Professional Documents

Culture Documents

Blowout Preventer (BOP)

Uploaded by

Energy TomorrowCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blowout Preventer (BOP)

Uploaded by

Energy TomorrowCopyright:

Available Formats

Blowout Preventer (BOP) Briefing Paper – 6.8.

10

All drilling rigs are equipped with well control systems, including a blowout preventer

(BOP), which is designed to close and stop the flow of oil in an emergency. In many

cases, rig operators may incorporate additional back-up methods as supplementary

safeguards to close the well.

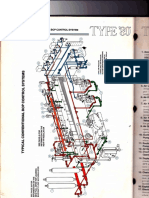

Subsea BOP systems, also known as BOP stacks, contain a series of ram BOPs, annular

BOPs and other devices, that are designed to close off the wellbore in various drilling

situations. As a first line of defense in a blowout, pipe ram BOPs and annular preventers

close around pipe in the well to stop the blowout surge. BOP stacks also have blind and

shear rams in the case of an extreme event. These rams are designed to close and seal the

entire wellbore to stop a blowout. Blind rams close to seal the wellbore if there is no pipe in

the well, while shear rams cut through pipe (if the drill is still in the well) to close and seal the

wellbore.

BOPs come in a variety of pressure ratings. Companies will choose the appropriate BOP

stack based on the expected conditions of the well.

BOPs have been in use for nearly a century. As drilling technologies have advanced, the

stress tolerances of these safety devices have improved. Engineers constantly test new

devices in labs mimicking the pressures and temperatures of the deep sea environment.

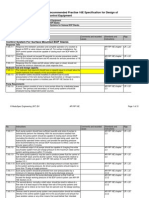

Minimum regulatory requirements for a subsea BOP stack call for one annular preventer,

two pipe ram BOPs and one blind/shear ram BOP. The BOPs must be pressure tested upon

installation and every 14 days thereafter and must be functionally tested every seven days.

Subsea well control systems contain multiple redundant systems that activate the well

control system (control panels), deliver power supplies to the BOPs (electric cables and

hydraulic lines), and control the functions of the BOP (control pods).

In addition, back-up control systems may be installed to operate selected functions of the

well control system in the event of power loss from the surface. Types of back-up control

systems include remotely operated vehicle (ROV) systems and acoustic control systems.

o An ROV backup system includes an operating panel mounted on the BOP stack

that will allow activation of certain BOP functions, including the ability to shut-in

the well in an emergency situation.

o An acoustic backup control system uses coded acoustic signals for

communication between the surface and sea floor. It may be used to control

selected critical BOP functions.

Additional systems can provide further safeguards, such systems include auto-shear and

deadman. An auto-shear system is designed to automatically seal the wellbore if the riser

were to disconnect above the BOP. A deadman system is designed to automatically close

the wellbore in the event of a simultaneous loss of hydraulic and electrical power supply to

both subsea control pads.

1220 L Street, NW | Washington, DC 20005-4070 www.api.org

You might also like

- BOP and Control SystemDocument79 pagesBOP and Control SystemGonzalo Guzman Jaimes100% (1)

- Blowout PreventerDocument13 pagesBlowout PreventerNelson TorresNo ratings yet

- Managed Pressure Drilling (MPD) Choke Manifold: Field Installation and Operation ManualDocument40 pagesManaged Pressure Drilling (MPD) Choke Manifold: Field Installation and Operation ManualЕТМ100% (3)

- Shaffer (Nov) Shearing Blind RamsDocument1 pageShaffer (Nov) Shearing Blind RamsOscar BustosNo ratings yet

- Operating Manual for 5/8”-5000psi Double (Single) Ram BOPDocument32 pagesOperating Manual for 5/8”-5000psi Double (Single) Ram BOPKurniadi WibowoNo ratings yet

- BOP Catalog vFEB20152 PDFDocument36 pagesBOP Catalog vFEB20152 PDFMadirley Pimenta100% (1)

- Size BOP Control SystemsDocument7 pagesSize BOP Control SystemsQadriNo ratings yet

- 11 5000 Hydril GK Screwed Annular Bop Spec SheetDocument1 page11 5000 Hydril GK Screwed Annular Bop Spec SheetJoel SNo ratings yet

- H&P ARG Rig 335 Equipment List From Final WoDocument12 pagesH&P ARG Rig 335 Equipment List From Final WoJuan Miguel Robledo100% (1)

- Choke Manifold EXPRODocument2 pagesChoke Manifold EXPROfurnaNo ratings yet

- Hydril GK Annular DataDocument2 pagesHydril GK Annular DataAndrés Ramírez100% (3)

- Rowan Rig 0082 BOP Control System Operation and Maintenance ManualDocument38 pagesRowan Rig 0082 BOP Control System Operation and Maintenance Manualcarlosorizaba100% (1)

- BOP Procedure Standard Operating ProcedureDocument51 pagesBOP Procedure Standard Operating ProcedureJacob Keemink100% (2)

- Koomey S&s ManualDocument0 pagesKoomey S&s Manualborregocr90% (10)

- Control Unit - Day3 - Test IntroDocument46 pagesControl Unit - Day3 - Test IntroMrityunjay Dhanraj100% (1)

- Parveen Well Head PDFDocument25 pagesParveen Well Head PDFRatnakar PatilNo ratings yet

- Casing Integrity TestingDocument1 pageCasing Integrity TestingKim MissonNo ratings yet

- Parker Drilling Rig 258Document2 pagesParker Drilling Rig 258Nathan Thillai100% (2)

- 11 5000 Shaffer Bolted Annular Bop Spec SheetDocument1 page11 5000 Shaffer Bolted Annular Bop Spec SheetJoel SNo ratings yet

- Drill Stem Test Part 1Document31 pagesDrill Stem Test Part 1Abdullah IshaqNo ratings yet

- Super Choke BasicsDocument10 pagesSuper Choke Basicsel_guariquenoNo ratings yet

- Calculating Well Head PressureDocument1 pageCalculating Well Head PressureonemilimeterNo ratings yet

- 12 Drilling PreventersDocument82 pages12 Drilling PreventersDavid Kusuma100% (1)

- Cameron Catalog 2006 020819 PDFDocument162 pagesCameron Catalog 2006 020819 PDFTitanBOPNo ratings yet

- Strata RCDDocument2 pagesStrata RCDDavid VilchesNo ratings yet

- How to Handle a Pack Off SituationDocument2 pagesHow to Handle a Pack Off SituationMohammad RizwanNo ratings yet

- API Flange Bolt & Ring Chart for Oil & Gas Piping SystemsDocument1 pageAPI Flange Bolt & Ring Chart for Oil & Gas Piping SystemsPrasetiyo SholehNo ratings yet

- BOP CLOSING UNITS (Koomey)Document1 pageBOP CLOSING UNITS (Koomey)SHRINIVAS100% (1)

- Cameron D Type Annular Bop ManualDocument5 pagesCameron D Type Annular Bop ManualLASDOS0% (1)

- Shaffer ShpericalDocument11 pagesShaffer Shpericaljeinerdt100% (1)

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedNo ratings yet

- DRAFT - Requirements For Pressure TestingDocument3 pagesDRAFT - Requirements For Pressure TestingAdhie WaelacxhNo ratings yet

- Controll Cabin OEM PDFDocument47 pagesControll Cabin OEM PDFOvRrj AhmedNo ratings yet

- LPR-N Tester Valve Funcionamiento 1Document33 pagesLPR-N Tester Valve Funcionamiento 1Александр КинтероNo ratings yet

- Surface Well Control Exercise No. 11 - Equipment - GeneralDocument27 pagesSurface Well Control Exercise No. 11 - Equipment - GeneralKaleem UllahNo ratings yet

- Koomey Air Operated Pumps and Pressure Test UnitsDocument1 pageKoomey Air Operated Pumps and Pressure Test UnitsAbde EsselamNo ratings yet

- MGS Capacity CalculatorDocument13 pagesMGS Capacity CalculatorRodolfo MendezNo ratings yet

- Blowout Preventer PDFDocument2 pagesBlowout Preventer PDFdazaev1100% (1)

- CAD Product Brouchure 2010Document11 pagesCAD Product Brouchure 2010jlmunozvNo ratings yet

- Trip Sheet For RigDocument1 pageTrip Sheet For Rigankurume1984100% (1)

- API RP 16E Control SysDocument31 pagesAPI RP 16E Control SysAaron Higgins100% (1)

- Oil & Gas Manifold SystemsDocument1 pageOil & Gas Manifold SystemsAntonyNo ratings yet

- Mudline Suspension SystemDocument5 pagesMudline Suspension SystemNagaraju JallaNo ratings yet

- Parveen Casing Head Housing (PCHH) Dimensions & SpecsDocument25 pagesParveen Casing Head Housing (PCHH) Dimensions & SpecsGerman PinedaNo ratings yet

- Drilling Tools CatalogDocument96 pagesDrilling Tools CatalogRzvn100% (1)

- Tc148-2 Manual GV O&mDocument20 pagesTc148-2 Manual GV O&mFam Escalante OnofreNo ratings yet

- Formation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsDocument6 pagesFormation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsJamalNo ratings yet

- BOP control unit accumulator bottles and calculationsDocument35 pagesBOP control unit accumulator bottles and calculationsMrityunjay Dhanraj67% (3)

- HydrilDocument46 pagesHydrilAdolfo AnguloNo ratings yet

- Well Control HamiltonDocument80 pagesWell Control HamiltonAnonymous JMuM0E5YO100% (2)

- BOP Stack Manual (Read Only) 29101801Document561 pagesBOP Stack Manual (Read Only) 29101801adnan0307100% (2)

- BOP Accumulator UnitsDocument18 pagesBOP Accumulator Unitsjosegutierrez88201050% (2)

- Well Control EquipDocument36 pagesWell Control EquipAhmed BakrNo ratings yet

- OTC-23473-MS - New Generation Control System For 20ksi Subsea BOP - Shanks - 2012Document12 pagesOTC-23473-MS - New Generation Control System For 20ksi Subsea BOP - Shanks - 2012Anonymous TYj74uwNo ratings yet

- Wireline (Rev.15.8.12)Document5 pagesWireline (Rev.15.8.12)hNo ratings yet

- Subsea BOP Stack SystemsDocument10 pagesSubsea BOP Stack SystemsAdam WattsNo ratings yet

- Basra University For Oil and Gas Oil and Gas Engineering College Oil and Gas EngineeringDocument6 pagesBasra University For Oil and Gas Oil and Gas Engineering College Oil and Gas EngineeringYaqeen MohammadNo ratings yet

- NORSOK Standard Design Requirements for Subsea Production SystemsDocument26 pagesNORSOK Standard Design Requirements for Subsea Production SystemsCarolina TelesNo ratings yet

- Blowout PreventorsDocument7 pagesBlowout PreventorsRachitPandeyNo ratings yet

- ICH3800 Class 7: 1st Semester 2022Document92 pagesICH3800 Class 7: 1st Semester 2022catalinaNo ratings yet

- Know The Facts On Keystone XL?Document3 pagesKnow The Facts On Keystone XL?Energy TomorrowNo ratings yet

- Investing in New JobsDocument1 pageInvesting in New JobsEnergy TomorrowNo ratings yet

- Energy Solutions PrimerDocument13 pagesEnergy Solutions PrimerAaron MonkNo ratings yet

- Investing in The Promise of AmericaDocument1 pageInvesting in The Promise of AmericaEnergy TomorrowNo ratings yet

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- Pipelines, Investing in SafetyDocument1 pagePipelines, Investing in SafetyEnergy TomorrowNo ratings yet

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- API Comments On DOE LNG Export StudyDocument24 pagesAPI Comments On DOE LNG Export StudyEnergy TomorrowNo ratings yet

- Investing in Quality JobsDocument1 pageInvesting in Quality JobsEnergy TomorrowNo ratings yet

- Investing in CommunitiesDocument1 pageInvesting in CommunitiesEnergy TomorrowNo ratings yet

- U.S. Liquefied Natural Gas Exports: America's Opportunity and AdvantageDocument38 pagesU.S. Liquefied Natural Gas Exports: America's Opportunity and AdvantageEnergy TomorrowNo ratings yet

- America SpokeDocument1 pageAmerica SpokeEnergy TomorrowNo ratings yet

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- The Keys To Energy SecurityDocument2 pagesThe Keys To Energy SecurityEnergy TomorrowNo ratings yet

- It's Cold OutsideDocument1 pageIt's Cold OutsideEnergy Tomorrow0% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- API Blogger Conference Call On Gas Prices - 03.26.12Document10 pagesAPI Blogger Conference Call On Gas Prices - 03.26.12Energy TomorrowNo ratings yet

- Artic E-Series - Fuel Consumption - ARPP080219Document1 pageArtic E-Series - Fuel Consumption - ARPP080219widanto0apriawanNo ratings yet

- Ethyl BenzeneDocument10 pagesEthyl Benzenenmmpnmmpnmmp80% (5)

- Mechanical Engineering Thermodynamics II - Lecture 03 - 27 SepDocument25 pagesMechanical Engineering Thermodynamics II - Lecture 03 - 27 SepThineshraaj Naidu Jaya RamanNo ratings yet

- TCS P 104 02 R0Document13 pagesTCS P 104 02 R0sathishlinshanNo ratings yet

- Bajada Power PlantDocument14 pagesBajada Power PlantRey Francis FamulaganNo ratings yet

- Murphy CodigoDocument4 pagesMurphy CodigoGonzalo VillarroelNo ratings yet

- Alkylation, Dealkylation, and HydrodealkylationDocument3 pagesAlkylation, Dealkylation, and HydrodealkylationJoy MorilesNo ratings yet

- BS&W Models 4528EZ & 4728 Monitors FMCDocument14 pagesBS&W Models 4528EZ & 4728 Monitors FMCFernando MendezNo ratings yet

- Petromax LanternDocument9 pagesPetromax LanternbatacurloNo ratings yet

- Chemical-Resistance-List-2014-Jun - tcm54-28039 Jotun1Document31 pagesChemical-Resistance-List-2014-Jun - tcm54-28039 Jotun1Ibrahim KhalilNo ratings yet

- Refinery OverviewDocument79 pagesRefinery Overviewchikukotwal100% (1)

- SR-1054 Serie 40 Applications 2010-10Document14 pagesSR-1054 Serie 40 Applications 2010-10Carlos GutierrezNo ratings yet

- 165 E06Document7 pages165 E06Emad SatariNo ratings yet

- Brochure - Thermol-DDocument4 pagesBrochure - Thermol-Dajeeit8No ratings yet

- Comparacion 797B 797FDocument20 pagesComparacion 797B 797FpsalaspaNo ratings yet

- Coelmo 60 kVA PDT113T2-ne PDFDocument2 pagesCoelmo 60 kVA PDT113T2-ne PDFEmily BullockNo ratings yet

- Dando Mintec-18 - Mineral Exploration Rig AustraliaDocument2 pagesDando Mintec-18 - Mineral Exploration Rig AustraliaTaylor Oughton50% (2)

- Economix Agitator Data SheetDocument2 pagesEconomix Agitator Data Sheetdumb2471817No ratings yet

- Re07300 1202Document2 pagesRe07300 1202Walter JosephNo ratings yet

- Lucas Td5 DiagnosticDocument14 pagesLucas Td5 Diagnosticandrzej100% (1)

- Filtros 793DDocument4 pagesFiltros 793DDAnielNo ratings yet

- JD Dpaf F THFDQ FSF FHD KHW WPL L Vupnghus FsDocument11 pagesJD Dpaf F THFDQ FSF FHD KHW WPL L Vupnghus FsLokuliyanaNNo ratings yet

- A Project Report On Oil Rigs123Document17 pagesA Project Report On Oil Rigs123Somasekhar Koushik Ayalasomayajula100% (1)

- Propylene ProductionDocument24 pagesPropylene ProductionFadlan BaharNo ratings yet

- Fire and Explosion HazardsDocument10 pagesFire and Explosion Hazardsاحمد الجزار2007No ratings yet

- Biomass Gasification PDFDocument29 pagesBiomass Gasification PDFHotib PerwiraNo ratings yet

- Flammable Chemicals ExplainedDocument33 pagesFlammable Chemicals ExplainedBani Hafidz NazaliNo ratings yet

- CK2500 II BrochureDocument8 pagesCK2500 II BrochureNgười Chiến Sĩ ẤyNo ratings yet

- Sources of Air Pollution: Combustion, Stationary, Industrial & MobileDocument20 pagesSources of Air Pollution: Combustion, Stationary, Industrial & MobileRoda Gayle RañadaNo ratings yet

- Boiloers and Its Mountings 4Document53 pagesBoiloers and Its Mountings 4Kummitha ObulareddyNo ratings yet