Professional Documents

Culture Documents

Bieniawski RMR Updated

Uploaded by

Brahian Roman CabreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bieniawski RMR Updated

Uploaded by

Brahian Roman CabreraCopyright:

Available Formats

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

Innovating Tunnel Design by an Improved Experience-based

RMR System.

B. Celada and I. Tardguila

Geocontrol S.A., Madrid, Spain.

P. Varona

Geocontrol Ltda., Santiago, Chile.

A. Rodrguez

CDIAM., Madrid, Spain.

Z.T. Bieniawski

Bieniawski Design Enterprises, Arizona, U.S.A.

ABSTRACT: The Rock Mass Rating (RMR) System was introduced over 40 years ago, and since

then has become a worldwide reference, along with the Q system, for design applications involving

estimation of rock mass properties and tunnel support. A massive database of experience has been

recorded in the process. On the 25th anniversary of the last modification of the RMR System in

1989, known as the RMR89, an update of this index has now been performed to incorporate the

innovations introduced in recent decades and to improve its performance. For this purpose a database

of 2,298 cases of RMR89s was compiled from tunnel faces. Based on the experience gained in the

last decades, a new RMR14 has been developed, which has a new structure comprising five basic

parameters and three adjustment factors. Also a clear correlation between RMR89 and RMR14 is

provided and shows that the essence of the RMR System has been maintained for practical use.

1 INTRODUCTION

The criteria shown in Table 1 are used to

calculate the basic RMR, that is RMRb, which

is an intrinsic property of the rock mass.

To take into account the effect of the

orientation of the axis of a tunnel with respect to

the most important set of discontinuities in the

ground, the RMRb is obtained with the criteria

shown in Table 2.

The Rock Mass Rating (RMR) System was

introduced over 40 years ago (Bieniawski

1973). Since then it has become a worldwide

reference, along with the Q system, for design

applications involving estimation of rock mass

properties and tunnel support (Barton and

Bieniawski 2008, De Oliveira 2007).

The RMR classifies rock masses from 0 to

100 points, rating five parameters, according to

the criteria presented in Table 1.

Table 2. RMRb adjustment with respect to the orientation

of the axis of the tunnel versus discontinuities.

STRIKE PERPENDICULAR TO TUNNEL AXIS

Strike parallel

to Tunnel Axis

Irrespective of Strike Dip

Drive with dip

Drive against dip

0-20

Dip

Dip

Dip

Dip

Dip.

Dip

45-90

20-45

45-90

20-45

45-90

20-45

Very favorable Favorable Medium Unfavorable Very unfavorable Medium

Medium

0

-2

-5

-10

-12

-5

-5

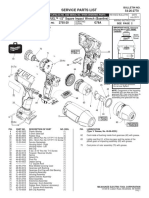

Table 1. Standard ratings to determine RMR after

Bieniawski (1989).

2

3

Parameter

Point-load

strength

index

Uniaxial

comp.

strength

Rating

Drill core Quality RQD

Rating

Spacing of discontinuities

Rating

Strengh

of intact

rock

material

Condition of

discontinuities

(See E)

Rating

Inflow per 10

m tunnel

length (l/m)

Ground (Joint water

press)/(Mayor

water

principal )

General

conditions

Rating

Range of values

> 10 MPa

4-10 MPa

2-4 MPa

1-2 MPa

> 250 MPa

100-250 MPa

50-100 MPa

25-50 MPa

15

90%-100%

20

>2 m

20

Very rough

surfaces Not

continuous

No separation

Unweathered

wall rock

30

12

75%-90%

17

0.6-2 m

15

Slightly rough

surfaces

Separation < 1

mm

Slightly

weathered walls

25

7

50%-75%

13

200-600 mm

10

Slightly rough

surfaces

Separation < 1

mm

Highly weathered

walls

20

4

25%-50%

8

60-200 mm

8

Slickensided

surfaces or

Couge < 5 mm

thick or

Separation 1-5

mm Continuous

10

None

< 10

10-25

25-125

0

Completely

dry

15

For this low rangeuniaxial compressive

test is prefered

5-25

MPa

1-5

MPa

<1

MPa

1

< 25%

3

< 60 mm

5

In 2000, Geocontrol SA introduced a

modification to the criteria for calculating the

RMRb, replacing the RQD assessment and the

spacing of the discontinuities by the number of

joints per meter in the face of the excavation

and extending the criteria for assessing the

condition of discontinuities, as shown in Table 3

(Geocontrol SA 2012).

Soft gouge > 5 mm

thick

or

Separation >5 mm

Continuous

0

> 125

< 0.1

0.1-0.2

0.2-0.5

> 0.5

Damp

Wet

Dripping

Flowing

10

1

05/05/2014

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

where RMRb = RMR basic of the rock mass,

without an effect of excavation,

F0 = Adjustment factor for the orientation of

tunnel axis with regard to the main set of

discontinuities in the rock mass (Table 2). F0 is

always negative.

Fe = Adjustment factor to account for an

excavation method.

Fs = Adjustment factor taking into account

stress-strain behaviour of the rock mass at the

tunnel faces.

The following sections present conceptually

the rating criteria for the new RMRb and the

adjustment factors proposed.

Table 3. Criteria for calculating the RMRb used by

Geocontrol since 2000.

2.1 New RMR structure

The new RMR structure maintains three

parameters composing the RMR89: uniaxial

compression strength of intact rock, number of

discontinuities per meter and the water effect.

The ratings for these parameters are the same

as those of RMR89 i.e. uniaxial compressive

strength has a maximum score of 15 points and

its rating is made by employing the graph

presented in Figure 1.

These changes eliminated the difficulty to

determine the RQD from excavation faces and

to obtain a good assessment of the condition of

the discontinuities in the ground.

In 2012, Geocontrol started a major R&D

Project, partly funded by the Spanish Centro

para el Desarrollo Tecnolgico e Industrial

(CDTI) with the aim to improve the accuracy

of the RMR System. This project ends in

February 2014.

By 2014, 25 years will have passed since the

publication of the RMR89 (Bieniawski 1989)

and after such a long period of time, it was

considered appropriate to update the RMR 89

taking into account the developments over the

last decades.

Figure 1. Ratings for strength of intact rock.

The number of discontinuities per meter is

evaluated with the graph in Figure 2 and its

maximum score is 40 points; (Lawson and

Bieniawski 2013).

2 CURRENT RMR UPDATE

The RMR update described in this paper

features establishing the criteria for rating the

parameters for calculating the RMRb aimed at

improving its accuracy by using two new

factors.

Accordingly, the RMR14 update is

represented by the expression:

RMR14 = (RMRb + F0) Fe Fs

(1)

Figure 2. Ratings for the density of discontinuities.

2

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

Finally, the effect of water, which has a

maximum score of 15 points, is rated according

to the data of Table 4.

discontinuities present on the rock mass, it is

proposed to continue using the criterion

currently employed, in accordance with Table 2.

This adjustment factor is called F0.

Table 4. Rating for the presence of water.

GROUND STATE

Dry

Slightly

humid

Humid

Dripping

Water

flow

Ratings

15

10

2.2.2 Excavation method

The excavation method, whether mechanical or

blasting, modifies the stress-strain behavior of

the ground in different ways with respect to the

RMR as determined at the faces excavated by

conventional methods.

The utilization of mechanical means (TBMs,

road headers or hydraulic hammers) is less

damaging to the remaining rock than blasting,

which implies an improvement in the behavior

of the excavated faces.

Regarding the use of blasting in tunnels, we

must remember that for RMR < 35 this is

practically not used and that for good quality

grounds, RMR > 80, the effect of blasting on the

remaining rock is not very significant, as long as

that the blasting is well planned and executed.

The research carried out by Geocontrol on

this project (2012-2014), has revealed that

explosives used in tunnels excavated in ground

with 35<RMR<80 only affect about 10-20 cm

of the surrounding rock.

Therefore, in the design of tunnels this effect

can be considered insignificant, especially as

that after each blast the excavation perimeter is

cleaned up to remove the affected rock

fragments.

The positive effect of mechanical excavation

was investigated by Alber (1993) and updated

by Bieniawski (2011) as shown in Figure 3.

The two new parameters included in the

updated RMR are the revised joints condition

and the rock alterability due to water (swelling).

The revised discontinuities condition, which

has a maximum rating of 20 points, is rated by

the following four aspects:

- Persistence (continuity) of discontinuities.

- Roughness of discontinuities measured

through the Joint Roughness Factor (JRC).

- Infilling type in the discontinuities.

- Degree of weathering of the planes in the

discontinuities.

The intact rock alterability, which has a

maximum rating of 10 points, is rated according

to the results of the Slake Durability Test, as

defined in standard ASTM D4644-87.

The ratings to assess the two new parameters

are listed in Table 5 and explained in paragraph

2.3.2.

Table 5. Ratings for new parameters of RMR14b.

Discontinuities Condition

Continuity

Roughness

Gouge

infilling

Weathering

<1m

5

Very

rough

5

1-3m

4

3-10m

2

> 10m

0

Rough

Smooth

Slickensided

Hard

< 5mm

5

Unweathered

5

0

Soft

> 5mm

2

Moderately

weathered

3

< 5mm

2

> 5mm

0

Highly

Decomposed

Intact Rock Alterability

> 85

10

Alterability Id2 (%)

60-85

30-60

8

4

< 30

0

2.2 Adjustment factors

It is proposed that the RMRb is adjusted by the

following three factors.

2.2.1 Tunnel axis orientation

To take into account the effect of the tunnel axis

orientation with respect to the major set of

Figure 3. Correlation between RMRD+B and RMRTBM.

3

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

According to the data from Figure 3, the

correlation proposed by Alber is very good for

RMRD+B > 40, but below this value it is too

optimistic. Therefore a new correlation curve is

proposed for RMRD+B < 40, which is marked

with a broken line in Figure 3.

When comparing the values of RMRD+B with

the corresponding ones of RMRTBM a new

correlation for RMRD+B < 40, based on the

results obtained and indicated in the Table 6, is

proposed.

Ideally, the RMR values estimated in the

project planning phase and those determined

during construction should be similar.

However, the reality is that, in addition to

operational errors, the effects of yielding of the

excavation face and walls causes an RMR at the

face to be significantly lower than expected

during the design phase.

This circumstance makes it necessary to

introduce a new factor (Fs) which allows for the

diminishing effect of yielding at the face.

To define Fs it is helpful to employ the

"ndice de Comportamiento Elstico" (ICE)

proposed by Bieniawski and Celada (2011),

which is defined by the equations:

Table 6. Improvement of RMRD+B when using TBM.

RMRD+B

20

40

60

80

RMRTBM

21

53

70

85

RMRTBM

RMRD+B

1.05

1.32

1.16

RMR 100

3704 ci e 24

for K 0 1 : ICE

(3 K 0 ) H

1.06

(4)

(5)

RMR 100

3704 ci e 24

for K 0 1 : ICE

(3K 0 1) H

According to the above, an expression was

developed for the adjustment factor related to

the excavation method (Fe), which is:

RMR

for RMR 40 : Fe 1 2

100

for RMR 40 :

Fe 1.32

Where:

ci = uniaxial compressive strength of intact

rock (MPa).

K0 = ratio of the horizontal to vertical virgin

stress.

H = tunnel depth (m).

F = shape coefficient, see Table 7.

RMR 40

25

(2)

(3)

Table 7. F values for calculating ICE.

Figure 4 shows the Fe as a function of RMR.

Underground excavation

Circular tunnel, = 6 m

1.3

Circular tunnel, = 10 m

1.0

Conventional tunnel, 14 m wide

0.75

Caverns 25 m wide x 60 m high

0.55

ICE makes it possible to predict the stressstrain behavior of the faces of the tunnels

classifying them into five categories as show in

Table 8.

Figure 4. Representation of Fe as function of RMR.

Note that Fe = 1 is used when the excavation

is performed by blasting.

Table 8. Designation of stress-deformation behavior

of a tunnel section as a function of the

ndice de Comportamiento Elstico (ICE).

2.2.3 Stress-Strain behaviour

The RMR should be determined in the design

phase of a tunnel using data from boreholes, and

during the construction of the tunnel by

geological mapping of the excavation surfaces.

4

ICE

Stress-deformation behaviour

> 130

Completely elastic

70-130

Elastic with incipient yielding

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

40-69

Moderate yielding

15-39

Intensive yielding

< 15

Mostly yielding

The discontinuities condition is rated in

accordance with the criteria contained in Table

9, which are derived from the Guidelines for

Classification of Discontinuity Conditions,

Bieniawski (1989), which means that the

maximum score for this parameter is 20 points.

According to the above, only the excavation

faces in which ICE < 70 will present substantial

deformation for significant variations in the

determination of RMR.

When the expressions were applied to the

RMR ratings over the last decades, particularly

when analyzing the RMR's obtained from

boreholes in the Chuquicamata Mine (Chile), it

was found that the factor Fs ranges between 0

and 1.3, according to Figure 5.

Table 9. Ratings for Discontinuities Condition.

<1m

1-3m

3-10m

> 10m

Very

rough

Rough

Smooth

Slickensided

Continuity

Roughness

Hard

Gouge

infilling

< 5mm

> 5mm

< 5mm

> 5mm

Unweathered

Moderately

weathered

Highly

Decomposed

Weathering

To define the intact rock alterability ratings,

a comparative study of this RMR update and the

RMR89 was performed by compiling a large

database established by Geocontrol.

Figure 5. Fs values depending on the ICE.

The graphic of Figure 5, can be adjusted with

the following expressions

15<ICE<70

ICE > 70

2.3.1 Database employed

Geocontrol has a database composed of 2,298

cases of tunnel sections, constructed by the

NATM, where the RMR89 has been

determined.

The average value of the basic RMR in this

database, without adjusting for the orientation of

the tunnel, is 51 points and its frequency

histogram is shown in Figure 6.

Fs=1,3

ICE < 15

Fs

2.3 100 ICE

7.1 100 ICE

Soft

(6)

Fs=1

2.3 Criteria for assessing the new parameters

of the RMR

RMR89

500

450

400

It has already been indicated that the RMR

update has retained two parameters of the

RMR89: uniaxial compressive strength and the

effect of water; the RQD and the discontinuities

spacing have been combined and are expressed

as the number of discontinuities per meter.

All of these factors are rated employing the

same criteria in the RMR89; therefore, one

needs only to establish the criteria for assessing

the discontinuities condition and the alterability

of the intact rock.

Frecuencia (N casos)

350

300

250

200

150

100

50

0

RMR89

15

20

25

30

35

40

45

50

55

60

65

70

75

80

26

70

151

282

254

259

294

311

455

183

Figure 6. Database RMR89 frequency histogram.

The highest value of RMR89, in the

database, is 73 points and the lowest one is 15

so the range has 58 points.

5

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

In this database, 68.5% of the cases are

between 65 and 40 points, which matches well

with the range of RMR in Spanish rock masses,

when the RMR is not adjusted for

discontinuities.

Figure 6 also shows that there are only five

cases with RMR>70; which also matches with

the usual practice that indicates that the RMR89

tends to concentrate the values in the central

third of its range.

third of the range to the upper third; thereby

solving the RMR89 defect, mentioned above.

If a correlation factor R = 1 is assigned to the

RMR89 it results in the correlation factor of

RMR14-II being R = 0.982; whereby it is

proved that, despite the RMR14-II sample shifts

towards the highest RMR values, this

correlation is not significantly worse.

According to the above, the ratings to take

into account the alterability in the RMR14 are

shown in Table 11.

2.3.2 Tested ratings for intact rock alterability

As indicated, the alterability of intact rock is

determined using the Slake Durability Test, as

defined in ASTM D 4644-87, which allows one

to obtain the index Id2.

In order to select the ratings for the

alterability, four hypotheses were considered,

which are presented in Table 10.

Table 11. Ratings for intact rock alterability.

Alterability Id2 (%)

60-85

30-60

8

4

> 85

10

< 30

0

2.4 RMR14 calculation

>98

95-98

85-95

60-85

30-60

<30

Table 12 summarizes all the ratings for

evaluation of the five parameters which

comprise the RMR14, without adjusting for the

tunnel axis orientation with respect to the most

important set of discontinuities.

RMR14-I

10

Table 12. Rating for calculating RMR14b.

RMR14-II

10

10

10

1. Strength of Intact Rock 2. Number of discontinuities

RMR14-III

10

RMR14-IV

10

10

Table 10. Ratings tested for alterability.

VALUES OF Id2 (%)

Hypothesis

Figure 7 shows the frequency histograms of

the four hypotheses to rate the alterability along

with the histogram of RMR89.

3. Discontinuities Condition

500

<1m

5

Very

rough

5

Continuity

450

400

Roughness

Frecuencia (N Casos)

350

300

200

150

Weathering

100

< 5mm

5

Unweathered

5

50

3-10m

2

> 10m

0

Rough

Smooth

Slickensided

Hard

Gouge

infilling

250

1-3m

4

Soft

> 5mm

2

Moderately

weathered

3

< 5mm

2

> 5mm

0

Highly

Decomposed

4. Presence of water

15

20

25

30

35

40

45

50

55

60

65

70

RMR89

26

70

151

282

254

259

294

311

455

183

RMR14-I

15

55

123

211

242

218

227

239

319

494

144

RMR14-II

44

80

144

219

231

221

241

248

467

375

75

16

80

RMR14-III

28

64

144

227

217

178

216

209

265

485

249

RMR14-IV

28

62

137

216

204

191

188

234

240

439

337

14

Ground state

Dry

Assessment

15

Slightly

wet

10

wet

Dripping

Water

flow

0

5. Alterability

Figure 7. RMR89 and the four hypothesis for the rock

alterability.

> 85

10

This figure clearly shows that the ratings

from hypothesis RMR14-II produce the desired

effect of distributing the sample from the central

6

Alterability Id2 (%)

60-85

30-60

8

4

< 30

0

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

The three adjustment factors are calculated

according to the information contained in Table

13.

Table 13. Adjustment Factors for RMR14.

I. Tunnel orientation versus that of discontinuities (F0)

STRIKE PERPENDICULAR TO TUNNEL AXIS

Strike parallel

to Tunnel Axis

Irrespective of Strike Dip

Drive with dip

Drive against dip

0-20

Dip

Dip

Dip

Dip

Dip.

Dip

45-90

20-45

45-90

20-45

45-90

20-45

Very favorable Favorable Medium Unfavorable Very unfavorable Medium

Medium

0

-2

-5

-10

-12

-5

-5

II. Mechanical excavation

Figure 8. Correlation between RMR14 and RMR89.

4 WORKS IN PROGRESS

This R & D project of Geocontrol, partly funded

by the CDTI, ends in February 2014 and by then

it is expected to perform the following two

tasks:

Software to calculate the RMR14: A software

that allows determination of the RMR14 and the

parameters for stress-strain calculations.

Empirical selection of supports: A chart that

provides an empirical guide for the support and

reinforcement of underground works, with

respect to their dimensions and the "stressstrain-behavior of the rock mass".

Most of all, the current update to the RMR

System is being conducted within the

framework of an innovative tunnel design

methodology termed "Interactive Structural

Design" (Diseo Estructural Activo, Celada

2011), as depicted in Figure 9 a, b and c.

III. Stress - Strain behavior

3 CORRELATION BETWEEN RMR89 AND

RMR14

5 CONCLUSIONS

Figure 8 shows an excellent correlation between

RMR89 and RMR14, calculated with 2,298

cases of the database, corresponding to the

equation:

RMR14 = 1.1 RMR89 + 2

Since its introduction in 1989, the RMR89 has

remained as an accepted worldwide tool to

characterize the behavior of rock masses.

Over the past decades there have been many

innovations to improve the RMR that have been

incorporated in this work, as the result of a

research project at Geocontrol, partially funded

by the CDTI.

(7)

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

Figure 9 a. The methodology of theInteractive Structural

Design (Diseo Estructural Activo, Celada 2011)

PHASE I. Site characterization.

Figure 9 b. PHASE II. Structural Design.

Proceedings of the World Tunnel Congress 2014 Tunnels for a better Life. Foz do Iguau, Brazil.

Furthermore, besides the adjustment factor

for the orientation of the tunnel already present

in the RMR89, the RMR14 includes two new

adjustment factors, one for the case in which the

excavation is carried out by mechanical means

and another one for the stress-strain behavior of

tunnel faces.

The new RMR14 correlates well with the

RMR89, based on a database containing 2,298

cases, and thus maintains the essence of the

RMR System used for over 40 years.

During the WTC in Brazil in May 2014, it is

expected to present software for calculating the

RMR14 and a comprehensive chart for

empirical determination of the support to be

installed in tunnels.

REFERENCES

Alber, G. 1993. Classifying TBM contracts. Tunnels &

Tunnelling, v. December, p.41-43.

Barton, N. and Bieniawski, Z.T. 2008. Setting the record

straight about RMR and Q. Tunnels & Tunnelling, v.

February, p.26-29.

Bieniawski, Z.T. 1973. Engineering Classification of

Jointed Rock Masses. The Civil Engineer in South

Africa, v.15, p.335-343.

Bieniawski, Z.T. 1989. Engineering Rock Mass

Classifications: a Complete Manual. New York: John

Wiley and Sons, 251p.

Bieniawski, Z.T.; Celada, B.; Aguado, D. and Rodrguez,

A. 2011. Forecasting tunnelling behavior. Tunnels &

Tunnelling, v. August, p.39-42.

Bieniawski, Z.T.; 2011. Errores en la aplicacin de las

clasificaciones Geomecnicas y su correccin.

Jornada sobre la Caracterizacin Geoctcnica del

Terreno. Madrid: ADIF. 35p.

Bieniawski, Z.T.; Celada, B.; Tardguila, I. and

Rodrguez, A. 2012. Specific energy of excavation in

detecting tunneling conditions ahead of TBMs.

Tunnels & Tunnelling, v. February, p.65-68.

Celada, B. 2011. Manual de Tneles y Obras

Subterrneas. Madrid: UPM. Captulo 23. p.850-854.

De Oliveira, T. 2007. Contribuo classificao

geomecnica de macios rochosos utilizando o

Sistema RMR. Monografia de Trabalho de Formatura

(TF-07/42). Orientador: Prf. Dr. Lindolfo Soares.

Universidad de Sao Paulo, Instituto de Geociencias,

Brasil.

Geocontrol S.A. 2012. Actualizacin del ndice Rock

Mass Rating (RMR) para mejorar sus prestaciones en

la caracterizacin del terreno. Centro para el

Desarrollo Tcnico Industrial (CDTI). Proyecto: IDI20120658. Madrid, Espaa.

Lowson, Alex and Bieniawski, Z.T. 2013. Critical

assessment of RMR-based tunnel design practices: A

practical engineers approach. In: Proc. RETC 2013.

Washington, DC: Society of Mining Engineers, p.180198.

Figure 9 c. PHASE III. Confirmation during construction.

In addition, in recent years, renewed

attention was paid to the RMR System because

of its applications to the assessment of rock

mass excavability (RME) and, especially, its

direct correlation with the Specific Energy of

Excavation (EEE) for TBMs has shown that it

can be used effectively to detect changes in

tunneling ground conditions, in real time, when

recording TBM performance and serving as a

warning of adverse conditions as construction

proceeds (Bieniawski and Celada, 2006).

The RMR update presented in this paper, and

called RMR14, has a new structure, which

consists of three parameters from the RMR89,

to which the modified discontinuities condition

and the effect of the alterability of the intact

rock have been added.

9

You might also like

- Rock Mass Characterization Using RMR SystemDocument18 pagesRock Mass Characterization Using RMR SystemJoseph AbrahamNo ratings yet

- 0085 BartonDocument8 pages0085 BartonR. Venugopala RaoNo ratings yet

- Barton, N. and E. Grimstad, 2014 Q-System - An Illustrated Guide Following 40 Years in Tunnelling. 43p, 79 FigsDocument44 pagesBarton, N. and E. Grimstad, 2014 Q-System - An Illustrated Guide Following 40 Years in Tunnelling. 43p, 79 FigsGeogeneralNo ratings yet

- Piles in Weak RockDocument240 pagesPiles in Weak RockRameshNo ratings yet

- Umbrella Arch Method Performance, Structural Behavior and DesignDocument15 pagesUmbrella Arch Method Performance, Structural Behavior and Designzimbazimba75No ratings yet

- TheQ slopeMethodforRockSlopeEngineeringDocument10 pagesTheQ slopeMethodforRockSlopeEngineeringSidharth MahajanNo ratings yet

- Tunnelling challenges overcome at Tala hydroelectric projectDocument9 pagesTunnelling challenges overcome at Tala hydroelectric projectAnanda SenNo ratings yet

- Effect of Rock Mass Quality On Construction Time in A Road TunnelDocument8 pagesEffect of Rock Mass Quality On Construction Time in A Road TunnelCamila Contreras CarrascoNo ratings yet

- Designing Sequential Excavation for Weak Rock TunnelsDocument8 pagesDesigning Sequential Excavation for Weak Rock TunnelstibammNo ratings yet

- Oslo Navet Tunnelboremaskiner NDocument55 pagesOslo Navet Tunnelboremaskiner NSérgio BernardesNo ratings yet

- Rocplane: Planar Sliding Stability Analysis For Rock SlopesDocument31 pagesRocplane: Planar Sliding Stability Analysis For Rock SlopesGonzalo Andres Bouldres VargasNo ratings yet

- Barton-TBM Tunnelling in Sheared and Fractured Rock Masses. Cartagena, ColombiaDocument36 pagesBarton-TBM Tunnelling in Sheared and Fractured Rock Masses. Cartagena, Colombiacastille1956No ratings yet

- NATM - A SEM MethodDocument3 pagesNATM - A SEM MethodIJRASETPublicationsNo ratings yet

- Desing Methods With Yielding SupportDocument13 pagesDesing Methods With Yielding SupportSriram NambiNo ratings yet

- A Study On Advances in Ground Improvement Techniques Mohammad BilalDocument12 pagesA Study On Advances in Ground Improvement Techniques Mohammad BilalFasee UllahNo ratings yet

- Identifying Dispersive Clays Using Pinhole Erosion TestsDocument28 pagesIdentifying Dispersive Clays Using Pinhole Erosion TestsAndyra Jaiz Baddu100% (1)

- Analysis of Diaphragm WallDocument6 pagesAnalysis of Diaphragm WallSanthosh BabuNo ratings yet

- Tunneling in HimalayasDocument4 pagesTunneling in HimalayassaritasohamNo ratings yet

- Expert System For D&B Tunnel ConstructionDocument6 pagesExpert System For D&B Tunnel ConstructionescillaNo ratings yet

- Beam-spring analysis for tunnel support designDocument13 pagesBeam-spring analysis for tunnel support designmetropodikasNo ratings yet

- Design in Rock Engineering PDFDocument25 pagesDesign in Rock Engineering PDFBrayan González CarvajalNo ratings yet

- SEM Mined Tunnel PDFDocument3 pagesSEM Mined Tunnel PDFqaisarmehboob82No ratings yet

- Measure forces in reinforced sprayed concrete ribsDocument14 pagesMeasure forces in reinforced sprayed concrete ribsJacky LeongNo ratings yet

- Design and Construction of The Billy Bishop City Airport Pedestrian Tunnel, Toronto, CanadaDocument8 pagesDesign and Construction of The Billy Bishop City Airport Pedestrian Tunnel, Toronto, CanadaAndrew Cushing100% (1)

- Compensation GroutingDocument37 pagesCompensation GroutingPablo RincónNo ratings yet

- Observational Methods and NATMDocument39 pagesObservational Methods and NATMKeshav KumarNo ratings yet

- Finite Element Slope Stability AnalysisDocument57 pagesFinite Element Slope Stability AnalysisAlexander P-b100% (1)

- Atkinson and Potts 1977Document13 pagesAtkinson and Potts 1977Amro Al-Hinai100% (1)

- Construction of Deep Plastic Concrete Cut-Off Wall in Upstream Coffer Dam of Punatsangchhu-I Hydropower Project, BhutanDocument8 pagesConstruction of Deep Plastic Concrete Cut-Off Wall in Upstream Coffer Dam of Punatsangchhu-I Hydropower Project, BhutanVetriselvan ArumugamNo ratings yet

- Design Challenges for Tall Building FoundationsDocument7 pagesDesign Challenges for Tall Building FoundationsJai ThakkarNo ratings yet

- Geology of MaharashtraDocument2 pagesGeology of MaharashtraMallinath JadhavNo ratings yet

- Geotechnical Model For Pipe Roof Supports in TunneDocument7 pagesGeotechnical Model For Pipe Roof Supports in TunneSudhakar GeoNo ratings yet

- Influence of Geological Conditions On deDocument29 pagesInfluence of Geological Conditions On deomeaveNo ratings yet

- Rock Mechanics and Tunneling ReportDocument4 pagesRock Mechanics and Tunneling ReportDevyani TewatiaNo ratings yet

- Code of Practice For Reinforcement of Rock Slopes With Plane Wedge FailureDocument16 pagesCode of Practice For Reinforcement of Rock Slopes With Plane Wedge FailurePabloNo ratings yet

- Vibro Replacement Columns For Shipyard Infrastructure at Pipavav - IsGI 2009Document7 pagesVibro Replacement Columns For Shipyard Infrastructure at Pipavav - IsGI 2009suvraNo ratings yet

- Analysis of Tunnel Stability in Very Weak RockDocument9 pagesAnalysis of Tunnel Stability in Very Weak RockoffiNo ratings yet

- Numerical Modelling of Railway Tunnel Excavation Using NATM MethodDocument30 pagesNumerical Modelling of Railway Tunnel Excavation Using NATM MethodAdrian TudorNo ratings yet

- Design of Tunnel LiningDocument16 pagesDesign of Tunnel LiningBhaskar Reddy100% (1)

- Temporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisDocument8 pagesTemporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisAndrew CushingNo ratings yet

- Pregrouting For Leakage Control and Rock Improvement 2165 784X 1000226Document4 pagesPregrouting For Leakage Control and Rock Improvement 2165 784X 1000226Abhilash UrsNo ratings yet

- Breakthroughs in Tunneling 2015: Tunneling in Cobbles and BouldersDocument39 pagesBreakthroughs in Tunneling 2015: Tunneling in Cobbles and BouldersswhuntNo ratings yet

- Textbook Engineering Geology and TunnelsDocument97 pagesTextbook Engineering Geology and TunnelsAbhushan NeupaneNo ratings yet

- Basics and Application of the Austrian Guideline for Geomechanical DesignDocument6 pagesBasics and Application of the Austrian Guideline for Geomechanical DesignNadim527No ratings yet

- Guide To Specification of Geotextiles - Newzealand PDFDocument0 pagesGuide To Specification of Geotextiles - Newzealand PDFthadikkaranNo ratings yet

- 61-65E - Compensation Grouting For Limiting Settlements of Two Railway Bridges Induced by A Twin-Tunnel ExcavationDocument13 pages61-65E - Compensation Grouting For Limiting Settlements of Two Railway Bridges Induced by A Twin-Tunnel Excavationno indicadoNo ratings yet

- Face Stability Analysis of Shallow Circular Tunnels in Cohesive-Frictional SoilsDocument14 pagesFace Stability Analysis of Shallow Circular Tunnels in Cohesive-Frictional SoilsRonald Cornejo MarmanilloNo ratings yet

- A Critical Review of Construction, Analysis and Behaviour of Stone ColumnsDocument22 pagesA Critical Review of Construction, Analysis and Behaviour of Stone ColumnsEman AhmedNo ratings yet

- Passive SupportDocument49 pagesPassive SupportYoon HeoNo ratings yet

- Portal DesignDocument8 pagesPortal DesignshishirpatleNo ratings yet

- Engineering Rock Properties for Stable SlopesDocument31 pagesEngineering Rock Properties for Stable Slopessuchismita majhiNo ratings yet

- 6 Some Important Features of Stone Column TreatmentDocument7 pages6 Some Important Features of Stone Column TreatmentBilal Ahmed BarbhuiyaNo ratings yet

- 2D Numerical Simulations of Soil Nail WallsDocument12 pages2D Numerical Simulations of Soil Nail WallsShahab KhaledNo ratings yet

- Chameliya Hydroelectric Project Underground Excavations Case StudyDocument77 pagesChameliya Hydroelectric Project Underground Excavations Case StudySaphal LamichhaneNo ratings yet

- Prediction of Compressive Strength From Other Rock Properties (USBM RI 6702)Document26 pagesPrediction of Compressive Strength From Other Rock Properties (USBM RI 6702)Tsakalakis G. KonstantinosNo ratings yet

- Stability of An Immersed Tunnel in Offshore Conditions Under Deep Water Wave ImpactDocument8 pagesStability of An Immersed Tunnel in Offshore Conditions Under Deep Water Wave ImpactRonald HeijmansNo ratings yet

- Uplift Capacity of Piles in Two Layered SoilDocument7 pagesUplift Capacity of Piles in Two Layered SoilIAEME PublicationNo ratings yet

- Rock Mass Strength For TunnelDocument21 pagesRock Mass Strength For TunnelShwan R AhmadNo ratings yet

- International Society for Rock Mechanics: List of Members 1980From EverandInternational Society for Rock Mechanics: List of Members 1980Rating: 3.5 out of 5 stars3.5/5 (2)

- Design of Mse JournalDocument44 pagesDesign of Mse JournalshoaibNo ratings yet

- Prediction of Field Behavior of Reinforced Soil Wall UsingDocument11 pagesPrediction of Field Behavior of Reinforced Soil Wall UsingBrahian Roman CabreraNo ratings yet

- (1983 Seed and Idriss) Evaluation of Liquefaction Potential Using Field Performance DataDocument25 pages(1983 Seed and Idriss) Evaluation of Liquefaction Potential Using Field Performance Datasanpaz75No ratings yet

- 052 2001 Peak or Residual Soil StrengthDocument31 pages052 2001 Peak or Residual Soil StrengthchristopherapssNo ratings yet

- Piled Raft FoundationDocument1 pagePiled Raft FoundationBrahian Roman CabreraNo ratings yet

- Settlement Shear WaveDocument1 pageSettlement Shear WaveBrahian Roman CabreraNo ratings yet

- SCPTu TestsDocument1 pageSCPTu TestsBrahian Roman CabreraNo ratings yet

- Raft FoundationDocument1 pageRaft FoundationBrahian Roman CabreraNo ratings yet

- Assessment of Critical State Shear Strength Properties of Copper TailingsDocument7 pagesAssessment of Critical State Shear Strength Properties of Copper TailingsBrahian Roman CabreraNo ratings yet

- Lectures in EnglishDocument7 pagesLectures in EnglishBrahian Roman CabreraNo ratings yet

- Opportunities For Enhanced Lean Construction Management Using Internet of Things StandardsDocument12 pagesOpportunities For Enhanced Lean Construction Management Using Internet of Things StandardsBrahian Roman CabreraNo ratings yet

- Subgrade Subbase tr525 PDFDocument132 pagesSubgrade Subbase tr525 PDFBrahian Roman CabreraNo ratings yet

- 3次元個別要素法による液状化現象の数値解析Document2 pages3次元個別要素法による液状化現象の数値解析Brahian Roman CabreraNo ratings yet

- Intensive Course LectureDocument2 pagesIntensive Course LectureBrahian Roman CabreraNo ratings yet

- The Wastes of Production in Construction A TFV Based TaxonomyDocument12 pagesThe Wastes of Production in Construction A TFV Based TaxonomyPeter Jean-jacquesNo ratings yet

- The Hoover DamDocument121 pagesThe Hoover DamCruceru RamonaNo ratings yet

- SMR Geomechanics Classification For ICRM 2003Document4 pagesSMR Geomechanics Classification For ICRM 2003inspiron11No ratings yet

- An Introduction to the Finite Element Method in Two DimensionsDocument104 pagesAn Introduction to the Finite Element Method in Two DimensionsJayNo ratings yet

- Geotechnical Engineering in America Before Columbus PDFDocument5 pagesGeotechnical Engineering in America Before Columbus PDFBrahian Roman CabreraNo ratings yet

- History of GeotechnicsDocument98 pagesHistory of GeotechnicsBrahian Roman CabreraNo ratings yet

- Displacement Based DesignDocument27 pagesDisplacement Based DesigngayalamNo ratings yet

- Howard Threshold 80Document32 pagesHoward Threshold 80Brahian Roman CabreraNo ratings yet

- Zara's Agile Supply Chain SuccessDocument11 pagesZara's Agile Supply Chain Successr_vivekanand100% (1)

- HowGeotechEnggShapedHistoryCalifornia RogersDocument97 pagesHowGeotechEnggShapedHistoryCalifornia RogersBrahian Roman CabreraNo ratings yet

- Shear Strength of Unsaturated SoilsDocument1 pageShear Strength of Unsaturated SoilsBrahian Roman CabreraNo ratings yet

- 01 Koskela Rooke Bertelsen Henrich - The TFV Theory of Production - New DevelopmentsDocument11 pages01 Koskela Rooke Bertelsen Henrich - The TFV Theory of Production - New DevelopmentsCarlosNoriegaNo ratings yet

- History of Geotechnical Earthquake Engineering in JapanDocument8 pagesHistory of Geotechnical Earthquake Engineering in JapanBrahian Roman CabreraNo ratings yet

- Intelligent Compaction System For Embankments in Highway ConstructionDocument1 pageIntelligent Compaction System For Embankments in Highway ConstructionBrahian Roman CabreraNo ratings yet

- The Development of A Small-Scale Geotechnical Teaching CentrifugeDocument8 pagesThe Development of A Small-Scale Geotechnical Teaching CentrifugeBrahian Roman CabreraNo ratings yet

- 2755 22 (G78A) Milwaukee PBDocument2 pages2755 22 (G78A) Milwaukee PBZeckNo ratings yet

- PDF 256372311 Pec QC With Answerpdf DDDocument6 pagesPDF 256372311 Pec QC With Answerpdf DDLee Robert OlivarNo ratings yet

- API 6D Valves Bonney Forge PDFDocument12 pagesAPI 6D Valves Bonney Forge PDFSQUALO_122No ratings yet

- Daftar Alat TSMDocument2 pagesDaftar Alat TSMagus ImawanNo ratings yet

- Summit Archive 1569863860Document50 pagesSummit Archive 1569863860mangelchavezNo ratings yet

- Main Bearing Journal: Shutdown SIS Previous ScreenDocument3 pagesMain Bearing Journal: Shutdown SIS Previous Screenariy yuli styawanNo ratings yet

- Refresher Day 3Document4 pagesRefresher Day 3Jevan A. CalaqueNo ratings yet

- Loop Back DSP Audio AppDocument12 pagesLoop Back DSP Audio AppGytis BernotasNo ratings yet

- SLVR Cartas PDFDocument18 pagesSLVR Cartas PDFEdgar David Ruelas ClarosNo ratings yet

- Driver Control Master NXT Service Manual 092137-8Document53 pagesDriver Control Master NXT Service Manual 092137-8Piero Capretti0% (1)

- Marking Fixture PresentationDocument31 pagesMarking Fixture PresentationAvinash JejurkarNo ratings yet

- Foundation Examples 9.7.2Document4 pagesFoundation Examples 9.7.2Muhannad AbdulRaoufNo ratings yet

- Accedian Networks EtherNID MetroNID 2pg FINAL 083112 PDFDocument2 pagesAccedian Networks EtherNID MetroNID 2pg FINAL 083112 PDFMark LamondNo ratings yet

- Iec61000 4 7 (Ed2.0) en - DDocument8 pagesIec61000 4 7 (Ed2.0) en - Dtwinvbooks100% (1)

- Manual Cessna 188 PG 01-108Document108 pagesManual Cessna 188 PG 01-108Nilton César LimaNo ratings yet

- Two-Way Floor SystemDocument11 pagesTwo-Way Floor SystemJason TanNo ratings yet

- Count rows in all tablesDocument25 pagesCount rows in all tablessatya1401No ratings yet

- Machine Tools Questions and Answers - GrindingDocument4 pagesMachine Tools Questions and Answers - GrindingRohit GhulanavarNo ratings yet

- RK-2001 Operation ManualDocument11 pagesRK-2001 Operation Manuale-ComfortUSANo ratings yet

- Weather and Aviation PDFDocument10 pagesWeather and Aviation PDFSergio GasparriNo ratings yet

- 5STR 03T2040Document8 pages5STR 03T2040Vikas PatelNo ratings yet

- Catalogo General KOBA 1000 - e - 2012revDocument21 pagesCatalogo General KOBA 1000 - e - 2012revTECNIMETALNo ratings yet

- Brochure Ef SchoolDocument2 pagesBrochure Ef SchoolperulapiaNo ratings yet

- Productdatasheet en or 088423855cDocument1 pageProductdatasheet en or 088423855cpieroNo ratings yet

- Plate Girder DesignDocument109 pagesPlate Girder Designhasib100% (3)

- Mevira CROSS2014 PDFDocument516 pagesMevira CROSS2014 PDFFajar RofandiNo ratings yet

- Ducha EmpotradaDocument1 pageDucha Empotradagilmar melendresNo ratings yet

- Operating Systems Concepts and ComponentsDocument42 pagesOperating Systems Concepts and ComponentsgtaclubNo ratings yet

- Hydrology Lecture01Document24 pagesHydrology Lecture01Mohd. YunusNo ratings yet

- CalibrationDocument7 pagesCalibrationstolen mechieducNo ratings yet