Professional Documents

Culture Documents

2008 - 7 - 4 4L30E Pump

Uploaded by

Jon RodriguezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2008 - 7 - 4 4L30E Pump

Uploaded by

Jon RodriguezCopyright:

Available Formats

PLAYING WITH FIRE

by Jon Rodriguez

4L30E Pump Interchange pressure and converter charge

issues.

2. Torque converter clutch regulator

valve wear. The pulse width modu-

lated apply of the converter is con-

trolled through the converter clutch

regulator valve. You’ve probably

W

elcome to the first edition

of Playing with Fire. In this

new series, we’re going to

cover the most common interchange

questions that we receive on the ATRA

HotLine.

Interchange is an important subject

because of the risk verses reward factor

that comes into play. Sometimes a dif-

ferent style part can be less expensive,

more plentiful, and in some cases such

as this one, improve the durability

of the transmission. All of which can

make the job more profitable. The risk?

Virtually none… as long as you handle

the interchange correctly.

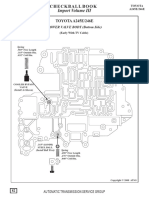

In this edition we’re going to look

at how to use a two-valve, on/off-style

lockup pump in place of the four-valve,

PWM-style lockup pump in 2000-2004

Trooper and Axiom 4L30E transmis-

sions.

There are two common reasons for

pump failure in the PWM-style pumps:

1. Pump gear and cavity wear. Any

galling or clearances above 0.003”

between the outer pump gear and

pump body, or between the inner

pump gear and crescent, aren’t

acceptable. Using a pump with

wear in these areas will reduce

pump volume and cause line Figure 1

4 GEARS July 2008

experienced code P1811 — trans- 3.5L engine. The spring behind the TCC con-

mission component slipping — in The other part of the system is the trol valve applies 4.5 lbs at working

both front- and rear-wheel drive TCC solenoid. Since an on/off-style height. With the valve’s signal land

GM transmissions, and the 4L30E lockup solenoid has a resistance of 18- being 0.12”, it’ll take about 38 lbs of

is no exception. The cause is wear 20 ohms and the PWM solenoid has a signal oil to switch the valve.

in the regulator valve bore, which resistance of 9.5-10.5 ohms, always use With the help of G&S Transmis-

reduces clamping force on the deli- the PWM style solenoid or the computer sions in Garden Grove, CA, we moni-

cate woven carbon converter clutch will set code P1860 (TCC solenoid elec- tored the TCC solenoid duty cycle in

material. trical circuit). a 2000 Trooper with the PWM-style

An important consideration is how pump and converter. The computer

Parts Differences lockup will feel after the changeover. started to signal the solenoid at about

This isn’t going to be an in-depth TCC apply will be firmer than it was 40 MPH, and quickly rose to 50% duty

look at the theory of both pumps. with the PWM system. Always discuss cycle. The duty cycle remained at 50%

Instead, we’re going to focus on how this with the customer before the conver- through third and fourth gears.

to identify the two systems’ parts, and sion; don’t wait until you’re finished to

what you need to change. For those of explain the difference. If you explain it

you who want the “whys” answered, beforehand, the customer will expect the

we’ll discuss that at the end of this difference and appreciate your efforts;

article. waiting until later, your explanation

CAUTION: Never attempt to cross starts to sound more like an excuse for a

the bellhousing, pump plate, and pump condition you weren’t expecting.

body. When making this conversion,

all three of these components must be Why It Works

the non-PWM style. These components Figure 5 shows the differences in

are completely different; mismatching the pump gasket area. The on/off pump

them will damage the transmission. is missing the additional machining

Refer to figure 1 to identify the differ- groove for the enable valve in the PWM

ent parts. pump. This won’t affect gasket sealing

The one part that can be modified or hydraulic operation.

to work with either system is the input The other difference is the addition

shaft. The fluid passages in both shafts of a front seal drainback hole that leads

are identical (figure 2). The one differ- straight to exhaust in the overdrive sec-

ence is the PWM-style shaft doesn’t tion. This is actually a better design,

have an orifice check valve at the con- because there’s less wormtrack area

verter end (figure 3). If possible, you for crossleaks to allow pressure to get

should use the on/off-style shaft with behind the front seal and cause front

the valve already installed, but if it isn’t seal popout.

available, you can install a new valve Now let’s look at the hydraulic

into the PWM shaft. The check valve is operation: Figure 5 shows the TCC

the same as the one in a 4L60E and is solenoid signal hole is in the identical

available from your transmission parts location in both pumps. The difference

supplier. is instead of the solenoid signal oil

Never use a shaft without the actuating the enable valve, the torque

valve; that will cause extremely firm converter clutch control valve, and the

TCC apply and will damage the TCC isolator valve, it now has only one

clutch material. responsibility: to shift the on/off con-

One final difference involves the verter clutch control valve to the apply Figure 2

torque converter itself: The PWM con- position.

verter uses a woven carbon clutch; the

on/off style uses a standard paper clutch

(figure 4). Since we’re going to convert

lockup apply to an on/off style, there’s

no need to spend the extra money on

the woven carbon-style clutch. In fact,

the woven carbon is more delicate than

the paper, and could be damaged if used

with a firm, on/off apply. The paper

clutch style converter can be ordered

by using the Rodeo Application with a Figure 3

GEARS July 2008 5

4L30E Pump Interchange

50% is low,

because the freshly-

built transmission had

a solid lockup and the

computer saw that

the clutch was fully

engaged at 50%. The

computer will con-

tinue to increase the

duty cycle until the

slip drops below 50

RPM. On the PWM

application, the clutch

is designed to slip no Figure 4

more than 50 RPM,

but usually slips under 5 RPM. computer will only set code P1811 with the pump area.

Second gear oil provides TCC when the slip is between 250 and 800

solenoid feed; basically it’s mainline RPM for seven seconds, and it has to I hope you enjoyed this first edi-

pressure. Using our solenoid dyno in occur three times in a row. tion of Playing with Fire as much as

the shop, we found that at 90 PSI — The other code is P0742 — TCC I did researching and writing it. If you

which would be a light throttle cruising stuck on. This code will only set if TCC have an interchange question you’d like

pressure — it takes a 45% duty cycle is commanded completely off and TCC to see addressed here, drop us a line

to achieve 50 lbs of signal oil to the slip is between –20 and 40 RPM for and we’ll see about presenting it in a

actuating side of the TCC control valve. two seconds, while throttle opening is future issue.

That’s plenty of pressure for our 38-lb above 20%. That isn’t a condition that Until then, remember: If you’re

valve to stroke. Voila! Lockup. From this modification should affect. going to play with fire, make sure you

that point, as line goes up, the duty That’s it. Lockup will work beau- pay attention and know exactly what

cycle will need less signal to engage tifully and line pressure will run the you’re doing. That way you won’t get

lockup. That’s okay; we still end up same as it did with the original pump. burned!

with lockup fully applied. As always, good rebuilding practice “A Special thanks to Raffi at ITC

The computer has two codes for dictates that all mating and mounting of Fresno, CA for his help with this

lockup ratio problems, and duty cycle surfaces be flat and torqued to specs. article.”

isn’t involved with either one. The You shouldn’t have any other problems

Figure 5

6 GEARS July 2008

The Choice is Simple.

Genuine ZF.

ZF 6-speed (6HP)

automatic parts,

kits and fluid

now available!

800.451.2595

www.zf.com/na

A quality product, a seamless installation, and a satisfied customer – the results of a genuine

remanufacturing process and the reasons why ZF makes the choice simple when it comes to

choosing a product that will exceed your customers’ expectations.

Mile-for-mile, Genuine ZF remanufactured automatic and manual transmissions last longer,

perform better, and are of greater value in the long run. Genuine ZF products are remanufactured

by expert technicians to exact factory specifications, utilizing only genuine parts and exclusive

testing technology.

For a ZF Authorized Distributor in your area, visit www.zf.com/na.

Driveline and Chassis Technology

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- CVT - F1cja PDFDocument38 pagesCVT - F1cja PDFShaneel PrasadNo ratings yet

- 2004 PDFDocument565 pages2004 PDFNICANOR KANA GAMARRANo ratings yet

- AA80EDocument2 pagesAA80EMothana HusbanNo ratings yet

- Atb209 Isuzu 4l80-E ...... High or Low PressureDocument3 pagesAtb209 Isuzu 4l80-E ...... High or Low PressureAleNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- Honda f4 Atsg Automatic Transmission Service GroupDocument88 pagesHonda f4 Atsg Automatic Transmission Service GroupCông Trần Minh0% (1)

- Posible Solucion A44de, Suzuki Geo Tracker 96-97-98Document1 pagePosible Solucion A44de, Suzuki Geo Tracker 96-97-98AleNo ratings yet

- Diagnostico y Overhaul A41 A40d Toyota TransmisionDocument66 pagesDiagnostico y Overhaul A41 A40d Toyota TransmisionWillian Jose Navarro ZepedaNo ratings yet

- Aa80e EngDocument772 pagesAa80e EngMarco MeloncelliNo ratings yet

- A540E/H & A541E: Technical Bulletin # 1098Document10 pagesA540E/H & A541E: Technical Bulletin # 1098haddadiNo ratings yet

- Dacco-2012 TURBINAS PDFDocument300 pagesDacco-2012 TURBINAS PDFCarlos QuinteroNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument1 pageTechnical Service Information: Automatic Transmission Service GroupDenis KonovalovNo ratings yet

- Hyundai d6gf1Document4 pagesHyundai d6gf1EduardoSalgueroNo ratings yet

- Play Ball Transmission TroubleshootingDocument5 pagesPlay Ball Transmission Troubleshootingcec985458No ratings yet

- GM 5L40E Automatic Diagrams and ListDocument9 pagesGM 5L40E Automatic Diagrams and ListBrayan Aragon diego100% (1)

- 10R80 Adaptive Learning Drive CycleDocument1 page10R80 Adaptive Learning Drive CyclemedicaluvNo ratings yet

- Automatic Transmission Service SpecificationsDocument5 pagesAutomatic Transmission Service SpecificationsJohn BacsikNo ratings yet

- 16K in PDFDocument2 pages16K in PDFossoskiNo ratings yet

- Aa80 eDocument1 pageAa80 eMothana Husban100% (1)

- 6L50-6L80-6L90 Updates and Product Issues: Presented By: Steve Garrett ATRA PresenterDocument42 pages6L50-6L80-6L90 Updates and Product Issues: Presented By: Steve Garrett ATRA PresenterEsquisof100% (1)

- Atsg Diagram Elec. Transm. 4r44e-4r55e-5r55e 1994-03Document26 pagesAtsg Diagram Elec. Transm. 4r44e-4r55e-5r55e 1994-03Ismael SantanaNo ratings yet

- AB60E Transmission OperationDocument1 pageAB60E Transmission OperationЙордан ВасилевNo ratings yet

- 41TE Accumulator PositionDocument10 pages41TE Accumulator PositionLula MarquesNo ratings yet

- AW450 43elDocument9 pagesAW450 43elAlan Borges Da SilvaNo ratings yet

- Toyota RAV4 wiring harness diagramDocument3 pagesToyota RAV4 wiring harness diagrammasakp100% (1)

- VW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFDocument68 pagesVW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFlucafelicianioanNo ratings yet

- Portals Raybestos Files PM 1340 2017.08.30 APC Catalog Without ImagesDocument349 pagesPortals Raybestos Files PM 1340 2017.08.30 APC Catalog Without ImagesJose Huanca100% (2)

- Master Solenoid Kit: MS KM-175Document1 pageMaster Solenoid Kit: MS KM-175Guilherme ZoboliNo ratings yet

- Technical Service Information 12-59Document8 pagesTechnical Service Information 12-59Planta Damiana2100% (1)

- Technical Service Information: Electronic Components (Cont'D)Document3 pagesTechnical Service Information: Electronic Components (Cont'D)Gina LópezNo ratings yet

- TransGo Catalog EnglishDocument44 pagesTransGo Catalog EnglishRaudol Raúl Camacho Espinoza100% (2)

- 30 80le PDFDocument120 pages30 80le PDFJhonnyNo ratings yet

- Jatco Products eDocument13 pagesJatco Products ehttps://smart69.ru/0% (1)

- Index: T H M 4 4 0 - T 4Document104 pagesIndex: T H M 4 4 0 - T 4Anonymous eExWojLxNo ratings yet

- 2014 Automatic V11 ECat CompleteDocument966 pages2014 Automatic V11 ECat Completesasha21123100% (2)

- Critical Wear Areas & Vacuum Test Locations: FORD 4R44E, 4R55E, 5R44E, 5R55EDocument2 pagesCritical Wear Areas & Vacuum Test Locations: FORD 4R44E, 4R55E, 5R44E, 5R55ECesar Isac PalominoNo ratings yet

- U140Document6 pagesU140HectorNo ratings yet

- RVB Catalog PDFDocument8 pagesRVB Catalog PDFMohammed MochrifNo ratings yet

- Import Checkball Vol III 82-92 PDFDocument11 pagesImport Checkball Vol III 82-92 PDFJulio Chalbaud100% (1)

- A500 Manual Valve Body KitDocument3 pagesA500 Manual Valve Body KitЮрій Полтавець0% (1)

- ATDocument164 pagesATjacor96100% (1)

- Honda CVT PDFDocument3 pagesHonda CVT PDFWagner Augusto100% (1)

- Valfe 60 50 t13Document10 pagesValfe 60 50 t13Zafer IlhanNo ratings yet

- U660e Zip inDocument11 pagesU660e Zip inGabriel Harper'100% (1)

- Transmission NoteDocument6 pagesTransmission Notesyariza ismailNo ratings yet

- Complete 11-21-13 W o Diagrams2Document510 pagesComplete 11-21-13 W o Diagrams2oliver leal50% (2)

- Repair Manual: ZF Getriebe GMBH SaarbrückenDocument104 pagesRepair Manual: ZF Getriebe GMBH SaarbrückenVIDAL ALEJANDRO GARCIAVARGASNo ratings yet

- Sonnax 77701-076-InDocument2 pagesSonnax 77701-076-InmiguelNo ratings yet

- TF 60 SNDocument5 pagesTF 60 SNyermain100% (1)

- Overhaul A140eDocument84 pagesOverhaul A140eDang Tien PhucNo ratings yet

- ZF 4 HP 20Document4 pagesZF 4 HP 20Irina VeresininaNo ratings yet

- Nissan CVT Clutch Point Relearn ProcedureDocument1 pageNissan CVT Clutch Point Relearn Proceduredamian berduscoNo ratings yet

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- 4l30e Pump ConversionDocument6 pages4l30e Pump ConversionNuman2100% (1)

- 3 PhaseDocument9 pages3 PhaseArnulfo LavaresNo ratings yet

- 4L60E Converter Valves:: Operation, Test Procedures and The Effects of WearDocument5 pages4L60E Converter Valves:: Operation, Test Procedures and The Effects of WeartranstechozNo ratings yet

- CVT Transmission Part2Document8 pagesCVT Transmission Part2ryba1100% (1)

- Mercancia Recien Llegada 27-01Document2 pagesMercancia Recien Llegada 27-01Juan Carlos Ruiz BarreraNo ratings yet

- Diagramas Eléctricos VOLKSWAGEN JETTA (1H2) 2.0L 4 Cil (ABA) 1996Document41 pagesDiagramas Eléctricos VOLKSWAGEN JETTA (1H2) 2.0L 4 Cil (ABA) 1996joseramirez1991007No ratings yet

- 2012 Nissan Versa Sedan Service Repair Manual PDFDocument18 pages2012 Nissan Versa Sedan Service Repair Manual PDFfjjsjekdmme100% (1)

- Parts Manual: Model T765A & T760A Engine BrakesDocument4 pagesParts Manual: Model T765A & T760A Engine BrakesJunior LesterNo ratings yet

- Chassis number/VIN Locations: Bentley S series/Rolls-Royce Silver Cloud and Derivatives 1955 - 1965Document18 pagesChassis number/VIN Locations: Bentley S series/Rolls-Royce Silver Cloud and Derivatives 1955 - 1965CésarNo ratings yet

- Calibrating Driver Assistance Systems Easily, Quickly and ProfitablyDocument4 pagesCalibrating Driver Assistance Systems Easily, Quickly and ProfitablyGivi KuparadzeNo ratings yet

- Load Chart Manlift - GenieDocument10 pagesLoad Chart Manlift - GenieFery RochmadiNo ratings yet

- Auris Touring Sport - PZ483-E5120-00 - Dog Guard + Divider - AIM - 002 - 854 - 1Document5 pagesAuris Touring Sport - PZ483-E5120-00 - Dog Guard + Divider - AIM - 002 - 854 - 1Roberto Gonzalo PelazNo ratings yet

- 2002 Tahoe Capacity Fluid TypesDocument4 pages2002 Tahoe Capacity Fluid TypesJoeNo ratings yet

- 2000 Jeep Grand Cherokee Service Manual (ALL)Document4 pages2000 Jeep Grand Cherokee Service Manual (ALL)Rob CirincioneNo ratings yet

- Mantrans PDFDocument1 pageMantrans PDFAnonymous GWmGTFuNo ratings yet

- Note!: Rear Shock Absorber For KTM RC390Document4 pagesNote!: Rear Shock Absorber For KTM RC390Joe deSanutsNo ratings yet

- Isuzu FSR 800 AMT Specification SheetDocument2 pagesIsuzu FSR 800 AMT Specification SheetYoganNo ratings yet

- 2006 Nissan Sentra 1.8L 4 Cylinder Engine Control System DiagramsDocument2 pages2006 Nissan Sentra 1.8L 4 Cylinder Engine Control System Diagramsjimmy diaz tafurNo ratings yet

- 2011 XRAY CatalogDocument58 pages2011 XRAY CatalogHerbert TesterNo ratings yet

- Side Airbag Sensor and Curtain Shield Airbag Sensor: Body Electrical - Srs Airbag System BE-87Document1 pageSide Airbag Sensor and Curtain Shield Airbag Sensor: Body Electrical - Srs Airbag System BE-87Maxi SardiNo ratings yet

- 2019 Outlander MAX XT enDocument1 page2019 Outlander MAX XT enEdwin TtitoNo ratings yet

- Sanjit Airbag PresentationDocument19 pagesSanjit Airbag PresentationSanjit kumarNo ratings yet

- Circuit Diagrams: Group 90Document151 pagesCircuit Diagrams: Group 90Arafa SalemNo ratings yet

- Re NR 69020001Document2 pagesRe NR 69020001LytmerAcuña100% (1)

- BTME 505 Automotive SystemsDocument2 pagesBTME 505 Automotive SystemsSumit SinghNo ratings yet

- Toyota 2008 Camry SE 2.4 y 3.5 Engine Performance - PDF Versión 1Document18 pagesToyota 2008 Camry SE 2.4 y 3.5 Engine Performance - PDF Versión 1FranciscoNo ratings yet

- Car Manufacturing ProcessDocument7 pagesCar Manufacturing ProcessAsad YameenNo ratings yet

- TM 9-1765a Bomb Service Truck M6Document128 pagesTM 9-1765a Bomb Service Truck M6AdvocateNo ratings yet

- Tributo FerrariDocument26 pagesTributo FerrariFiat500USA100% (1)

- Catalogo PvimexDocument425 pagesCatalogo Pvimexluis avilezNo ratings yet

- Opel InsigniaDocument13 pagesOpel Insigniadimsakel0% (1)

- 28 Dec 23 BKS (Mobil Jam 13.00) Final CustDocument35 pages28 Dec 23 BKS (Mobil Jam 13.00) Final Custze230994No ratings yet

- A Seminar On Automobile SafetyDocument23 pagesA Seminar On Automobile SafetyJash PatelNo ratings yet

- BMW Ix Specification Guide I20.pdf - Asset.1637886382519Document12 pagesBMW Ix Specification Guide I20.pdf - Asset.1637886382519Emanuel Gamboa ChacònNo ratings yet