Professional Documents

Culture Documents

An Experimental Investigation of Cyclic Hardening of 316 Stainless Steel and of 2024 Aluminium Alloy Under Multiaxial Loadings

Uploaded by

Pedro BernardesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Experimental Investigation of Cyclic Hardening of 316 Stainless Steel and of 2024 Aluminium Alloy Under Multiaxial Loadings

Uploaded by

Pedro BernardesCopyright:

Available Formats

Nuclear Engineering and Design 114 (1989) 345-353

North-Holland, Amsterdam

345

A N E X P E R I M E N T A L I N V E S T I G A T I O N O F C Y C L I C H A R D E N I N G O F 316 S T A I N L E S S

S T E E L A N D O F 2024 A L U M I N I U M A L L O Y U N D E R M U L T I A X I A L L O A D I N G S

A. B E N A L L A L , P. L E G A L L O a n d D. M A R Q U I S

LcdToratoire de M~canique et Technologie, E.N.S. de Cachan, C.N.R.S., Universit~ Paris 6, 61, avenue du President Wilson,

94230 Cachan, France

Received March 1988

This paper is concerned with the experimental behavior of a 316 stainless steel and a 2024 aluminium alloy at room

temperature and under complex nonproportional strainings in tension-torsion. The basic features of this behavior are

underlined and their interactions emphasized. It is observed that the response of these materials under general loading paths is

a balance between hardening and softening occurring respectively when the nonproportionality of the straining path is

increased or decreased.

6I

1. Introduction

The behavior of metallic materials under nonproportional loadings has been extensively investigated in the

last few years from the experimental as well as the

theoretical points of view. First experimental multiaxial

data have clearly shown that the constitutive models

developed owing to uniaxial or proportional experiments were not able to reproduce the metallic behavior

under more complex paths. The scope of the paper is

the understanding of the behavior of metals under

complex loadings. To this end, a 316 stainless steel and

a 2024 aluminium alloy have been chosen and tested at

room temperature under tension-torsion. In a first section, the three basic features of the multiaxial response

of these materials are described: additional hardening,

subsequent softening and cross-hardening effect. In the

last sections, it is shown via some complex tests how

these phenomena interact.

2,,: 02

\[

2. Experimental procedures

The materials chosen for this study were type 316

austenitic stainless steel and a 2024 aluminium alloy.

Thin walled tubular axial-torsional specimens (see fig.

1) were machined from bars. The heat treatment of

these bars involved for the first material, a soaking at

1050C for one hour followed by a quench in water,

and a T4 temper for the second. A MTS axial-torsion

0 0 2 9 - 5 4 9 3 / 8 9 / $ 0 3 . 5 0 Elsevier Science Publishers B.V.

L

Fig. 1. Tension-torsion tubular specimen.

346

A. Benallal et al. / Cyclic hardening of 316 stainless steel

servohydraulic testing m a c h i n e was coupled to a

M O T O R O L A 68K computer through an analogicaldigital C A M A C interface for data acquisition and signals command generation. Axial and shear strains were

measured by strain gages of rosette type (VISHAY

MMEP-08-125RA-120) bonded on the outer surface of

the gage length of the specimen. Axial and shear stresses

were obtained from the values of axial force and torque

measured by corresponding load cells taking into

account the area change of the specimen cross section.

All the tests presented in this paper were performed

at room temperature. Moreover, the equivalent total

strain rates used lie between 2 10 -4 and 3 ] 0 - 4

o.51

.5 r ~ (MPa)

[]

.600

S -1"

.600

_300

300

1 6,00

3. Basic features of nonproportional responses

q (tCPa)

In this part, the basic characteristics of the behavior

of the tested materials under nonproportional loadings

are isolated and described. Under cyclic proportional

strainings, the steady-state response is observed to be

completely defined by the so-called cyclic curve which

represents the maximal range of the Von Mises' equivalent stress 6 versus the maximal range of the equivalent plastic strain Ep. These last quantities are respectively defined by:

= ~ s

~P =

._300

-_600

[]

Fig. 2. Cyclic hardening under proportional and nonproportional loadings for the same equivalent total strain c = 0.53%.

316 stainless steel at room temperature: (a) straining paths, (b)

steady-state stress responses.

V~;/;j,

where sii denotes the stress deviator.

However, this does not hold for more complex paths

and the following phenomena are generally observed.

In this paper the contribution of the different types

of hardening (isotropic, kinematic, anisotropic) are not

distinguished. The state of cyclic hardening is charMPa

200

-200

-400

-200

0

AXIAL STRESS

200

[]

400

MPa

Fig. 3. Cyclic hardening under proportional and out-of-phase loadings for the same equivalent total strain E = 0.50% for aluminium

alloy at room temperature: (a) straining paths, (b) transient responses.

347

A. Benallal et aL / Cyclic hardening of 316 stainless steel

crM(MPa)

z

6.

600,~

~00.

'i

4e

3"

AM

MPa

Uniaxial

~reference

400+

300

o~

~

200

NonproporhonalIoadings

=e~sincot

200.

2

3

4

s

6

100

33

.zs

,5

~3

33

.66

33

45

60

~, =

~'~ sin (cot +)

.2

.4

- -

#.

uniaxial

reference

I : ~,,~'~ ~

100

0

t

0.1

I

l

l

0,2

0,3

0,4

maximum equivalent plastic strain

at the steady-state

0,5

(%)

Fig. 5. Dependence of the cyclic hardening on the strain path

shape. 2024 Al alloy.

"YB

=

~(%)

0

m

c "~

.~ N

300.

400

.6

.8

~D.

Fig. 4. Dependence of the cyclic hardening on the strain path

shape (ellipticalpath). 316 SS.

acterized by the maximum value of the equivalent stress

over a cycle.

3,1. Additional hardening

When compared to proportional loadings cyclic

hardening is higher under nonproportional loadings

(Lamba and Sidebottom [1], Kanazawa and Miller [2],

Callletand et al. [3], McDowell and Socie [4], Tanaka et

al. [5], Krempl and Lu [6], Benallal and Marquis [7]. As

a simple illustration, fig. 2 shows for 316 stainless steel

the steady-state responses for a pure cyclic tension and

out-of-phase cyclic tension-torsion tests with the same

equivalent total strain. It is clearly shown there that the

amount of cyclic hardening can be very high (600 MPa

compared to 350 MPa) and cannot be neglected in the

design of practical components especially for damage

evaluation. Fig. 3 shows on the other hand the transient

responses for the ahiminium alloy under the same types

of loadings. The additional hardening is generally dependent on the shape of the loading path as depicted in

COO

10

20

30

40

50

60

t,o

~

[]

0.5

-6

[]

Fig. 6. Subsequent softening for 316 SS: (a) swain path, (b) stress response during the tension loading.

70

80

348

A. Benallal et aL / Cycfic hardening of 316 stainless steel

MPa

~34oo

<

,7/4-3

50 cycles

circular path

~ 200

0 55 ~

' proportional

LU

,~100

_>

== 0

path

20

40

ACCUMULATED

[]

60

PLASTIC

80

STRAIN

100

( % )

Fig. 7. Subsequent softening for 2024 A! alloy: (a) strain path, (b) stress response during the circular path sequence and the

proportional path sequence.

fig. 4 for some elliptical strain paths in the case of 316

stainless steel. For a given value of the phase displacement ( ~ ) between the shear strain and the axial strain,

the higher the ratio P between the amplitudes of the

shear strata and the axial strain, the higher the hardening. For a given value of p, an increasing value of q, up

to 90 leads to an increase of the hardening. This effect

is also shown for aluminium alloy in fig. 5 through

circular and square paths, and some other cyclic strain

paths defined in the 4.3.

3. 2. Subsequent softening

The additional hardening described above is recovered whenever the nonproportionality of the loading

is decreased. Again, as a simple illustration for 316

stainless steel, fig. 6 shows the stress response in pure

tension just after the material has been subjected to an

out-of-phase circular tension-torsion strain path. It can

be seen that the stress is decreasing. This effect is again

sketched in fig. 7 for the aluminium alloy. In all the

tests carried out up to now at r o o m temperature this

softening was observed to be not complete.

3.3. Cross-hardening effect

This effect appears when after a proportional loading in a given direction, the subsequent loading is a

proportional straining but in another direction. Once

more, simple illustrations are given in fig. 8 for 316

stainless steel and in fig. 9 for the aluminium alloy.

They show the stress responses in a test composed of

two sequences: a pure tension loading followed by a

pure torsion one in the case of 316 stainless steel, and

500~

mp,j

400 ~

--

300 4-

..

cyclic

tension

~M =08 % i

cyclic

torsion

YM /'~ =08 %

g

0,8 ~o

n~rnber of cyctes

0

100

200

300

[]

Fig. 8. Illustration of the cross-hardening effect for 316 SS: (a) straining path, (b) maximum equivalent stress over a cycle versus

number of cycles.

A. Benallal et aL / Cyclic hardening o]'316 stainless steel

349

400

300

uJ

JLU

~>'>

O 200

OO

4

50 cycles

I~

proportional path (45) ' -

50 cycles

proportional path (135)

.q~) 100

20

40

60

80

ACCUMULATED PLASTIC STRAIN (%)

100

120

Fig. 9. Illustration of the cross-hardening effect for 2024 AI alloy: (a) straining path, (b) maximum equivalent stress versus number of

cycles.

in-phase tension-torsion straining followed by a sequence with a phase displacement of 180 for the

second one.

STRALNHISTORY

L~ Ti~-I~_q I, Y : Y. '~" (~'-*)

--5 " I

~_

600

4. General responses under nonproportional Ioadings

This section is devoted to an analysis of how the

three phenomena described above are combined and

interact during complex straining pathS. It can be argued

indeed that the resulting behavior of 'the material is a

balance between hardening and softening. In the following, three complex tests are presented from which many

qualitative properties of the hardening and softening

under nonproportional loadings can be exhibited.

500"

cL

400-

,,

II

i iL

i

300

q alent

tress

l,

,,,,

2'.... :.!,;81

I

--CROSSnHARDENI NG

4.1. Out-of-phase sequential test

pIastlc stra;n

The first test presented herein was carried out on 316

stainless steel. The first sequence is a pure tension

straining. The next seven are elliptical paths in total

strain space, some with constant phaselag and variable

ratios of shear strain-axial strain amplitudes, the others

with variable phaselag and constant amplitudes ratios

(see fig. 10). It can be noted that not only the amount of

hardening increases with nonproportionality but also

the rate of this hardening. The last sequences are a

return to a pure tension test displaying incomplete

softening and a pure torsion loading where it must be

pointed out that the amount of cross hardening obtained is almost the same as that shown in fig. 8

although the levels of strain and the histories of loading

are different in the two tests.

o5&-?

~ 200

E

~E

o :~

100

o0

2'oo

Number of cycles

'

400

Fig. 10. Out-of-phase sequential test for 316 SS: Evolution of

the additional hardening and its rate with p and for elliptical paths. Subsequent softening and cross-hardening effects.

350

A. Benallal et aL / Cyclic hardening of 316 stainless steel

123

:7

9 8

IJ

I

,

500

.@

/43

,

r

400,.

300.

200.

Ep

100.

_ _ _

i=3

n=4

t 130

~ I

....

5;0.

--10'00.

~5'00.

+ - . ~ P(%/

.....

20o0.

Fig. 11. 'Star' test for 316 SS: (a) typical sequence, (b) evolution of the maximum equivalent stress over a cycle with the accumulated

plastic strain. For each sequence (,~:x) means that x cycles have been completed before the ninth sequence and ( ",~:y) means that

y cycles have been carried out after the ninth sequence. [ ] denotes the number of diameters completed in one cycle in a given

sequence.

4.2. "Star' test

The second complex test, again related to 316 stainless steel and described below, consists of nine sequences. Each of the eight first sequences, (i =

1, 2 . . . . . 8) is composed of n = 2 (i-1) diameters in total

strain space, equally distributed, as explained in fig.

l l a . During the loading, these diameters are completed

in one cycle. For instance, in the case of figure l l a , a

cycle of the loading path is O A O B O C O D O E O F O G O H O . N o t e that i = 1 corresponds to a proportional loading (pure tension was considered here). FinaUy, the last sequence is a circular out-of-phase test. In

the whole test the maximum equivalent strain was kept

constant and equal to 0.5%. We can see in fig. l l b that

after many cycles under pure tension, a large amount of

hardening with a bigger rate is obtained during sequence 2.

More hardening is observed in sequence 3, although

not very important and from sequence 4 up to 8 continuous softening occurs. If it is rather easy to consider

that the smaller the angle between two successive diameters the smaller the hardening (when this angle is

small, the loading can be almost considered as propor-

tional), it must be pointed out that the m a x i m u m of

hardening is obtained for an angle of 45 o. This is surely

an important result for the definition of the nonproportionality of a loading when looking to the development

of a constitutive model. Now, when considering sequence 9 a large amount of hardening is again obtained;

this additional hardening is the same as that obtained

directly under a circular path (fig. 2) or subsequent to

another strain history as for example in fig. 10. Finally,

when returning to sequences 8, after the circular path,

continuous softening occurs.

0.51

Fig. 12. Typical strain path sequence in stairs test.

351

A. Benallal et al. / Cyclic hardening of 316 stainless steel

Ql[/~~

/,~.~0//~

Q //~.~

<

~

--

-~50 ~4_--~

p,

128

64

32

16

Number

of s t a i r s

Fig. 13. 'Stairs' test for 316 SS: (a) Evolution of the equivalent stress with the accumulated plastic strain for the whole test. Fo~ each

sequence (/~ : x) means that x cycles have been completed before the circular path and ( "~ : y) means that y cycles were carried out

after. [ ] denotes the number of steps in a given sequence; (b) comparison of the transient stress responses for the nine first

sequences. For the sake of clearness, the plot of the loops is shifted after each sequence in the o direction.

4.3. "Stairs" test

The continuity between proportional and nonproportional loadings has been studied by means of a

'stairs' test: after stabilization under proportional

straining under combined tension-torsion with a maxim u m equivalent total strain equal to 0.5%, the material

is subjected to 8 sequences of stairs joining the ends of

this radial path. The first sequence is composed of 128

steps. In the others, this number is continuously divided

by 2 so that the last one contains only one step (see fig.

12). Within a sequence, a cycle of the loading path is

obtained by climbing the stairs up to the end of the

radial path, climbing down as far as the other end. For

instance in the case of the 4-step sequence, the loading

cycle is O A B C D C B A O E F G H G F E O as explained in

352

A. Benallal et al. / Cyclic hardening of 316 stainless steel

MPa

o

<

400

300

200

_><

~J

number of steps

100

o

o

50

100

150

200

250

ACCUMULATED

PLASTIC

STRAIN

-,

300

s eps

EL

(%)

[]

Fig. 14. 'Stairs' test for 2024 A1 alloy: (a) Evolution of the maximum equivalent stress over a cycle with the accumulated plastic strain

from the proportional sequence to the one stair sequence. For each sequence the maximum equivalent strain is equal to 0.75%. (b)

Comparison of the steady state loops for the nine sequences. For sake of clearness, the plot of the loops is shifted after each sequence

in the o direction.

fig. 12. Again the maximum equivalent total strain is

kept constant throughout all the test and set equal to

0.5%.

In fig. 13a, it can be clearly seen for 316 stainless

steel that non significant hardening occurs during sequences 2 to 7, leading to the fact that the continuity

between proportional and nonproportional loadings is

well verified. Additional hardening becomes very im-

portant only at the ninth sequence. More hardening is

obtained if the loading is extended to a square path and

it is again increased when going to a circular path. At

this stage, one can notice again that the amount of

additional hardening observed for this last path is again

the same as that obtained for the same path but through

different prestrain histories (figs. 2, 6 and 10) N o w if

the loading path is reversed (that is going from the

Table 1

Classification of nonproportional tests with respect to hardening

CYCLIC

~ROPORTIONAL PROFORTIONAI

STRAIN

PATHS

128 STEPS

32 STEPS

2 STEPS

340

380

330

330

330

270

270

270

290

350

350

360

370

e, 7/~3

1 STEP

plane

2 8RANCHES

4 BRANCHES

SQUARE

CIRCLE

350

370

570

590

420

I = 61 2024 AL

HARDENING

330

320

430

AT

500

THE

STEADY

510

530

STATE

( MPa )

A. Benallal et al. / Cyclic hardening of 316 stainless steel

circular path to the radial one through the same sequences) the material is seen to be continuously softenhag. Fig. 13b sketches the transient stress response for

each of the sequences. Figs. 14a and 14b present some

of the above results for the aluminium alloy.

It can also be noticed in fig. 11 how the rates of

hardening and softening abruptly j u m p at the beginning

of sequence 8: in the hardening part when going from

sequence 7 to 8 and in the softening part when going

from sequence 9 to 8.

5. Classification of nonproportional tests

In view of the above results and the tests carried out,

the following qualitative classification given in table 1 is

suggested. The tests are classified by increasing hardening. Of course, this classification is given for the same

maximum total equivalent strain. For a fixed value of

this strain, the shape of the path and the amount of

hardening attained are given. This classification can

help provide a definition of the nonproportionality of a

loading.

353

References

[1] H.S. Lamba and J. Sidebottom, Cycle plasticity under

nonproportional loadings, J. Eng. Mat. Teeh. 100 (1978)

96-103.

[2] K. Kanazawa, K.J. Miller and M.W. Brown, Cyclic deformation of 1% Cr. Mo, V steel under out-of-phase loads,

Fat. Eng. Mat. Struct. 2 (1979) 217-228.

[3] G. Cailletaud, H. Kaczmarek and H. Policella, Some elements on multiaxial behavior of 316 stainless steel at room

temperature, Mech. Mater. 3 (1984) 333-347.

[4] D.L. Mac DoweU and D.F. Socie, Transient and stable

deformation behavior under cyclic nonproportional loadings, in: K.J. Miller and M.W. Brown, eds., Biaxial-Multiaxial Fatigue, ASTM-STP 853 (1983) 64-87.

[5] E. Tanaka, S. Murakami and M. Ooka, Effects of strain

paths shapes on nonproportional cyclic plasticity, J. Mech.

Phys. Solids 33 (1986) 559-575.

[6] E. Krempl and H. Lu, The hardening and rate dependent

behavior of fully annealed AISI type 304 stainless steel

under biaxial in-phase and out-of-phase strain cycling at

room temperature, J. Eng. Mat. Tech. 106 (1984) 376-382.

[7] A. Benallal and D. Marquis, Constitutive equations for

cyclic nonproportional elasto-viscoplasticity, J. Eng. Mat.

Tech. 101 (1987) 326-336.

You might also like

- Passive Energy Dissipation Systems - M. C. ConstantinouDocument321 pagesPassive Energy Dissipation Systems - M. C. ConstantinouEdy GalvisNo ratings yet

- Passive Energy Dissipation Systems - M. C. ConstantinouDocument321 pagesPassive Energy Dissipation Systems - M. C. ConstantinouEdy GalvisNo ratings yet

- Introduction To Structural Dynamics and Aeroelasticity PDFDocument10 pagesIntroduction To Structural Dynamics and Aeroelasticity PDFPedro BernardesNo ratings yet

- (Alan Wickens) Fundamentals of Rail Vehicle DynamicDocument299 pages(Alan Wickens) Fundamentals of Rail Vehicle DynamicEmad SatariNo ratings yet

- Trincas e Edifícios - Causas, Prevenção e Recuperação Eng. Ercio ThomazDocument173 pagesTrincas e Edifícios - Causas, Prevenção e Recuperação Eng. Ercio ThomazPedro BernardesNo ratings yet

- A K Chopra Solution Manual PDFDocument536 pagesA K Chopra Solution Manual PDFsharan3186% (73)

- Cubic Spline InterpolationDocument15 pagesCubic Spline Interpolationkjchauhan100% (2)

- ساب2000 V10Document74 pagesساب2000 V10Walif Dababat100% (8)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ashby Materials Selection ChartsDocument18 pagesAshby Materials Selection Chartspeter_prabhat0% (1)

- Calculation of Von Mises Stress at Plastic DeformationDocument4 pagesCalculation of Von Mises Stress at Plastic DeformationMaurizio FalconieriNo ratings yet

- Properties of SolidsDocument91 pagesProperties of Solidsshreyamammachen22No ratings yet

- BRB Perforated Core Zhou YDocument17 pagesBRB Perforated Core Zhou YmocanuNo ratings yet

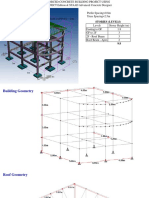

- 2 Storeys BuildingDocument30 pages2 Storeys BuildinglavyNo ratings yet

- Strength of Material CH-1 Ppt-1Document26 pagesStrength of Material CH-1 Ppt-1Nura Guyo67% (3)

- Why Are Metals Ductile and Ceramics Brittle?Document25 pagesWhy Are Metals Ductile and Ceramics Brittle?Vu VoNo ratings yet

- Batista2010 (Effective Section Method... )Document12 pagesBatista2010 (Effective Section Method... )Saul Cristian Choque LoayzaNo ratings yet

- Geotextile Encased Columns (GEC) : Load Capacity & Geotextile SelectionDocument10 pagesGeotextile Encased Columns (GEC) : Load Capacity & Geotextile SelectionGustavo Andres Mayorga RehbeinNo ratings yet

- Evaluation of The Remoulded Shear Strength of Offshore Clays and Application To Pipeline-Soil and Riser-Soil InteractionDocument45 pagesEvaluation of The Remoulded Shear Strength of Offshore Clays and Application To Pipeline-Soil and Riser-Soil Interactionmarius_onoNo ratings yet

- 10 BirthDeathDocument20 pages10 BirthDeathChetan B ArkasaliNo ratings yet

- Physics Past Paper Cape 2007-2011Document58 pagesPhysics Past Paper Cape 2007-2011Romon Deane90% (10)

- Introduction To Materials TestingDocument6 pagesIntroduction To Materials Testinggosaye desalegnNo ratings yet

- JCSR 2004 Integral Stub Dicleli AlbhaisiDocument22 pagesJCSR 2004 Integral Stub Dicleli AlbhaisipostensadosNo ratings yet

- Material Properties of HY 80 Steel After 55 Years of Operation For FEM ApplicationsDocument13 pagesMaterial Properties of HY 80 Steel After 55 Years of Operation For FEM Applicationsedvin burgaNo ratings yet

- Steel column design assessmentDocument12 pagesSteel column design assessmentĄlmost ĄwhisperNo ratings yet

- Biot Willis 1957Document8 pagesBiot Willis 1957Sohrab GheibiNo ratings yet

- Johnson - Cook Strength Models For Mild and DP 590Document6 pagesJohnson - Cook Strength Models For Mild and DP 590Yanyan2009No ratings yet

- Common Errors and Warnings in Convergence Problems PDFDocument2 pagesCommon Errors and Warnings in Convergence Problems PDFMark Nassef NaguibNo ratings yet

- Introduction of Geophysics, 1st Year PDFDocument135 pagesIntroduction of Geophysics, 1st Year PDFDr. Khan Muhammad0% (1)

- Beam 188Document28 pagesBeam 188alibaba011No ratings yet

- Types of Loading ME 311 - 4Document15 pagesTypes of Loading ME 311 - 4Nakshatra Patil 4-Year B.Tech. Mechanical EngineeringNo ratings yet

- Assessing Damaged Pipelines Transporti - 2022 - Journal of Pipeline Science andDocument7 pagesAssessing Damaged Pipelines Transporti - 2022 - Journal of Pipeline Science anddr theosNo ratings yet

- A Shortcoming in The Geometrically Non-Linear Shakedown TheoremDocument2 pagesA Shortcoming in The Geometrically Non-Linear Shakedown TheoremRui CbNo ratings yet

- Design of Plate GirderDocument85 pagesDesign of Plate Girdersamirbendre1100% (2)

- CE 581 Reinforced Concrete StructuresDocument82 pagesCE 581 Reinforced Concrete StructuresCelil OrakNo ratings yet

- Chapter 2 - Stress and Strain of Axially Loaded MembersDocument37 pagesChapter 2 - Stress and Strain of Axially Loaded MembersAbel MulugetaNo ratings yet

- 2g3 Unconfined Compressive TestDocument5 pages2g3 Unconfined Compressive TestSyukri Abd Kadir100% (1)

- Strength of Materials Equations and ConceptsDocument99 pagesStrength of Materials Equations and ConceptsVokNo ratings yet

- Concrete Filled Steel Columns for Tall BuildingsDocument20 pagesConcrete Filled Steel Columns for Tall BuildingstaosyeNo ratings yet