Professional Documents

Culture Documents

A Review On Rapid Control of A Brushless Motor in An Hybrid System

Uploaded by

sunil kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Review On Rapid Control of A Brushless Motor in An Hybrid System

Uploaded by

sunil kumarCopyright:

Available Formats

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 02 | Feb-2016

p-ISSN: 2395-0072

www.irjet.net

A Review on Rapid Control of a Brushless Motor in an Hybrid System

Sunil Kumar1 Gagan Deep2

1 M.Tech

2Assistant

Scholar, Electrical Engineering Department, BUEST Baddi, Himachal Pradesh, India

Professor, Electrical Engineering Department, BUEST Baddi, Himachal Pradesh, India

---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract - The test displaying of the exchange capacity of a

without neglecting that the basic essential for the use of this

sort of controller is the consistent quality and relentless

quality. Examinations related to the PID control application

on a motor furthermore, [5], [6], have reported that is

amazingly standard to forbid the derivational part from an

incredible control structure subsequent to extra advanced

electronic contraptions are physically required and of higher

costs, which offer rate to levels of nanoseconds so that the

derivational action offers pace to the major part, this is to

modify the misstep in the steady state of the relative get in

the control system. By in advance said examinations there is

a need in the change of tuning strategies that can be joined in

hardware modules, this paper is occupied with finding the

development or methodology for the parameters tuning [7].

The need to tune gets on time capable to change in

accordance with different convincing limits has taken

various examiners to apply the fluffy method of reasoning to

arrange controllers prepared to tune grabs persistently of an

awesome control, in view of their adaptability and

ampleness when moving nearer nonlinear unverifiable

structures in their yield response [8].

Plans, for instance, [9] complete a rate control for a

brushless motor using inherited counts in light of soft basis

to survey the semantic rules and to tune the parameters of

the controller on line, using a Digital Signal Processor (DSP)

for speed data acquisition, improving execution and the

quality in the fuzzy hereditary control. A perfect PID speed

control is proposed by [10] using a quadratic straight

controller for a dc brushless motor with a dynamic model of

second demand, the controller just gets the indication of the

goof and it doesn't have to enter the complete states for the

pace.

DC voltage three-phase brushless synchronous electric motor

(Brushless DC Electric Motor) for a hybrid system or

framework is displayed, the bench framework comprises of an

engineering in parallel utilizing gadgets for force division

called electromagnetic grips, that comprise in a twofold

channel pulley, a curl and a drag plate, these grip were

associated with the motors bolt in this hybrid or cross breed

framework, permitting a person control of both. The

distinguished exchange capacity is utilized to outline

furthermore, to reproduce a control of precise velocity being

utilized the Root-Locus strategy and Fuzzy Logic to autotune

the relative vital increases. The essential goal is to synchronize

the motor velocities to make productive the fuel use in the

ignition engine. The recreation of the control framework in

shut circle is made in the Simulink apparatus and is composed

with Siso tool or device from the numerical software Matlab.

The framework recognizable proof is led through the System

Identification Toolbox of Matlab with information

procurement of precise rate, voltage and sampling time.

Key Words: Brushless motor, Electromagnetic clutches,

velocity, feedback control, and fuzzy logic.

1. INTRODUCTION

These days the conventional control procedures cannot

satisfy the most critical needs to enhance dynamic

frameworks, electronic circuits, and modern procedures,

among others. Amid the last couple of years the control

activity for controlled variables inside of a criticism design

control has been connected inside and out with manmade

brainpower with the reason of giving a productive answer

for the control of yield variables of superordinated

frameworks that not as a matter of course present a direct

relationship with an info sign of the framework. The fuzzy

control offers leeway to utilize phonetic terms like: enough,

minimal, much, something, among others. This puts forth

bring the problem expression up in the base terms, which

would make a profoundly prepared individual in the region

[1].

Past work by [2], [3], [4], consider the need to complete

feasible controllers in the propelled control of brushless

motors, from which the most broadly perceived are the PID

controller, controller by fuzzy basis and the mix between

these: neuro-fuzzy frameworks, fuzzy genetic calculations,

2016, IRJET

Impact Factor value: 4.45

2. Literature Review

By methodologies the execution of a great fuzzy controller

prepared to tuning constantly the relating and crucial grabs,

using an expansion variable scope, overcame the root locus

plot of the polynomial typical for a trade limit in open circle,

and the element showing of the brushless motor is

coordinated through the reviewing of data connected with

the test data assembled, moreover a close examination of the

flashing reactions is performed concerning customary PI

control and a PI with feathery justification. In the control

structure, the control variable is the exact rate of the

brushless motor and a controlled variable is the voltage sent

towards a trapezial speed shifter. The exact rate control is

the major focus of this examination since it synchronizes the

|

ISO 9001:2008 Certified Journal

Page 722

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 02 | Feb-2016

p-ISSN: 2395-0072

www.irjet.net

pace in the cross breed system. For the control structure

blueprint is vital to describe firstly the key fragments of the

individual motors control, besides the colossal control

system, and in conclusion the configuration of the trial data

securing. The efficiency in the structure depends on upon the

arranging of the most basic portions for the pace

transmission towards a mandrel of pulleys, containing in two

rowlocks that allow the exact bearing, created by the

relationship of A-49 bunches, towards the electrical motor

and too towards the combustin engine, the grasps are driven

with a period of power for the building points of interest of

the hold, and controlled additionally with an on/off control

thinking, being controlled by an interface conduced in

Simulink of Matlab.

Figure 2: Incremental encoder with optic encoder.

2.3 Calculation for Angular Speed

2.1 Architecture of the Hybrid System

The criticism control of the velocity Figure 3 was intended to

examining the kind of unsettling influence that creates

insecurity to the framework, changing the reaction to a set

point and making a nonlinear relationship in the middle of's

information and yield variables, and in addition expanding

the quantity of shafts and zeros in the dynamic

demonstrating of the framework. An incremental encoder

was utilized for the examining the rakish speed, this encoder

has 3 photograph transmissive sensors that were adjusted to

the bolt of the electrical engine permitting to compute the

time Figure 2b, concurring on the quantity of spaces in the

encoder, the optical plate of encoder has 480 openings

Figure 2c.

The efficiency in the structure depends on upon the

arranging of the most basic fragments for the pace

transmission towards a mandrel of pulleys, containing in two

rowlocks that allow the exact bearing, created by the

relationship of A-49 bunches, towards the electrical motor

and too towards the blazing engine, the hold are driven with

a period of power for the grasp building determinations, and

controlled too with an on/off control thinking Figure 1, being

controlled by an interface conduced in simulink of Matlab.

Figure 1: Hybrid bench system with parallel architecture.

Figure 3: Experimental setup for the angular velocity

feedback control of the electric motor.

2.2 Electromagnetic Clutch or Grips

Thus angular speed was calculated in the following way,

equation (1).

(1)

Where

the angular speed (rpm), T is is the time

necessary for the encoder sampling each slot (min) and c is

the number of detected slots.

An electromagnetic clutches were used for power division by

means of a Sanden SD 508 clutch, this clutch has double

pulley Figure 2a one of them is used to join the brushless

motor with a mandrel pulley by means of a rubber band.

2016, IRJET

Impact Factor value: 4.45

ISO 9001:2008 Certified Journal

Page 723

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 02 | Feb-2016

p-ISSN: 2395-0072

www.irjet.net

2.4 Experimental Setup

In order to apply the control action that allows correcting

the error, a feedback control was implemented by an

interface in Matlab Simulink tool environment, and a PID

control action was used equation (2).

Where

is the manipulated variable in our case the electric

motor voltage,

is the proportional controller gain,

is

the derivative controller gain,

is the integral controller

gain, e(t) represents the signal error; that is the difference

between the output variable and the setpoint. The relative

control gives a counterbalance between the yield variable

and the setpoint. The fundamental activity remedies the

deviation in unfaltering condition of the real mistake, this

control activity stays coordinating until the blunder tends to

zero. The subsidiary control activity which permits to expect

to the procedure yield, thusly the PID control activity has a

rapidly change for blunder between the measure rakish rate

and the setpoint of the precise rate. With a specific end goal

to distinguish the exchange work that portrays the dynamic

conduct of the brushless engine, a microcontroller's interface

of serial correspondence through gathering of content chains

in ASCII code was executed. The inspecting of the rakish

speed of the engine bolt, the time examined by the

incremental encoder and the voltage of the rate variator. The

interface was outlined in the instrument Matlab's Simulink,

utilizing a Query Intrument piece. The piece doesn't have

information ports. The piece has a yield port relating to the

information got from the securing instrument and gets the

information in content chains in skimming number of 64

bits.

Figure 4: Block Diagram: (a) classic controller (b) fuzzyproportional controller (c) fuzzy-proportional integral

controller.

3. Conclusion

According to previous approaches the outline

demonstrates that a fuzzy controller combined with a work

of art PI controller applied to control the angular speed of

the hybrid system has the advantage to autotune in real time

the increases for the control activity, rise and setting time

are lessened contrasted and the sole utilization of RootLocus and Ziegler-Nichols strategies. The corresponding

control activity in the criticism framework has a deviation

from the setpoint, in this way we pick a PI controller activity

to amend the blunder in relentless state to get a stable

transient reaction.

As an aftereffect of the execution of coupled control strategy,

the brushless engine acted effectively to expand execution

and control the precise speed. This examination is an initial

phase in the coordination between fuzzy control and PI

control methodologies utilizing a solitary universe of talk

from the phonetic variables, with a

2.5 Block diagram of the fuzzy controller

architecture

The block diagram implemented in Simulink of the control

system i.e. classic controller, fuzzy-proportional and fuzzy

proportional integral Figure4. The fuzzy gain is autotuned

using the methods previously mentioned.

REFERENCES

1) Sivanandam and Deepa, Introduction to Fuzzy Logic in

MATLAB. Springer, First edition, 2007.

2) Wang H, Design and Implementation of Brushless DC

Motor Drive and Control System. Procedia

Engineering, pp. 22192224, 05, 2012.

2016, IRJET

Impact Factor value: 4.45

ISO 9001:2008 Certified Journal

Page 724

International Research Journal of Engineering and Technology (IRJET)

e-ISSN: 2395 -0056

Volume: 03 Issue: 02 | Feb-2016

p-ISSN: 2395-0072

www.irjet.net

3) Cox, E., Fuzzy Fundamentals. Spectrum Magazine of

IEEE, vol. 106, pp. 5861, 1992.

4) Gunes M, & Dogru N, Fuzzy Control of Brushless

Excitation System for Steam Turbogenerators IEEE

Transactions on Energy Conversion, pp. 844852, 08,

2010.

5) Chong G, and Li Y, PID control system analysis, design,

and technology IEEE Transaction Control System

Technology ,pp. 55595576, 2005.

6) Rubaai A, Castro Sitiriche, M. J, and R. Ofoli, A., Design

and Implementation of Parallel Fuzzy PID Controller for

High-Performance Brushless Motor Drives: An

Integrated Environment for Rapid Control

Prototyping, IEEE Transactions on Industry

applications, pp. 10901098, 2008.

7) Li and Chong G, Patents, software, and hardware for

PID control IEEE Control System, pp. 4254, 2006,

2013.

8) Weirong J, Haibo, and Jianping, L. Simulation and

Design of Integral Separation Adaptive Fuzzy Control

System for Brushless DC Motor ICCIS, pp. 11941197,

2013.

9) Xia C, Guo P, Shi T, and Wang, M. Speed Control of

Brushless DC Motor Using Genetic Algorithm Based

Fuzzy Controller ICIMA IEEE, pp. 460 464, 2004.

10) Ruey Yu, and Che Hwang, R. Optimal PID Speed

Control of Brushless DC Motors Using LQR Approach

ICSMC, pp. 473478, 2004.

2016, IRJET

Impact Factor value: 4.45

ISO 9001:2008 Certified Journal

Page 725

You might also like

- Unit 45 Industrial Systems AssignmentDocument6 pagesUnit 45 Industrial Systems AssignmentTân Nguyễn75% (4)

- Simulation & Controlling of Brushless DC Motor Using PI/Fuzzy HybridDocument4 pagesSimulation & Controlling of Brushless DC Motor Using PI/Fuzzy Hybridsunil kumarNo ratings yet

- Standard Electrical SymbolsDocument40 pagesStandard Electrical Symbolssilviamenegazzo100% (13)

- Simulation & Controlling of Brushless DC Motor Using PI/Fuzzy HybridDocument4 pagesSimulation & Controlling of Brushless DC Motor Using PI/Fuzzy Hybridsunil kumarNo ratings yet

- Result PPRDocument5 pagesResult PPRMayuri Chauray-shindeNo ratings yet

- Induction Motor Speed Control Using Fuzzy Logic Controller: AbstractDocument15 pagesInduction Motor Speed Control Using Fuzzy Logic Controller: AbstractAvinash VenkatNo ratings yet

- Modelling of Neural Network Based Speed Controller For Vector Controlled Induction Motor DriveDocument4 pagesModelling of Neural Network Based Speed Controller For Vector Controlled Induction Motor DriveEditor IJRITCCNo ratings yet

- Sensorless Vector Control of Induction Motor ThesisDocument7 pagesSensorless Vector Control of Induction Motor Thesisjencloudcleveland100% (2)

- DC Link Approach To Variable-Speed, Sensorless,: Induction Motor DriveDocument5 pagesDC Link Approach To Variable-Speed, Sensorless,: Induction Motor DrivesamirmansourNo ratings yet

- A0408 05-0112 PDFDocument12 pagesA0408 05-0112 PDFIJMERNo ratings yet

- Artificial Neural Network Based Speed and Torque Control of Three Phase Induction MotorDocument4 pagesArtificial Neural Network Based Speed and Torque Control of Three Phase Induction MotorIjsrnet EditorialNo ratings yet

- Artificial Neural Network Based Speed and Torque Control of Three Phase Induction MotorDocument11 pagesArtificial Neural Network Based Speed and Torque Control of Three Phase Induction MotorGovinda RiawanNo ratings yet

- Electric Power Systems Research: F. Beltran-Carbajal, A. Valderrabano-Gonzalez, J.C. Rosas-Caro, A. Favela-ContrerasDocument6 pagesElectric Power Systems Research: F. Beltran-Carbajal, A. Valderrabano-Gonzalez, J.C. Rosas-Caro, A. Favela-ContrerasAndrei GhitaNo ratings yet

- BPS Plagiarism ReportDocument11 pagesBPS Plagiarism ReportSanjay ShelarNo ratings yet

- Sliding Mode Control of Induction Motor ThesisDocument6 pagesSliding Mode Control of Induction Motor Thesiss0kuzej0byn2100% (2)

- Implementation of Pid Trained Artificial Neural Network Controller For Different DC Motor DriveDocument13 pagesImplementation of Pid Trained Artificial Neural Network Controller For Different DC Motor DriveMuruganandam MasilamaniNo ratings yet

- Artificial Neural Network Based Controller For Speed Control of An Induction Motor Using Indirect Vector Control MethodDocument7 pagesArtificial Neural Network Based Controller For Speed Control of An Induction Motor Using Indirect Vector Control MethodAshwani RanaNo ratings yet

- Direct Torque Control of Induction Motor Using Artificial Neural NetworkDocument7 pagesDirect Torque Control of Induction Motor Using Artificial Neural NetworkMohamed SomaiNo ratings yet

- PID Controller Design for Stepper Motor Speed Control in MATLABDocument14 pagesPID Controller Design for Stepper Motor Speed Control in MATLABramsastryNo ratings yet

- DSP-Based Experimental Rig With The Doubly-Fed Induction Generator ForDocument12 pagesDSP-Based Experimental Rig With The Doubly-Fed Induction Generator Fordebasis250No ratings yet

- Genetic Algorithm Optimized PI and Fuzzy Sliding Mode Speed Control For DTC DrivesDocument6 pagesGenetic Algorithm Optimized PI and Fuzzy Sliding Mode Speed Control For DTC DrivesFrancisco Liszt Nunes JuniorNo ratings yet

- Simulation of Speed Control of Brushless DC Motor, With Fuzzy Logic ControllerDocument6 pagesSimulation of Speed Control of Brushless DC Motor, With Fuzzy Logic ControllerPradeepAgrahariNo ratings yet

- Speed Control of Induction Motor Using Fuzzy LogicDocument4 pagesSpeed Control of Induction Motor Using Fuzzy LogicEditor IJRITCCNo ratings yet

- Robust Predictive Current Control For A Sensorless IM Drive Based On Torque Angle RegulationDocument7 pagesRobust Predictive Current Control For A Sensorless IM Drive Based On Torque Angle RegulationDanielle GontijoNo ratings yet

- Simulation of Direct Current (D.C) Electrical Motor Speed ControlDocument10 pagesSimulation of Direct Current (D.C) Electrical Motor Speed ControlAsteraceae ChrysanthNo ratings yet

- Sensorless DTC of induction motor with sliding mode controllersDocument20 pagesSensorless DTC of induction motor with sliding mode controllersMuhammad UmarNo ratings yet

- Matrix AdvantagesDocument14 pagesMatrix AdvantagesAdeline WinsterNo ratings yet

- DC Motor Speed C BcontrolDocument6 pagesDC Motor Speed C BcontrolRoger RozarioNo ratings yet

- Fuzzy Very Important - InterviewDocument10 pagesFuzzy Very Important - InterviewkarthicktamilmaniNo ratings yet

- Speed Control of Brushless DC Motor Using Fuzzy Logic ControllerDocument9 pagesSpeed Control of Brushless DC Motor Using Fuzzy Logic ControllerIOSRjournalNo ratings yet

- Vector Control Simulation of AC MotorDocument16 pagesVector Control Simulation of AC MotorJosedocampocastro100% (1)

- 1#a Comparative Study of PI Fuzzy and ANN Controllers For Chopper Fed DC Drive With Embedded Systems ApproachDocument17 pages1#a Comparative Study of PI Fuzzy and ANN Controllers For Chopper Fed DC Drive With Embedded Systems ApproachalialibabaNo ratings yet

- Powers Ys 555Document6 pagesPowers Ys 555makroumNo ratings yet

- Sensors Used in HEVDocument4 pagesSensors Used in HEVvishiwizard100% (1)

- Nicola - Marcel - ICATE 2016Document6 pagesNicola - Marcel - ICATE 2016Marcel NicolaNo ratings yet

- Induction Motor Speed Control ThesisDocument7 pagesInduction Motor Speed Control ThesisPaperWritingServicesReviewsUK100% (2)

- Comparison of The Speedy Estimate Methods of The Induction MotorsDocument12 pagesComparison of The Speedy Estimate Methods of The Induction MotorsTELKOMNIKANo ratings yet

- Different Types of Speed Controllers For Brushless DC Motor - A ReviewDocument10 pagesDifferent Types of Speed Controllers For Brushless DC Motor - A ReviewGJESRNo ratings yet

- Design of PID Controller For Automatic Voltage Regulator and Validation Using Hardware in The Loop TechniqueDocument15 pagesDesign of PID Controller For Automatic Voltage Regulator and Validation Using Hardware in The Loop TechniqueroyclhorNo ratings yet

- Speed Control of A 2HP DC MotorDocument25 pagesSpeed Control of A 2HP DC MotorEdul BrianNo ratings yet

- Comparative Analysis of Field Oriented Control of BLDC Motor Using SPWM and SVPWM TechniquesDocument6 pagesComparative Analysis of Field Oriented Control of BLDC Motor Using SPWM and SVPWM TechniquesTony starkNo ratings yet

- Cascade Control of PM DC Drives Via Second-Order Sliding-Mode TechniqueDocument9 pagesCascade Control of PM DC Drives Via Second-Order Sliding-Mode TechniqueAdrián LaraNo ratings yet

- Docs 3396757885dc8d92655bafDocument11 pagesDocs 3396757885dc8d92655bafRival PratamaNo ratings yet

- 08 July 2013Document5 pages08 July 2013IJBSTRNo ratings yet

- Power System Stability Enhancement With Genetically Optimized SVC ControllerDocument6 pagesPower System Stability Enhancement With Genetically Optimized SVC ControllertinazdrilicNo ratings yet

- To Study, Analysis and Implementation of Power Quality Improvement Using DSTATCOM With ANN Back Propagation AlgorithmDocument8 pagesTo Study, Analysis and Implementation of Power Quality Improvement Using DSTATCOM With ANN Back Propagation AlgorithmEditor IJTSRDNo ratings yet

- Neural Network Based Closed Loop Speed Control of DC Motor Using Arduino Uno.Document4 pagesNeural Network Based Closed Loop Speed Control of DC Motor Using Arduino Uno.seventhsensegroupNo ratings yet

- An Intelligent Electro-Hydraulic Servo Drive Positioning: Detiček, E. - Župerl, UDocument11 pagesAn Intelligent Electro-Hydraulic Servo Drive Positioning: Detiček, E. - Župerl, Upolat035No ratings yet

- Fuzzy Control of Ac InductionDocument6 pagesFuzzy Control of Ac Inductionapi-19667371100% (1)

- Ijert Ijert: Control of Three Phase BLDC Motor Using Fuzzy Logic ControllerDocument5 pagesIjert Ijert: Control of Three Phase BLDC Motor Using Fuzzy Logic ControllergbksnNo ratings yet

- Microturbine FuzzyDocument7 pagesMicroturbine FuzzyTariq KhanNo ratings yet

- Microprocessor Based Digital PID Controller For Speed Control of D.C. MotorDocument6 pagesMicroprocessor Based Digital PID Controller For Speed Control of D.C. MotorSwapnica GarreNo ratings yet

- Improvement of Power System Transient Stability Using An Intelligent Control MethodDocument9 pagesImprovement of Power System Transient Stability Using An Intelligent Control MethodKhubaib AhmedNo ratings yet

- Speed Control of BLDC Motor Using Hybrid ControllerDocument49 pagesSpeed Control of BLDC Motor Using Hybrid ControllerAswani MucharlaNo ratings yet

- Fractional-Order PID Controller for a Buck ConverterDocument17 pagesFractional-Order PID Controller for a Buck Converterkarim belaliaNo ratings yet

- DC Series Motor ControlDocument12 pagesDC Series Motor Controldapparao100% (1)

- Microcontroller Controlled BLDC Drive for Electric VehiclesDocument4 pagesMicrocontroller Controlled BLDC Drive for Electric VehiclesAvinash Babu KmNo ratings yet

- Major Project Report Devu FinalDocument42 pagesMajor Project Report Devu FinaldeenaNo ratings yet

- Direct Torque Control of Induction Motor ThesisDocument5 pagesDirect Torque Control of Induction Motor Thesiscrystaljacksonnewhaven100% (2)

- Open Ended LabDocument8 pagesOpen Ended LabIHZAM ZIANo ratings yet

- PI Controller Relay Auto-Tuning Using Delay and Phase Margin in PMSM DrivesDocument11 pagesPI Controller Relay Auto-Tuning Using Delay and Phase Margin in PMSM Drivesrizk86No ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Pretreatment For Powder CoatingDocument15 pagesPretreatment For Powder Coatingsateeshsingh100% (1)

- SJVNL Apprentice Posts NotificationDocument3 pagesSJVNL Apprentice Posts NotificationtongocharliNo ratings yet

- FIS for Image Contrast EnhancementDocument4 pagesFIS for Image Contrast Enhancementsunil kumarNo ratings yet

- 170Document5 pages170sunil kumarNo ratings yet

- Rural Questionnare V 5 0 ManualDocument10 pagesRural Questionnare V 5 0 Manualsunil kumarNo ratings yet

- Sample Thesis ReportDocument62 pagesSample Thesis ReportSiwa KanagarajNo ratings yet

- A 252929Document46 pagesA 252929sunil kumarNo ratings yet

- Digital Signal Processing Notes-1 PDFDocument445 pagesDigital Signal Processing Notes-1 PDFWar Machine100% (2)

- Plating Kaizen Sheet 7.02.09Document6 pagesPlating Kaizen Sheet 7.02.09sunil kumarNo ratings yet

- AMIE Study Material & Admission Packages AMIE (I) Study Circle, RoorkeeDocument58 pagesAMIE Study Material & Admission Packages AMIE (I) Study Circle, Roorkeesunil kumarNo ratings yet

- EC01 - 2014 Gate 2014 Question PaperDocument17 pagesEC01 - 2014 Gate 2014 Question Paperrakesh_rodyNo ratings yet

- GATE 2013 Electrical Engineering Previous Year Paper PDFDocument20 pagesGATE 2013 Electrical Engineering Previous Year Paper PDFArif Hussain AlamNo ratings yet

- Lec 1Document48 pagesLec 1Alwin Anno SastraNo ratings yet

- Brushless DC Motors Are A Type of Synchronous MotorDocument16 pagesBrushless DC Motors Are A Type of Synchronous MotorPathanjali KumarNo ratings yet

- Energy Conversions IncDocument5 pagesEnergy Conversions Incsunil kumarNo ratings yet

- BLDC Motor Speed ControlDocument8 pagesBLDC Motor Speed Controlsunil kumarNo ratings yet

- Harsha WeldingFederal Mogul 15 11Document1 pageHarsha WeldingFederal Mogul 15 11sunil kumarNo ratings yet

- 3 1Document19 pages3 1api-3717843100% (1)

- Siemens Micro Master 420 ManualDocument218 pagesSiemens Micro Master 420 Manualamiteshdinda100% (1)

- SynopsisDocument11 pagesSynopsissunil kumarNo ratings yet

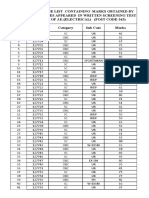

- Roll Number Wise JE(Electrical) Marks ListDocument3 pagesRoll Number Wise JE(Electrical) Marks Listsunil kumarNo ratings yet

- Stepper Motor Speed ControlDocument5 pagesStepper Motor Speed Controlsunil kumarNo ratings yet

- Symbols For EarthDocument5 pagesSymbols For Earthsunil kumarNo ratings yet

- Entrepreneurship DevelopmentDocument12 pagesEntrepreneurship DevelopmentRohit ShindeNo ratings yet

- Common Earth Symbols ExplainedDocument5 pagesCommon Earth Symbols Explainedsunil kumarNo ratings yet

- 1 Entrepreneurship and Development Lab Front PageDocument7 pages1 Entrepreneurship and Development Lab Front Pagesunil kumarNo ratings yet

- Report WritingDocument5 pagesReport Writingsunil kumarNo ratings yet

- A Review On Rapid Control of A Brushless Motor in An Hybrid SystemDocument4 pagesA Review On Rapid Control of A Brushless Motor in An Hybrid Systemsunil kumarNo ratings yet

- Automatic Control For Mechanical Engineers by M. Galal Rabie - OptDocument176 pagesAutomatic Control For Mechanical Engineers by M. Galal Rabie - OptSusan LamNo ratings yet

- CSTR Temperature Control Using IMC-PIDDocument29 pagesCSTR Temperature Control Using IMC-PIDS Kiong TingNo ratings yet

- Adaptive Control SystemsDocument16 pagesAdaptive Control Systemsrenuka mulaNo ratings yet

- Embedded Projects for Plantation Irrigation and Home AutomationDocument40 pagesEmbedded Projects for Plantation Irrigation and Home AutomationKathir VelNo ratings yet

- 02 WgetDocument260 pages02 WgetesquisofNo ratings yet

- UDC3300 HoneywellDocument92 pagesUDC3300 HoneywellCarlos VivasNo ratings yet

- Basic Control Theory PDFDocument74 pagesBasic Control Theory PDFJoshuaNo ratings yet

- Control System Notes by HPK Kumar PDFDocument56 pagesControl System Notes by HPK Kumar PDFlaiba100% (3)

- Filament Sizing Machine Options for Customized Yarn ProcessingDocument20 pagesFilament Sizing Machine Options for Customized Yarn Processingbalanbhoo100% (1)

- EAS309 Flight Dynamics ControlDocument2 pagesEAS309 Flight Dynamics ControlJamilah MrafiNo ratings yet

- T2265 PDFDocument0 pagesT2265 PDFMerlin PokamNo ratings yet

- Heat T: Eurotherm and NadcapDocument12 pagesHeat T: Eurotherm and NadcapR JNo ratings yet

- Introduction to Control Systems BasicsDocument73 pagesIntroduction to Control Systems BasicsJoseph Jeremy100% (1)

- Development of Autonomous Unmanned Aerial Vehicle Research Platform - Modeling Simulating and Flight TestingDocument202 pagesDevelopment of Autonomous Unmanned Aerial Vehicle Research Platform - Modeling Simulating and Flight TestingFabio CardosoNo ratings yet

- Arduino PID Control LED BrightnessDocument9 pagesArduino PID Control LED BrightnessAntonio GonzalezNo ratings yet

- Analysis and Development of The PLCDocument127 pagesAnalysis and Development of The PLCCiubotaru Diana ClaudiaNo ratings yet

- Test and Control System Development and Application of Landing Gear Drop Test RigDocument7 pagesTest and Control System Development and Application of Landing Gear Drop Test RigAli100% (1)

- MEC308 CONTROL ENGINEERINGDocument2 pagesMEC308 CONTROL ENGINEERINGAlakshendra JohariNo ratings yet

- Block DiagramsDocument26 pagesBlock DiagramsdebjittNo ratings yet

- 13s11 Combustion PDFDocument36 pages13s11 Combustion PDFAnonymous otUd3TzINo ratings yet

- Control System Performance PDFDocument18 pagesControl System Performance PDFChibueze EzeokaforNo ratings yet

- TWLC - Tempered Water Logic Controller: The Intelligent ControlDocument30 pagesTWLC - Tempered Water Logic Controller: The Intelligent Controlbaljak1No ratings yet

- Speed Control System Steam TurbinesDocument2 pagesSpeed Control System Steam TurbinesbagastcNo ratings yet

- M07 ControlDocument71 pagesM07 ControlLê Văn TrườngNo ratings yet

- Fully Automated Burner Management System Using PLCDocument80 pagesFully Automated Burner Management System Using PLCGanesh Seetharaman100% (1)

- RT0x0 Flyer EnglishDocument6 pagesRT0x0 Flyer EnglishRaymond LO OtucopiNo ratings yet

- RF Ablation (Needles and Designs)Document3 pagesRF Ablation (Needles and Designs)Pedro MatiasNo ratings yet

- PID Control Project - ReportDocument11 pagesPID Control Project - ReportAnonymous hnYxNZk100% (4)

- A Fuzzy Logic Temperature Controller For Preterm NeonateDocument16 pagesA Fuzzy Logic Temperature Controller For Preterm Neonatebudi_umm100% (1)