Professional Documents

Culture Documents

Permit To Work Form-Hanwha-Rev1

Uploaded by

rizwanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Permit To Work Form-Hanwha-Rev1

Uploaded by

rizwanCopyright:

Available Formats

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Rev. Date : 0728JanMar--2014

Contract No.: 14-KB-001

Doc. No.: MD-512-3000HS-HS-PRO-2007Doc.

No.: MD-512-3000-PCCS-PRO-0005

PROCEDUREPERMIT TO WORK

PROCEDURE

Rev. No.: A01

PRCEDUREPERMIT TO WORK PROCEDURE

MD-512-3000-HS-HS-PRO-2007

MD-512-3000-PC-CS-PRO-0005

zRev.

No.

Rev. Date

Description of

Revision

Prepared By

Checked By

Approved By

Approved By

(Employer)

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Rev. Date : 0728JanMar--2014

Contract No.: 14-KB-001

Doc. No.: MD-512-3000HS-HS-PRO-2007Doc.

No.: MD-512-3000-PCCS-PRO-0005

A01

28-Mar-14

PROCEDUREPERMIT TO WORK

PROCEDURE

Issue For Approval

K. W.

KANG

D. K. KIM

Rev. No.: A01

Y. H. Lim

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

REVISION INDEX

Rev

AA01

Date

28 Jan 21Mar , 2014

Description

Issue for Approval

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

TABLE OF CONTENTS

1

INTRODUCTION.........................................................................................5

OBJECTIVE.................................................................................................5

DEFINITIONS AND ABBREVIATIONS...................................................5

RESPONSIBILITY.......................................................................................6

4.1.................................................................................................................. Site Manager

................................................................................................................................ 6

4.2.........................................................................................................Site HSE Manager

................................................................................................................................ 6

4.3...............................................................................................................PTW Approver

................................................................................................................................ 7

4.4................................................................................................................PTW Receiver

................................................................................................................................ 7

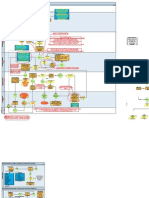

4.5...................................................................................Discipline Supervisor/Engineer

................................................................................................................................ 8

4.6..............................................................................................................HSE Supervisor

................................................................................................................................ 8

4.7.................................................................................Underground Facilities Engineer

................................................................................................................................ 9

AREA CLASSIFICATION..........................................................................9

TYPES OF PERMIT TO WORK SYSTEM............................................10

TYPES OF WORK REQUIRING PTW...................................................10

7.1.......................................................................................................................Cold Work

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

.............................................................................................................................. 11

7.2.........................................................................................................................Hot Work

.............................................................................................................................. 11

7.3......................................................................................................................Excavation

.............................................................................................................................. 12

7.4...................................................................................................Confined Space Entry

.............................................................................................................................. 13

7.5.............................................................................................................Crane Operation

.............................................................................................................................. 13

7.6..............................................................................................................Radiation Work

.............................................................................................................................. 13

7.7...............................................................................................................Electrical Work

.............................................................................................................................. 14

OPERATIONAL PROCEDURE FOR PERMIT TO WORK SYSTEM

14

8.1......................................................................................................Application of PTW

.............................................................................................................................. 14

8.2.................................................................................Review and Verification of PTW

.............................................................................................................................. 14

8.3......................................................................................................Registration of PTW

.............................................................................................................................. 15

8.4..........................................................................................................Approval of PTW

.............................................................................................................................. 15

8.5.........................................................................................................Receiving of PTW

.............................................................................................................................. 15

8.6.............................................................................................................Closing of PTW

.............................................................................................................................. 16

8.7.....................................................................................................Revalidation of PTW

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

.............................................................................................................................. 16

8.8.....................................................................................................Cancellation of PTW

.............................................................................................................................. 17

EMERGENCY OF PTW............................................................................17

ATTACHMENT 1 COLD WORK PERMIT.................................................18

ATTACHMENT 2 HOT WORK PERMIT....................................................19

ATTACHMENT 3 EXCAVATION PERMIT.................................................20

ATTACHMENT 4 CONFINED SPACE ENTRY PERMIT.........................21

ATTACHMENT 5 CRANE OPERATION PERMIT....................................23

ATTACHMENT 6 RADIATION WORK PERMIT......................................24

ATTACHMENT 7 ELECTRICAL WORK PERMIT...................................25

1

INTRODUCTION.........................................................................................4

OBJECTIVE.................................................................................................4

REFERENCE DOCUMENTS.....................................................................4

DEFINITIONS AND ABBREVIATIONS...................................................5

4.1.................................................................History of Recent Contracts Completed

................................................................................................................................ 5

4.1.1 Storm Water........................................................................................5

4.1.2 Surface Water.....................................................................................5

4.1.3 Foul Water.............................................................................................6

4.2....................................................................................................................................................Storage

................................................................................................................................ 6

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

4.2.1

4.2.2

4.2.3

4.2.4

Fuels, Oils, Paints, & Chemicals.................................................6

Security..................................................................................................7

Marking...................................................................................................7

Removal..................................................................................................8

4.3.........................................................................................................................Waste Management

................................................................................................................................ 8

4.3.1 Waste Minimization.........................................................................8

4.3.2 Waste Treatment & Storage.........................................................9

4.3.3 Waste Disposal...................................................................................9

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

INTRODUCTION

THIS DOCUMENT DEFINES THE PROJECT CONTROL

GUIDELINE OF INVOICING PROCEDURE FOR

MONITORING AND CONTROL OF THE CONTRACTORS

SCOPE OF WORK OF UMM WUAL EPC PHOSPHATE

PROJECT PHOSPHORIC ACID PLAN IN THE KINGDOM OF

SAUDI ARABIA

3

4

OBJECTIVE

THE PURPOSE OF THE PROJECT CONTROL PROCEDURE IS

TO ESTABLISH A METHODOLOGY IN RELATION TO THE

WORK OF PROJECT CONTROL SYSTEM WHICH ENSURES

THAT CONTROL OF THE WORK IS CARRIED OUT IN A

MANNER CONSISTENT WITH THE PLANNING PROGRESS

CONTROL REGIME BASED ON CONTRACT REQUIREMENT.

THE KEYS TO EFFECTIVE PROJECT CONTROL ARE;

PLANNING AND SCHEDULING

PROGRESS MEASUREMENT

COST CONTROL

10

11

REFERENCE DOCUMENTS

12

THIS DOCUMENT IS BASED ON HENCS CORPORATE AND

PROJECT PROCEDURES AND FUNDAMENTALLY

INCORPORATES THE REQUIREMENTS AS NOTED IN THE

FOLLOWING EMPLOYER PROJECT DOCUMENTS.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

13

EMPLOYER DOCUMENTS

14

15

........................................................................................................................

......MD-101-SMPM-PM-GE-PEI-0001 GENERAL REQUIREMENTS

16

........................................................................................................................

........................................................................................................................

...............................MD-101-SPPM-CP-GE-PEI-0007 CONTRACTOR

PROCUREMENT REQUIREMENTS

17

........................................................................................................................

........................................................................................................................

.....MD-101-SMPM-PC-CC-PEI-0001PROGRESS MEASUREMENT

SYSTEM REQUIREMENTS

18

19

20

CONTRACT NO.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

21

DEFINITIONS AND ABBREVIATIONS

22

EMPLOYER :

23

PMC..............................................................................................................

........................................................................................................................

........................................................................................................................

.....................................................................................................................

24

CONTRACTOR: HANWHA ENGINEERING AND

CONSTRUCTION (HENC)

25

HISTORY OF RECENT CONTRACTS COMPLETED

26

AS INFORMED EARLIER, WE WILL EXECUTE THE

PROJECT AS A CONSORTIUM. THE PARTIES OF THE

CONSORTIUM (COLLECTIVELY, CONSORTIUM, BIDDER,

CONTRACTOR, OR WE HEREINAFTER)WILL BE AS

FOLLOWS; MORE DETAILS OF EACH PARTY ARE

DESCRIBED IN SUB-SECTION 2.02 OF TECHNICAL

PROPOSAL AND SECTION 3 (FORM B) OF UNPRICED

COMMERCIAL PROPOSAL.

27

28

EMPLOYER DOCUMENTS

29

30

HANWHA ENGINEERING & CONSTRUCTION

CORPORATION (HANWHA)

31

NOW HANWHA HAS THE ORGANIZATION WITH

EXPERIENCE RANGING FROM REFINERY THROUGH

PETROCHEMICAL AND DOWN TO FINE CHEMICALS

THROUGHOUT VARIOUS PROJECTS. WE HAVE ALSO

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

FURNISHED OUR PEOPLE WITH LOTS OF TOOLS AND

FACILITIES SO THAT THEY CAN WORK EFFICIENTLY AND

SAFELY, WHICH ENABLE US TO BE CERTIFIED FOR ISO

9001 AND 14001 AS SITE DRAINAGE

32

STORM WATER

33

STORM WATER RUNOFF WILL BE CONTROLLED SO THAT

DISCHARGED WATER QUALITY WILL MEET THE QUALITY

OF THE RECEIVING WATER. RAIN WATER WILL BE

DIVERTED AS MUCH AS POSSIBLE FROM FLOWING

ACROSS THE CLEARED AREAS BY MEANS OF

INTERCEPTOR TRENCHES UPSTREAM OF THE

CONSTRUCTION OR IT WILL BE CHANNELED.

INTERCEPTOR TRENCHES WILL BE DESIGNED TO

MINIMIZE EROSION. DRAINAGE WILL BE RE-ROUTED TO

THE NATURAL DRAINAGE SYSTEM. SEDIMENT

RETENTION SHOULD BE PROVIDED, AS NEEDED, DURING

CONSTRUCTION TO REDUCE OR PREVENT SILT

TRANSPORT FROM THE CLEARED AREAS TO THE

DRAINAGE.

34

Surface Water

35

SURFACE WATER WILL BE DRAINED FROM THE WORK

AREAS INTO LOCAL DRAINAGE AND WILL NOT BE

ALLOWED TO POOL UPON CLEARED AREAS. ALL

STAGNANT WATER OR OTHER SITES FOR POTENTIAL

BREEDING OF HARMFUL INSECTS ON CLEARED AREAS

SHALL BE MINIMIZED.

36

FOUL WATER

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

37

SEWAGE WILL BE PRODUCED AT TOILET FACILITIES, BY

LAUNDRY AND CLEANING ACTIVITIES AND IN COOKING

OPERATIONS. GREASE FROM THE COOKING OPERATIONS

WILL BE REMOVED BY MEANS OF OIL/GREASE TRAPS

PRIOR TO DISCHARGE INTO THE SANITARY WASTE

WATER SYSTEM. THE GREASE WILL BE MIXED WITH A

SORBENT MATERIAL AND MANAGED AS A SOLID WASTE.

LAUNDRY FACILITIES WILL USE LOW PHOSPHATE

DETERGENTS TO PREVENT DISCHARGE OF THIS

NUTRIENT IN THE TREATED EFFLUENT.

38

ALL SANITARY WASTEWATER WILL BE DIRECTED TO

PACKAGE TERTIARY SEWAGE TREATMENT SYSTEMS OR

TO A SEPTIC SYSTEM APPROVED BY THE EMPLOYER AND

THAT MEETS THE STANDARDS SET FORTH IN THE SAUDI

LAW.

39

STORAGE

40

FUELS, OILS, PAINTS, & CHEMICALS

41

DIESEL WILL BE THE PRIMARY FUEL ON SITE DURING

CONSTRUCTION. ALL GASOLINE WILL BE UNLEADED.

DIESEL FUEL WILL BE USED FOR POWER GENERATION

AND VEHICLE OPERATION.

42

SMALL SPILLS ARE MOST LIKELY WHEN FUEL IS

TRANSFERRED TO AND FROM TANKS. SMALL SPILLS LESS

THAN 18.95 LITERS (5 GALLONS) WILL BE MANAGED, IF

NEEDED, USING SORBENT MATERIALS WHICH WILL BE

PROVIDED BY CONTRACTOR IN A FUEL SPILL KIT AT THE

SITE.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

43

HYDROCARBON CONTAMINATED SOIL WILL BE

EXCAVATED AND TAKEN TO A VOLATILIZATION PAD

WHICH WILL BE CONSTRUCTED SPECIFICALLY FOR THIS

PURPOSE. PERSONNEL WILL RESPOND TO SIGNIFICANT

SPILLS (GREATER THAN 18.95 LITERS) BY NOTIFYING THE

SITE ENVIRONMENTAL MANAGER. HYDROCARBON

SPILLS INTO SURFACE WATER WILL BE CONTAINED AND

REMOVED BY THE SPILL RESPONSE TEAM.

44

LUBRICANTS WILL BE RECEIVED IN STEEL DRUMS, OR

BULK STORAGE TANKS IF PRACTICAL. TO THE EXTENT

POSSIBLE, WASTE LUBRICANTS WILL BE RETURNED TO

THE ORIGINAL CONTAINERS AND A LABEL INDICATING

THAT THE PRODUCT IS INTENDED FOR

RECYCLE/DISPOSAL WILL BE APPLIED. WASTE LUBE OIL

WILL BE STORED AT THE POINT OF USE UNTIL TAKEN TO

A DESIGNATED APPROVED STORAGE FACILITY THAT

CONTAINS A ROOF AND CONTAINMENT BERMS. OIL

FILTERS WILL BE PUNCTURED AND GRAVITY DRAINED OF

OIL PRIOR TO DISPOSAL IN THE SOLID WASTE LANDFILL.

45

WASTE LUBRICATING OIL DRUMS WILL BE STORED ON

PALLETS IN THE APPROVED COVERED STORAGE AREA.

OIL WILL BE TAKEN OFF SITE BY CONTRACTOR FOR

RECYCLING IN THE QUICKEST TIME POSSIBLE TO AVOID

A BUILDUP OF WASTE OIL DRUMS ON SITE. SORBENT

MATERIALS PROVIDED AT THE DRUM STORAGE FACILITY

WILL BE USED IN THE EVENT OF SPILLS OR LEAKS.

LARGE SPILLS WILL BE MANAGED ACCORDING TO THE

PETROLEUM SPILL MANAGEMENT PLAN PREPARED BY

THE CONTRACTOR.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

46

HAZARDOUS WASTE WILL BE REMOVED FROM SITE

BEFORE THE 90-DAY STORAGE TIME LIMIT HAS EXPIRED.

47

SECURITY

48

HAZARD ASSESSMENT WILL BE CARRIED OUT BY

CLARIFICATION OF:

49

THE EXPECTED DURATION AND FREQUENCY OF BEING

EXPOSED,

50

THE TYPE OF EXPOSURE I.E. VAPOR, DUST, OR LIQUID,

INHALATION OR ABSORPTION BY CONTACT, AND

51

MEANS OF REDUCING POTENTIAL RISK TO TOLERABLE

LEVEL I.E. KEEPING IN TIGHTLY SEALED CONTAINERS,

ISOLATING THE OPERATOR FROM THE MATERIAL (BY

PERSONAL PROTECTIVE EQUIPMENT, OR BARRIERS,

ETC.) OR MODIFYING OR IMPROVING THE OPERATION

METHODS.

52

HAZARDOUS MATERIALS, SUCH AS RADIOISOTOPES,

CHEMICALS, ETC., WILL BE KEPT IN SUITABLE

CONTAINERS ACCEPTED BY HSE MANAGER. THE

CONTAINERS WILL BE PROPERLY LABELED TO IDENTIFY

THE CONTENTS, NATURE OF HAZARD, HANDLING,

PRECAUTIONS, ETC.

53

AREAS WHERE HAZARDOUS MATERIALS ARE USED OR

STORED AND AREAS WHERE HAZARDOUS CONDITIONS

EXIST WILL BE IDENTIFIED AND PROPERLY ISOLATED

WITH ENCLOSURES OR BARRICADES.

54

EXPOSURE TO X-RAYS AND LASERS WILL BE STRICTLY

CONTROLLED. ALL RADIOGRAPHERS WILL BE TRAINED

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

PERSONNEL, AND ALL RADIOACTIVE SOURCES WILL BE

CONTROLLED UNDER THE PERMIT TO WORK PERMIT

SYSTEM. AREAS IN WHICH RADIOGRAPHY IS TAKING

PLACE WILL BE ROPED OFF TO RESTRICT THE ACCESS OF

UNAUTHORIZED PERSONNEL. NO RADIO-ACTIVE

MATERIAL WILL BE STORED ON SITE.

55

MARKING

56

ANY TOXIC SUBSTANCES PROHIBITED POSSESSING OR

USING BY LAW AND REGULATION, SUCH AS ASBESTOS OR

ASBESTOS CONTAINING PRODUCT, PCBS, ETC. WILL NOT

BE USED ON THIS PROJECT.

57

FOR OTHER TOXIC SUBSTANCES, SUCH AS CHEMICALS,

INCLUDING SOLVENTS, CATALYST, ETC., THE SUBCONTRACTORS OR SUPPLIERS WILL SUBMIT MATERIAL

SAFETY DATA SHEETS (MSDS) TO HSE MANAGER FOR

INFORMATION. MATERIAL SAFETY DATA SHEETS WILL BE

USED FOR RISK ASSESSMENT AND ESTABLISHING RISK

CONTROL MEASURE, WHICH WILL COVER HOW THE

SUBSTANCES ARE STORED, USED AND DISPOSED WHILE

THEY ARE ON THE SITE.

58

THE ASSESSMENTS WILL STATE THE PRECAUTIONS TO BE

TAKEN BY PERSONNEL WHO USE OR CONTACT THE

SUBSTANCES ON THE WORK SITE.

59

WRITTEN INSTRUCTIONS FOR HANDLING OF HAZARDOUS

SUBSTANCES WILL BE ESTABLISHED AND DISPLAYED

NEAR THE HANDLING AND STORAGE LOCATION. THE

INSTRUCTIONS WILL INDICATE:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

60

SUBSTANCE NAME

61

NATURE OF THE HAZARD (S)

62

HANDLING PRECAUTIONS

63

EMERGENCY TREATMENT AFTER EXPOSURE TO THE

SUBSTANCE

64

SPILL CLEAN-UP

65

REMOVAL

66

THE INVENTORY OF HAZARDOUS SUBSTANCES SHOULD

BE RECORDED AND UPDATED, PERIODICALLY INCLUDING

THE NAMES OF SUBSTANCES, THE VOLUME BROUGHT IN

AND THE VOLUME CONSUMED ANY INCIDENT REPORTS,

ETC.

67

SPECIAL HSE TRAINING WILL BE GIVEN TO EMPLOYEES

WITH A RISK EXPOSED TO HAZARDOUS SUBSTANCES.

PERSONNEL EXPOSED TO OR HANDLING SPECIFIC TOXIC

CHEMICALS OR SUBSTANCES OR RADIOACTIVE

SUBSTANCES WILL RECEIVE PERIODIC MEDICAL

EXAMINATIONS.

68

WASTE MANAGEMENT

69

WASTE MINIMIZATION

70

WASTE MINIMIZATION MEANS THE REDUCTION, TO THE

EXTENT PRACTICABLE, OF THE VOLUME, THE TOXICITY

LEVEL OF THE WASTE GENERATED, THE TREATMENT

REQUIRED AND DISPOSAL. WASTE MINIMIZATION

FOCUSES ON SOURCE REDUCTION, RECYCLING AND

TREATMENT FOR REUSE. SOME OPPORTUNITIES EXIST

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

FOR WASTE MINIMIZATION AND EFFORTS WILL BE MADE

TO EXPLOIT THEM.

71

NON-HAZARDOUS CONSTRUCTION WASTE MATERIALS

GENERATED DURING CONSTRUCTION, I.E., SCRAP METAL,

SCRAP WOOD, TIMBER, ETC., WILL BE COLLECTED AND

KEPT FOR FUTURE DISPOSAL. ITEMS THAT MAY BE

RECYCLED ARE:

72

TIMBER AND WOOD PACKING FOR GENERAL USAGE;

73

BATTERIES, FOR LEAD CONTENT;

74

OFF-CUTS FROM METALS WILL BE COLLECTED AND SOLD

TO SCRAP BUYERS;

75

GLASS WASTE WILL BE COLLECTED AND RESOLD TO

GLASS WASTE BUYERS;

76

EXCAVATED FILL MATERIAL AND CONCRETE WASTE

WILL BE USED AS MUCH AS POSSIBLE FOR BACKFILL

PURPOSES; THIS MAKES ECONOMIC SENSE AS WELL AS

CAUSING LEAST DISRUPTION TO THE ENVIRONMENT,

OTHERWISE EXCAVATED MATERIALS WILL BE DUMPED

IN DESIGNATED AREAS; AND

77

WASTE OIL WILL BE STORED TEMPORARILY PRIOR TO

DISPOSAL.

78

WASTE TREATMENT & STORAGE

79

THE SERVICE FOR WASTE COLLECTION AND

TRANSPORTATION WILL BE SUBCONTRACTED TO A

LOCAL WASTE MANAGEMENT SUBCONTRACTOR.

SUBCONTRACTOR IS RESPONSIBLE FOR COLLECTION,

FINAL SEGREGATION OF WASTE TO RECYCLE, REUSE AND

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

DISPOSAL OF AT AN APPROVED OUTSIDE WASTE

DISPOSAL FACILITY AWAY FROM SITE. SUBCONTRACTOR

WILL ALSO BE RESPONSIBLE FOR RECORDING WASTE

PER THE SPECIFIED FORMAT AND SUBMITTING THE

RELATED DOCUMENTS TO CONTRACTOR HSE TEAM.

80

HOWEVER THE FOLLOWING MEASURES WILL BE TAKEN

IN GENERAL:

81

WASTE WILL BE TRANSPORTED IN A SAFE AND

RESPONSIBLE MANNER;

82

PROHIBIT THE OVERLOADING OF VEHICLES WITH WASTE

LOADS;

83

PROVIDE CONTAINMENT OR VINYL BAG DURING

TRANSPORTATION; AND

84

VEHICLES SHALL BE PROVIDED WITH NETTING OR

TARPAULIN TO PREVENT FLYING OF WASTE.

85

WASTE DISPOSAL

86

Waste will be finally disposed of two ways based on whether it has a

value or not. Waste of "value" i.e. that which can be sold to recyclers or

handed over free of cost. Waste of "no value" will be disposed of at

approved and designated waste disposal areas only by local Waste

Disposal Subcontractor.INTRODUCTION

This procedure will be applied to the Contractor controlled Site preparation,

construction, pre-commissioning and commissioning activities for the Hanwha

Overseas Project.

87

OBJECTIVE

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

The procedure is designed to provide a safe system of work that can be applied to

works identified by virtue of perceived risks, as requiring a PTW and provisions

contained in this document have been developed to ensure adequacy of control over

the safe conduct of activities on site.

88

DEFINITIONS AND ABBREVIATIONS

Employer : Saudi Arabian Mining Company (Maaden)

PMC : Fluor

Contractor: Hanwha Engineering and Construction (HENC)

Sub-Contractor: Contractors Design & Engineering, Fabrication and

Erection contractor.

HSE: Health, Safety & Environment

PTW: Permit to Work, A document endorsed by respective person who

wishes to perform non-routine or potentially hazardous work within a

restricted area.

LEL: Lower Explosive Limit, The percentage of flammable or explosive gas

in air below which, the combustion will not take place.

LV/HV: Low Voltage/High Voltage

Cold Work: Work where there is no energy or potential source of ignition.

It is a work which has been assessed and found to contain residual risk that

can be tolerated. It may cause injury, equipment damage or environmental

harm if it is not carried out with due care, attention and strict adherence to

instructions specified to perform it safely.

Hot Work: Work in which heat is applied or generated or there is a

generation of spark that can ignite combustible material and can cause fire

or explosion. It includes welding, cutting, application of flame, grinding,

riveting, etc.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Hazardous Work: Work with a reasonable risk of personnel injury,

equipment damage or environmental harm unless safety precautions are

taken.

Examples: hot work, confined space entry, excavation, work on combustible /

toxic lines/pressurized systems, entry into hazardous atmosphere with the use

of breathing apparatus, radiography (ionizing radiation), diving operations,

work on live electrical equipment etc.

Work on Live Equipment: Work intended to be carried out on equipment

which is live and contains potentially harmful energy. This type of work is

permitted i) only when the equipment cannot be made dead (isolated &

earthed) and ii) for a period less than 8 hrs. A pre-work risk assessment

shall be completed and the work performed in line with organizational

procedures.

Work at Height: Work which is carried out above the ground where there

is a risk of persons or material falling or structures collapsing.

89

89.1

RESPONSIBILITY

Site Manager

Site Manager has the sole authority to approve the permit and he will be PTW

Approver for work activities from site preparation to pre-commissioning and

Contractor Commissioning Manager will be the PTW Approver during

commissioning in Hanwha Overseas Project..

Site Manager can nominate a Discipline Superintendent as a PTW Approver during

his absence and for better operation of construction site. The name of nominated

Discipline Superintendent shall be informed to the related personnel.

Site Manager will hold ultimate responsibilities in ensuring a PTW procedure is

developed, effectively implemented and regularly updated and maintained to suit the

current construction activities throughout the project.

89.2

Site HSE Manager

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Site HSE Manager shall be responsible for the continuous monitoring of the

implementation of this procedure.

Site HSE Manager will provide feedback on performance and assist Contractor and

Sub-Contractor to plan and coordinate the work to effectively implement the

requirements of the procedure.

89.3

PTW Approver

PTW Approver shall be responsible to:

be fully aware of site conditions, the type of work to be carried out and all

the requirements stated in the Permit.

conduct an onsite inspection together with PTW Receiver to ensure that site

conditions are safe to permit the work and all requirements stated in the

PTW are implemented prior to the approval of the PTW.

withhold the issuance of the PTW if the requirements are not met, or site

conditions are not safe for the work to be carried out.

advise PTW Receiver of appropriate countermeasures to be taken, if

noticing the presence of any other potential hazards, risks that may

jeopardize the safety of the worker, tools or equipment.

ensure that all required safety-monitoring measurements are properly done

and so stated in the PTW.

ensure that all personnel involved in the work are fully aware of emergency

procedures.

Once informed the work is completed, PTW Approver shall visit the site jointly with

PTW Receiver to ensure that the work is ceased and the site is kept clean and tidy

and that there is not any ignition material.

89.4

PTW Receiver

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Task Supervisors of Sub-Contractor who are directly responsible for the work stated

in the PTW will be a PTW Receiver.

PTW Receiver will fully brief the work crew to ensure that requirements are clearly

understood by the crew under his supervision.

PTW Receiver will be responsible to:

ensure that the work is performed in accordance with the conditions

specified in the permit. He will remain at the work site to supervise the

work.

ensure that under no circumstances will by him or his crew change the

original scope of the work, which is described in the permit.

request a new permit in the event a change in the scope of the work

becomes necessary.

stop the work immediately, whenever site conditions are drastically

changed, in collaboration with Safety Supervisor, and inform PTW

Approver of the change for further instruction.

stop the work immediately and shut down all equipment upon the

occurrence of an emergency.

report the completion of the work or the expiration of the validity of a

PTW to PTW Approver, and ensure that the site is kept clean and tidy

without any smouldering/ignition sources remaining before leaving the

work area.

request for revalidation of a PTW at least two hours before the expiration,

if the work in progress requires extending the time of validity stated in the

PTW.

89.5

Discipline Supervisor/Engineer

Contractor Supervisor/Engineer will define the scope of the work requested in the

PTW.

Contractor Supervisor/Engineer will be responsible to:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

ensure that all sections of PTW are duly completed.

ensure that all required safety precautionary measures are stated in the

PTW and he will consult their Contractor safety supervisor for professional

advice.

conduct an onsite inspection jointly with PTW Receiver to ensure that site

conditions are safe to commence the work and all requirements stated in

the PTW are satisfied prior to issuance of the permit.

advise PTW Receiver of appropriate countermeasures to be taken, if

noticing the presence of any other potential hazards, risks that may

jeopardize the safety of the worker, tools or equipment.

check that all required safety-monitoring measurements are executed as

stated in the PTW.

ensure that all personnel involved in the work are fully aware of established

emergency procedures.

ensure that a pre-work meeting between all key personnel from Contractor

and Sub-Contractors involved in the work are carried out prior to work

commencement.

89.6

HSE Supervisor

HSE Supervisor will verify the PTW and will advise PTW Approver if the

requirements are not met, or site conditions are not safe for the work to commence.

Only after complete verification of the PTW and compliance of work area to safety

requirements will the Contractor Safety Supervisor endorse the PTW.

The HSE Supervisor will be responsible:

To advise a PTW Receiver of appropriate countermeasures to be taken, if

noticing the presence of any other potential hazards or risks that may

jeopardize the safety of the worker, tools or equipment.

To ensure that all required gas monitoring measurements by Sub-

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Contractor are carried out and confirmed prior to issuance of Confined

Space Entry Permit, as well as Hot Work Permits in areas under operation,

and that regular monitoring is done and noted on the PTW.

To maintain a log sheet and assigns control numbers to all Permits to Work

applications.

for full clerical control of the system including retention of the closed out

Work Permits and distribution to relevant parties.

89.7

Underground Facilities Engineer

Contractor Underground Facilities Engineer will be fully aware of the underground

components already installed, which has been constructed under his responsibility.

The Underground Facilities Engineer will check the applied Excavation Permit,

confirm and give comments so that the work might not damage any existing

underground facilities.

The Underground Facilities Engineer will be appointed for the following facilities;

U/G electric & telecom cables (temporary)

U/G electric & telecom cables (permanent)

U/G piping (permanent)

U/G temporary facilities (except electrical)

Civil (permanent)

90

AREA CLASSIFICATION

Throughout construction phase, the following areas will be categorized as follow:

Grass Root Area

Existing Facilities Areas

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Grass Root Areas are areas fenced up by Contractor allocated for the purpose of

construction for the Hanwha Overseas Project.

These areas will include the following:

Main construction worksite

Temporary Facilities

Lay-down area

Accommodation area

Existing Facilities Areas are all Client existing facilities areas including main

construction site and temporary facility sites during initial site survey and site

preparation phase prior to fencing up.

91

TYPES OF PERMIT TO WORK SYSTEM

During the project activities, two types of work permit system will be enforced:

Contractor Permit to Work System

Client Permit to Work System

The Contractor Permit to Work System shall be governed by this procedure and

cover the following project phases in Green Root Area:

Site Preparation

Construction

Pre-commissioning

The Client Permit to Work System will be implemented on site early before the

beginning of plant commissioning activities and any activities in Existing Facilities

Areas and also can be implemented during commissioning stage.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

92

TYPES OF WORK REQUIRING PTW

Any work failing into the following categories which executed by Sub-Contractor

shall require obtaining the PTW issued by the Contractor. Sub-Contractor shall not

commence the work activities which described in the following section without the

related PTW and shall follow the procedure of this PTW Procedure.

92.1

Cold Work

This PTW is required for the following activities that does not fall into the Hot

work, Excavation, Confined Space Entry, Crane Operation, Radiation Work,

Electrical Work and Removal of Platform, Grating, Handrail and Stair Threads. The

following activities are as below:

All works that involve the removal of platform, grating, handrail, stair

threads and other parts of a structure which may expose workers to hazard

of falling from a height.

Pneumatic test

Seal a vessel or re-charge a line Clearing of punch list items on equipment

that has not yet been commissioned or operated.

Clearing of punch list items on equipment that has not yet been

commissioned or operated.

Other required works

Additional work activities shall be applied this Cold Work Permit after Client and

Contractor agrees to apply the additional work activities required PTW.

92.2

Hot Work

Any work in a live, restricted or commissioned area requires a PTW. Particular care

and attention will be given to the selection of tools and equipment to be used in the

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

area in case ignition sources may be introduced. But a Hot Work Permit is required

precisely because an ignition source is introduced.

The following are potential ignition sources which involve spark travel:

Brazing

Grinding

Burning

Dry abrasive blasting

Chipping including use of a needle gun

Welding

Open fires and smoking materials

Explosives

Other potential ignition sources may include, but are not limited to, the following:

Cathodic protection

Electric tools or lights

Energized electrical work in classified area

Extension cords equipped with non-explosion proof connector

Generators

Internal combustion engines

Iron sulfide exposed to air (if not kept wet)

Soldering

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Vehicle

Any work in a live, restricted or commissioned area requires a PTW. Particular care

and attention will be given to the selection of tools and equipment to be used in the

area in case ignition sources may be introduced.

Hot Work is required for any work that will introduce heat and ignition sources (e.g.

welding, grinding, plate cutting using oxy-acetylene gas, etc.) and performed in any

of the following areas:

Inside occupied office areas

Within 15 meters of hydrocarbon source

In a confined space

Other areas where hot work permit is deemed necessary by Contractor

depending on work location and degree of fire hazard within the work area

constant gas monitoring may be required.

92.3

Excavation

Excavation is required for any excavation work carried out in following all areas:

Inside of any operational areas

Within 3 meters of underground pipeline, cables

Within 3 meter of underground facilities

Any other excavation not covered in 3 items above but has a depth of more

than 1.5 meters.

Pile driving, soil boring, drilling, sheet piling and other similar activities that expose

underground facilities to risk of being damaged are covered by the provisions of this

section.

All existing underground services within the vicinity of excavation will be

confirmed by authorized Contractor personnel. Location map showing the location

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

and depth of services will be attached to the permit prior to approval.

92.4

Confined Space Entry

Confined space entry is required for any of the following work categories:

Any entry into manholes

Any entry into vessels, stacks, silos and other enclosed spaces

Any entry into and carrying out of works inside steel tanks

Any entry into other spaces not mentioned above where ;

-

There is a possibility of oxygen deficiency

Harmful air contaminants have the potential hazard or are likely to be

present

Access or egress is restricted.

Where an excavation depth exceeds 1.2 meters.

92.5

Crane Operation

Crane Operation covers all lifting activities that require lifting study, i.e., Class 2, 3

and complex lifts as defined. For clarification purposes, lifting of 20 or 40 long

container is classified under Class 1 lift provided the weight limit of 20 ton is not

exceeded.

92.6

Radiation Work

Radiation Work covers all site works that involve the use of radioactive materials,

specifically for testing of welded joints.

Radiography shall only be carried out subject to 24 hours in advance notification for

radiation work at site. Before a PTW for Radiation Work is issued, the notification

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

shall be given to all Sub-Contractors and Client/PMC and Contractor.

Note: Radiography shall only be carried out by competent/certified NDE

technician(s) in tine with the Sub-Contractors duly approved procedure and such

activities will be programmed wherever possible after normal working hours.

92.7

Electrical Work

The Electrical Work is required for all electrical works under the following

conditions:

When de-energization of existing power line or equipment is required,

before energization of LV/HV cable or equipment

When the work to be carried out is in close proximity (less than 3.0 meters)

to an existing high voltage line or permanent electric equipment.

During testing and commissioning of permanent equipment or at any time

when exposure to live circuit is present.

Reconnect electricity

Electrical Work Permit is not required during routine maintenance of generators and

operation of welding machines used during the construction stage.

93

93.1

OPERATIONAL PROCEDURE FOR PERMIT TO WORK

SYSTEM

Application of PTW

Sub-Contractors task Supervisor (PTW Receiver) prepares relevant PTW and

submits application (fill in carbon copy format consisting of 3-color copies

(white/red/yellow) to Contractor Supervisor/Engineer for review and verification

before 14:00 hours on the day before commencement of work. When necessary,

further explanation or check list which shows the location and the detail of the work

will be attached.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

93.2

Review and Verification of PTW

Contractor Supervisor/Engineer scrutinizes the contents of each PTW Application

and verifies that all the pertinent safety precautions and requirements are clearly

specified therein.

Contractor Supervisor/Engineer confirms in the field the preparedness of work area

and correctness of information contained in the PTW Application. He then signs on

the PTW upon verification.

For excavation permits, Contractor Supervisor/Engineer (including electrical

engineer) will coordinate with assigned Contractor responsible personnel (basically

line Managers/Superintendents) who are authorized to check and ascertain the

presence of any underground facilities within the vicinity of planned excavation.

The Contractor assigned Supervisor/Engineer signs on the appropriate space

provided.

Hot Work Permits require verification and endorsement by Contractor Safety

Supervisor in-charge of the live area where work will be conducted.

After review and verification, Contractor Supervisor/Engineer submits the PTW to

the Contractor Safety Supervisor for control check.

93.3

Registration of PTW

Contractor Safety Supervisor assigns a control number and registers the PTW on a

log sheet.

The control number of the Permits is controlled and classified for each SubContractors PTWs.

Contractor HSE Supervisor will serve permit to Contractor Supervisor/Engineer

with comments considering site conditions.

93.4

Approval of PTW

PTW is forwarded to PTW Approver by Contractor Supervisor/Engineer for

approval.

PTW Approver checks and signs Permits to Work after check the working condition

at site.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

93.5

Receiving of PTW

Before work commencement, Joint Site Inspection will be conducted at the work

site, where Contractor Supervisor/Engineer will bring the PTW (full set). Contractor

Supervisor/Engineer, Contractor Safety Supervisor and PTW Receiver will come to

the work site together to check for compliance to requirements stated in the PTW.

In case of Confined Space Entry Permit, oxygen and harmful air content will be

measured by Contractor Safety Supervisor before the work commencement and

periodically during the work. The test results will be recorded on the work permit.

Contractor Safety Supervisor measures oxygen level and checks for presence of

flammables and/or toxic gas at worksite before comment of work and every 20

minutes during the Confined Space Work.

A pre-work meeting attended by Contractor Supervisor/Engineer and SubContractor personnel will take place before PTW is executed.

A copy of the Approved PTW (white, red copy) is given by the Contractor

Supervisor/Engineer to the PTW Receiver.

Yellow copies will be attached on PTW Notice Board at Contractor office.

Red copies will be displayed on PTW Notice Board nearby working area at site by

the Receiver and white copies will be filled (or kept) at Sub-Contractor office.

93.6

Closing of PTW

When the day of work is completed and no further work is to take place under a

PTW, immediately, the PTW Receiver will check that the work has been completed

and the work site is safely closed.

The PTW Receiver will sign off and return the PTW (red and yellow copies) with

the Contractor Supervisor/Engineers signature to Contractor Safety Supervisor for

closing immediately upon completion.

93.7

Revalidation of PTW

Validity of the PTW will be restricted to hours as specified in the PTW. No works

will be carried out after the validity has expired unless revalidation of the PTW is

obtained or a new PTW is approved by the PTW Approve.

If the work in progress is deemed to extend beyond the validity period, the PTW

Receiver will obtain revalidation from the PTW Approver at least two hour before

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

expiry.

In case that the work is not completed within the validity period, the PTW Receiver

returns the PTW (red and yellow copies) with the Contractor Supervisor/Engineer

signature to the PTW Approver for revalidation at least two hours before expiry.

PTW Approver revalidates and returns permit (red and yellow copies) to the PTW

Receiver through Contractor Supervisor/Engineer.

93.8

Cancellation of PTW

An approved PTW will be automatically cancelled under the following conditions:

There is a complete change in activities from than the ones specified in the

permit.

Work area is deemed unsafe, requiring work to be suspended.

An emergency situation exists.

A canceled PTW will be marked by Contractor Safety Supervisor accordingly and

returned to Contractor HSE supervisor for filing.

A canceled PTW cannot be revalidated; hence, a new PTW application will be made

prior to resumption of work.

94

EMERGENCY OF PTW

When an emergency, such as a fire incident, has taken place the Receive of the PTW

will immediately stop all works and shut down all equipment.

All permits to Work will be nullified by the Receiver of permit. No work will be

resumed unless new Permits to Work have been issued out by the Approver.

Prior to the issuance of a new PTW, the Approver of the PTW will visit the work site

to ensure that there is no imminent hazard/risk present and that the work site is safe

for work to proceed.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

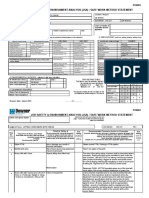

ATTACHMENT 1

COLD WORK PERMIT

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Details of Work:

Work Location:

Description of Hazards:

Expected Work Period: From

hrs To

hrs

Date:

Other Permit Required:

Task Supervisor Company/Name/Position:

Workers:

No. of Workers:

Signature:

SignatureNo. of

Equipment & Tools to be used:

Personal Protective Equipment (PPE)

..............................................

Helmet

Safety Glass

Goggle

Face Shield

Must Mask

Mask-Respirator

Mask-Comp. Air Line

Mask-Airl ine-Blower

Mask-Self-Contained

Ear Plug

Ear Muff

Leather Glove

Cotten Glove

Rubber Glove

Pastic Glove

Safety Shoes

Rubber Safety Boots

Full Body harness

Work Visual Jacket

Life Jacket

Signal Flag

Rubber Glove

Rain Coat

Fire Extinguisher

Warning Sign/Notices

Barricade

Lighting

Life Line

Scaffoding/Work Platform

Road Closure

Watch Man

Signal Man

Special Training

Safety Personnel Covered

Leather Glove

Gas Test

Work Place Safety Precaution

Permit Approval

Validity of the Permit: From

hrs. To

Reviewed by (Contractor Line S/V)

Name/ Position:

Control Check by (Contractor HSE Supervisor) Name/ Position:

Approved by

Name:/ Position:

Received by (Sub-Contractor S/V)

Name/ Position:

................

hrs.

Date:

SiSiggnature:

Si Signature:

Signature:

/

Signature:

Permit Revalidation

Day

Date

Time

Prepared

Approved

Permit closure

Closed by (Receiver) Name:/ Position:

(Approver) Name/ Position:

/

/

Date/Time closed:

Date/Time closed:

Signature:

Signature:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

ATTACHMENT 2

HOT WORK PERMIT

Details of Work:

Work Location: SKCH Southren lay down

Description of Hazards:

Expected Work Period: From 5am

hrs To 7AM

hrs

Date: 9 JAN 2016

Other Permit Required:

Task Supervisor Name/ Position: GANESH

/SUP

Signature:

No. of Workers: 4

Equipment & Tools to be used:

Safety Checks: Y: Yes

N: No,

N / A: Not Applicable

Item

NA

Remarks

Depressurized, drained, flushed, purged

Isolated/blinded from system

Process, utility, electrical

No combustible material

Explosion proof electrical equipment

Fire wall

Earthing against static electricity

Caution sign boards

Standby fire fighting equipment

Safety instructions given to workers

Flammable Gas Testing Results: Before work start

Name

Time

Content

Signature

Comments/Remarks:

Permit Approval

Validity of the Permit: From 5am

Reviewed by (Contractor Line S/V)

hrs

To 7AM

hrs

Name/ Position:

Date: 09

/

JAN 2016

Signature:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Control Check by (Contractor HSE Supervisor)

Name/ Position:

Signature:

Approved by

Received by (Sub-Contractor S/V)

Name:/ Position;

Signature:

Name/ Position:

Signature:

Permit closure

Closed by (Receiver) Name:/ Position

(Approver) Name/ Position:

/

/

Date/Time closed:

Signature:

Date/Time closed:

Signature:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

ATTACHMENT 3

EXCAVATION PERMIT

Details of Work:

Location of Work:

Depth of the excavation:

Expected Work Period: From

hrs To

hrs

Date:

Other Permit Required:

Task Supervisor Company/ Name/Position:

Signature:

No. of Workers:

Equipment & Tools to be used:

Safety Checks: Y: Yes

N: No,

N / A: Not Applicable

Item

NA

Underground obstructions identified (marked sketch attached)

Remarks

Hand digging required to locate obstruction

Marking for exact excavation location

Approved Work Method Statement provided

For deeper than 1.5 m

Shoring/support, or slope provided

Adequate ingress/egress provided

For deeper than 1.5 m

Signs & robust barricade provided

Along/Around excavation

Drainage system provided

Workers received safety training

Disposal area for excavated soil identified

Access along the excavation maintained

At least 1 meter wide

Underground Obstructions:

Description

NA

Checked - - Comment by:

U/G electric & telecom cables

U/G piping

U/G temporary facilities, Civil(Permanent)

Special Notes:

Permit Approval:

Validity of the Permit: From

hrs to

hrs

Date

Reviewed by (Contractor Line S/V)

Name/ Position:

Signature:

Control Check by (Contractor HSE Supervisor)

Name/ Position:

Signature:

Approved by

Name/ Position:

Signature:

Date:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Received by (Sub-Contractor S/V)

Name/ Position:

Signature:

Permit closure:

Closed by (Receiver) Name/ Position:

Date/Time closed:

Signature:

(Approver) Name/ Position:

Date/Time closed:

Signature:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

ATTACHMENT 4

CONFINED SPACE ENTRY PERMIT

Details of Work:

Work Location:

Description of Hazards:

Expected Work Period: From

hhrs To

hrs

Date:

Other Permit Required:

Task Supervisor Company/ Name/ Position:

Signature:

................. No. of Workers:

Equipment & Tools to be used:

Safety Checks Y: Yes

N: No,

N / A: Not Applicable

Item

NA

Remarks

No hazardous substances present

Inside vessel

Isolated/blinded from system

process,utility, elec.

No combustible material inside

Natural/forced ventilation provided

Breathing apparatus being used

specify type

Explosion proof electrics furnished

If necessary

Adequate lighting provided

Flame proof low voltage

Look out or rescue staff standing by outside confined space

Tally board present

Workers to work in pairs

Lifeline to be furnished

safety harnesses to be worn

Standby rescue equipment

Workers received safety training

Other necessary precautions

Communication with work party inside

To raise alarm

Communication to raise alarm in HSE department

Atmospheric Measuring Result

O2 Content Results:

Name

Time

Flammable Gas Testing Results :

Content

Signature

Name

Time

Content

Signature

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Remarks:

Remarks:

Permit Approval:

Validity of the Permit: From

hrs .

To

hrs

Reviewed by (HAMWHA Line S/V)

Name/ Position:

Control Check by (Contractor Safety Supervisor)

Name/ Position:

Approved by

Name/ Position:

Received by (Sub-Contractor S/V)

Name/ Position:

hrs.

Date:

Signature:

Signature:

Signature:

Signature:

Permit Revalidation

Revalidated

Approver

Time: From

Name/ Position:

hrs

To

hrs

Date/ Time:

Date :

Signature:

Permit closure

Closed by (Receiver) Name/Position:

(Approver) Name/Position:

Date/Time closed:

Signature:

Date/Time closed:

Signature::

Pre-work Meeting Attendance:

Contractor (Name & Signature)

Sub-Contractor (Name & Signature)

1.

1.

2.

2.

3.

3.

4.

4.

5.

5.

6.

6.

7.

7.

8.

8.

9.

9.

10.

10.

11.

11.

12.

12.

13.

13.

14.

14.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

15.

15.

16.

16.

17.

17.

18.

18.

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

ATTACHMENT 5

PERMIT

CRANE OPERATION & LIFTING

Details of Work:

Location of Work:

Description of Hazards:

Expected Work Period: From

hrs To

hrss

Date:

Other Permit Required: :

Crane Type :

Model No. :

Vehicle No.:Operator Name:

Registration by:

Type of the Load to be lifted:

Certificate No.:

Validity:

Maximum Weight of the Load:

Task Supervisor Company/ Name/ Position:

Workers:

Crane Operator Name:

Safety Checks

Sling-man:

Y: Yes

Item

Signature:

No. of

Signalman Name:

N: No,

N / A ; Not Applicable

Y N N/A

Crane operator holding valid Licence

Remarks

No. Validity:

Crane travel routes determined

Crane operating area determined

Crane siting on firm foundation

Outrigger Padding

Area roped off & signs displayed

Underground facilities protected

By metal plates, etc.

Overhead power cables protected

Control access

Equip. facilities in vicinity guarded

All safe guards furnished

Sling wire certified or tested

SWL

Lifting Gear colur coded

Other necessary Precautions:

Permit Approval

Validity of the Permit: From

hrs.

To

hrs .

Date:

Reviewed by (HAMWHA Line S/V)

Name/ Position:

Signature:

Control Check by (Contractor Safety Supervisor)

Name/ Position:

Signature:

Approved by

Name/ Position:

Signature:

Received by (Sub-Contractor S/V)

Name/ Position:

Signature:

Permit Revalidation

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Time:

From

hrs

Revalidated

Date :

Approver

Name/ Position:

Signature:

Permit closure

Closed by (Receiver ) Name/ Position:

Date/Time closed:

(Approver) Name/ Position:

Date/Time closed:

Signature:

Signature:

To

o

hrs

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

ATTACHMENT 6

RADIATION WORK PERMIT

Details of Work:

Work Location:

Description of Hazards:

Expected Work Period: From

hrs To

hrs Date:

Other Permit Required:

Task Supervisor Company/ Name/ Position:

Signature:

No. of Workers:

Details of Classified Workers carrying out Work :

Name

ID No.

License No.

Detail of Radiation Source

(a) Gamma-ray or X-ray apparatus ( Mmake/ type ) :

(kV)

(b) Sealed source type:

(c)

Sstrength: _______

Max. tube voltage: _______

Ccuries

Serial No:

Safety Checks:

Y: Yes

N: No,

N/A: Not Applicable

Item

NA

Remarks

Radiation areas barricaded

Caution notice posted

Radiation area boundaries monitored

Warning lights etc. positioned

Rad. meters checked & calibrated

Remote handling equip. checked

Sealed source container checked

Other Necessary Precautions

Permit Approval

Validity of the Permit: From

hrs. To

................

hrs.

Reviewed by (Contractor Line S/V)

Name:/ Position:

Signature:

Control Check by (Contractor Safety Supervisor)

Name/ Position:

Signature:

Approved by

Name/ Position:

Signature:

Date:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Received by (Sub-Contractor S/V)

Name/ Position:

/:

Signature:

Permit Revalidation

Revalidated

Approver

Time

From

hrs ToO

Name/ Position:

hrs

Date :

SignatuSignaturerere :

Permit closure

Closed by (Receiver): Name/ Position:

(Approver): Name:/Position:

Date/Time closed:

/

Date/Time closed:

Signature:

Signature:

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

ATTACHMENT 7

ELECTRICAL WORK PERMIT

Details of Work:

Work Location:

Description of Hazards:

Expected Work Period: From

hrs To

hrs

Date:

Other Permit Required:

Task Supervisor Company/Name/ Position:

Signature:

No. of Workers:

Equipment & Tools to be used:

Safety Checks:

Y: Yes

N: No,

N/A: Not Applicable

Item

A. Work Requiring Isolation

Isolation plan provided

Approved Work Method Statement Provided

All switch boxes double locked up

Warning notices provided

Work area fenced or roped off or screened

Apparatus dead proved by test

Earthing provided

Other necessary precautions

B. Work on Live Equipment

Approved Work Method Statement provided

Safety equipment provided

- Insulating rubber gloves

- Insulating rubber boots

- Insulating rubber mats

- Other tools and equipment

Danger & caution notice posted& Access Controlled

Safety Training Provided

Other necessary precautions

Special Note

NA

Remarks

UMM WUAL PHOSPHATE

PROJECT Phosphoric Acid Plant

Contract No.: 14-KB-001

Doc. No.: MD-512-3000PC-CS-PRO-0005

PROCEDURE

Rev. Date : 07-Jan-2014

Rev. No.: A01

UMM WUAL PHOSPHATE PROJECT

Phosphoric Acid Plant

Any Electrical work that requires isolation will have a Checklist for the Electrical Isolation Certificate and will be duly signed and witnessed by the

Contractor Electrical Engineer responsible for the work.

Permit Approval

Validity of the Permit: From

hrs s.

To

hrs

Reviewed by (Contractor Line S/V)

Name/ Position:

Control Check by (Contractor Safety Supervisor)

Name:/ Position:

Approved by

Received by (Sub-Contractor S/V)

Date:

Signature:

/

Signature:

Name:/ Position:

Signature:

Name/ Position:

Signature:

Permit Revalidation

Revalidated Time: From

Approver

hrs To

Name/ Position:

.....

hrs

Signature

Permit closure

Closed by (Receiver) Name/ Position:

: /

(Approver) Name/ Position:

/ :

Date/Time closed:

Date/Time closed:

Signature:

Signature:

Pre-work Meeting Attendance:

Contractor (Name/ Position & Signature)

Sub-Contractor (Name/ Position & Signature)

1.

1.

2.

2.

3.

3.

4.

4.

5.

5.

Date :

You might also like

- HSE Action TrackerDocument3 pagesHSE Action TrackerLouis Danny90100% (1)

- 010 - Permit To Work Procedure Feb 2013Document61 pages010 - Permit To Work Procedure Feb 2013vdeviv100% (1)

- PDO LSRs Notes EnglishDocument24 pagesPDO LSRs Notes Englishcmrig74No ratings yet

- Hse PlanDocument48 pagesHse Plansellitt ngNo ratings yet

- EPC-5 Project Incident RegisterDocument6 pagesEPC-5 Project Incident RegisterAgung Tri SugihartoNo ratings yet

- 3S HSE MS Docs ContentDocument85 pages3S HSE MS Docs Contentrashid zamanNo ratings yet

- TM 9-1751 Cylinder, Radial, Gasoline Engine (Continental Model R975-C1) 1944Document237 pagesTM 9-1751 Cylinder, Radial, Gasoline Engine (Continental Model R975-C1) 1944Kelsey Yuen50% (2)

- Diesel GensetDocument2 pagesDiesel Gensetvega f ankaNo ratings yet

- Permit To Work Procedure (10.11.2018)Document20 pagesPermit To Work Procedure (10.11.2018)Bebe BucătaruNo ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- OLNG Permit to Work ProcedureDocument46 pagesOLNG Permit to Work ProcedureMauro MLR50% (4)

- HSE Committee Meeting Rev1Document25 pagesHSE Committee Meeting Rev1Khaled Ismail100% (1)

- 24 - Excavation and Trenching Procedure V2.0 PDFDocument46 pages24 - Excavation and Trenching Procedure V2.0 PDFSAFETY R50% (2)

- Safety ActivitiesDocument37 pagesSafety ActivitiesEleonor Maderazo100% (1)

- Incident Accident RegisterDocument2 pagesIncident Accident RegisterMuruganNo ratings yet

- Permit To Work Procedure OHS820Document8 pagesPermit To Work Procedure OHS820Andre MarsNo ratings yet

- Confined Space Entry ProgramDocument18 pagesConfined Space Entry ProgramHaleem Ur Rashid BangashNo ratings yet

- Safety Violation NoticeDocument1 pageSafety Violation NoticeJAZPAKNo ratings yet

- All Forms HSE Docs by Hseprof Com 1697423389Document76 pagesAll Forms HSE Docs by Hseprof Com 1697423389ahmedalderbi801No ratings yet

- HSE Monitoring SampleDocument1 pageHSE Monitoring SamplerwerwerwNo ratings yet

- Confined Space Rescue PlanDocument2 pagesConfined Space Rescue PlanSara Scherer80% (5)

- Permit To WorkDocument12 pagesPermit To WorkRaymund Pilayre100% (2)

- Hot Work PermitDocument2 pagesHot Work PermitAndiWSutomoNo ratings yet

- Permit To Work Systems Hsg250Document1 pagePermit To Work Systems Hsg250paramjyot_sabharwal0% (1)

- Permit To Work ProcedureDocument25 pagesPermit To Work ProcedureGordon Watson100% (1)

- 01.01. HSE ManagementDocument64 pages01.01. HSE ManagementHussainNo ratings yet

- 4.01 IOEC Rigs Commisioning Project HSE PlanDocument59 pages4.01 IOEC Rigs Commisioning Project HSE Planhshobeyri100% (2)

- Financial Market and Portfolio Management Assignment 2Document6 pagesFinancial Market and Portfolio Management Assignment 2leeroy mekiNo ratings yet

- Contractor HSE Management ProcedureDocument9 pagesContractor HSE Management ProcedureWinnie Eldama100% (1)

- HSE Training HistoryDocument1 pageHSE Training HistorysubhanmusadiqNo ratings yet

- F-07-Safety Violation Notice Rev02Document1 pageF-07-Safety Violation Notice Rev02HRTYRNo ratings yet

- Permit To Work ProcedureDocument5 pagesPermit To Work ProceduresinghajitbNo ratings yet

- ESIA WaadDocument463 pagesESIA WaadRRHH100% (3)

- Method Statement of Static Equipment ErectionDocument20 pagesMethod Statement of Static Equipment Erectionsarsan nedumkuzhi mani100% (4)

- Safety AlertDocument1 pageSafety Alertjithin shankarNo ratings yet

- Weekly HSE Inspection Form-MTHLDocument138 pagesWeekly HSE Inspection Form-MTHLdeepak925No ratings yet

- Health, Safety and Environmental Management Plan for South Treatment PlantDocument55 pagesHealth, Safety and Environmental Management Plan for South Treatment PlantIsaac Asante-AmponsahNo ratings yet

- Rev1 Construction Site Health and Safety Plan PDFDocument91 pagesRev1 Construction Site Health and Safety Plan PDFZantar AbdelhaqNo ratings yet

- Electrical Power System Design For Industrial FacilitiesDocument29 pagesElectrical Power System Design For Industrial Facilitiesgusgon521292100% (1)

- B-Positioning XA RA XO XDDocument2 pagesB-Positioning XA RA XO XDSorin100% (1)

- Y-Site Drug Compatibility TableDocument6 pagesY-Site Drug Compatibility TableArvenaa SubramaniamNo ratings yet