Professional Documents

Culture Documents

A Citizen's Guide To Soil Vapor Extraction and Air Sparging

Uploaded by

Huy NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Citizen's Guide To Soil Vapor Extraction and Air Sparging

Uploaded by

Huy NguyenCopyright:

Available Formats

A Citizens Guide to Soil Vapor

Extraction and Air Sparging

What Are Soil Vapor Extraction And

Air Sparging?

Both soil vapor extraction, or SVE, and air sparging

extract (remove) contaminant vapors from below

ground for treatment above ground. Vapors are the

gases that form when chemicals evaporate. SVE

extracts vapors from the soil above the water table by

applying a vacuum to pull the vapors out. Air sparging,

on the other hand, pumps air underground to help

extract vapors from groundwater and wet soil found

beneath the water table. The addition of air makes the

chemicals evaporate faster, which makes them easier

to extract with another technology, such as SVE.

Both methods are used for chemicals that evaporate

easilylike those found in solvents and gasoline. These

chemicals are known as volatile organic compounds,

or VOCs.

How Do They Work?

Extraction:

SVE involves drilling one or more extraction wells into

the contaminated soil to a depth above the water table,

which must be deeper than 3 feet below the ground

surface. Attached to the wells is equipment (such as

a blower or vacuum pump) that creates a vacuum.

The vacuum pulls air and vapors through the soil

and up the well to the ground surface for treatment.

Sometimes the ground must be paved or covered with

a tarp to make sure that the vacuum does not pull air

from above into the system. Pulling in clean air would

reduce the efficiency of the cleanup. The cover also

prevents any vapors from escaping from the ground to

the air above.

Air sparging involves drilling one or more injection

wells into the groundwater-soaked soil below the

water table. An air compressor at the surface pumps

air underground through the wells. As air bubbles

through the groundwater, it carries contaminant vapors

upward into the soil above the water table. The mixture

of air and vapors is then pulled out of the ground for

treatment using SVE.

Treatment:

Extracted air and contaminant vapors, sometimes

referred to as off-gases, are treated to remove any

harmful levels of contaminants. The off-gases are first

piped from the extraction wells to an air-water separator

to remove moisture, which interferes with treatment.

The vapors are then separated from the air, usually by

pumping them through containers of activated carbon.

The chemicals are captured by the carbon while clean

air exits to the atmosphere. (See A Citizens Guide to

Activated Carbon Treatment [EPA 542-12-001.]).

Filter materials other than activated carbon may be

used. In a process called biofiltration, tiny microbes

(bacteria) are added to break down the vapors into

gases, such as carbon dioxide and water vapor.

Another option is to destroy vapors by heating them to

high temperatures.

How Long Will They Take?

Cleaning up a site using SVE or air sparging may take

several years. The actual cleanup time depends on

several factors. For example, cleanup may take longer

where:

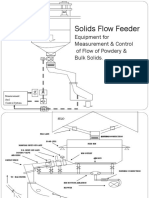

Illustration of a combined air sparging and SVE system.

Contaminant concentrations are high.

The contaminated area is large or deep.

The soil is dense or moist, which slows the

movement of vapors.

These factors vary from site to site.

Are SVE And Air Sparging Safe?

When properly designed and operated, SVE and air sparging pose little

risk to site workers or the community. Treatment of the vapors involves no

harmful chemicals that must be transported to the site. Chemical vapors

are contained from extraction to treatment so they cannot be accidentally

inhaled by anyone nearby. Only clean air that meets air quality standards

is released. The air released to the atmosphere following treatment

may be sampled to make sure all harmful vapors have been removed

or destroyed.

How Might It Affect Me?

Area neighborhoods may experience some increased truck traffic as the

equipment for SVE or air sparging is delivered and later removed. Installation

of the systems involves the use of drilling rigs and sometimes other heavy

machinery to install wells, blowers, and treatment equipment. Sheds or

larger buildings may be built to house the treatment systems, keeping any

noise to a minimum. Workers will visit these systems regularly to ensure they

are working.

Why Use Soil Vapor Extraction And Air Sparging?

SVE and air sparging are efficient ways to remove VOCs above and below the

water table. Both methods can help clean up contamination under buildings,

and cause little disruption to nearby activities when in full operation. SVE and

air sparging are often used together. SVE and air sparging are being used

or have been selected for use at approximately 285 and 80 Superfund sites,

respectively.

Example

Both SVE and air sparging are

being used to clean up several

acres of contaminated soil and

groundwater at the Vienna PCE

Superfund site in West Virginia.

Two dry cleaning facilities

contaminated the area with PCE

(also known as perchloroethene

or perc), a solvent used to clean

clothing, forcing the shutdown of

the towns drinking water wells.

In 2005, construction of the

cleanup systems was completed

and included 74 air sparging

wells, 34 extraction wells,

and four treatment buildings.

The off-gases are piped to an

air-water separator, followed by

containers of activated carbon

for treatment. By 2010, 1,618

pounds of PCE had been

removed and PCE concentrations had decreased by as much

as 99% in some wells. EPA will

continue to operate the systems

and monitor PCE levels until

cleanup objectives have been

reached throughout the site.

For More Information

For more information on this

and other technologies in the

Citizens Guide Series, contact:

Pipes transport vapors from the

underground SVE extraction well

to treatment.

Above-ground treatment system includes two tanks of

activated carbon.

U.S. EPA

Technology Innovation &

Field Services Division

Technology Assessment Branch

(703) 603-9910

Or visit:

www.cluin.org/sve

www.cluin.org/airsparging

NOTE: This fact sheet is intended solely as general information to the public. It is not intended, nor can it be relied upon, to create any

rights enforceable by any party in litigation with the United States, or to endorse the use of products or services provided by specific

vendors. The Agency also reserves the right to change this fact sheet at any time without public notice.

United States

Office of Solid Waste and

Environmental Protection

Emergency Response

Agency

(5102G)

EPA 542-F-12-018

September 2012

www.epa.gov/superfund/sites

www.cluin.org

You might also like

- A Citizens Guide To Soil Vapor Extraction and Air SpargingDocument2 pagesA Citizens Guide To Soil Vapor Extraction and Air SpargingAnthony WrightNo ratings yet

- Addis Ababa University: Institute of TechnologyDocument17 pagesAddis Ababa University: Institute of Technologyashe zinabNo ratings yet

- AerationDocument2 pagesAerationglo lipaodNo ratings yet

- Literature - Air Stripping of VOC's From WaterDocument19 pagesLiterature - Air Stripping of VOC's From WaterAlejandro Castillo VélezNo ratings yet

- Duct Cleaning PDFDocument4 pagesDuct Cleaning PDFMaazARazaNo ratings yet

- Harme, Jaylord Z. Assignment Engineering Utilities 2ce-1Document22 pagesHarme, Jaylord Z. Assignment Engineering Utilities 2ce-1Jaylord HarmeNo ratings yet

- K Brian & E RochaisDocument16 pagesK Brian & E RochaisLuigi Andrew MercadoNo ratings yet

- Soil Vapour ExtractionDocument7 pagesSoil Vapour Extractionbelinda abigaelNo ratings yet

- Activated Sludge Process (ASP)Document14 pagesActivated Sludge Process (ASP)ShabanaNo ratings yet

- Water Pollution Control TechnologiesDocument6 pagesWater Pollution Control Technologiesirfan aminNo ratings yet

- Water Pollution Control TechnologiesDocument6 pagesWater Pollution Control Technologiesirfan aminNo ratings yet

- Aeration Tank Class Presentation SlideDocument6 pagesAeration Tank Class Presentation Slidesuman subediNo ratings yet

- Environmental Pollution: Causes, Effects and Control in 40 CharactersDocument33 pagesEnvironmental Pollution: Causes, Effects and Control in 40 CharactersDhanush GNo ratings yet

- StrippersDocument6 pagesStrippersDiliniNo ratings yet

- Air Pollution ControlDocument16 pagesAir Pollution ControlMadridSpainNo ratings yet

- ET-unit-2A Air PollutionDocument18 pagesET-unit-2A Air PollutionSharonNo ratings yet

- Environmental Pollution Control TechniquesDocument41 pagesEnvironmental Pollution Control TechniquesSanket VaghelaNo ratings yet

- VOC-Free Wave SolderingDocument4 pagesVOC-Free Wave SolderingmhafizanNo ratings yet

- Activated Sludge - Print VersionDocument5 pagesActivated Sludge - Print VersionAnurag SatyarthNo ratings yet

- Air Pollution Control For Industrial ApplicationsDocument19 pagesAir Pollution Control For Industrial ApplicationsJohn Jhay CanlasNo ratings yet

- Lecture 32 33Document7 pagesLecture 32 33Naga Varshini MeenakshisundaramNo ratings yet

- Lab Report (Environmental)Document38 pagesLab Report (Environmental)Muhammad ShahbazNo ratings yet

- Air PollutionDocument27 pagesAir PollutionVincentNo ratings yet

- Introduction Venturi ScrubberDocument3 pagesIntroduction Venturi ScrubberNurul HazimahNo ratings yet

- Stripping Column: Haldia Institute of TechnologyDocument14 pagesStripping Column: Haldia Institute of TechnologyArnab DasNo ratings yet

- Confined Space VentilationDocument9 pagesConfined Space VentilationARULSELVAN MURUGESANNo ratings yet

- Condensation and BiofiltrationDocument19 pagesCondensation and BiofiltrationTHABILE MUSWEDENo ratings yet

- Air CleanersDocument12 pagesAir CleanersAnonymous 9pKSMxb8100% (1)

- Aqm Assignment 2Document44 pagesAqm Assignment 2nithin M SNo ratings yet

- ET Unit 2A Air PollutionDocument18 pagesET Unit 2A Air PollutionSharonNo ratings yet

- ScrubbersDocument5 pagesScrubbersleoboyaliNo ratings yet

- Control of Air Pollution: III Year / Semester VI Sch1310 - Environmental Pollution and Control Unit-IiDocument14 pagesControl of Air Pollution: III Year / Semester VI Sch1310 - Environmental Pollution and Control Unit-IiJuvilasri Vignesh NKNo ratings yet

- Environmental EngineeringDocument16 pagesEnvironmental Engineeringwnmajid72No ratings yet

- Air Pollution Control TechniquesDocument35 pagesAir Pollution Control TechniquesAhad Kanak ProttoyNo ratings yet

- ET Unit 2A Air PollutionDocument18 pagesET Unit 2A Air PollutionYash JinghaNo ratings yet

- Removal of Biodegradable OrganicsDocument2 pagesRemoval of Biodegradable OrganicsStellaNo ratings yet

- Confined Space Ventilation MethodsDocument2 pagesConfined Space Ventilation Methodsreda mesbahNo ratings yet

- Aeration Improves Water Quality Through Oxidation and Removal of Harmful CompoundsDocument4 pagesAeration Improves Water Quality Through Oxidation and Removal of Harmful CompoundsDeep DebnathNo ratings yet

- Biological Treatment of Waste WaterDocument36 pagesBiological Treatment of Waste Waternagpal_aakash100% (1)

- Maren Vi Final CoverageDocument28 pagesMaren Vi Final CoverageJoshua CandagananNo ratings yet

- Cce 408Document4 pagesCce 408Neetor TendekayiNo ratings yet

- Designing an air purification systemDocument11 pagesDesigning an air purification systemISHAAN GOYALNo ratings yet

- Unit 4 Apc MaterialDocument24 pagesUnit 4 Apc Material505 DedeepyaNo ratings yet

- AcousticsDocument5 pagesAcousticsarchi042No ratings yet

- Vacuum Toilet EvacDocument7 pagesVacuum Toilet Evacdevendra singh100% (1)

- ADVANCED WATER TREATMENTDocument15 pagesADVANCED WATER TREATMENTjaikumar.er2No ratings yet

- Vapor Degreasing ProcessDocument12 pagesVapor Degreasing Process1275812718100% (1)

- Diagram and Description of a Shipboard Sewage Treatment PlantDocument5 pagesDiagram and Description of a Shipboard Sewage Treatment PlantJosephine FilesNo ratings yet

- Exp 2Document7 pagesExp 2Philip Anthony MasilangNo ratings yet

- Air Pollution ControlDocument29 pagesAir Pollution ControlAngel ServinasNo ratings yet

- Air PollutionDocument29 pagesAir PollutionAngel ServinasNo ratings yet

- Mechanical and Electrical EquipmentsDocument45 pagesMechanical and Electrical EquipmentsJohanson GoNo ratings yet

- Scrubber BasicsDocument3 pagesScrubber BasicsherikNo ratings yet

- Essential Components and Functions of Air WashersDocument6 pagesEssential Components and Functions of Air WashersorganicspolybondNo ratings yet

- Presenter Tip: To Demonstrate The Difference Between Supplying Air Into A Confined Space (Called "Pushing Air")Document2 pagesPresenter Tip: To Demonstrate The Difference Between Supplying Air Into A Confined Space (Called "Pushing Air")reda mesbahNo ratings yet

- NAWTEC18-3507: Comparison of Acid Gas Control Technologies in Efw FacilitiesDocument10 pagesNAWTEC18-3507: Comparison of Acid Gas Control Technologies in Efw FacilitiesPunki KokoNo ratings yet

- Sistema de OzonoDocument47 pagesSistema de OzonoPedro Aguirre BandaNo ratings yet

- OCE551 - Air Pollution Control EngineeringDocument21 pagesOCE551 - Air Pollution Control EngineeringUMA MAKESHWARAN TNo ratings yet

- Storage Tanks Selection, Design, Testing, Inspection, and Maintenance: Emission Management and Environmental Protection: Emission Management and Environmental ProtectionFrom EverandStorage Tanks Selection, Design, Testing, Inspection, and Maintenance: Emission Management and Environmental Protection: Emission Management and Environmental ProtectionNo ratings yet

- Install Dual Speed Motors For Couch Pit AgiatorDocument2 pagesInstall Dual Speed Motors For Couch Pit AgiatorHuy NguyenNo ratings yet

- Solutions in Doctor Blades: Lantier TechnologyDocument20 pagesSolutions in Doctor Blades: Lantier Technologyhira kurniaNo ratings yet

- Poly Meng SlidesDocument252 pagesPoly Meng SlidesHuy NguyenNo ratings yet

- Tiêu Chuẩn Stone Paper 3Document3 pagesTiêu Chuẩn Stone Paper 3Huy NguyenNo ratings yet

- 3 1 製漿系統的優化與診斷 Andritz 龐松韜 經理 6格Document2 pages3 1 製漿系統的優化與診斷 Andritz 龐松韜 經理 6格Huy NguyenNo ratings yet

- CBE 4009 Polymer Processing - 3. Introduction To Polymer ProcessingDocument41 pagesCBE 4009 Polymer Processing - 3. Introduction To Polymer ProcessingHuy NguyenNo ratings yet

- 2-1-Press Felt Conditioning and Cleaning-6格Document18 pages2-1-Press Felt Conditioning and Cleaning-6格Huy Nguyen100% (1)

- 4 1Document3 pages4 1Huy NguyenNo ratings yet

- 3-2-1-篩選的節能技術介紹-ANDRITZ 梁貴明 經理-6格Document3 pages3-2-1-篩選的節能技術介紹-ANDRITZ 梁貴明 經理-6格Huy NguyenNo ratings yet

- 1-2-BVG 2019-02-28 Super ECC Strainer SPS-6格Document11 pages1-2-BVG 2019-02-28 Super ECC Strainer SPS-6格Huy NguyenNo ratings yet

- A New Technology To Manufacture Polypropylene Foam Sheet and Biaxially Oriented Foam FilmDocument101 pagesA New Technology To Manufacture Polypropylene Foam Sheet and Biaxially Oriented Foam FilmHuy NguyenNo ratings yet

- Extrusion of Blown Film: Josip MauričDocument47 pagesExtrusion of Blown Film: Josip MauričlinchonNo ratings yet

- EXT HAN BR SheetandFilm enDocument24 pagesEXT HAN BR SheetandFilm enHuy NguyenNo ratings yet

- Stone PaperDocument1 pageStone PaperHuy NguyenNo ratings yet

- Paper SpecsDocument6 pagesPaper SpecsHuy NguyenNo ratings yet

- Product Paper SCADocument99 pagesProduct Paper SCAHuy NguyenNo ratings yet

- FSC 9310 Printing Paper JCP A182 February 1, 1999 No. 2 Coated Text, Gloss-FinishDocument1 pageFSC 9310 Printing Paper JCP A182 February 1, 1999 No. 2 Coated Text, Gloss-FinishHuy NguyenNo ratings yet

- ChristieDocument130 pagesChristieHuy Nguyen100% (1)

- FSC 9310 Printing Paper JCP A262 February 1, 1999 No. 2 Coated Text, Dull-FinishDocument1 pageFSC 9310 Printing Paper JCP A262 February 1, 1999 No. 2 Coated Text, Dull-FinishHuy NguyenNo ratings yet

- Double A 80gsmDocument2 pagesDouble A 80gsmHuy NguyenNo ratings yet

- FSC 9310 Printing Paper JCP A181 February 1, 1999 No. 1 Coated Text, Gloss-FinishDocument1 pageFSC 9310 Printing Paper JCP A181 February 1, 1999 No. 1 Coated Text, Gloss-FinishHuy NguyenNo ratings yet

- FSC 9310 Printing Paper JCP A205 February 1, 1999 Litho (Gloss) Coated BookDocument1 pageFSC 9310 Printing Paper JCP A205 February 1, 1999 Litho (Gloss) Coated BookHuy NguyenNo ratings yet

- How to remove watermark from PDF filesDocument179 pagesHow to remove watermark from PDF filesHuy NguyenNo ratings yet

- FSC 9310 Printing Paper JCP A260 February 1, 1999 Dull Coated Offset BookDocument1 pageFSC 9310 Printing Paper JCP A260 February 1, 1999 Dull Coated Offset BookHuy NguyenNo ratings yet

- Book 19. Evironmental Control - Standard ContentDocument137 pagesBook 19. Evironmental Control - Standard ContentHuy NguyenNo ratings yet

- 9.5 - Miikkulainen - Velocity For BL Spray COntrolDocument14 pages9.5 - Miikkulainen - Velocity For BL Spray COntrolHuy NguyenNo ratings yet

- FSC 9310 Printing Paper JCP A262 February 1, 1999 No. 2 Coated Text, Dull-FinishDocument1 pageFSC 9310 Printing Paper JCP A262 February 1, 1999 No. 2 Coated Text, Dull-FinishHuy NguyenNo ratings yet

- Book 1. Economics of The Pulp and Paper Industry - Standard ContentDocument106 pagesBook 1. Economics of The Pulp and Paper Industry - Standard ContentHuy Nguyen100% (1)

- 6.4 - Keiser - Superheater Tube CorrosionDocument30 pages6.4 - Keiser - Superheater Tube CorrosionHuy NguyenNo ratings yet

- 5.3 - Haaga - Experiences of Biggest Recovery Boiler PDFDocument12 pages5.3 - Haaga - Experiences of Biggest Recovery Boiler PDFfirmanXimanullangNo ratings yet

- Compressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume ConcreteDocument8 pagesCompressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume ConcreteAboalmaail AlaminNo ratings yet

- Chassis (LS17) PDFDocument10 pagesChassis (LS17) PDFlasky11No ratings yet

- Torque ValuesDocument1 pageTorque ValuesfadhlidzilNo ratings yet

- Blasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyDocument3 pagesBlasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyEjike Francis ChizobaNo ratings yet

- Green Finance For Green GrowthDocument24 pagesGreen Finance For Green GrowthSreejith BhattathiriNo ratings yet

- Transportation System, Analysis and Modelling (CE-632) : Carried Out by Group-3Document15 pagesTransportation System, Analysis and Modelling (CE-632) : Carried Out by Group-3Naman Kumar100% (2)

- Price List (011) New2020 PDFDocument3 pagesPrice List (011) New2020 PDFAyush BansalNo ratings yet

- Cisco CCNA SecurityDocument85 pagesCisco CCNA SecurityPaoPound HomnualNo ratings yet

- Monocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ADocument2 pagesMonocrystalline - 50Wp - 200Wp: 50W - 200W 17.20V - 30.10V 27.5A - 7.85A 21.10V - 36.10V 2.95A - 8.34ARia IndahNo ratings yet

- PDF 7758Document2 pagesPDF 7758José Antônio CardosoNo ratings yet

- Side Wall SprinklerDocument6 pagesSide Wall SprinklerLasandu WanniarachchiNo ratings yet

- 64-2103 Tweco Pistolas WeldskillDocument6 pages64-2103 Tweco Pistolas WeldskillcarlosNo ratings yet

- Solids Flow Feeder Equipment for Precise Measurement & ControlDocument7 pagesSolids Flow Feeder Equipment for Precise Measurement & ControlAbhishek DuttaNo ratings yet

- ETH Names DivisionsDocument10 pagesETH Names Divisionsichigo_bleach00No ratings yet

- How to Size a Fire Pump and Understand Performance CurvesDocument12 pagesHow to Size a Fire Pump and Understand Performance CurvesAmar kobitaNo ratings yet

- Technology in Supply Chain ManagementDocument8 pagesTechnology in Supply Chain ManagementjasmineNo ratings yet

- Sample:OPS-English Evaluation FormDocument3 pagesSample:OPS-English Evaluation FormshieroNo ratings yet

- Floor ManualDocument35 pagesFloor ManualGihan ChathurangaNo ratings yet

- Restaurant Pub VIP Lounge Camp Pune SaleDocument4 pagesRestaurant Pub VIP Lounge Camp Pune SaleChandrashekhar Naikare0% (1)

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDDocument6 pagesMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaNo ratings yet

- Google Earth y Civil CadDocument3 pagesGoogle Earth y Civil CadRodneyNo ratings yet

- Internal Architecture of Intel 8086, FinalDocument24 pagesInternal Architecture of Intel 8086, FinalAshek E Elahi SohanNo ratings yet

- VTT R 01177 17Document27 pagesVTT R 01177 17Joseph BookerNo ratings yet

- ExMED Debrief 2019Document16 pagesExMED Debrief 2019Hamilton WintersNo ratings yet

- DBX DriveRack PA 2 BrochureDocument2 pagesDBX DriveRack PA 2 BrochureSound Technology LtdNo ratings yet

- (Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerDocument332 pages(Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerFuadAshadLNo ratings yet

- Modern Soil Stabilization TechniquesDocument25 pagesModern Soil Stabilization TechniquesSagar Jha100% (3)

- Dsi Suspa Systems Eta 07 0186 Suspa Wire Ex enDocument48 pagesDsi Suspa Systems Eta 07 0186 Suspa Wire Ex enAnonymous TxhyGfNo ratings yet

- Is 15560 - 2005Document12 pagesIs 15560 - 2005kalpanaadhiNo ratings yet

- HTML5 Element Cheatsheet 2019Document1 pageHTML5 Element Cheatsheet 2019vVvNo ratings yet