Professional Documents

Culture Documents

Mech Design

Uploaded by

zbhdzpCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mech Design

Uploaded by

zbhdzpCopyright:

Available Formats

THEUNIVERSITYOFTECHNOLOGYINLODZ

BASICMECHANICAL

DESIGN

[StandardExtractsAndOtherMaterials]

Zbigniew Zdziennicki

[2008]

[The booklet contains useful materials for Mechanical Engineering Design and

Workshop subject for students of International Faculty of Engineering]

CONTENTS

Part I

STANDARD EXTRACTS

Metric trapezoidal threads..

Recommended tolerance for trapezoidal thread...

Lip seals.

Shaft lifts of gear reducers...

Recommended diameters for journals of shaft ends.

Recommended gear ratios

Surface quality according PN-EN ISO 1302:2004.

Retaining rings..........................................................................................

Hexagon headed bolts..

Square-head machine bolts.

Socket head bolts..

Stud bolts...

Standard hex nuts.

Hex jam nuts.

Spring lock washers.

Parallel keys.............................................................................................

Shoulders with relief groove

34

5

6

7

8

9

9

10 11

12 13

14

15

16

17

18

19

20

21

Part II

OTHER MATERIALS

Preferred metric sizes...

Recommended fit systems and diameter series......

Installation of components on drive shafts

Mounting arrangements of a pulley or a sprocket.

Chamfers

Cap of a screw jack main dimensions..................................................

Alternative designs of the cap..................................................................

Ball knobs with collar...

Centre holes with thread..

Drain plug..................................................................................................

Breathers....................................................................................................

Guide date for dimensions of gear cases.

Caps for bearing housings...

Distance rings and sleeve for shafts

Distance rings and sleeve for housings

Youngs moduli for various metals.

Poissons ratios for various metals.

Recommended journals of shaft ends cylindrical ones..

Dimensions of keyseats.

Relation of hardness numbers.

Recommended number of pinion teeth according to Niemann

Spur gear design formulas...

Length Excesses Recommended for Threads........................................

Casting Rib Design...................................................................................

22

23

24

25

25

26

26

27

27

28

28

29

30

31

32

33

33

34

35

36

37

37

38

39

METRIC TRAPEZOIDAL THREADS

PN ISO 2904: 1996

Thread Size

Diameter

mm

1

8

9

10

11

12

14

16

18

20

22

24

26

28

30

32

Pitch

mm

2

1.5

1.5

2

1.5

2

2

3

2

3

2

3

2

4

2

4

2

4

3

5

8

3

5

8

3

5

8

3

5

8

3

6

10

3

6

10

Major Dia of

Nut, Dr

mm

3

8.30

9.30

9.50

10.30

10.50

11.50

11.50

12.50

12.50

14.50

14.50

16.50

16.50

18.50

18.50

20.50

20.50

22.50

22.50

23.00

24.50

24.50

25.00

26.50

26.50

27.00

28.50

28.50

29.00

30.50

31.00

31.00

32.50

33.00

33.00

Major Dia of

Screw, d

mm

4

8.00

9.00

9.00

10.00

10.00

11.00

11.00

12.00

12.00

14.00

14.00

16.00

16.00

18.00

18.00

20.00

20.00

22.00

22.00

22.00

24.00

24.00

24.00

26.00

26.00

26.00

28.00

28.00

28.00

30.00

30.00

30.00

32.00

32.00

32.00

Pitch Dia of

Thread, Dp=dp

mm

5

7.25

8.25

8.00

9.25

9.00

10.00

9.50

11.00

10.50

13.00

12.50

15.00

14.00

17.00

16.00

19.00

18.00

20.50

19.50

18.00

22.50

21.50

20.00

24.50

23.50

22.00

26.50

25.50

24.00

28.50

27.00

25.00

30,50

29.00

27.00

Minor Dia of

Nut, D

mm

6

6.50

7.50

7.00

8.50

8.00

9.00

8.00

10.00

9.00

12.00

11.00

14.00

12.00

16.00

14.00

18.00

16.00

19.00

17.00

14.00

21.00

19.00

16.00

23.00

21.00

18.00

25.00

23.00

20.00

27.00

24.00

20.00

29.00

26.00

22.00

Minor Dia of

Screw, dr

mm

7

6.20

7.20

6.50

8.20

7.50

8.50

7.50

9.50

8.50

11.50

10.50

13.50

11.50

15.50

13.50

17.50

15.50

18.50

16.50

13.00

20.50

18.50

15.00

22.50

20.50

17.00

24.50

22.50

19.00

26.50

23.00

19.00

28.50

25.00

21.00

METRIC TRAPEZOIDAL THREADS cont.

PN ISO 2904: 1996

Thread Size

Diameter

mm

1

34

36

38

40

42

44

46

48

50

52

55

60

Pitch

mm

2

3

6

10

3

6

10

3

7

10

3

7

10

3

7

10

3

7

12

3

8

12

3

8

12

3

8

12

3

8

12

3

9

14

3

9

14

Major Dia of

Nut, Dr

mm

3

34.50

35.00

35.00

36.50

37.00

37.00

38.50

39.00

39.00

40.50

41.00

41.00

42.50

43.00

43.00

44.50

45.00

45.00

46.50

47.00

47.00

48.50

49.00

49.00

52.50

51.00

51.00

52.50

53.00

53.00

55.50

56.00

57.00

60.50

61.00

62.00

Major Dia of

Screw, d

mm

4

34.00

34.00

34.00

36.00

36.00

36.00

38.00

38.00

38.00

40.00

40.00

40.00

42.00

42.00

42.00

44.00

44.00

44.00

46.00

46.00

46.00

48.00

48.00

48.00

50.00

50.00

50.00

52.00

52.00

52.00

55.00

55.00

55.00

60.00

60.00

60.00

Pitch Dia of

Thread, Dp=dp

mm

5

32.50

31.00

29.00

34.50

33.00

31.00

36.50

34.50

33.00

38.50

36.50

35.00

40.50

38.50

37.00

42.50

40.50

38.00

44.50

42.00

40.00

46.50

44.00

42.00

48.50

46.00

44.00

50.50

48.00

46.00

53.50

50.50

48.00

58.50

55.50

53.00

Minor Dia of

Nut, D

mm

6

31.00

28.00

24.00

33.00

30.00

26.00

35.00

31.00

28.00

37.00

33.00

30.00

39.00

35.00

32.00

41.00

37.00

32.00

43.00

38.00

34.00

45.00

40.00

36.00

47.00

42.00

38.00

49.00

44.00

40.00

52.00

46.00

41.00

57.00

51.00

46.00

Minor Dia of

Screw, dr

mm

7

30.50

27.00

23.00

32.50

29.00

25.00

34.50

30.00

27.00

36.50

32.00

29.00

38.50

34.00

31.00

40.50

36.00

31.00

42.50

37.00

33.00

44.50

39.00

35.00

46.50

41.00

37.00

48.50

43.00

39.00

51.50

45.00

39.00

56.50

50.00

44.00

RECOMMENDED TOLERANCE FOR TRAPEZOIDAL

THREAD

(in accordance with PN-ISO 2903/Ak)

Internal thread

Class of thread

External thread

Length of engagement

N

Fields of thread tolerance

Fine

6H

7H

6e

6g

7e

Middle

7H

8H

7e

7g

8e

Coarse

8H

9H

8c

8e

9c

Note: Preferred fits are in the bolded frames.

N normal (like for nut)

L large.

LIP SEALS

PN-72/M-86964

Designation of a radial oil seal that is A kind and possesses: inside diameter (diameter of the

shaft) d = 30 mm, outside diameter D = 50 mm, height b = 10 mm:

LIP SEAL A 30x50x10 PN-72/M-86964

D

d

20

25

30

35

40

45

50

55

60

70

80

90

100

35

40

(47)

50

(52)

55

(62)

65

70

72

75

80

85

90

10

10

10

10

10

100

110

10

10

12

10

12

120

b

7

7

10

7

7

10

10

7

10

10

7

10

10

10

7

10

10

7

10

10

10

10

10

8

10

8

10

10

10

10

10

8

10

10

10

If the main purpose of the seal is to prevent lubricant from leaving the housing, the seal

should be fitted with the lip facing inwards (see figure below).

12

12

SHAFT LIFTS OF GEAR REDUCERS

PN-79/M-88507

1st Choice

[mm]

2nd Choice

[mm]

Deviation

[mm]

63

71

80

90

100

112

0.5

125

140

160

180

200

220

250

280

315

-1.0

355

Note: 3rd choice is omitted

RECOMMENDED DIAMETERS FOR JOURNALS OF SHAFT

ENDS IN GEAR REDUCERS

PN-M-85000: 1998

Table 1. Diameters and max torques for journals of high speed shaft ends

d

[mm]

10

12

14

16

18

20

22

25

28

Tin

[Nm]

8.0

16.0

22.4

31.5

45.0

63.0

90.0

125.0

180.0

d

[mm]

30

32

35

38

40

42

45

50

55

Tin

[Nm]

200

350

355

400

500

560

710

1000

1400

d

[mm]

60

65

70

75

80

85

90

100

110

Tin

[Nm]

1600

2240

2800

3150

4000

4500

5600

8000

11200

d

[mm]

125

130

140

150

160

180

200

Tin

[Nm]

16000

18000

22400

25000

31500

45000

63000

Note: Max transverse force loading the journal in its middle should not exceed

250 Tin [N]

Table 2. Diameters and max torques for journals of slow speed shaft ends

d

[mm]

18

20

22

25

28

30

32

Tout

[Nm]

31.5

45

63

90

125

140

180

d

[mm]

35

40

45

48

50

55

60

Tout

[Nm]

2350

355

500

560

710

1000

1120

d

[mm]

70

75

80

90

100

110

125

Tout

[Nm]

2000

2240

2800

4000

5600

8000

11200

d

[mm]

140

160

180

200

220

250

280

Note: Max transverse force loading the journal in its middle should not exceed:

1. 125 Tin

[N] for one-stage gear reducers, and

2. 250 Tin [N] for multi-stages gear reducers.

Tout

[Nm]

15000

22400

31500

45000

63000

90000

125000

RECOMMENDED GEAR RATIOS

PN 76/ M-88513

1st choice

2nd choice

1st choice

2nd choice

1st choice

2nd choice

2.5

6.3

1.12

2.8

7.1

1.25

3.15

1.4

3.55

1.6

10

1.8

4.5

11.2

12.5

2.24

5.6

14

SURFACE QUALITY ACCORDING PN EN ISO 1302: 2004

Class

Procedure

N1

Ra

0.025

Roughness []

Rz

0.3

N2

0.05

0.6

N3

0.1

1.1

Lapped/Polished

N4

0.2

1.8

1.6

Lapped/Polished

N5

0.4

2.8

2.5

Honed

N6

0.8

4.8

2.5

Ground

N7

1.6

Turned with diamond

N8

3.2

16

Milled

N9

6.3

32

Turned

N10

12.5

57

16

N11

25.0

110

16

N12

50.0

220

25

Rt

0.6

Sawed

10

RETAINING RINGS

PN-81/M-85111

d

17

18

20

22

24

25

26

28

30

32

35

36

38

40

42

45

48

50

55

56

60

63

65

70

72

75

D0

15.7

16.5

18.5

20.5

22.2

22.2+0.21

24.2-0.42

25.9

27.9

29.6

32.2+0.25

33.2+0.50

35.2

36.5

38.5+0.39

41.5-0.78

44.5

45.8

50.8

51.8

55.8+0.46

58.8-0.92

60.8

65.5

67.5

70.5

D1

16.2

17.0

19.0

21.0

22.9

23.9

24.9

26.6

28.6

30.3

33.0

34.0

36.0

37.5

39.5

42.5

45.5

47

52

53

57

60

62

67

69

72

b

2.3

2.4

2.6

2.8

3.0

3.0

3.1

3.2

3.5

3.6

3.9

4.0

4.2

4.4

4.5

4.7

5.0

5.1

5.4

5.5

5.8

6.2

6.3

6.6

6.8

7.0

S = Max axial force loading the retaining ring

g

1.0

f

1.1

h

1.2

1.5

1.2

1.3

1.7

1.5

1.6

2.1

2.6

3.0

1.75

1.85

3.8

2.0

2.15

4.5

2.5

2.65

S[kN]

5.1

6.7

7.5

8.3

9.9

10.5

10.8

14.7

15.9

20.6

26.2

27.1

28.5

37.3

39.2

42.1

45.1

55.9

61.7

62.7

67.6

68.8

73.5

78.9

81.3

84.3

11

RETAINING RINGS Cont.

PN-81/M-85111

d

37

38

40

42

45

47

48

50

55

56

60

62

63

65

70

75

80

85

88

90

100

105

110

120

130

140

D0

39.8+0.50

40.8-0.25

43.5+0.78

45.5-0.39

48.5

50.5

51.5

54.2

59.2

60.2+0.92

64.2-0.46

66.2

67.2

69.2

74.5

79.5

85.5

90.5

93.5+1.08

95.5-0.54

105.5

112

117

127

137+1.26

147-0.63

D1

39.0

40.0

42.5

44.5

47.5

49.5

50.5

53

58

59

63

65

66

68

73

78

83.5

88.5

91.5

93.5

104

109

114

124

134

144

b

3.6

3.7

3.9

4.1

4.3

4.4

4.5

4.6

5.0

5.1

5.4

5.5

5.6

5.8

6.2

6.6

7.0

7.2

7.4

7.6

8.4

8.7

9.0

9.7

10.2

10.7

S = Max axial force loading the retaining ring

1.5

1.6

3.0

1.75

1.85

3.8

2.0

2.15

4.5

2.5

2.65

3.0

3.15

4.0

4.15

5.3

6.0

S[kN]

26.6

27.6

39.7

41.7

42.2

42.7

42.9

59.5

62.2

59.5

60.9

60.5

60.4

76.6

82.5

88.2

109.8

116.6

120.5

123.5

137.2

164.6

172.5

188.2

102.9

118.5

12

HEXAGON HEADED BOLTS

PN-EN ISO 4014: 2004

This is only part of the tabulation in the Standard.

13

HEXAGON HEADED BOLTS

PN-EN ISO 4017: 2004

This is only part of the tabulation in the Standard.

14

SQUARE-HEAD MACHINE BOLTS

PN-86/K-80005

This is only part of the tabulation in the Standard.

15

SOCKET HEAD BOLTS

PN-EN ISO 4762: 2001

This is only part of the tabulation in the Standard.

16

STUD BOLTS

PN-ISO 888: 1996

This is only part of the tabulation in the Standard.

17

STANDARD HEX NUTS

PN-EN ISO 4032: 2004

This is only part of the tabulation in the Standard.

18

HEX JAM NUTS

PN-EN ISO 4035: 2004

This is only part of the tabulation in the Standard.

19

SPRING LOCK WASHERS

PN-77/M- 82008

This is only part of the tabulation in the Standard.

20

PARALLEL KEYS

PN-70/M- 86005

21

SHOUDERS WITH RELIEF GROOVE

PN-58/M- 02043

Dimensions of Relief Grooves

Diameter

Type of the Groove

d [mm]

from

to

A&B

b

b1

C&D

c

R1

10

10

18

18

30

30

80

0.3

3.3

1.5

0.6

80

----

0.4

2.3

0.2

1.5

0.4

0.1

a1

--1

b2

b3

---

---

---

0.2

1.6

1.4

2.5

2.2

3.7

3.4

0.1

1.6

0.3

2.5

22

PREFERED METRIC SIZES

The preferred numbering system has played a major role in the development of metric

standards. This is a geometrical series of numbers adopted worldwide. Its first known

application was in the 1870s by Charles Renard, a French army captain who reduced the

different diameters of rope for military balloons from 425 to 17. The R5, R10 and R20 series

refers to the Renard 5 (first choice sizes 60 % increments), Renard 10 (second choice sizes 25

% increments) and Renard 20 (third choice sizes 12 % increments) series of preferred

numbers standardized in ISO 3.

Nominal metric sizes are identical where the metric system has been in use for several years.

Here is how the preferred metric nominal sizes were developed and how these chosen sizes

reflect preferred metric standard sizes for threaded fasteners, steel plates, sheets, bars, etc

already in use throughout the world.

The presentation of preferred sizes gives designers and users a logical selection and the

benefits of rational variety reduction. The second-choice size given should only be used when

it is not possible to use the first choice, and the third choice should be applied only if a size

from the second choice cannot be selected. With this procedure, common usage will tend to

be concentrated on a limited range of sizes, and a contribution is thus made to variety

reduction. However, the decision to use a particular size cannot be taken on the basis that one

is first choice and the other not. Account must be taken of the effect on the design, the

availability of tools, and other relevant factors.

23

RECOMMENDED FIT SYSTEMS & DIAMETER SERIES

1. TOLERANCES IN ACCORDANCE WITH PN-EN 20286-2:1996 STANDARD

Fits of hole basis system

H11/d11

H7/f7, H8/f9

H8/h8

H8/js7

H7/k6

H7/n6

H7/p6

H7/s7

Clearance

Transition

Close

Easy running fit

Running fit

Slide fit

Push fit

Light keying fit

Heavy keying fit

Very light drive fit

Drive fit

Fits of shaft basis system

D11/h11

F9/h8

U8/h7

Z8/h7

Clearance

Close

Easy running fit

Running fit

Very heavy drive fit 1

Very heavy drive fit 5

2. FIT SYSTEM FOR ROLLING BEARING

H7/js6

H7/k6

K7/h6

N7/h6

H8/h8

For rotational shaft

For rotational housing

With adapter sleeve

Notice: The fit systems do not concern keys, taper keys, pins.

Fits:

U8/h7

Steel on steel (cool)

Z8/h7

Cast iron on steel (cool)

Z8/h7

Steel on steel (hot)

3. DIAMETERS

Hub diameters of gears, sprockets, pulleys in accordance with their bores,

approximately:

Bore

Hub

Bore

Hub

10

20

80

120

(12)

(25)

90

130

(15)

(30)

100

150

(18)

(36)

20

36

(22)

(40)

25

45

30

55

35

60

40

70

45

75

50

80

60

100

65

105

Diameters of shafts, journals & pins

6, 8, 10, 12, (14), (15), 16, (17), (18), 20, (22), 25, (28), 30, (32), 35, 40, 50, 55, 60, 65, 70, 75, 80,

(85), 90, (95), 100, (105), 110, (115), 120, 125.

3.3. Bores

6, 8, 10, 12, (14), (15), 16, (18), 20, (22), 25, (28), 30, 32, 35, (38) 40, 42, (45), 47 50, (52), 55,

60, (65), (68) (70), (72), 75, 80, (85), 90, (95), 100, (105), 110, (115), 120, (125), 130, 140, 150,

(160), (180), (190), (195), 200, (210), 220, (230).

( ) not recommended

24

INSTALLATION OF COMPONENTS ON DRIVE SHAFTS

Hammering on the shafts can cause brinelling of the reducer bearings shortening the bearing

life. So reducer products should be supplied with a tapped hole on the output shaft of the

reducer as an aid when installing couplings and sprockets (see figure below).

The following table shows the shaft diameter range and the available thread size.

Shaft Diameter [mm]

Over 16 up to 21

Over 21 up to 24

Over 24 up to 30

Over 30 up to 38

Over 38 up to 50

Over 50 up to 85

Over 85 up to 130

Over 130

Thread Size

M6

M8

M10

M12

M16

M20

M24

M30

Thread Depth [mm]

16.0

19.0

22.0

28.0

36.0

42.0

50.0

63.0

Figure below shows an example of a mounting jig for mounting couplings or hubs onto a

reducer output shaft.

In some cases, the thrust bearing at the mounting jig is required.

25

MOUNTING ARRANGMENT OF A PULLEY OR SPROCKET

Figure below shows the correct mounting arrangements of a pulley or chain sprocket to avoid

excessive overhung loads.

Correct mounting arrangement d of a pulley or chain wheel to avoid inadmissibly high

overhung loads

For easier installation use a lubricant (applied to the bore of the hub) or preheat the

component to approximately 80C.

CHAMFERS

d

[mm]

over

--16

20

30

40

50

d

[mm]

c [mm]

to

16

20

30

40

50

60

1

1

1.5

2

2

3

from

60

80

100

120

150

200

c [mm]

to

80

100

120

150

200

250

3

3

4

4

4

5

26

CAP OF A SCREW JACK MAIN DIMENSIONS

ALTERNATIVE DESIGNS OF THE JACK CAP

27

BALL KNOBS WITH COLLAR

d H8

d1

d2 *)

Cylindrical Pin

according to

PN-89/M-85021

16

12

10

18

1.9

2.5

2h8 x 10

25

10

18

14

28

2.9

3h8 x 16

32

12

22

18

35

2.9

3h8 x 20

*) Bores d2 should be bored during assembly

CENTRE HOLES WITH THREAD

(Non-standard ones)

d1

d2

l1

I2

I3

l4

Shaft

min

min

Dia.

M8

8.4

3.6

19

25

20

M10

10.5

4.7

7.5

22

30

30,35

M12

13

9.5

28

37.5

40

M16

17

12

36

45

50,60

28

DRAIN PLUG

BREATHERS

Alternative design A

Alternative design B

29

GUIDE DATE FOR DIMENSIONS OF GEAR CASES

Component

Wall thickness

Designation

Note

for bottom box

g = 24 0.1T2 6 mm

T2 [Nm] torque of

for top box

g1 = 0.9 g 6 mm

thickness (at foot)

e = (0.8K1.0 ) g

output shaft

e1 = (0.8K1.0 ) g1

Reinforcement &

cooling webs

height

h 5g

h1 5g1

Bolt diameters

casting slope

20

for foundation

d1 = 3 4 T2 10 mm

for bearings

d 2 = 0.8 d1 8 mm

d 3 = (0.7 K0.8)d 2

for flange

thickness

Flange

s = 1 .5 d 2

s1 = 1.3 d 2

width

k1 = 3d 2

thickness

s2 = 1.5 d1

Foundation feet

width

k2 = 4 d1

a = k2 + g

wheel wall

Distances

wheel bottom

wheel - wheel

L 0.6 g

L1 2.5 g

L3 0.4 g

T2 [Nm] torque of

output shaft

30

CAPS FOR BEARING HOUSINGS

(Blind and for lip seal ones)

D1

h11, d11

0.1

47

50

60

(72)

80

(85)

90

100

110

120

125

140

160

180

58

63

73

83

91

96

101

111

121

133

138

153

175

195

D2

D3

d3

-0.1

72

78

88

98

106

111

116

126

136

153

158

173

197

217

45

50

58

70

78

82

87

97

106

116

120

136

153

173

6.6

d1

min

H8

13

15

4

4

6

17

20

7

5

11

22

35

40

40

55

65

72

75

85

90

100

110

110

120

31

DISTANCE RINGS AND SLEEVES

FOR SHAFTS

Ring l d

Dimensions non-applied

t1 = 0.04

Sleeve

35 40

45

50

t1 = 0.06

t1 = 0.03

30

t1 = 0.06

t1 = 0.03

25

t1 = 0.06

t1 = 0.03

20

t1 = 0.05

16

t1 = 0.05

14

t1 = 0.05

12

t1 = 0.04

10

t1 = 0.025

t1 = 0.025

0.04

0.04

0.05

0.05

0.05

0.06

0.06

0.06

0.06

0.08

0.08

0.08

0.08

0.08

Ring

6

7

8

t1 = 0.025

21

26

31

37

42

47

52

58

68

73

78

90

100

110

t1 = 0.025

2.5

t1 = 0.025

D11

16

20

25

30

35

40

45

50

60

65

70

80

90

100

l -0.1 ; t1

t2

t1= 0.025

t1= 0.025

Sleeve l > d

32

DISTANCE RINGS AND SLEEVES

FOR HAUSINGS

Ring l D

Dimensions non-applied

30

35

40

t1 = 0.05

t1 = 0.05

t1 = 0.05

t1 = 0.06

Sleeve

45 50

t1 = 0.06

25

t1 = 0.06

20

t1 = 0.04

t1 = 0.03

16

t1 = 0.04

t1 = 0.025

t1 = 0.03

t1 = 0.025

0.06

0.06

0.06

0.06

0.06

0.08

0.08

0.08

0.08

0.08

0.08

0.08

0.1

0.1

0.1

0.1

0.1

0.12

0.12

t1 = 0.03

t1 = 0.025

35

40

45

47

54

60

64

66

71

75

80

85

90

100

110

130

140

150

170

t1 = 0.025

2.5

t1 = 0.025

d11

42

47

52

55

62

68

72

(75)

80

85

90

(95)

100

110

120

140

(150)

160

180

l -0.1 ; t1

Ring

10 12 14

t2

t1= 0.025

t1= 0.025

Sleeve l > D

33

YOUNGS MODULI FOR VARIOUS METALS

Materials

Youngs Modulus, E

------

x 105 N/mm2

Steel

2.07

Stainless Steel

1.90

Ductile Cast Iron

1.66

Titanium

1.14

Brass, Bronze

1.10

Grey Cast Iron

1.04

Aluminum

0.72

Magnesium

0.45

POISSONS RATIOS FOR VARIOUS METALS

Materials

Poissons,

Steel

0.28

Iron

0.28

Titanium

0.34

Copper

0.35

Aluminum

0.34

Magnesium

0.33

34

RECOMMENDED JOURNALS OF SHAFT ENDS CYRINDRICAL ONES

Diameter, d

mm

10

12

14

16

18

20

22

25

28

30

32

35

38

40

42

45

50

55

60

70

75

80

85

90

100

110

125

Field

Tolerances

Deviations

mm

+0.007 (+0.010)

-0.002 (+0.001)

+0.008 (+0.012)

-0.003 (+0.001)

j6 (k6)

+0.009 (+0.015)

-0.004 (+0.002)

+0.011 (+0.018)

-0.005 (+0.002)

k6

30

25

40

28

50

36

60

42

80

58

110

82

140

105

170

130

210

165

+0.018

+0.002

+0.030

+0.011

m6

Length, l

Long Journals Short Journals

mm

mm

23

20

+0.035

+0.013

+0.040

+0.015

35

DIMENSIONS OF KEYSEATS

36

RELATION OF HARDNESS NUMBERS

37

RECOMMENDED NUMBER OF PINION TEETH

ACCORDING TO NIEMANN

Proposed treatment

Heat treated up to 230 BHN

More than 300 BHN

Grey iron

Nitrided

Case hardened

1:1

3260

3050

2645

2440

2132

Gear ratio

2:1

4:1

2955

2550

2745

2340

2340

2135

2135

1931

1929

1625

8:1

2245

2035

1830

1626

1422

SPUR GEAR DESIGN FORMULAS

To Obtain

Pitch diameter

Circular pitch

Module

No. of teeth

Addendum

Dedendum

Outside diameter

Root diameter

Base circle diameter

Base pitch

Tooth thickness at

standard pitch

diameter

Center distance

From Known

Module

Module

Diametral pitch

Module and pitch

diameter

Module

Module

Module and pitch

diameter or number of

teeth

Pitch diameter and

module

Pitch diameter and

pressure angle

Module and pressure

angle

Module

Module and number of

teeth

Contact ratio

Outside radii, base circle

radii, center distance,

pressure angle

Backlash (linear)

Change in center

distance

Backlash (linear)

Change in tooth

thickness

Backlash (linear) along Linear backlash above

line-of-action

pitch circle

Backlash, angular

Linear backlash

Min. number teeth for Pressure angle

no undercutting

*)

All linear dimensions in millimeters

Use This Formula*)

D = mN

pc = m = (D)/m

m = 25.4/Pd

N = D/m

a=m

b = 1.25m

Do = D+2m = m(N+2)

Dr = D-2.5m

Db = Dcos

pb = mcos

T = 0.5m

C = 0.5m(N1+N2)

mp =

Ro1 Rb1 + Ro 2 Rb 2 C sin

m cos

B = 2(C)tan

B = T

BLA = Bcos

B* =6.88(B/D) (arc minutes)

Nc = 2/sin2

38

LENGHT EXCESSES RECOMMENDED FOR THREADS

Thread

pitch, p

0.5

0.7

0.8

1.0

1.25

1.5

1.75

2.0

2.5

3.0

3.5

4.0

L

1

1

2

2

2

2

3

3

3

4

4

4

min L1

2

2.5

3

4

5

6

7

8

10

12

13

14

Excess

min L2

1

1.5

1.5

2

2.5

3

3.5

4

5

6

7

8

min L3

4

5

5.5

8

10.5

12

14.5

15

17

21

24

27

min a1

0.8

1.0

1.2

1.5

1.8

2.2

2.5

3.0

3.5

4.5

5.0

6.0

39

CASTING RIB DESIGN

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

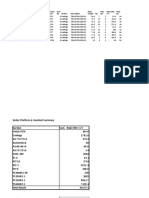

- Maryland Metrics Thread Data Charts: British Thread - Coarse Pitch - BSWDocument3 pagesMaryland Metrics Thread Data Charts: British Thread - Coarse Pitch - BSWsrdzaNo ratings yet

- Power Screw Example ProblemsDocument2 pagesPower Screw Example ProblemsJosafatNo ratings yet

- High Tensile: Hexagon Nuts EN ISO 4032 (DIN 934)Document2 pagesHigh Tensile: Hexagon Nuts EN ISO 4032 (DIN 934)plex015No ratings yet

- ACME Threads PDFDocument2 pagesACME Threads PDFfarshid jamshidi50% (2)

- NPT Thread DimensionsDocument1 pageNPT Thread DimensionsRamnandan MahtoNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分337 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分337 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分301 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分301 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分159 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分159 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分335Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分335zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分167Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分167zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分127 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分127 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分225Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分225zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分177 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分177 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分149Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分149zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分167Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分167zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分135 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分135 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分121 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分121 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分135 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分135 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分275Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分275zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分189 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分189 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分190 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分190 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分379Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分379zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分177Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分177zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分305 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分305 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分301 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分301 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分283Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分283zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分317Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分317zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分327 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分327 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分303 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分303 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分311Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分311zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分313Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分313zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分311Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分311zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分301Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分301zbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分117 PDFDocument1 pageTIC-Wireline Tools and Equipment Catalog - 部分117 PDFzbhdzpNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分337Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分337zbhdzpNo ratings yet

- High-Purity PFA Fine Thread Flare FittingsDocument12 pagesHigh-Purity PFA Fine Thread Flare FittingsAlexNo ratings yet

- Minimum Thread Engagement Formula and Calculation ISODocument2 pagesMinimum Thread Engagement Formula and Calculation ISOmohanjatinderNo ratings yet

- Boiler StructureDocument100 pagesBoiler StructureumashankarsinghNo ratings yet

- MECH4914 Design Project B: Bolted Joint StiffnessDocument25 pagesMECH4914 Design Project B: Bolted Joint StiffnessahmedNo ratings yet

- Titanium Locking Screw and Bolts For Im Nails.J3686CDocument2 pagesTitanium Locking Screw and Bolts For Im Nails.J3686CDIEGO GOMEZNo ratings yet

- Iso 9974-2 Metric Port PDFDocument3 pagesIso 9974-2 Metric Port PDFJai Bhandari0% (1)

- High Tensile Stock ListDocument68 pagesHigh Tensile Stock ListJJ FloresNo ratings yet

- Standard Rack Assembly Instructions: Tools RequiredDocument3 pagesStandard Rack Assembly Instructions: Tools RequiredYongki Adi Pratama PutraNo ratings yet

- Metric Pitch Diameters Pg55Document1 pageMetric Pitch Diameters Pg55Saidas sekaranNo ratings yet

- FastenerDocument3 pagesFastenerFlourdeliza Hernandez MaalihanNo ratings yet

- Bolt Depot - Pilot Hole Sizes For Wood ScrewsDocument2 pagesBolt Depot - Pilot Hole Sizes For Wood ScrewsarqmemofirsNo ratings yet

- TorqSeal Butterfly Face 150 PDFDocument1 pageTorqSeal Butterfly Face 150 PDFSandeep BhatiaNo ratings yet

- DIN standards for bolts screws and studsDocument2 pagesDIN standards for bolts screws and studsRollentNo ratings yet

- Thread Identification ChartDocument4 pagesThread Identification ChartIvan DuncanNo ratings yet

- Brikksen Product CatalogDocument129 pagesBrikksen Product CataloghamzadarbarNo ratings yet

- JIS B1186 Hex Bolts Classes, Grades, Mechanical PropertiesDocument4 pagesJIS B1186 Hex Bolts Classes, Grades, Mechanical PropertiesMario HanamiciNo ratings yet

- BSPT & BSPP Threads Dimensions: Read: Putin's Priceless World Cup MomentDocument3 pagesBSPT & BSPP Threads Dimensions: Read: Putin's Priceless World Cup MomentguslohNo ratings yet

- Anti-vibration mount assembly drawings and parts listDocument6 pagesAnti-vibration mount assembly drawings and parts listabdul rosidNo ratings yet

- ThrdsDocument47 pagesThrdsfrancisdimeNo ratings yet

- Hague Fasteners Guide to Screw Thread Sizes (British StandardDocument6 pagesHague Fasteners Guide to Screw Thread Sizes (British Standardn1ghtfallNo ratings yet

- Daihatsu Centurion Del Atlantico Operation Manual Section 14Document62 pagesDaihatsu Centurion Del Atlantico Operation Manual Section 14Mads AndreassenNo ratings yet

- Bolts & Power Screws Multiple Choice QuestionsDocument6 pagesBolts & Power Screws Multiple Choice QuestionsEjNo ratings yet

- 590sr - Case Super-R Backhoe Loader (01/04 - 12/06) 09 - Loader/backhoe 440 (01) - Long Telescopic ArmDocument3 pages590sr - Case Super-R Backhoe Loader (01/04 - 12/06) 09 - Loader/backhoe 440 (01) - Long Telescopic ArmIliyan VasilevNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesHEMANTKHERANo ratings yet

- 2020 Honda Rebel Cowl InstallDocument2 pages2020 Honda Rebel Cowl InstallMarkDe Weekend TravellerNo ratings yet