient as a function of slenderness and eccentricity

So :

n 0, 6 k c (8)

n : normal stress applied

- the bending moment applied M must verify:

M 0, 08 Z u c

(9)

Zu : Module side of the gross section of the wall

Hence

0, 08 Zu c y

I

(10)

t : shear stress applied

We know that in a granular material:

t n tg c

(11)

: friction angle of the earth;

c : cohesion of the soil.

- The eccentricity of the head and foot of the wall must verify:

t I

n t L y

h

0, 05t

450

h : height of the wall;

L : length of the wall.

t: thickness of the wall.

(12)

40

M. A. El Azreq et al.

The result is a system of four equations; the unknowns are the three dimensions of the wall.

n 0, 6 k c

t 0, 08 Z u c y

I

tg c

n

t

t I

h

0, 05t

n t L y 450

Is obtained after solving the system:

h

14

t

0, 02

(13)

t

L

(14)

3-2 optimization calculation by nonlinear dynamics

Calculating nonlinear dynamics will be achieved partly with the software ANSYS

calculation, for that first step is to model a wall of mud.

To validate the correlation between the computer model and the actual wall, a

comparison between the results obtained by experimental tests and numerical

calculations will be performed.

3-2-1 Uniaxial compression test and displacement spectrum

of unstabilised rammed earth wall : [2]

The purpose of these tests is to study the mechanical behavior of the wall of mud

by laboratory tests, why approaches on three different scales are adopted,

Figure.16

Figure 16: mud wall

SANSWALL

41

The first is to scale the walls on site. Dynamic measurements were performed on

site to determine the displacement response of the wall as a consequence of the

acceleration.

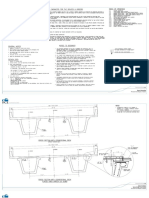

The wall "L" chosen, has the geometric properties shown in the diagram below

Figure 17:

Figure 17: geometry of the mud wall studied

To determine the natural frequencies of the wall, several shocks were applied in

different directions on the wall and the response was recorded through

accelerometers and a data acquisition system. The position of the sensors on the

wall and the location of the shock are shown schematically in Figure 18 [9]

Figure 18 : location of shocks

The results of displacement response obtained are similar to those performed on

an adobe house built in unstabilized mud Figure 19:

Figure 19: displacement spectrum frequency

42

M. A. El Azreq et al.

The second approach is on the scale of a representative volume element (RVE),

samples were manufactured by the same craftsman manufacturer of ramming

mixes on site. The uniaxial compression test perpendicular to the bed which was

conducted shows results below in Figure 20

Figure 20: uniaxial compression test

Finally, with regard to the latter approach, on the microscopic scale, tests were

performed on compressed earth blocks (BTC) equivalents, which can replace the

cob samples to facilitate the procedure of laboratory tests. A homogenization

procedure is set up to find the relation between the compressive strength and

modulus of elasticity of BTC and REV.

SANSWALL

43

3-2-2 Modeling and validation of the wall:

From previous results, related to the physical properties of clay figure21, a wall

was modeled using the ANSYS calculation software with the same dimensions as

the prototype object of testing, the coarse mesh was made, taking into account the

polygonal shape chosen to represent the grains in chapter 2:

Figure 21: ANSYS modelisation of wall

The experimental vertical deformation according to the applied stress is compared

with the maximum plastic deformation vertical calculated with the ANSYS.

Figure 22: vertical deformation

44

M. A. El Azreq et al.

It is found that the two curves are almost superimposed.

On the other hand, superimpose on the same graph the curves of elastic and

plastic deformation obtained by ANSYS based on the linear load figure23, the

intersection occurs at the level of strain 10-3, which shows that the plastic

deformations start from this value.

Figure 23: horizontal deformation

However, experience shows as shown in figure24 indeed from this deformation,

the behavior becomes plastic. [2], [9]

Figure 24: plastic deformation

According to the displacement response spectrum of the wall given by ANSYS

figure25, we find that the maximum displacement is 5,66.10-5mm, which is very

close to the value 4,7.10-5mm given by the experimental curve of figure19

SANSWALL

45

Figure 25: directional displacement

These three observations show that the model adopted is quite appropriate to

represent the actual behavior of an mud wall.

3-2-3 Capacity curve and dynamic behavior:

Based on the results obtained by ANSYS software, we plot the capacity curve of

the wall figure26:

Figure 26: capacity curve of mud wall

46

M. A. El Azreq et al.

Figure 27: damage suffered by the wall

The yield stresses and resistance are given by the curve figure28:

Figure 28: yield resistance wall

We wish to study the stability of the wall by nonlinear dynamic analysis. The

equation governing the behavior of swing is similar to that of a single localized

mass: [3], [6]

Figure 29: stability model for mud wall

SANSWALL

47

M e a e t Ce t F( e t ) M e a g t (15) The wall is of mud, so we can

not consider the infinitely rigid, and to overcome this difficulty we choose to

model it as two springs in series, whose stiffness k are identical figure30. Below

the modeling for the study of horizontal earthquake. [6]

Figure 30: springs model of wall

The stiffness k of the springs is given by the model of rupture of the wall figure31:

[6]

Figure 31: force displacement relationships

k0

With

6M e g

220,8kNm1

h

and the total stiffness

k

F0

k0 1372,8kNm 1

(17)

e

Thus, two modes of vibration, pulsation of the two modes are given by: [7]

(16)

48

M. A. El Azreq et al.

m 2

k

2

m 2

2k

2

0 (18)

By solving the system found : [7]

k

12 0, 764 114(19)

m

k

22 5, 24 781,89(20)

m

We deduce the period, frequency and eigenvectors of each mode (Table2) [7]

TABLE2

Mode

T (sec)

f (Hz)

u1

1

0,58

1,69

1,17

2

0,22

4,45

-0,171

u2

With damping = 2%, we find the pseudo acceleration:[8]

1 0,15 g

2 0,175 g

And we deduce the horizontal accelerations of the masses :[7]

1,17 0,175 g

0,15 g

0, 724 0,1g

0,171 0, 03 g

0,175 g

0, 277 0, 05 g

The relative displacements, for a given mode are measured by dividing the

acceleration by the square of the pulsation Table 3: [7]

TABLE3

Mode

u1

u2

horizontal displacement (mm)

1

2

15mm

0,89mm

1,25mm

1,49mm

For the first method we find that the movements are excessive.

The potential energy E for each mode table 4 can be calculated by the formula: [7]

1

E U t KU (21)

2

SANSWALL

49

TABLE4

Mode

Energy

%

1

0,107

100%

2

0,00062

0,57%

We see that mode 1 is clearly dominant and can only be preserved in practice.

The results are then compared to the eigenmodes given by the software ANSYS

figure32 and Table 5

0,175g

-0,03g

(15mm)

0,1g

(1,25mm)

(0,89mm)

0,05g

(1,49mm)

Figure 32: modal displacements

TABLE5

Method

Mode

Displacement

Frequency

Manual

calculation

1

2

15mm

1,49mm

1,69Hz

4,45Hz

ANSYS

1

24,3mm

9,23Hz

2

32mm

16,35Hz

50

M. A. El Azreq et al.

According to the method of dynamic analysis reveals that the displacement of the

wall is excessive and it increases with decreasing the square of its pulse.

From equation (7) we deduce a condition on the wall height h

So to reduce wall displacement we just check:

2h2

58,86h 3390,33 0

(26)

0, 764

And therefore for values 0, 25s T 0,65s

2

And pulse 93 631

We deduce that h must be between:

2,05m h 5,5m

In comparison with the computer codes in different countries: [6]

4 Technical implementation and reinforcement of the wall:

In this section we will study the possibilities of building mud walls from the

current knowledge of earthquake of earth construction and most studies are

performed on adobes. After watching the current state of knowledge of earthquake

of earth construction, solutions building adobe walls are proposed. These

reinforcements are important and will serve to strengthen existing homes or apply

for new homes.

SANSWALL

51

4-1 "Arm" the mud walls: [2]

Walker and Morris [2] propose the use of steel reinforcement for reinforcing mud

walls. The density and arrangement of reinforcement depends on the seismic zone

is located or the building. The Figure33 shows an example of this type of

reinforcement. This type of reinforcement is not recommended by other studies.

This technique of seismic strengthening is proposed by the standard of New

Zealand.

Figure 33: steel

reinforcement

4-2 Reinforcement of flexible screens outside the wall: [2]

Several studies have tried this type of reinforcement (Blondet and Aguilar, Tolles

et al.) Adobe houses on small scales to real scale. These homes are tested on the

shake table. The Figure34 shows an example of a house tested in the study of

Aguilar and Blondet. Movements of a real earthquake are simulated the vibration

table. Results show that although there is damage, houses reinforced polymers in

these screens can prevent a total breakdown. This technique has improved the

seismic capacity of these adobe houses. However, the disadvantage of this

technique is the increased cost of construction (and the roasting time of

installation). Studies of the effectiveness of this type of seismic strengthening of

the adobe walls and the economic problem are needed.

Figure 34: adobe house with mesh

52

M. A. El Azreq et al.

4-3 vertical ties:

Minke [2] encourages the use of vertical reinforcing bars but against, it

discourages the placement of the horizontal bars in the adobe walls. The reason is

that the shear force can not be transferred by bars since cohesion between them

and the earth is very low. Thus, horizontal reinforcing elements weaken the

structure and cause horizontal cracks. In addition, in practice it is difficult to

ensure proper grooming with the presence of these horizontal elements.

Figure 35: vertical reinforcing

Vertical bars are made of bamboo or steel. Figure35 illustrates the application of

vertical ties in the mud walls.

The technique of vertical ties inside the wall was applied to the adobe walls

stabilized in studies of Hamilton and al. Morris and Walker, with the use of

prestressed steel tie rods. These rods are placed in the tubes placed in the

formwork ties to protect against corrosion by moisture from the land of mud.

These ties are introduced preload after ramming the wall. The use of prestressing

can decrease the amount of the tie rods necessary, with respect to the normal

technical tie rods. This reduces not only the work of the location of reinforcement

but also facilitates the grooming of mud. With prestressed anchors, for each wall,

there would need 2 rods at both ends of the wall to support the seismic force

"plan" of the wall and pulling the middle of the wall to support the seismic force

"off plan" the wall. This technique is quite applicable to the adobe walls and

opens a new way of building adobe houses new or existing by its efficiency and

simplicity of design compared to other techniques presented in previous sections.

Further studies on this technique remain to be implemented.

SANSWALL

53

4-4 Implementation: [2]

The current forms are wider than conventional forms for rapid manufacturing on

site. They are also more rigid to support the damage the height of the pneumatic

dame (currently they are usually metal)

Figure 36: manufacturing wall

Prefabrication has also increased. Figures 36 and 37 show the manufacture of

factory built ramming mixes, transportation and implementation.

Figure 37: prefabrication wall

54

M. A. El Azreq et al.

5 Conclusion

Through this article, we try to make a modest contribution in the development of

earth construction, while trying to preserve one of the main assets, namely

sustainable development. To this end we propose a mud wall composed entirely

of natural materials and recyclable, the wall of mud SANS.

The first optimization, on the composition of mud, is derived from a fractal model

of soil built by computer, and the stabilization of the soil with organic and

inorganic elements.

Regarding the optimization of the geometry of the wall, this paper presented a

dynamic approach in parallel with a static "classical" to measure the ratios of

these dimensions. Dynamic analysis was performed using the software ANSYS

nonlinear calculation, where model of the wall was validated by comparing results

with experimental tests.

Finally a summary of existing solutions building mud houses was achieved.

Solutions suitable for mud walls have been proposed as the use of vertical ties

inside or outside the mesh wall.

The results of this study and studies in the literature show that the construction of

earthquake-resistant earthen houses is possible. The problem is the optimum

choice of several criteria: technical, economic and cultural.

References

[1] A. DOUCET, La terre crue pour un autre dveloppement : La technique de

construction en terre crue adapte aux contraintes techniques et au contexte

culturel dune communaut, Travail de fin dtudes pour lobtention du

diplme dingnieur civil architecte, UNIVERSIT DE LIGE, pp 56-68,

2005

[2] A.Kapra, V.Davidovici, Calcul dynamique des structures en zone

sismique,pp112-119,1982.

[3] BUI Quoc-Bao, Stabilit des structures en pise : durabilit, caractristiques

mcaniques, thse prsente linstitut national des sciences appliques de

Lyon pour obtenir le grade de docteur 29-182P, 2008.

SANSWALL

55

[4] Direction des Equipements Publics, Ministre de lEquipement et des

Transports du Maroc, Rglement parasismique des constructions en terre,

(Draft), Cherrabi, RPCT2008, 16-23P, 39-44P, 2008

[5] E.Perrier, Structure gomtrique et fonctionnement hydrique des sols

simulations exploratoires, ORSTOM Edition, $4: pp 68-80, 1995.

[6] Khalid M. Mosalam, State-of-the-Art on Seismic Retrofit:The Case of

Earthen Construction in Morocco,pp38-46,2011.

[7] L.Fontaine, R.Anger, Btir en terre : du grain de sable larchitecture,

BELIN 175P, 2010.

[8] M. A. El Azreq, A. El Hammoumi, A. Iben Brahim, A. El Mouraouah, M.

Kerroum, K. Gueraoui, M. Kasmi, A. Birouk, Spectrum Response of Earthen

Buildings, IRECE, vol.1.n.4: pp 266-274, 2010.

[9] O.Mottier, Vulnrabilit sismique des constructions en pis, MASTER

ENTPE 33P, 2007.

[10] PRACTICAL ACTION, additives to clay: organic additives, The

Schumacher Centre for Technology and Development, 2008.

[11] Romain Anger, Laetitia Fontaine, Hugo Houben, Patrice Doat, Henri Van

Damme, Christian Olagnon et Yves Jorand, La terre, un bton comme les

autres ? Quelques mcanismes de stabilisation du matriau terre,

TERRA2008, pp 222-225, 2008.

56

Received: October, 2012

M. A. El Azreq et al.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Prestressed Concrete Design PrinciplesDocument7 pagesPrestressed Concrete Design Principlesassis alihNo ratings yet

- Post-Tensioned Timber Buildings in New Zealand: Research, Design and Implementation Into Real Case StudiesDocument1 pagePost-Tensioned Timber Buildings in New Zealand: Research, Design and Implementation Into Real Case StudiesMangisi Haryanto ParapatNo ratings yet

- Aizaz Ahmad.: EducationDocument2 pagesAizaz Ahmad.: EducationEngr Aizaz AhmadNo ratings yet

- Pier Cap PSC Multi StageDocument87 pagesPier Cap PSC Multi Stagesanyogitasawant5No ratings yet

- ACI 423.5R-99 Partially Prestressed ConcreteDocument37 pagesACI 423.5R-99 Partially Prestressed ConcreteingpulgarNo ratings yet

- CONSTRUCTION TECHNOLOGY: STRUCTURAL SYSTEMS AND CONSTRUCTION METHODSDocument43 pagesCONSTRUCTION TECHNOLOGY: STRUCTURAL SYSTEMS AND CONSTRUCTION METHODSKabilesh SNo ratings yet

- FinalReport - Bridge ProjectDocument302 pagesFinalReport - Bridge ProjectMohamed GamalNo ratings yet

- Analysis of Precast Building System DesignDocument7 pagesAnalysis of Precast Building System Designshashank adigaNo ratings yet

- PCI Zone6 Curved Spliced GirdersDocument20 pagesPCI Zone6 Curved Spliced GirdersRodrigo LameirasNo ratings yet

- BUER GROUND AnchorDocument12 pagesBUER GROUND AnchorSatish Debnath100% (1)

- Lecture 1 - IntroductionDocument11 pagesLecture 1 - IntroductionOmar ShamaylehNo ratings yet

- SDM Volume3Document541 pagesSDM Volume3Plamen VassilevNo ratings yet

- Indian Railways DocumentDocument21 pagesIndian Railways DocumentSabari NathanNo ratings yet

- EBCS EN 1992-1-1 - 2013 - EBCS 2 - Final PDFDocument1 pageEBCS EN 1992-1-1 - 2013 - EBCS 2 - Final PDFMulu Gebrekiros100% (1)

- ACI Technical Notes-3Document7 pagesACI Technical Notes-3Moloy GoswamiNo ratings yet

- Item Rate BoQ for Construction of Major BridgesDocument37 pagesItem Rate BoQ for Construction of Major BridgesKota Rajesh ReddyNo ratings yet

- Design of Concrete Structure II Sessional: Dhaka University of Engineering & TechnologyDocument22 pagesDesign of Concrete Structure II Sessional: Dhaka University of Engineering & TechnologyumrumrumrNo ratings yet

- BBR CMI Tendon Brochure - Optimize PDFDocument32 pagesBBR CMI Tendon Brochure - Optimize PDFWenix008 OniNo ratings yet

- Cracks & Crack Control in Concrete Structures-2Document12 pagesCracks & Crack Control in Concrete Structures-2Kiran N S GowdaNo ratings yet

- Crosswalk Between 7th and 8th Editions of AASHTO LRFD Bridge Design SpecificationsDocument159 pagesCrosswalk Between 7th and 8th Editions of AASHTO LRFD Bridge Design SpecificationsdiablopapanatasNo ratings yet

- CorossionDocument76 pagesCorossionviswamanojNo ratings yet

- Chapter 5 Anchorage ZonesDocument14 pagesChapter 5 Anchorage ZonesNoorhazlinda100% (1)

- C935.20846 AstmDocument4 pagesC935.20846 Astmf_dbdominguesNo ratings yet

- Roof DecksDocument56 pagesRoof DecksshingkeongNo ratings yet

- 2017 Technical Data Guide For Precast, Prestressed Concrete Hollow-Core PlankDocument40 pages2017 Technical Data Guide For Precast, Prestressed Concrete Hollow-Core PlankAdam JonesNo ratings yet

- Temperature Effect On Prestressed Integral Bridge BeamDocument107 pagesTemperature Effect On Prestressed Integral Bridge BeamgabemzamanNo ratings yet

- 1bridge CriteriaDocument14 pages1bridge CriteriarowatersNo ratings yet

- Vertical anchor design methodsDocument29 pagesVertical anchor design methodsLesego MatojaneNo ratings yet

- Post Tensioning Cables in Prestressed Structures.Document92 pagesPost Tensioning Cables in Prestressed Structures.hasib100% (3)

- High Capacity Concrete Anchor SystemsDocument56 pagesHigh Capacity Concrete Anchor SystemsMin Thiha NaingNo ratings yet