Professional Documents

Culture Documents

Differences between Welding Procedure Specification and Welder Performance Qualification

Uploaded by

Fazeel Rick MohammedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Differences between Welding Procedure Specification and Welder Performance Qualification

Uploaded by

Fazeel Rick MohammedCopyright:

Available Formats

Good day,

The following gives a brief definition and highlights the differences between a Welding

Procedure Specification (WPS) and a Welder Performance Qualification (WPQ). The Welding

Procedure Specification (WPS) provides direction to the welder or welding operators for making

sound and quality production welds as per the requirements of specified codes and/or standards,

in case we are utilizing BS EN ISO Standards and AWS D1.1 code for the qualification of the WPS

and WPQ. The purpose of the WPS is to guide welders to the accepted procedures so that

repeatable and trusted welding techniques are used. A WPS is developed for each material alloy

and for each welding type used. Specific codes and/or engineering societies are often the driving

force behind the development of a company's WPS. A WPS will provide in detail the required

welding variables for specific application to assure repeatability by properly trained welders.

These variables includes but not limited to:- Base Metal, Welding Process, Welding Amperage, Arc

Voltage, Travel Speed, Joint Design, Preheat Temperature, Electrodes, Thickness of material, etc.

The WPS will also give ranges of the above variables (where applicable)to use as a

guideline when making production welds for the welder or welding operator to stay within the

limits of the qualified WPS.

A WPS is supported by a Procedure Qualification Record (PQR). A PQR is a record of the

actual values taken and recorded during a test weld performed and tested mechanically by a

certified laboratory to ensure that the procedure will produce a good sound weld.

According BS EN ISO Standards the required testing specified for the WPS in question

to be qualified includes:- Visual testing, Radiographic examination, Surface crack detection

(Magnet particle testing/liquid penetrant testing), Tensile testing, Bend testing, Impact testing,

Hardness testing and Macroscopic examination.

After the WPS is qualified, Welder Performance Qualification (WPQ) will be conducted

and documented, this is to demonstrate that the welder has the necessary skill to produce a

satisfactory weld under the conditions used in production as detailed in the approved WPS.

Testing according to BS EN ISO Standards for welder qualification includes:-Visual testing,

Radiographic testing and Bend testing.

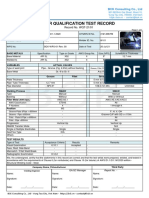

After a welder successfully completes and passes his /her welding test he/she would be

issued a Welder Performance Qualification Record (WPQR) or welders cert.

Keep in mind after a WPS is qualified it will be valid indefinitely, but the WPQR will

expire if a welder has not performed welding of the specific process for more than a 6 month

duration/period (the company need to keep record/ continuity of their welders to avoid

expiration), but he/she can be re-qualified/re-tested under the provisions of the previously

qualified WPS.

You might also like

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- 05-Welder Certification PDFDocument11 pages05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Material Test Report Welder Qualification Butt Weld PipeDocument2 pagesMaterial Test Report Welder Qualification Butt Weld PipeSyed Mahmud Habibur RahmanNo ratings yet

- WPS PQR CompressedDocument5 pagesWPS PQR CompressedBalaje MantravadiNo ratings yet

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- PIPELINE WELD NUMBERING SYSTEMDocument9 pagesPIPELINE WELD NUMBERING SYSTEMgst ajah100% (2)

- PTS-1012 - RA Hardness Test ReportDocument1 pagePTS-1012 - RA Hardness Test ReportPetrotrim ServicesNo ratings yet

- NDT L-III Specialist, RTFI Inspector, Sr. welding/NDE Engineer, SR NDT L-III Co-OrdinatorDocument12 pagesNDT L-III Specialist, RTFI Inspector, Sr. welding/NDE Engineer, SR NDT L-III Co-OrdinatorMahesh Pandit Pandit100% (2)

- 8384-2602-SQ-0720 B1 Spec Welding and NDTDocument100 pages8384-2602-SQ-0720 B1 Spec Welding and NDTHướng PhạmNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- Radiography Test Inspection Free NDT Sample Procedure 1 4Document5 pagesRadiography Test Inspection Free NDT Sample Procedure 1 4Alam MD SazidNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Welder Qualification Manual Revision 5Document20 pagesWelder Qualification Manual Revision 5Hugo RodriguezNo ratings yet

- Ultrasonic Test Procedure: Rev. Date Prepared by Reviewed ApprovedDocument8 pagesUltrasonic Test Procedure: Rev. Date Prepared by Reviewed Approvedkevin desaiNo ratings yet

- Russindo Group Vacuum Box Test ProcedureDocument5 pagesRussindo Group Vacuum Box Test ProcedureIkhsan Dalimunthe100% (2)

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- Petronas Technical Standards: Shop and Field Fabrication of Steel PipingDocument30 pagesPetronas Technical Standards: Shop and Field Fabrication of Steel PipingAli YarahmadiNo ratings yet

- Welder Qualification Test Record for NDBDocument1 pageWelder Qualification Test Record for NDBAli HammoudaNo ratings yet

- PWHT Procedure for Boiler OverhaulDocument10 pagesPWHT Procedure for Boiler OverhaulDedy Trianda100% (1)

- 10 Procedure For PWHT PDFDocument5 pages10 Procedure For PWHT PDFeghashangzadeh100% (1)

- Dolly TestDocument1 pageDolly TestmaheshNo ratings yet

- OCTGDocument1 pageOCTGMurugananthamParamasivam100% (1)

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocument76 pagesDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazNo ratings yet

- Finished Goods Packing & Dispatch ProcedureDocument2 pagesFinished Goods Packing & Dispatch ProcedurePratik KarekarNo ratings yet

- Comparison Between API-1104 21st Ed & 22nd EdDocument13 pagesComparison Between API-1104 21st Ed & 22nd EdsadashiwNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Punch Points For Piping EngineersDocument8 pagesPunch Points For Piping EngineersVignesh MohanNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- 17-05 Dimensional ControlDocument1 page17-05 Dimensional ControlRyan GillespieNo ratings yet

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- 6GR RequirementsDocument1 page6GR Requirementswalitedison100% (1)

- General Welding Procedure - Rev0Document27 pagesGeneral Welding Procedure - Rev0Jayan VKNo ratings yet

- PWHT ProcedureDocument10 pagesPWHT ProcedureSang Nguyen QuangNo ratings yet

- D-p5-Bv-pd-005 - Paut, Issue 01, Rev 00 - Phased Array TestingDocument40 pagesD-p5-Bv-pd-005 - Paut, Issue 01, Rev 00 - Phased Array TestingThinh NguyenNo ratings yet

- Itp Line PipeDocument8 pagesItp Line Pipekaml100% (1)

- Weld Repair Procedure Tapis Rev.ADocument3 pagesWeld Repair Procedure Tapis Rev.AaszlizaNo ratings yet

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Cswip IitsDocument5 pagesCswip IitsSafiq UddinNo ratings yet

- Tuv India Private Limited: Inspection Visit ReportDocument5 pagesTuv India Private Limited: Inspection Visit ReportAkhtar aliNo ratings yet

- 2011-IWE IIW Sep OKDocument1 page2011-IWE IIW Sep OKanon_837486352No ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- Magnetic Particle Examination of WeldsDocument4 pagesMagnetic Particle Examination of WeldsshruthiNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- PAUT CatalogueDocument2 pagesPAUT CataloguebenmedNo ratings yet

- APSM WPS 008R Rev. 0Document3 pagesAPSM WPS 008R Rev. 0Amir NorNo ratings yet

- WPS-GMAW-IN06 (Total)Document4 pagesWPS-GMAW-IN06 (Total)Wellington S. FrançaNo ratings yet

- WPSDocument25 pagesWPSWaqas WaqasNo ratings yet

- Hardness Testing ProcedureDocument6 pagesHardness Testing Procedurevaradaraj n sharmaNo ratings yet

- Senior Welding Inspector NDT Report ChecklistDocument4 pagesSenior Welding Inspector NDT Report ChecklistAdil HasanovNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- UT ProcedureDocument14 pagesUT ProcedureKarim ChenwiNo ratings yet

- Sample List Detail Welding MapDocument3 pagesSample List Detail Welding MapMuhammad Fitransyah Syamsuar Putra83% (6)

- Welding Procedure TablesDocument51 pagesWelding Procedure TablesEswaran0% (1)

- HRP Ii WPS STR 299aDocument4 pagesHRP Ii WPS STR 299aRohiNo ratings yet

- Radiall SMA 127-1Document60 pagesRadiall SMA 127-1sav33No ratings yet

- VXN150 Vixion Fender PDFDocument1 pageVXN150 Vixion Fender PDFHarris Jum'aniandaNo ratings yet

- Contract Welding and Inspection Plan for Pulang Pisau Power Plant ProjectDocument44 pagesContract Welding and Inspection Plan for Pulang Pisau Power Plant ProjectSamid MidmidNo ratings yet

- Laser Light Cable (LLK-B) Spare Parts CatalogDocument6 pagesLaser Light Cable (LLK-B) Spare Parts CatalogBuentello B GonzalezNo ratings yet

- Catalogo de Partes Ak 3w200 2014Document44 pagesCatalogo de Partes Ak 3w200 2014Fredy Giovanny Parra Talero100% (1)

- Amp CablesDocument2 pagesAmp CablesSimlim SqNo ratings yet

- A4-P 1.0 enDocument4 pagesA4-P 1.0 enshani5573No ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- WPS List PDFDocument2 pagesWPS List PDFNAVANEETH NAVANINo ratings yet

- Welding ReportDocument3 pagesWelding ReportJoseph KavinNo ratings yet

- A320-20 Standard PracticesDocument37 pagesA320-20 Standard Practices867189399No ratings yet

- Tex32 PDFDocument5 pagesTex32 PDFragkaraNo ratings yet

- SCC500D Hydraulic Crawler Crane PDFDocument86 pagesSCC500D Hydraulic Crawler Crane PDFMohamed Rashed100% (2)

- Ultratech Cement Particulars Test Results Requirements of - CompressDocument1 pageUltratech Cement Particulars Test Results Requirements of - CompressJerry TomNo ratings yet

- C 595 - 00 Norma ASTM Materiales Cemento / Cement ClassificationDocument7 pagesC 595 - 00 Norma ASTM Materiales Cemento / Cement ClassificationAngelNo ratings yet

- Welding Inspection ReportDocument14 pagesWelding Inspection ReportManoj KumarNo ratings yet

- Repuestos Con Movimiento IndividualDocument5 pagesRepuestos Con Movimiento IndividualFrancoNo ratings yet

- Welder IdentificationDocument9 pagesWelder Identificationdandiar1No ratings yet

- BS en 287-6-2010Document26 pagesBS en 287-6-2010CocaCodaNo ratings yet

- BROCO Standard Line Series Electrical Fittings and Accessories Price ListDocument14 pagesBROCO Standard Line Series Electrical Fittings and Accessories Price ListKiyahNo ratings yet

- D10 11M-D10 11-2007PVDocument6 pagesD10 11M-D10 11-2007PVFiroj KhanNo ratings yet

- CTS Welder (Pipe) NSQFDocument33 pagesCTS Welder (Pipe) NSQFzaki amNo ratings yet

- Loctite PDFDocument4 pagesLoctite PDFOsvaldo Cansigno PeláezNo ratings yet

- Bolt TableDocument1 pageBolt TableErebert C. CaracasNo ratings yet

- ME 131 Lec 11.0 Fundamentals of JoiningDocument23 pagesME 131 Lec 11.0 Fundamentals of JoiningRainier Gemuel TomNo ratings yet

- Module 2 - Welding and Cutting Proccess PDFDocument148 pagesModule 2 - Welding and Cutting Proccess PDFTuhoyito TarahaoNo ratings yet