Professional Documents

Culture Documents

Epigard Zinc Rich Primer PDF

Uploaded by

Karthimeena MeenaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epigard Zinc Rich Primer PDF

Uploaded by

Karthimeena MeenaCopyright:

Available Formats

DATA SHEET NO.

2006-005

EPIGARD ZINC RICH PRIMER

A two pack polyamide cured high build high performance epoxy Zinc Rich Primer with optimum

loading of zinc dust for excellent cathodic protection of blast cleaned steel structures. This primer

is compatible with a wide range of topcoats and it enhances protective property of a paint system

to a great extent. This primer is widely used where a long-term protection is required in saline and

corrosive environment.

PRODUCT INFORMATION

Colour

Grey

Finish

Matt

Flash Point

Above 20o C

Mixing Ratio

Base : Accelerator

3 : 1 (by volume)

Volume Solids

38 % approximately

Recommended

dry film

thickness

35 - 50 microns per

coat

Corresponding

wet film

thickness

92 - 132 microns

Theoretical

Spreading Rate

10.9 7.6 Sq.metre

per litre

SURFACE PREPARATION

STEEL SURFACES:

Degrease and blast clean to Sa 2 grade

minimum of Swedish specification SIS - 05 5900 - 1967. No other mode of surface

preparation is acceptable. Steel profile not to

exceed 75 microns. Surface should be

perfectly clean and dry before application of

Epigard Zinc Rich Primer.

Painting over weathered Zinc primer:

On weathering a white deposit of zinc salt may

appear on the surface. These are to be

removed by water scrubbing, sand / grit

sweeping etc. before overcoating.

APPLICATION DETAILS

Method of application:

Drying time

Touch dry - 60 minutes

Handleable 4 - 6 hours

Full cure-

7 days

Interval before

Overcoating

Minimum - 18 hours

Maximum - Indefinite

Storage life

Upto 6 months so long

as the material is stored

in sealed containers

under

standard

warehouse

storage

condition.

Dry Heat

Resistance

Upto 300o C (Intermittent)

Conventional / Airless spray

Brush for small areas only

Airless spray recommended for getting uniform

film build.

Use of mechanical stirrer is suggested for

mixing the base part and then subsequently

for mixing Base with Accelerator. Mixed paint

to be kept stirred during application to avoid

any pigment settlement and Gun clogging.

Notes on Airless Spray:

Tip Range : - 17 - 26 thou.

Total out put fluid pressure

2500 3000 psi.

(176 210 kg/sq.cm.)

Pot life:

3 - 5 hours.

Thinner

Thinner 6756

LIMITATIONS

USES

Being Zinc based the coating is not resistant

to acid and alkali solutions.

A superior Zinc Rich Primer for protection of

Refineries, Power Plants, Petro-chemical

units, Gas Plants, Fertilizer Units, pen stock,

sluice gates etc.

Pg 1

DATA SHEET NO. 2006-005

EPIGARD ZINC RICH PRIMER

SYSTEM SELECTION GUIDE

1st COAT

2nd COAT

Epigard Zinc

Rich Primer

Epigard HB MIO

Brown / Grey

Epigard 4 Finish /

Shalithane Finish /

Epithane HB Finish

Epigard 4 Finish

/ Shalithane

Finish / Epithane

HB Finish

SURFACE

Steel

3rd COAT

4th COAT

- do -

- do -

Bipigard CTE XL

Black / Bipigard

580 HB CTE

Black

Bipigard CTE XL

Black / Bipigard 580

HB CTE Black

- do -

- do -

Epigard XL HB

533 / TL HB 533

Finish

Epigard XL HB 533 /

TL HB 533 Finish

- do -

- do -

Chlorokote HB

MIO

Chlorokote Finish /

Chlorokote HB Finish

Chlorokote Finish

/ Chlorokote HB

Finish

CHEMICAL RESISTANCE GUIDE (With suitable top coat)

EXPOSURE

SPLASH &

SPILLAGE

FUMES & OUTDOOR

EXPOSURE

Acids

Good

Good

Alkalis

Good

Good

Solvents

Excellent

Excellent

Salt

Excellent

Excellent

Water

Excellent

Excellent

NOTES

1. This cancels all previous literature on this product and is subject to revision without notice

2. Do not apply when temperature falls below 10o C or rises above 50o C and when relative

humidity rises above 90%. Do not apply during rain, fog or mist.

3. Use off mixed paint within stipulated pot life period.

4. Use of thinners other than supplied or approved by Shalimar may adversely affect product

performance and void product warranty whether express or implied.

HEALTH AND SAFETY

Please refer to the separate safety data sheet available with detailed information.

PRECAUTION

For proper curing of film, ambient temperature should not be lower than 10o C.

>> DISCLAIMER <<

The information in this leaflet is given in good faith. The company will not be

liable for loss or damage howsoever caused including liability for negligence,

which may be suffered by the user of the data contained therein. It is the user's

responsibility to conduct all necessary tests to confirm the suitability of any

product or system for their intended use. No guarantee of result is extended

since conditions of use are beyond our control.

Head Office:

5th Floor, C Wing, Oberoi Garden Estate

Chandivali Farm Road, Chandivali

Andheri (E), Mumbai - 400072

Phone: 022-28574043 / 6147

Fax: 022-28573725

Email: indl@shalimarpaints.com

Nov 2006

Pg 2

You might also like

- Epigard Rich Primer - 2006-005 PDFDocument2 pagesEpigard Rich Primer - 2006-005 PDFabdulyunus_amirNo ratings yet

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDocument2 pagesDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyNo ratings yet

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDocument2 pagesDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyNo ratings yet

- 2006-008 (NXPowerLite)Document2 pages2006-008 (NXPowerLite)vijayakumar_samyNo ratings yet

- DATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / RedDocument2 pagesDATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / Redvijayakumar_samyNo ratings yet

- Berger MIO Coating Brown.253140503Document2 pagesBerger MIO Coating Brown.253140503Gaurav TripathiNo ratings yet

- Tuffkote Protective CoatingsDocument2 pagesTuffkote Protective CoatingsioginevraNo ratings yet

- Epiplus 556Document2 pagesEpiplus 556hareesh13h100% (1)

- Shop primer data sheetDocument2 pagesShop primer data sheetKarthimeena MeenaNo ratings yet

- 058 - Guard Coal Tar EpoxyDocument3 pages058 - Guard Coal Tar EpoxyhemajsuryaNo ratings yet

- Zinc Anode 304 MZ Ds 099 02Document2 pagesZinc Anode 304 MZ Ds 099 02Power PowerNo ratings yet

- 003 - Red Lead Primer PDFDocument3 pages003 - Red Lead Primer PDFMohamed RiyaazNo ratings yet

- D9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetDocument2 pagesD9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetPrashant MalveNo ratings yet

- SYNTHETIC ROZP PRIMER 12744 SPECDocument2 pagesSYNTHETIC ROZP PRIMER 12744 SPECmahotkatNo ratings yet

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 pagesAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNo ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinNo ratings yet

- 004 - Zinc Chromate PrimerDocument3 pages004 - Zinc Chromate PrimeridiotfellowNo ratings yet

- Interprime 160Document0 pagesInterprime 160Mehman NasibovNo ratings yet

- Epoxy primer protects steel and concrete surfacesDocument3 pagesEpoxy primer protects steel and concrete surfacesPRERAKNo ratings yet

- DS 164 02 ZincAnode304 MZSDocument2 pagesDS 164 02 ZincAnode304 MZSPower PowerNo ratings yet

- Shalimar Aluminium PaintDocument2 pagesShalimar Aluminium PaintDeepak Tantuway100% (1)

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- DS 122 Rev 01 Epilux 4 High Build Epoxy FinishDocument2 pagesDS 122 Rev 01 Epilux 4 High Build Epoxy FinishSuriya NaanNo ratings yet

- Guard Epoxy Red Oxide Primer PDFDocument3 pagesGuard Epoxy Red Oxide Primer PDFStathis MoumousisNo ratings yet

- Interprime 198 PDFDocument4 pagesInterprime 198 PDFandreaju2013No ratings yet

- PTI Zinc Chromate MSDSDocument3 pagesPTI Zinc Chromate MSDSSkySupplyUSANo ratings yet

- Interzinc 52: Epoxy Zinc-RichDocument4 pagesInterzinc 52: Epoxy Zinc-RichKrishna VachaNo ratings yet

- Rust O Cap PDFDocument1 pageRust O Cap PDFBharat Tailor100% (2)

- Interzinc 52Document4 pagesInterzinc 52mirzaaliNo ratings yet

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- Resist GTI - English (Uk) - Issued.06.12.2007Document4 pagesResist GTI - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Technical Data:: Oasis Epoxy ST 8800alDocument2 pagesTechnical Data:: Oasis Epoxy ST 8800alMaurice DavisNo ratings yet

- Epoxy Zinc Phosphate Primer 8600Document2 pagesEpoxy Zinc Phosphate Primer 8600Maurice DavisNo ratings yet

- 0091 Amercoat 91 PDS May 08Document2 pages0091 Amercoat 91 PDS May 08donaldoguerreroNo ratings yet

- Xylar Data SheetDocument3 pagesXylar Data Sheetsarath6725No ratings yet

- Lux A Prime 1501Document2 pagesLux A Prime 1501paulloh64100% (1)

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Polyurethane Topcoat: Product Description Technical DataDocument2 pagesPolyurethane Topcoat: Product Description Technical DataRoohian AliNo ratings yet

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyDocument3 pagesTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- Cloverdale EcosheetDocument2 pagesCloverdale EcosheetJennyNo ratings yet

- Resist 78 Technical Data SheetDocument4 pagesResist 78 Technical Data SheetPaulSwinbankNo ratings yet

- TDS - Resist 86Document4 pagesTDS - Resist 86EricNo ratings yet

- Jotazinc PDFDocument4 pagesJotazinc PDFAnonymous YtgIj2A9nWNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Protective Coating-3Document0 pagesProtective Coating-3Sivaratnam NavatharanNo ratings yet

- (Painting) Jotamastic 87Document5 pages(Painting) Jotamastic 87Mohd FadliNo ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- PDS - EP-10 Etch PrimerDocument2 pagesPDS - EP-10 Etch Primercarlogeretto2No ratings yet

- Primastic UniversalDocument5 pagesPrimastic UniversalaleventNo ratings yet

- PC 7048 - Asian Epoxy Dual CoatDocument3 pagesPC 7048 - Asian Epoxy Dual CoatGunjan GaganNo ratings yet

- Apcoguard SF 725Document3 pagesApcoguard SF 725kiran vargheseNo ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Intergard 251 Tech Data SheetDocument0 pagesIntergard 251 Tech Data SheetL Mahender ReddyNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- (P0) R C Columns-Rectangular-Biaxial Bending-Section design-IS456Document25 pages(P0) R C Columns-Rectangular-Biaxial Bending-Section design-IS456KhanthavelNo ratings yet

- RCC52 Column Chart GenerationDocument6 pagesRCC52 Column Chart GenerationKarthimeena MeenaNo ratings yet

- First Col DSN Fina RCC-Biaxial-BendingDocument7 pagesFirst Col DSN Fina RCC-Biaxial-BendingmukhleshNo ratings yet

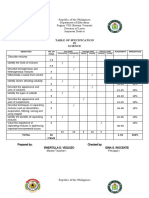

- Worksheet in Roof Structure - Up4Document8 pagesWorksheet in Roof Structure - Up4Karthimeena MeenaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Agitator DesignDocument130 pagesAgitator DesignAdrales Kristine75% (4)

- Model 20 HT and GT AgitatorsDocument12 pagesModel 20 HT and GT AgitatorsKarthimeena MeenaNo ratings yet

- Bottom and Shell Bom - Up12Document27 pagesBottom and Shell Bom - Up12Karthimeena MeenaNo ratings yet

- Acoples Rigidos LIGHTNINDocument48 pagesAcoples Rigidos LIGHTNINDIEGO SANCHEZNo ratings yet

- Agitators GBDocument2 pagesAgitators GBKarthimeena MeenaNo ratings yet

- WIND GIRDER-Bill of Material: ProfileDocument3 pagesWIND GIRDER-Bill of Material: ProfileKarthimeena MeenaNo ratings yet

- Preventing Dust FormationDocument12 pagesPreventing Dust FormationKarthimeena MeenaNo ratings yet

- Performance LogDocument1 pagePerformance LogsstuparusNo ratings yet

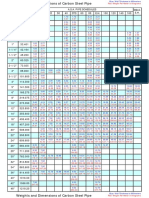

- Seamless Pipe - SCHDocument1 pageSeamless Pipe - SCHKarthimeena MeenaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

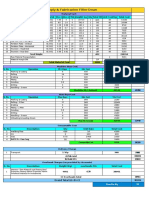

- Manpower Rate Calcutn 1Document2 pagesManpower Rate Calcutn 1Karthimeena MeenaNo ratings yet

- Shed For Rock Unloading & Screening Area - Greenstar: STD Weig HT Unit Weight Sub Qty Sub WeightDocument13 pagesShed For Rock Unloading & Screening Area - Greenstar: STD Weig HT Unit Weight Sub Qty Sub WeightKarthimeena MeenaNo ratings yet

- Metric Dimensions and Weights of Seamless and Welded Steel Pipe PDFDocument1 pageMetric Dimensions and Weights of Seamless and Welded Steel Pipe PDFAnonymous xcFcOgMiNo ratings yet

- EPF Form No 10 CDocument4 pagesEPF Form No 10 Capi-370495692% (13)

- HR AluminiumDocument1 pageHR AluminiumKarthimeena MeenaNo ratings yet

- BOX TANK-Static 1-1Document7 pagesBOX TANK-Static 1-1Karthimeena MeenaNo ratings yet

- Foundation BoltDocument2 pagesFoundation BoltKarthimeena MeenaNo ratings yet

- Thiraviam Engineering PVT Limited: Approval For Work EstimateDocument2 pagesThiraviam Engineering PVT Limited: Approval For Work EstimateKarthimeena MeenaNo ratings yet

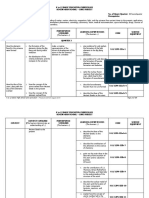

- Construction of ESP - Rev1ADocument23 pagesConstruction of ESP - Rev1AKarthimeena MeenaNo ratings yet

- Material ProcurmentDocument1 pageMaterial ProcurmentKarthimeena MeenaNo ratings yet

- Drum FilterDocument1 pageDrum FilterKarthimeena MeenaNo ratings yet

- SS Conical Tank - HWPDocument1 pageSS Conical Tank - HWPKarthimeena MeenaNo ratings yet

- Abi Feed Water Inlet Nozzle No:1 Material CostDocument1 pageAbi Feed Water Inlet Nozzle No:1 Material CostKarthimeena MeenaNo ratings yet

- Incentive Scheme Eligible Amount Against Fabrication: in RsDocument1 pageIncentive Scheme Eligible Amount Against Fabrication: in RsKarthimeena MeenaNo ratings yet

- Bavai 06.01.17 Modal - 2Document37 pagesBavai 06.01.17 Modal - 2Karthimeena MeenaNo ratings yet

- Book of Abtracts Erem 6thDocument203 pagesBook of Abtracts Erem 6thSaiful Azhar Ahmad TajudinNo ratings yet

- Sediments and ErosionDocument17 pagesSediments and ErosionRavi UraiyaNo ratings yet

- 2 Agrostudies Temperature ManagementDocument62 pages2 Agrostudies Temperature ManagementYolaina EdwarNo ratings yet

- Raw Mix Design by Rashid Jamal (16.02.2017)Document20 pagesRaw Mix Design by Rashid Jamal (16.02.2017)Muhammad AwaisNo ratings yet

- Cold AsphaltDocument440 pagesCold AsphaltDem Hasi100% (1)

- Astm F 480Document26 pagesAstm F 480ViswanathNo ratings yet

- Periodical Test in SCIENCE Melc BasedDocument6 pagesPeriodical Test in SCIENCE Melc Basedaiko idioNo ratings yet

- HGS - Donaldson DFF 2015Document37 pagesHGS - Donaldson DFF 2015Abass BILANo ratings yet

- AP Biology Pea Germination LabDocument3 pagesAP Biology Pea Germination Labg2gusc38No ratings yet

- Quantification of Phase Transformation Kinetics of 18 WT.% Ni C250 Maraging SteelDocument11 pagesQuantification of Phase Transformation Kinetics of 18 WT.% Ni C250 Maraging SteelNelson AlvarezNo ratings yet

- BFAR-NIFTDC: Fisheries Research and Training CenterDocument25 pagesBFAR-NIFTDC: Fisheries Research and Training CenterRocel MislangNo ratings yet

- Getinge 46-Series Washer Disinfector: Configuration SheetDocument10 pagesGetinge 46-Series Washer Disinfector: Configuration SheetDany RobinNo ratings yet

- Oeko-Tex Standard 100 CertificatesDocument61 pagesOeko-Tex Standard 100 CertificatesKee SarakarnkosolNo ratings yet

- MSDS IzonilDocument2 pagesMSDS Izonilabdul azizNo ratings yet

- Design and Performance Evaluation of A Screw Press Separator For Separating Dairy Cattle ManureDocument10 pagesDesign and Performance Evaluation of A Screw Press Separator For Separating Dairy Cattle ManureDaniel SouzaNo ratings yet

- Shotcrete Training and CertificationDocument35 pagesShotcrete Training and Certificationdnavarrete01No ratings yet

- CHMG 131 - Course Outline Spring 2017 PDFDocument2 pagesCHMG 131 - Course Outline Spring 2017 PDFFuad EsberNo ratings yet

- Amphiprotic vs Amphoteric: Understanding the Difference Between These Acid-Base TermsDocument1 pageAmphiprotic vs Amphoteric: Understanding the Difference Between These Acid-Base TermsbabeNo ratings yet

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDocument1 pageASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaNo ratings yet

- (CG) SHS Core - Physical Science PDFDocument17 pages(CG) SHS Core - Physical Science PDFFeinrir0% (1)

- En-10079 Definition of Steel ProductsDocument44 pagesEn-10079 Definition of Steel ProductshugocoimbraNo ratings yet

- Distillation Column DesignDocument17 pagesDistillation Column DesignMazan ShaviNo ratings yet

- Questions for Removal Exam Gas Laws and StoichiometryDocument3 pagesQuestions for Removal Exam Gas Laws and StoichiometryJoniele Angelo AninNo ratings yet

- 6 - Review - Avances en Tipos de Hidrogeles y Remoción de ColorantesDocument27 pages6 - Review - Avances en Tipos de Hidrogeles y Remoción de ColorantesAlejandro PérezNo ratings yet

- Bessemer Converter Furnace Refractory ProcessDocument4 pagesBessemer Converter Furnace Refractory ProcessHariman El EmirNo ratings yet

- Foreign MatterDocument6 pagesForeign MatterAnonymous XuiUo2ThNo ratings yet

- Site Lab Checklist1Document4 pagesSite Lab Checklist1layaljamal2No ratings yet

- CHEM 1020 Gen Chem II Michael SwansonDocument5 pagesCHEM 1020 Gen Chem II Michael SwansonJether MarañonNo ratings yet

- Chapter 6 KineticDocument11 pagesChapter 6 KineticPHƯƠNG ĐẶNG YẾNNo ratings yet