Professional Documents

Culture Documents

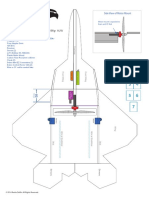

F-15 Park Jet Plans Assembly Drawing Tiled

Uploaded by

Nestor Omar Ambesi0 ratings0% found this document useful (0 votes)

60 views2 pagesF 15 , armado

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentF 15 , armado

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

60 views2 pagesF-15 Park Jet Plans Assembly Drawing Tiled

Uploaded by

Nestor Omar AmbesiF 15 , armado

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Notes:

* All parts made from 6mm Depron or BlueCore foam unless

otherwise indicated

* If using BlueCore, peel the plastic covering off both sides

of all fuselage parts (leave the skin on all wing and

empennage parts)

* Sand all wing and empennage leading edges round and

apply a piece of 3M Satin tape around the leading edge to

add smoothness and durability

* Flaperon and stabilator flight controls recommended.

* Recommended control deflections (all dimensions

measured at root trailing edge):

Stabilators: +/- 2.0" High, +/- 1.5" Low

Ailerons: +/- 1.5" High, +/- 1.0" Low

Flaps: 0 up, 1.25" down

* Use -40% exponential on elevator and ailerons

* Launch with 10 deg flaps, land with up to 30 deg flaps.

For improved manuevering in small fields, set 10 deg flaps.

* Elevator-to-flap mixing will provide improved maneuverability.

Set it up so that 15 degrees of down flaps is provided with

full up stabilator inputs.

* Choose a power system that provides 15-20 oz static thrust

and a 45-50 mph pitch speed.

* Recommended brushed power system: GWS EPS-350C

with C gearing (5.33), 8x6 GWS SF prop, 11.1V 1200 mAh

Lipo battery

* Recommended brushless power system: Himaxx 2015-4100,

4.4 gearing, 9x6 APC SF prop, 11.1V 1200 mAh Lipo battery

* Use a heat gun to gently bend the foam in the fuselage

to pre-form it to the shapes shown

Sand fuselage corners

round as shown below

(not to scale)

Optional: If fuselage is too

hand launching, cut sm

bottom as shown to allow

fuselage for launch. Also

fuselage with 1/4"

wing sp

Canop

or foam

Removable canopy mounted

with two bamboo skewers

forward and two Velcro strips aft

Scale in inches

Span: 27.9"

Wing area: 257 sq in

Weight: 15.0 - 18.0 oz RTF

Wing loading: 9.2 oz/sq ft

Designed and drawn by Steve Shumate

Copyright 2004 All Rights Reserved

Nosecone made from

laminated foam sheets

or foam block carved

to shape

Battery mounted to fuselage

floor with a strip of Velcro

(to allow CG adjustment)

Full-span flaperons (flap/aileron

break shown for aesthetics only)

.21" dia carbon tube spar

elage is too wide for comfortable

hing, cut small holes in fuselage

own to allow gripping the center

aunch. Also reinforce the center

ge with 1/4" balsa triangle stock.

Optional engine fairings made from foam

sheet sanded to rounded shape

1" x .75" 1/32" ply

wing spar joint doublers

(top and bottom)

3.25"

3.75"

Flaperon servos

(use 1/32" music

wire pushrods)

.157" x 11.5" carbon tube pivoting inside

three short pieces of 3/16" aluminum tubing

Cover wing leading edge with

a strip of 3M Satin tape for

smoothness and durability

Cover stabilator leading edge and root

with 3M Satin tape for strengthening

Cut 45 deg bevel in flaperon

leading edge and hinge with

3M Satin tape

Make fin tips from

1/4" square balsa

Canopy made from laminated foam sheets

or foam block carved to shape

uselage

Velcro

Aft canopy mount made

from 1/4" balsa triangle

with Velcro on top

3/8" sq x 4"

hardwood

motor mount

Cut hatch for access

to radio equipment

GWS EPS-350

motor shown

(no right or

down thrust)

Dashed lines indicate balsa

triangle stock at corners (see

parts templates for details)

Receiver

Stabilator servo

(use 1/32" music

wire pushrod)

.75" x .75" 1/64" ply

bearing supports

(4 total)

Use servo arm for control horn

(drilled out to fit carbon tube)

You might also like

- Polaris Parts Templates (Tiled)Document20 pagesPolaris Parts Templates (Tiled)Leandro AlvarengaNo ratings yet

- F-14 Park Jet (Assembly Drawing)Document2 pagesF-14 Park Jet (Assembly Drawing)John MondoNo ratings yet

- T-38 Park Jet Plans (Assembly Drawing)Document2 pagesT-38 Park Jet Plans (Assembly Drawing)souheil_souNo ratings yet

- Assembly Manual for Zagi 60 and Zagi 60 Tazz Electric Flying WingDocument24 pagesAssembly Manual for Zagi 60 and Zagi 60 Tazz Electric Flying WingAlexandre P. CruzNo ratings yet

- F-15 Park Jet Plans (Parts Templates Scaled 150 Tiled)Document42 pagesF-15 Park Jet Plans (Parts Templates Scaled 150 Tiled)donlynNo ratings yet

- Blu-Baby 24 Parts Kit TiledDocument4 pagesBlu-Baby 24 Parts Kit TiledSavu DanielNo ratings yet

- MF-35 Lightning TDocument3 pagesMF-35 Lightning TAngel NietoNo ratings yet

- Fe 25 e 6Document2 pagesFe 25 e 6juanNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled) BETA2Document16 pagesT-38 Park Jet Plans (Parts Templates Tiled) BETA2Emerson URNo ratings yet

- Su-37 Park Jet Plans (Parts Templates Tiled)Document28 pagesSu-37 Park Jet Plans (Parts Templates Tiled)colo0% (1)

- Polaris Parts Templates 75 Scaled NontiledDocument1 pagePolaris Parts Templates 75 Scaled NontiledSavu DanielNo ratings yet

- F-15 Park Jet Plans (Parts Templates Tiled)Document18 pagesF-15 Park Jet Plans (Parts Templates Tiled)EricsonNo ratings yet

- F-22 Construction GuideDocument28 pagesF-22 Construction Guideibmace100% (1)

- Su-37 Park Jet Plans (Assembly Drawing Tiled)Document2 pagesSu-37 Park Jet Plans (Assembly Drawing Tiled)coloNo ratings yet

- Ecss e HB 32 20 - Part 5a PDFDocument435 pagesEcss e HB 32 20 - Part 5a PDFNasos MasourasNo ratings yet

- BumperDocument33 pagesBumperAbhishek VermaNo ratings yet

- TecnoMETAL 2D DrawingDocument430 pagesTecnoMETAL 2D DrawingSaid KciouiNo ratings yet

- Catia V5 Interview Questions and AnswersDocument2 pagesCatia V5 Interview Questions and Answerspriyankar007No ratings yet

- WAAM by HarpuneetDocument25 pagesWAAM by Harpuneethpsingh0078No ratings yet

- Mitsubishi: Real Paper ModelDocument9 pagesMitsubishi: Real Paper Modelfbejar_1No ratings yet

- Power Contact Wall Chart (M39029) Brochure Document Library VersionDocument1 pagePower Contact Wall Chart (M39029) Brochure Document Library Versionrafael climacoNo ratings yet

- F-18 Park Jet Construction Guide Rev ADocument20 pagesF-18 Park Jet Construction Guide Rev ASzymon WójcikNo ratings yet

- Metal Structure DesignerDocument2 pagesMetal Structure DesignerWONNER156No ratings yet

- Examples 2Document625 pagesExamples 2ManuelDarioFranciscoNo ratings yet

- Super Bandit Park Jet (Parts Templates Scaled 75 Tiled)Document9 pagesSuper Bandit Park Jet (Parts Templates Scaled 75 Tiled)Ahmad Khanif FikriNo ratings yet

- Polaris Assembly Drawing (Nontiled) PDFDocument1 pagePolaris Assembly Drawing (Nontiled) PDFSavu DanielNo ratings yet

- F-22 Plans 22wsDocument8 pagesF-22 Plans 22wsJosephRomeraloNo ratings yet

- F22 FOAM Construction GuideDocument26 pagesF22 FOAM Construction GuideFilip Lisičin100% (1)

- NX Nastran 8 Basic Dynamic Analysis User's GuideDocument373 pagesNX Nastran 8 Basic Dynamic Analysis User's GuideMSC Nastran BeginnerNo ratings yet

- Pro e 4 Install GuideDocument1 pagePro e 4 Install GuidePrawin RamNo ratings yet

- F-22 Park Jet (Parts Templates Scaled 120 Tiled)Document28 pagesF-22 Park Jet (Parts Templates Scaled 120 Tiled)Ronald Cardenas GNo ratings yet

- Wireframe and Surface Design: CATIA TrainingDocument55 pagesWireframe and Surface Design: CATIA Trainingkishore99939No ratings yet

- Pawnee Parts - FullDocument1 pagePawnee Parts - FullAlejandro LabléeNo ratings yet

- 2020R1 StructuresDocument193 pages2020R1 Structuresagrbovic100% (1)

- DLK PDFDocument930 pagesDLK PDFАндрей НадточийNo ratings yet

- Abaqus For Catia v5 Tutorial - Schroff - GoodDocument30 pagesAbaqus For Catia v5 Tutorial - Schroff - GoodLarry MarNo ratings yet

- Merged RubberDocument16 pagesMerged RubberngejooNo ratings yet

- Tutorial Fluent (Dados NETO)Document216 pagesTutorial Fluent (Dados NETO)Suellen Freire Rigatto100% (1)

- 07 AV WeatherStripDocument9 pages07 AV WeatherStripVinnie IngallsNo ratings yet

- Snice Mirage 2000 Plan v2 FinalDocument1 pageSnice Mirage 2000 Plan v2 FinalLalith Kumar100% (1)

- Ansa v13.1.2 Release NotesDocument18 pagesAnsa v13.1.2 Release Notesharsh14363No ratings yet

- Cinema TicsDocument40 pagesCinema TicsAlexandru Precup0% (1)

- Generative Drafting (ISO) : CATIA TrainingDocument149 pagesGenerative Drafting (ISO) : CATIA Trainingkishore99939No ratings yet

- F-22 Park Jet (Assembly Drawing) PDFDocument1 pageF-22 Park Jet (Assembly Drawing) PDFVikram DamleNo ratings yet

- Geomagic Q12 GuideDocument30 pagesGeomagic Q12 Guidecmm5477No ratings yet

- Su-37 Park Jet Plans (Assembly Drawing Tiled) PDFDocument2 pagesSu-37 Park Jet Plans (Assembly Drawing Tiled) PDFcoloNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Wing Installation (Left Shown)Document1 pageVan'S Aircraft, Inc.: Figure 1: Wing Installation (Left Shown)Mark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Match-Drilling Map BoxDocument1 pageVan'S Aircraft, Inc.: Figure 1: Match-Drilling Map BoxMark Evan SalutinNo ratings yet

- Maruti Suzuki Training ReportDocument26 pagesMaruti Suzuki Training ReportRehan Sharma100% (2)

- Instruction Design With Studio ShapeDocument124 pagesInstruction Design With Studio ShapenghiaNo ratings yet

- CATIA V5 Tutorials: Mechanism Design & AnimationDocument36 pagesCATIA V5 Tutorials: Mechanism Design & AnimationValentinNo ratings yet

- 03 SculptingDocument25 pages03 SculptingKesava PrasadNo ratings yet

- Design Airfoils in SolidWorksDocument2 pagesDesign Airfoils in SolidWorksMazhar36No ratings yet

- Tutorial Iron ManDocument219 pagesTutorial Iron ManDavid Landa100% (4)

- By Graham Smith: Top View RudderDocument1 pageBy Graham Smith: Top View RudderSergio De Manuel GálvezNo ratings yet

- Build SE5a indoor flyer : step-by-step guideDocument3 pagesBuild SE5a indoor flyer : step-by-step guideairsoft doença100% (1)

- F-15 Park Jet Plans Assembly Drawing Tiled PDFDocument2 pagesF-15 Park Jet Plans Assembly Drawing Tiled PDFoambesiNo ratings yet

- F-15 Park Jet Plans (Assembly Drawing) Rev CDocument2 pagesF-15 Park Jet Plans (Assembly Drawing) Rev CMAIG ElectricosNo ratings yet

- Foame IIx Park FlyerDocument1 pageFoame IIx Park FlyerAlex OctaNo ratings yet

- Curtiss P-40 WarhawkDocument9 pagesCurtiss P-40 WarhawkAviation/Space History LibraryNo ratings yet

- Diffraction Grating HandbookDocument204 pagesDiffraction Grating HandbookCamilo LimaNo ratings yet

- Cessna 182Document28 pagesCessna 182Liliana Acosta de Ambesi0% (1)

- How To Grind Lathe ToolsDocument16 pagesHow To Grind Lathe Toolscharlie20377240100% (11)

- Piper J-3 CubDocument24 pagesPiper J-3 CubNestor Omar AmbesiNo ratings yet

- Cessna 182Document28 pagesCessna 182Liliana Acosta de Ambesi0% (1)

- Financial Monitoring SystemDocument13 pagesFinancial Monitoring SystemSachie Delizo Gabad100% (1)

- Development of Transportation in India 1976Document6 pagesDevelopment of Transportation in India 1976VijayuduGnanamkondaNo ratings yet

- Ms - Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMs - Installation of Electric PVC Conduits and AccessoriesDuel TimeNo ratings yet

- 2018-05 Greengauge21 Beyond - HS2WEBDocument220 pages2018-05 Greengauge21 Beyond - HS2WEBscribdstorageNo ratings yet

- BIT Sindri Placement StatisticsDocument15 pagesBIT Sindri Placement StatisticsSaurabh YadavNo ratings yet

- Underpinning: TypesDocument5 pagesUnderpinning: TypesEnggUsmanZafarNo ratings yet

- 1 Maritime TransportDocument413 pages1 Maritime TransportWondwosen Tiruneh100% (1)

- Index - Foundation of Software TestingDocument3 pagesIndex - Foundation of Software TestingJItendra KNo ratings yet

- Draft of Reflection PaperDocument2 pagesDraft of Reflection PaperAkshaya LakshminarasimhanNo ratings yet

- Eicher Motors Initiating CoverageDocument15 pagesEicher Motors Initiating CoverageNikhil SinghalNo ratings yet

- P Nagar, Near Ordnance Factory: 0t, R111 KOTA / S T. / CAIDocument2 pagesP Nagar, Near Ordnance Factory: 0t, R111 KOTA / S T. / CAISupradeep GoudNo ratings yet

- BookDocument170 pagesBookPriscyla RoqueNo ratings yet

- Black&Decker 3" X 21" Dragster Belt SanderDocument6 pagesBlack&Decker 3" X 21" Dragster Belt SanderwdowiuueNo ratings yet

- Jawaban Sertifikasi SAPDocument4 pagesJawaban Sertifikasi SAPanggie100% (2)

- Academic Task 3 Simulation QuestionsDocument9 pagesAcademic Task 3 Simulation QuestionsAnshulNo ratings yet

- Conveyor Design PDFDocument73 pagesConveyor Design PDFRamesh Subramani RamachandranNo ratings yet

- Packing Instructions for Safe TransportDocument50 pagesPacking Instructions for Safe TransportDhaman A KokaNo ratings yet

- Rounding Into Shape: SPECIAL REPORT: Global Automation and Manufacturing Summit PreviewDocument100 pagesRounding Into Shape: SPECIAL REPORT: Global Automation and Manufacturing Summit PreviewHứa Thông TriệuNo ratings yet

- Distance Rate Time Word ProblemsDocument4 pagesDistance Rate Time Word Problemsapi-286443551No ratings yet

- Venkata Maheedhar K V Voice:9441797872Document6 pagesVenkata Maheedhar K V Voice:9441797872anon-739858No ratings yet

- Business Plan Summary for MGVCL FY 2011-16Document160 pagesBusiness Plan Summary for MGVCL FY 2011-16havejsnjNo ratings yet

- Blanking and PiercingDocument5 pagesBlanking and PiercingSatheesh Sekar100% (1)

- Company Brochure 2023Document2 pagesCompany Brochure 2023Leon du PlessisNo ratings yet

- AS400 Questions and AnswersDocument4 pagesAS400 Questions and Answerssenthilj82No ratings yet

- E - Noetix Generator For OBI EE PlusDocument2 pagesE - Noetix Generator For OBI EE PlusNarayana AnkireddypalliNo ratings yet

- Expertly Manufactured Weights: For Reliable Testing ApplicationsDocument24 pagesExpertly Manufactured Weights: For Reliable Testing Applicationsihyaalbantani2321No ratings yet

- Tec PecDocument23 pagesTec PecALI BEN AMORNo ratings yet

- Conveyance Security-Aeo Check List PDFDocument3 pagesConveyance Security-Aeo Check List PDFRajula Gurva ReddyNo ratings yet

- Biw Basic Document - Iit ProjectDocument6 pagesBiw Basic Document - Iit ProjectArshadNo ratings yet