Professional Documents

Culture Documents

Cotta Transfer Case Lube Plan

Uploaded by

Matias Alfredo Contreras KöbrichCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cotta Transfer Case Lube Plan

Uploaded by

Matias Alfredo Contreras KöbrichCopyright:

Available Formats

Cotta Transmission Company

Technical Bulletin

TB97-101

Lubrication of Cotta Gearboxes

Rev. Date: Apr 15

Rev.: 8

Note: Products listed in this bulletin are typical lubricants. Cotta does not recommend

any specific manufacturers product for use in our gearboxes.

CAUTION: USE OF LUBRICANT ADDITIVES IN A COTTA GEARBOX IS STRICTLY

PROHIBITED EXCEPT BY PRIOR WRITTEN AUTHORIZATION BY COTTA

TRANSMISSION COMPANY.

CAUTION: SOME ANTI-SCUFF (EP) ADDITIVES ARE CORROSIVE TO COPPER, BRASS,

BRONZE, AND/OR ALUMINUM. IF THE LUBRICANT WILL COME INTO

CONTACT WITH THESE METALS (e.g. heat exchangers), CONSULT YOUR

LUBRICANT MANUFACTURER TO VERIFY THAT THE EP ADDITIVES WILL

NOT DAMAGE THE SYSTEM COMPONENTS.

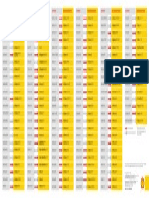

Standard Product Line Lubrication Guidelines:

NOTE: This bulletin is an update to the green Speed Reducer nameplate and the

lubricant viscosities listed on this bulletin should be used instead of the printed

lubricants on the nameplate. The lubricant requirements stamped on the blue

Speed Increaser or yellow nameplate supersedes this table.

The following lubricant viscosities listed are guidelines for Cotta standard gearboxes. All values

listed are ISO viscosity grades. Values in parenthesis are former AGMA lubricant numbers. An

S after the viscosity grade indicates a synthetic requirement.

Ambient Temperature

-40F to +14F

14F to 50F

50F to 95F

95F and above

-40C to -10C -10C to +10C

10C to 35C

35C and above

100S

100S

220

320

Speed Reducers

(3S)

(3S)

(5)

(6)

AR2053, SR2, SR3,

SR972, GR15,

GR16, GR1600,

GR3200, GR975

& others

46S

68S

68

68

Speed Increasers

(1S)

(2S)

(2)

(2)

AO2053, SI2, SI3,

GO1500, GO1700,

GO1900

& others

Input <2300

Input <2300

Input <2300

Input <2300

Transfer Cases

68S (2S)

100S (3S)

220 (5)

320 (6)

and Pump Drives

Input >2300

Input >2300

Input >2300

Input >2300

TR2059, TR2205,

46S (1S)

68S (2S)

100 (3)

150 (4)

TR2237, PD100s,

PD200s, PD300s

& others

NOTES:

1) The pour point of the lubricant must be at least 9F (5C) below the minimum ambient

temperature. If the ambient temperature approaches the pour point, sump heaters or

synthetic lubricant may be required to facilitate starting and ensure proper lubrication.

Page 1

Printed copies are uncontrolled

Cotta Transmission Company

Technical Bulletin

TB97-101

Lubrication of Cotta Gearboxes

Rev. Date Apr 15

Revision: 8

Petroleum R&O lubricants:

The Cotta standard lubricant recommendation is a petroleum based rust and oxidation

inhibited gear lubricant. These are lubricants that have been formulated to include

chemical additives which provide system rust protection and oxidation resistance.

Acceptable R&O lubricants are listed in Table 1. Maximum sump temperature for these

lubricants is 203F (95C). If a units sump temperature exceeds this value, or if the unit

is exposed to cold starting conditions, a cooler and/or synthetic lubricant will need to be

used.

Former AGMA

Viscosity Grade

ISO Viscosity Grade

Viscosity @ 104F

(40C) (cSt)

Manufacturer

32

28.8-35.2

46

41.4-50.6

68

61.2-74.8

100

90-110

150

135-165

Lubricant

Lubricant

Lubricant

Lubricant

Lubricant

Chevron

Citgo

Machine Oil R&O 32

Machine Oil R&O 46

Machine Oil R&O 68

Machine Oil R&O 100

Machine Oil R&O 150

Pacemaker 32

Pacemaker 46

Pacemaker 68

Pacemaker 100

Pacemaker 150

Phillips 66

Multipurpose R&O 32

Multipurpose R&O 46

Multipurpose R&O 68

Multipurpose R&O 100

Multipurpose R&O 150

Mobil

DTE Light

DTE Medium

DTE Heavy Medium

DTE Heavy

DTE Extra Heavy

Shell

Morlina S2 B - 32

Morlina S2 B - 46

Morlina S2 B - 68

Morlina S2 B - 100

Morlina S2 B - 150

Texaco

Regal R&O 32

Regal R&O 46

Regal R&O 68

Regal R&O 100

Regal R&O 150

AGMA Viscosity

Grade

ISO Viscosity Grade

Viscosity @ 104F

(40C) (cSt)

Manufacturer

220

198-242

320

288-352

Lubricant

Lubricant

Chevron

Citgo

Machine Oil AW 220

Machine Oil AW 320

Pacemaker 220

Pacemaker 320

Phillips 66

Multipurpose R&O 220

Multipurpose R&O 320

Mobil

DTE BB

DTE AA

Shell

Morlina S2 B - 220

Morlina S2 B - 320

Texaco

Regal R&O 220

Regal R&O 320

Table 1 - Petroleum R&O Lubricants

Page 2

Printed copies are uncontrolled

Cotta Transmission Company

Technical Bulletin

TB97-101

Lubrication of Cotta Gearboxes

Rev. Date Apr 15

Revision: 8

Synthetic gear lubricants:

Synthetic lubricants differ from petroleum based liquids in that they are not found in

nature, but are manufactured chemically with special properties to enhance

performance or accommodate severe operating conditions. In general, synthetic

lubricants have the advantage of being stable over a wider range of operating

temperatures, have a higher viscosity index, and in some cases have greater load

carrying capacity and better lubricity. Acceptable synthetic lubricants are listed in Table

2. Maximum sump temperature for synthetic lubricants is 225F (107C). If the units

sump exceeds this temperature, a cooler will need to be added to the system.

Former AGMA

Viscosity Grade

ISO Viscosity Grade

Viscosity @ 104F

(40C) (cSt)

Manufacturer

0S

1S

2S

3S

4S

32

28.8-35.2

46

41.4-50.6

68

61.2-74.8

100

90-110

150

135-165

Chevron

Lubricant

Lubricant

Lubricant

Lubricant

Lubricant

Tegra Compressor 32

-------

Phillips 66

Syncon R&O 32

Syncon R&O 46

Syncon R&O 68

Syncon R&O 100

Syncon R&O 150

Mobil

SHC 624

SHC 625

SHC 626

SHC 627

SHC 629

Shell

Tellus S4 ME 32

Tellus S4 ME 46

Morlina S4 B 68

Morlina S4 B 100

Morlina S4 B 150

Texaco

Pinnacle 32

Pinnacle 46

Pinnacle 68

Pinnacle 100

Pinnacle 150

Tegra Compressor 68 Tegra Compressor 100 Tegra Compressor 150

Table 2 - Synthetic Gear Lubricants

Anti-scuff Lubricants (formerly Extreme Pressure):

These lubricants are petroleum or synthetic based liquids with chemical additives such

as sulfur-phosphorus which produce a protective film to provide anti-scuff properties.

Anti-scuff lubricants may be used instead of the R&O lubricants providing there is no

copper, brass, or bronze components that will be damaged by the additives in the

lubricant. Items such as spray nozzles, heat exchangers, labyrinth seals, or some

bearings may be significantly damaged by some anti-scuff lubricants. Items such as

bronze shift forks, however, will not be significantly damaged by the additives. Consult

your lubricant manufacturer and Cotta Transmission before using anti-scuff lubricants.

Page 3

Printed copies are uncontrolled

You might also like

- MSDS PeakDocument2 pagesMSDS PeakPaulus SNo ratings yet

- Ecf9 Nh3 ManualDocument20 pagesEcf9 Nh3 Manualgonza100% (1)

- Codigo Producto Codigo NuevoDocument422 pagesCodigo Producto Codigo Nuevofiltros y lubricantes la nacionalNo ratings yet

- Cylinder PDFDocument3 pagesCylinder PDFdinhvuNo ratings yet

- 3628504R1Document279 pages3628504R1truckman1000No ratings yet

- John Deere 5Document16 pagesJohn Deere 5ManoNo ratings yet

- Brochure MVD XLPDDocument5 pagesBrochure MVD XLPDBorislav LewandowskiNo ratings yet

- En Additin RC 93210Document2 pagesEn Additin RC 93210Dinesh babuNo ratings yet

- Lux M10Document40 pagesLux M10simonNo ratings yet

- Illustrated Parts List: RTO-14908LL November 2008Document34 pagesIllustrated Parts List: RTO-14908LL November 2008Agustin FigueroaNo ratings yet

- DIWA Voith List of LubricantsDocument18 pagesDIWA Voith List of LubricantsJako MishyNo ratings yet

- NSeries Specification IsuzuDocument2 pagesNSeries Specification IsuzuByte_Rafael100% (2)

- Rosa 2014Document122 pagesRosa 2014I Putu Gede DarmayasaNo ratings yet

- Heil 4000 FeaturesDocument1 pageHeil 4000 FeaturesBogdan NgrNo ratings yet

- SAP Catalog HeavyDutyDivision LDocument176 pagesSAP Catalog HeavyDutyDivision LUrias SanchezNo ratings yet

- Cat NGEO EL350: (Natural Gas Engine Oil)Document2 pagesCat NGEO EL350: (Natural Gas Engine Oil)Alfonso Alberto ArguelloNo ratings yet

- Service Bulletin Trucks: SRS, AirbagDocument43 pagesService Bulletin Trucks: SRS, AirbagSherzad ChemNo ratings yet

- LightHouse 3.11 Advanced Operation Instructions 81370-14-EN PDFDocument388 pagesLightHouse 3.11 Advanced Operation Instructions 81370-14-EN PDFAditi DasNo ratings yet

- 9074 Fuller Manual 8LLDocument2 pages9074 Fuller Manual 8LLpanchoNo ratings yet

- Filtros Mack Gu813 - Motor MP8 PDFDocument1 pageFiltros Mack Gu813 - Motor MP8 PDFNicolas Prieto MolinaNo ratings yet

- Mack T13 Engine Lubricant TestDocument2 pagesMack T13 Engine Lubricant TestFrank FareNo ratings yet

- MPX English Final Version VOLUME 3Document878 pagesMPX English Final Version VOLUME 3Adrian MacayaNo ratings yet

- Link Belt HTC 8660Document8 pagesLink Belt HTC 8660Diana Gabriela VillaNo ratings yet

- Electrically Powered Shear Machines GuideDocument16 pagesElectrically Powered Shear Machines GuidedrmassterNo ratings yet

- DS450 Shop Manual (Prelim)Document94 pagesDS450 Shop Manual (Prelim)GuruRacerNo ratings yet

- Jenbacher: Determining The Initial PH Value (Iph) of Used Lubrication Oil As Defined in Ti 1000-0099BDocument2 pagesJenbacher: Determining The Initial PH Value (Iph) of Used Lubrication Oil As Defined in Ti 1000-0099BArîfNo ratings yet

- Shellzone AFC 50-50Document2 pagesShellzone AFC 50-50Jorge Arrieta TorresNo ratings yet

- Safety Data Sheet: Product Name: Volvo Synthetic Gearbox Oil 97315Document10 pagesSafety Data Sheet: Product Name: Volvo Synthetic Gearbox Oil 97315Hendry PardedeNo ratings yet

- English - ComponentesDocument2 pagesEnglish - ComponentesChristopher Jesus Reàtegui OlivaresNo ratings yet

- Tata Spacio Soft TopDocument72 pagesTata Spacio Soft TopxtempNo ratings yet

- Stem-1 - Frac TankDocument1 pageStem-1 - Frac TankMohamed El-SawahNo ratings yet

- Shell Grease Portfolio Conversion Guide Provides Replacement RecommendationsDocument1 pageShell Grease Portfolio Conversion Guide Provides Replacement RecommendationsLuis Angel CabreraNo ratings yet

- FM 300Document5 pagesFM 300Happy DealNo ratings yet

- Shell lubricants portfolio guideDocument1 pageShell lubricants portfolio guideCara GutierrezNo ratings yet

- Motor Scania y Sus PartesDocument6 pagesMotor Scania y Sus PartesFabiana ChusitNo ratings yet

- Cat TdtoDocument2 pagesCat TdtoAhmed GhonimyNo ratings yet

- International 4400Document4 pagesInternational 4400marioNo ratings yet

- YugosDocument204 pagesYugosDIEGO FRAUSTONo ratings yet

- 2009 Commercial Truck BrochureDocument17 pages2009 Commercial Truck BrochureGateway Chevrolet Cadillac100% (1)

- Faresindustries Catalogue Handlers EN PDFDocument28 pagesFaresindustries Catalogue Handlers EN PDFdan PaulNo ratings yet

- NEHS0708Document9 pagesNEHS0708Victor Nunez100% (1)

- Mantenimineto Caterpillar Antes de OperarDocument4 pagesMantenimineto Caterpillar Antes de OperarTeofilo Flores100% (1)

- Wirtgen WS 2200Document8 pagesWirtgen WS 2200walk001No ratings yet

- Mobil ATF 333Document2 pagesMobil ATF 333ppanagos5664No ratings yet

- Standardization Guide 2019 PDFDocument32 pagesStandardization Guide 2019 PDFCarlos LoboNo ratings yet

- Shell Rimula R4X BrochureDocument4 pagesShell Rimula R4X BrochureAdiWijayaNo ratings yet

- Equivalentes Lubriplate - VariosDocument105 pagesEquivalentes Lubriplate - VariosLanAndreNo ratings yet

- AHQ 76 Nos - Hulift Semi Electric Manual Godrej NosDocument22 pagesAHQ 76 Nos - Hulift Semi Electric Manual Godrej NosAnup Kumar singhNo ratings yet

- Cummins: Fault Code: 373 PID: P232, S233 SPN: 1077 FMI: 3Document5 pagesCummins: Fault Code: 373 PID: P232, S233 SPN: 1077 FMI: 3Enrrique LaraNo ratings yet

- Value Original Value UnitDocument2 pagesValue Original Value UnithoangnhuphuocNo ratings yet

- Vox Conversoes PDFDocument107 pagesVox Conversoes PDFZorlac GreenNo ratings yet

- 560 Rev E Manual - 10-14Document79 pages560 Rev E Manual - 10-14Luis Guillermo Echeverri LopezNo ratings yet

- Toma de Fuerza - MACKDocument377 pagesToma de Fuerza - MACKing_adalbertop0% (1)

- MeritorDocument104 pagesMeritorDANIELNo ratings yet

- AFEX - Control UnitDocument2 pagesAFEX - Control UniteduardoNo ratings yet

- Patterns On Glass or FilmDocument24 pagesPatterns On Glass or FilmAfeitaKalaiNo ratings yet

- Linkbelt HTC11100 SpecDocument16 pagesLinkbelt HTC11100 SpecDaniel Cáceres TrujilloNo ratings yet

- Aries F450 F550 ManualDocument19 pagesAries F450 F550 Manualedbodie33% (3)

- Lubrication Guidelines for Cotta GearboxesDocument3 pagesLubrication Guidelines for Cotta GearboxesMatias Alfredo Contreras KöbrichNo ratings yet

- Elsvare Gas Turbine Lube OilDocument36 pagesElsvare Gas Turbine Lube OilshaonaaNo ratings yet

- Powercore Overview PresentationDocument22 pagesPowercore Overview PresentationMatias Alfredo Contreras KöbrichNo ratings yet

- Murphy Powercore: Full Control of Your Engine Becomes Reality With Murphy'S Powercore Controller and Panel SolutionsDocument4 pagesMurphy Powercore: Full Control of Your Engine Becomes Reality With Murphy'S Powercore Controller and Panel SolutionsMatias Alfredo Contreras KöbrichNo ratings yet

- P50B - 2.0 User's ManualDocument25 pagesP50B - 2.0 User's ManualMatias Alfredo Contreras KöbrichNo ratings yet

- Manual Parts - Series 110000, 120-, 140Document27 pagesManual Parts - Series 110000, 120-, 140Matias Alfredo Contreras KöbrichNo ratings yet

- Elife-Drive H Series Application Reference Manual RevB v2.4Document80 pagesElife-Drive H Series Application Reference Manual RevB v2.4Matias Alfredo Contreras KöbrichNo ratings yet

- Ruggerini RD180-280Document18 pagesRuggerini RD180-280ruralhermit0% (1)

- Relay - AFS19-24C - Afs-Spst-ContactorsDocument14 pagesRelay - AFS19-24C - Afs-Spst-ContactorsMatias Alfredo Contreras KöbrichNo ratings yet

- Superior Turnkey Panel Offers Complete Control, Familiarity Across ApplicationsDocument2 pagesSuperior Turnkey Panel Offers Complete Control, Familiarity Across ApplicationsMatias Alfredo Contreras KöbrichNo ratings yet

- Powercore Tec-10: Turnkey Electronic ControllerDocument2 pagesPowercore Tec-10: Turnkey Electronic ControllerMatias Alfredo Contreras KöbrichNo ratings yet

- Pushrod Cable Retermination Guide enDocument60 pagesPushrod Cable Retermination Guide enMatias Alfredo Contreras Köbrich100% (1)

- Vanguard 18hp - Engine # 3564470373F1Document61 pagesVanguard 18hp - Engine # 3564470373F1Matias Alfredo Contreras KöbrichNo ratings yet

- Vcam 6 Vcam 5 POSM Quick Setup Guide VXMT Eng V1.2 Publish 20210326Document5 pagesVcam 6 Vcam 5 POSM Quick Setup Guide VXMT Eng V1.2 Publish 20210326Matias Alfredo Contreras KöbrichNo ratings yet

- 1104D-44T Engine (PN1835 Jan08)Document2 pages1104D-44T Engine (PN1835 Jan08)Marinewants TwoBeinuNo ratings yet

- Ruggerini RD180-280Document18 pagesRuggerini RD180-280ruralhermit0% (1)

- Cummins 6B/6BT/6BTA-M Marine Engine General Data SheetDocument2 pagesCummins 6B/6BT/6BTA-M Marine Engine General Data SheetMuebles Sanabria100% (1)

- Cargo 1319+1519+1719-186hpDocument2 pagesCargo 1319+1519+1719-186hpEusebius QuinoNo ratings yet

- Manual Partes - FD750D-AS02-ENDocument22 pagesManual Partes - FD750D-AS02-ENMatias Alfredo Contreras KöbrichNo ratings yet

- FR91695 (1) QSCDocument3 pagesFR91695 (1) QSCJuan Diego SarangoNo ratings yet

- Manual Propietario - FD750DDocument45 pagesManual Propietario - FD750DMatias Alfredo Contreras KöbrichNo ratings yet

- Service Data - FH601D - EN - Spartan 738Document1 pageService Data - FH601D - EN - Spartan 738Matias Alfredo Contreras KöbrichNo ratings yet

- 3 MBE900 04aDocument10 pages3 MBE900 04aJorge A Salinas100% (1)

- Caterpillar® Engine SpecificationsDocument6 pagesCaterpillar® Engine Specificationsmaman96100% (3)

- Sewer Parts - American Sewer Parts 2016Document134 pagesSewer Parts - American Sewer Parts 2016Matias Alfredo Contreras KöbrichNo ratings yet

- Tech Info - DD13 Engine - DDC-SVC-BRO-0001 - 2019Document40 pagesTech Info - DD13 Engine - DDC-SVC-BRO-0001 - 2019Matias Contreras Köbrich100% (1)

- Maxxforcedrivertraining EnglishDocument2 pagesMaxxforcedrivertraining EnglishMatias Alfredo Contreras KöbrichNo ratings yet

- Transfer CaseDocument20 pagesTransfer CaseMatias Alfredo Contreras KöbrichNo ratings yet

- New Engine Oil Training API FA-4 API CK-4Document25 pagesNew Engine Oil Training API FA-4 API CK-4angel017No ratings yet

- Diagrama Electronico DT466Document2 pagesDiagrama Electronico DT466Aldo Fran Vargas82% (22)

- Catálogo - UEMSI PDFDocument60 pagesCatálogo - UEMSI PDFMatias Alfredo Contreras KöbrichNo ratings yet

- Mast Pumpen TP4 - 1 DIN 14425Document1 pageMast Pumpen TP4 - 1 DIN 14425Matias Alfredo Contreras KöbrichNo ratings yet

- Kvpy Pee PDFDocument9 pagesKvpy Pee PDFstudysteps.inNo ratings yet

- 03 MAN D2Z2IM ACT350xx ENDocument24 pages03 MAN D2Z2IM ACT350xx ENAlfonso Lopez toroNo ratings yet

- Ccu Sem (2010-05-05) PDFDocument181 pagesCcu Sem (2010-05-05) PDFBích Đỗ DanhNo ratings yet

- Table 4E4A - Current Carrying Capacity in AmpereDocument1 pageTable 4E4A - Current Carrying Capacity in AmperesalvuNo ratings yet

- Method of Lighting CalculationsDocument3 pagesMethod of Lighting CalculationsSpencer Josh RegedorNo ratings yet

- LG Refridge ServiceManualDocument79 pagesLG Refridge ServiceManualMichael Dianics100% (1)

- Kinetic and Potential Energy PracticeDocument1 pageKinetic and Potential Energy Practicealchemist2000No ratings yet

- 200VLD-H SS No EconomizerDocument2 pages200VLD-H SS No EconomizerAnas ElwakilNo ratings yet

- The Krebs Cycle ExplainedDocument12 pagesThe Krebs Cycle ExplainedHo Man ChanNo ratings yet

- Understanding ThermodynamicsDocument4 pagesUnderstanding Thermodynamicscory kurdapyaNo ratings yet

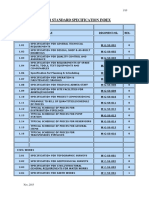

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Objective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaDocument4 pagesObjective and Scope and Importance of Mineral Beneficiation With Special Reference To IndiaVidya Sagar100% (1)

- The Design, Development and Future of Electric Vehicle: Prof. Eric ChengDocument18 pagesThe Design, Development and Future of Electric Vehicle: Prof. Eric ChengDeepak ChaurasiaNo ratings yet

- Model AR Ellipse® Annular Flow Meter PDFDocument2 pagesModel AR Ellipse® Annular Flow Meter PDFjhorlanNo ratings yet

- Fabric Expansion JointsDocument28 pagesFabric Expansion Jointswarmachine269889No ratings yet

- Introduction To The OpenDSSDocument4 pagesIntroduction To The OpenDSSanoopeluvathingal100No ratings yet

- 2007 Bachu Etal CO2 Storage Capacity EstimationDocument14 pages2007 Bachu Etal CO2 Storage Capacity EstimationArindam Obzi GuptaNo ratings yet

- Equipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorDocument2 pagesEquipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorAndi Wardiman AnwarNo ratings yet

- Utilization of Waste From Rice ProductionDocument17 pagesUtilization of Waste From Rice ProductionEmilia_P100% (2)

- Microstructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersDocument22 pagesMicrostructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersAlmerindo JuniorNo ratings yet

- Hydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Document22 pagesHydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Thulasidasan JeewaratinamNo ratings yet

- ECU Mount-On-Engine Vibration StudyDocument6 pagesECU Mount-On-Engine Vibration StudyElroy LeeNo ratings yet

- Distillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedDocument3 pagesDistillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedReyes, Ishmael Edward John U.No ratings yet

- Resume Dr. R.N.MukerjeeDocument13 pagesResume Dr. R.N.MukerjeeRahul Mukerjee100% (1)

- ABB Terminal BlocksDocument236 pagesABB Terminal BlocksBenoit LefebvreNo ratings yet

- Design and Generating Energy As A Car Alternator TDocument7 pagesDesign and Generating Energy As A Car Alternator TJohnny TestNo ratings yet

- MeasurementDocument4 pagesMeasurementJemason100% (1)

- RP Manuale D'uso e Manutenzione - CAVALLINO CE PDFDocument24 pagesRP Manuale D'uso e Manutenzione - CAVALLINO CE PDFMiraNo ratings yet

- Current Transformer - Electrical Notes & ArticlesDocument47 pagesCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- Factors Affecting Potential EnergyDocument3 pagesFactors Affecting Potential EnergyArgyll PaguibitanNo ratings yet