Professional Documents

Culture Documents

Methods & Rates For Structural Steelwork Erection

Uploaded by

Anonymous qEPNPwA0 ratings0% found this document useful (0 votes)

12 views8 pages;lll;

Original Title

Methods & Rates for Structural Steelwork Erection

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document;lll;

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views8 pagesMethods & Rates For Structural Steelwork Erection

Uploaded by

Anonymous qEPNPwA;lll;

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

THE CHARTERED

INSTITUTE

‘OF BUILDING

ISSN 0262-6632

Englemere, Kings Ride, Ascot, Berkshire SL5 8B

No 14 1990

Telephone Ascot (0990) 23355

TECHNICAL

INFORMATION

SERVICE

Methods and rates for

structural steelwork

erection

by M.W. Emsley BTech

F.C. Harris BEng MSc PhD CEng MCIOB

‘Margaret Emsiey is a civil engineer who has professional ex-

perience both in contracting and consulting engineering. She

hhas carried out research at Loughborough University of

Technology in the general area of construction productivity.

Since 1986 she has been a lecturer in the Department of

Building Engineering at UMIST where her research interests

have extended into the fields of site organisation and computer

simulation.

Frank Harris is Professor of Construction Studies in the School

of Construction, Engineering and Technology at Wolverhamp-

ton Polytechnic. He also holds the appointments of Visiting Pro-

fessor at Loughborough University of Technology and Visiting

Fellow at the Universities of both New Mexico, USA and New

‘South Wales, Australia. He is the author of five textbooks and

hhas written numerous research papers reflecting his wide rang-

ing interests in construction management.

Series Editor: Peter Harlow

INTRODUCTION

The accuracy of estimating and planning within the building

industry isa reflection of the accuracy and reliability of the pro-

duction data available. Whilst there is a plethora of data

available, much of it is disparate in nature. Productivity data,

supplied in estimator’s handbooks, generally exhibit a large

range of values. Contractor's own data, obtained from feed-

back from site, is of limited value in determining productivity

data as the objectives of data collection are different in both

cases. It is only by the application of work study techniques.

‘that accurate and reliable productivity data can be obtained.

This paper describes erection methods and rates for medium

sized structural steel frames. Method statements, for the erec-

tion phase, are supplemented with sketches. Output data, giv.

ing erection rates, have been obtained by the application of

appropriate work study techniques. This work has emanated

from a Science and Engineering Research Council grant (SERC),

awarded to the Department of Civil Engineering at

Loughborough University of Technology, to evaluate produc:

tion output for construction labour and plant2; structural

steelwork was one of eight construction activities studied.

DATA COLLECTION

Work study techniques have been used to good effect in

‘manufacturing industry for some considerable time but have

had varying impact on building where the transient nature of

the workforce, the rapidly changing conditions and short dura-

tion of seemingly unique assignments, would seem to restrict

their successful implementation. However, research has

demonstrated that suitable methods of data collection can be

developed to assist in improving productivity for construction

work also’.

The application of work study encompasses both the techni

ques of method study and work measurement.

‘Method study is the recording of work procedures in order to

effect improvements. Ultimately the application of this techni-

ue leads to better planning and control and the improved use

of manpower, plant and material

Production data may be obtained by the application of work

‘measurement techniques. The British Standard Glossary of

Terms used in work study and organisation and methods*

defines work measurement as ‘The application of techniques

esigned to establish the time for a qualified worker to carry

‘out a task at a defined rate of working.”

‘Two widely used work measurement techniques are activity

sampling and time study. Both these techniques have been

refined and adapted for use in the construction industry and

hhave been used to collect data on site. Research has shown

that activity sampling is the most appropriate procedure for

obtaining productivity data where a large number of activities

are been carried out by many men and machines; time study

is more suited to operations of cyclical nature with few

resources involved.®

The technique of activity sampling involves the observation of

‘2 group of men and/or machines, and the recording of which

activity they are engaged upon at precise moments. Observa

tions are usually made at fixed pre-determined intervals.

In the studies reported here observations were made at one

‘minute intervals, on both the erection gang and the crane us-

ed in the operation. Standard data sheets were prepared and

Used to record the data. To facilitate this, codes were used to

identity each activity. Some activities are unique toa given trade

bbut many (eg fetch) are common to all trades.

Each observation is given a ‘rating’ on a scale of 50 to 125,

‘according to British Standards Rating Scale * where 100

represents standard rate,

The theory of activity sampling requires that sufficient obser-

vations are taken to satisfy the limits of accuracy for a given

confidence level. These requirements were met in each case.

‘An operation invariably comprises many events or elements,

and the technique of time study necessitates the recording of

the actual time when breakpoints occur in the cycle of events,

which constitute an operation. For example, the action of pick:

ing up a structural steel column, moving it into position and

lowering it on to the holding down bolts is one element in the

overall erection of a structural steel column, The breakpoints

in the operation which define this particular element are ‘crane

2

‘commences to lift column’ and ‘commence screwing nuts on

to holding down bolts’. The time which has elapsed between

these two breakpoints can therefore be assigned to the ele-

ment, in the operation, which the breakpoints define.

DATA ANALYSIS

Basic operation times, for a given operation, are determined

‘from the folllowing procedure:

(a) basic element times are determined for each element

‘comprising the operation;

(b) _ basic time for operation contingency work is determined;

(©) the basic element times and operation contingency

allowance are assembled to give the basic operation time.

Where time study was used basic element times were obtain

ed directly. In the case of activity sampling, basic element times

were obtained by mutliplying the average number of observa-

tions, attributable to that element, by the average time dura-

tion between observations. In both cases appropriate ad-

justments were made for the rate of working. Times for ac-

tivities associated with an operation which cannot be measured

directly have been expressed in terms of a contingency

allowance which is added to the basic element times to give

‘the basic operation time.

‘The following operations have been considered:

(unloading of structural steel components;

(ii) erection of structural steel columns;

(iil) erection of structural steel beams;

(iv) lining and levelling of structural steel frames;

(W) erection of roof purlins.

The analysis of the data produced results which could be

Classified into three distinct categories:

© firstly, that where there was no correlation between the

basic element time and a related variable (eg, weight of the

section), other than the number of components involved:

© secondly, that category where basic element time was found

to depend upon one variable, and so there was correlation

between that variable and the basic element time;

© ‘finally, that category where there was correlation between

the basic element times and two variables (eg, length and

Weight per unit length of the section)

A statistical package ‘Minitab’ was used to analyse the basic

element times. For example, in the analysis of data for the erec-

tion of a structural steel column, a regression equation was pro-

duced by considering combinations of functions of

weight/length, total weight and length. For each equation pro:

duced the coefficient of determination R was examined. This

isa measure of the amount of variation, in basic element times,

from those predicted. For example if R? = 23.5% then the

‘regression equation accounts for only 23.5% of the observed

variation in basic element times. Therefore, a high value of R°

indicates a good correlation between variables. A t-test was per-

formed to indicate whether the functions chosen were useful

predictors in the regression equation. An analysis of variance

was also performed to assess whether there was any statistical

significance between the basic element times from site to site.

DISCUSSION OF RESULTS

Operational information

The data for the operations considered have been summaris-

ed under the following headings:

Operation

Method

Method Description: Erection Gang

Materials and Tools Required

Basic Operation Times

Each operation has also been illustrated with sketches for each

‘element of the operation.

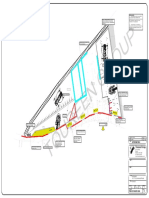

Figures 1 and 2 illustrate the operational information, described

above, for the erection of structural steel columns and beams

respectively.

‘The Basic Operation Times are summarised in Table 1. These

times have been derived by applying the analytical procedures

described in the preceding section.

Table 1: Basic Operation Times

Operation Basic Operation Time

Unloading of structural

steel components,

3.00 minutes per tonne

Erection of a structural stee!

column minutes

4.27 + 0.0332 (length) +

10.65 (weight/length)

Erection of a structural steel

beam

10.6 + 0.513 (length) +

74,53 (weightllength) minutes

‘To line and level a column

using a theodolite in one

direction and a measuring

‘tape in the other

= 12.13 minutes

Lining and levelling of

structural steelwork

To line and level a column

using a measuring tape in

both directions

1.68 minutes

Erection of roof purtir

0.5 minutes per metre length

+ 1.67 minutes per sag rod

Note:— unit of length = metre

unit of weightiength = tonnes/metre

‘The Basic Operation Times for the erection of columns and

beams may be tabulated for various combinations of unit weight

or total weight and length. Alternatively, the information may

be displayed graphically. An example for the erection of a struc-

tural steel beam is given in Figure 3.

Crane utilisation levels

Crane utilisation levels have been defined as

time spent by the crane working

inal ope By ties crate ents Too)

time the crane available for work

Values vary but a typical value was found to be approximately

65%.

Planning times

‘The basic operation time, for a given operation, is a measure

of productivity. However, intermittent periods of unproductive

time occur, with varying frequency, throughout the working day.

‘These periods need to be quantified, in order that planning

times, which include periods of both productivity and unproduc-

tivity, may be obtained.

tt may be argued that the system of rating allows for any varia-

tion in output. However, investigations have shown that there

is little variation in the rate at which operatives work, providing,

there is work available. Far more fundamental to the maximis+

ing of productivity is the minimising of unproductive time.

Therefore, in an attempt to evaluate unproductive time, a con-

‘cept of site factors has been developed. These are, indirectly,

a measure of unproductive time throughout the working day.

‘This study has shown that basic operation times are constant

from site to site. Site factors vary from site to site. The overall

site factor TF is a number by which basic operation times must

‘be multiplied in order to give planning times. The determina-

tion of planning times, therefore, for any one site, requires in-

tegration of both basic operation times and site factors, in order

that the conditions peculiar to that site may be incorporated

in the final result.

‘A detailed discussion of the derivation of site factors is outside

the scope of this paper. On the five sites studied the average

ite factor for the structural steelwork gangs, was in the range

of 1.23 to 1.54 and this represents the increase required in

basic operation times to give planning times. In fact when these

factors are compared with those obtained for other trades they

are comparatively low, which is indicative of a high degree of

motivation and effectiveness.

The build up of planning times is best illustrated by the follow-

ing example. It considers the unloading, erection of columns,

erection of beams and lining and levelling associated with a

‘small steel framed building, on one of the sites visited. In sim:

ple terms this comprised a frame with 12 columns, in a 3 by

4 grid. Each column was connected, at roof height, by beams

in both directions. No purlins were specified.

Operation: Unloading of structural stee! components,

56.30 tonnes at 3.00 per tonne

= 168.90 minutes

Operation: The erection of structural steel columns

Basic Operation Time = 4.27 + 0.0332 (length) + 10.65

(weightilength)

Total Basic

Section Size Length No. __ Operation

305 X 305 X 97 kgim 4.485m 4 21.81 minutes

305 X 305 X97 kgim 4.742m 421.84 minutes

305 X 305 X 97 kgim 5.148 4 21.90 minutes

Total 65.55 minutes

Operation: The erection of structural steel beams

Basic Operation Time = 0.66 + 0.513 (length) + 10.65

(weight/length)

Total Basic

Section Size Length No. Operation Time

915 X 305 X 179 kgim 13.500m 4125.56 minutes

800 X 210 X 109 kgim 13.500m 3 47.13 minutes

689 X 191 X 74 kg/m 10.305m 10 114.62 minutes

915 X 305 X 149 kgim 16.230m 10 194.31 minutes

Total = 481.61 minutes

Operation: The lining and levelling of structural steel frames

To line and level a structural steel framed building.

4 columns in length x 3 columns in width

Including all internal columns

Basic Operation Time = 154.00 minutes

Total Basic Operation Time

(for the four operations considered)

= 870.06 minutes

Site Factor TF (for the whole gang over

the duration of the job)

1.42

Planning Time (per gang)

(compares with 1200 minutes actual time)

= 1236.48 minutes

Itis interesting to note that structural steel erection, on the

sites observed, mostly took place in gangs of three operatives.

However, when that number was either increased, or decreas:

ed, there was no statistical significance between the basic

operation times.

Internal delay (or interference) expressed by site factor IF is

inherent in the erection of structural steelwork. However, these

studies indicated no correlation between internal delay and the

overall site factor TF.

A plot of crane utilisation levels versus site factor due to inter:

nal interference IF indicates that higher levels of crane utilisa

tion are obtained for larger values of IF. This trend is as ex

pected, as, to maximise use of the crane, itis necessary to sub-

ject the operatives to an increased amount of internal in-

terference (ie, waiting while the crane is working). This may

‘not necessarily be the optimum solution, as this will depend

(on the relative costs of labour and plant.

Examination of crane utilisation levels compared with overall

Site factor TF indicates that maximum crane utilisation occurs

when TF is minimised. This again would be expected as

minimum TF equates to maximum operative efficiency.

‘A graph of daily output, in tonnes, against site factor TF, is

‘shown in Figure 4. itis difficult to draw any precise conclusions

{rom this, as on days when unloading, and lining and levelling,

are occurring, the tonnage of steel erected willbe reduced. Also

the tonnage of steel erected will depend on the size and weight

Of the sections involved. However, it serves to illustrate the

trend that increased productivity occurs when efficiency of

labour is optimised. It also gives an indication of the tonnage

which could reasonably be expected to be erected during a

given day.

CONCLUSION

‘A combination of the techniques of activity sampling and time

study has been used to observe the structural steel erection

phase of five medium sized steel framed buildings. These

techniques have been shown to be both appropriate and ef-

fective tools in determining productivity data.

Output has been measured, both globally, and as basic element

times required to erect component.

4

Equations have been derived for the basic operation times to

erect structural steel columns and beams. These have been

found to depend upon both length and weight per unit length

of the components. The basic operation times for the unloading,

and lining and levelling of structural steel components have

‘been found to depend upon one variable only. The basic opera-

tion time for the erection of purlins has been found to depend

‘upon both length and the number of sag rods.

The data collected have also been used to obtain a series of

site factors, which are a measure of the motivation of the

operatives, and the effectiveness of the management. On the

sites studied these factors indicated that steel erectors were,

generally, highly motivated when compared with other con

struction operatives.

Crane utilisation levels have been measured and found, as ex-

ected, to be dependent upon these site factors.

Daily output is increased where efficiency, indicated by the site

factors, is increased though some allowance must be made for

the size of each component.

The planning times predicted by these equations, modified by

the overall site factor, compared favourably with the actual

times taken

In conclusion, application of work study techniques and subse-

quent rigorous data analysis, can lead to the determination of

accurate productivity data which will, ultimately, lead to im-

proved estimating and planning.

REFERENCES

1. ROSE, K.J. (1986) Variability of estimating constants, BSc

project report, Department of Building Engineering, UMIST.

2. HARRIS, F.C., An evaluation of production output for con-

struction labour and plant, SERC Research Grant GRIB

55138, 1981-1984.

3. GEARY, R., (1962) Work Study Applied to Building, Godwin.

4. BRITISH STANDARDS INSTITUTION (1979). Glossary of

Terms used in work study and organisation and method. BS

3138,

5. EMSLEY, M.W. and HARRIS, F.C., (1986) Work study is im-

portant to construction, Building Technology and Manage-

‘ment, April, pp 10-15.

BASIC OPERATION TIMES

operation

Erection to a structural steel beam.

Method

A crane is used to erect a structural steel beam.

Method Description: Erection Gang

Chains are fastened around the beams to be lifted, and the crane

moves the beam to its designated position. Bolt holes in the bean

are aligned with the corresponding bolt holes in the column, at both

ends, and the beam bolted to the column.

Materials and Tools Required

(a) Crane

(b) Lifting tackle

(ce) Nuts and bolts

(4) Spanners to fit bolts

(e) Ladders

Figure 1: Operational information for the erection of a structural stee! column

METHOD STATEMENT.

‘The erection of 8

1 Cheek reduced

level st underside

‘of column bateplate

2, Place shims

3. Undo nuts on

hlaing down bolts

4, Reter to dige

(if races}

5, Fasten chains to

top of column

8. Guice column ait

emoved by the

7. Lower column onto

holding down bolts

8. Screw nuts onto

otging down bolts

and tighten

2. Roughly check plumb

10. Undo eneins

11. Move erane jib to

Figure 2: Method statement for the erection of a structural steel column

26

22 +

1

4

10

(sanuiw) 3WIL NOLLVH3d0 DISVE

(metres)

LENGTH

Figure 3: Basic Operation Times (Minutes)

For the erection of structural steel beams

Time (minutes) v Length (metres) v Weight (ke/metre)

+ r

2 a ° .

(Auep) @319343 1331S JOVNNOL

1.50

1.40

1.30

1.20

1.10

{Structural steel erectors)

T

SITE FACTOR F

Figure 4: Tonnage stee! erected (daily) v Site Factor TF (Structural stee! frames)

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- DD Cen TS 1992-4-1-2009Document68 pagesDD Cen TS 1992-4-1-2009Kovacs Zsolt-IstvanNo ratings yet

- General foundation notes and detailsDocument1 pageGeneral foundation notes and detailsAnonymous qEPNPwANo ratings yet

- Data Center-55000 Sqft-A1Document1 pageData Center-55000 Sqft-A1Anonymous qEPNPwANo ratings yet

- General Notes:: SSL +72.910 MDocument1 pageGeneral Notes:: SSL +72.910 MAnonymous qEPNPwANo ratings yet

- Data Center Campus-A1Document1 pageData Center Campus-A1Anonymous qEPNPwANo ratings yet

- General Notes:: Finishes To Architects Details Finishes To Architects DetailsDocument1 pageGeneral Notes:: Finishes To Architects Details Finishes To Architects DetailsAnonymous qEPNPwANo ratings yet

- Ewp ZZ XX M3 S 0001 Wip 200609 PDFDocument1 pageEwp ZZ XX M3 S 0001 Wip 200609 PDFAnonymous qEPNPwANo ratings yet

- General notes for foundation drawingDocument1 pageGeneral notes for foundation drawingAnonymous qEPNPwANo ratings yet

- General notes for construction drawingsDocument1 pageGeneral notes for construction drawingsAnonymous qEPNPwANo ratings yet

- Geometric Properties: Ed C, RDDocument1 pageGeometric Properties: Ed C, RDAnonymous qEPNPwANo ratings yet

- General Notes:: W A LLDocument1 pageGeneral Notes:: W A LLAnonymous qEPNPwANo ratings yet

- Slab Soffit: 4"concrete LineDocument1 pageSlab Soffit: 4"concrete LineAnonymous qEPNPwANo ratings yet

- General Notes:: W A LLDocument1 pageGeneral Notes:: W A LLAnonymous qEPNPwANo ratings yet

- Point Loads: Party Wall 292-01.196.19 - L&P Loads - S - 100 - 01Document4 pagesPoint Loads: Party Wall 292-01.196.19 - L&P Loads - S - 100 - 01Anonymous qEPNPwANo ratings yet

- Toureen Group: Stage3 - Piling + UnderpinningDocument1 pageToureen Group: Stage3 - Piling + UnderpinningAnonymous qEPNPwANo ratings yet

- Temporary welfare measures during demolitionDocument1 pageTemporary welfare measures during demolitionAnonymous qEPNPwANo ratings yet

- Case 2Document8 pagesCase 2Anonymous qEPNPwANo ratings yet

- DsdaDocument6 pagesDsdaAnonymous qEPNPwANo ratings yet

- Owo Ewp ST DRW X B6 10 0300Document1 pageOwo Ewp ST DRW X B6 10 0300Anonymous qEPNPwANo ratings yet

- N010 - C1 PDFDocument1 pageN010 - C1 PDFAnonymous qEPNPwANo ratings yet

- Multilateral. Multilateral.: Construction IssueDocument1 pageMultilateral. Multilateral.: Construction IssueAnonymous qEPNPwANo ratings yet

- J. Bloggs Checked: S. SmithDocument1 pageJ. Bloggs Checked: S. SmithAnonymous qEPNPwANo ratings yet

- Crane Plan Appendix B - 60 TonDocument1 pageCrane Plan Appendix B - 60 TonAnonymous qEPNPwANo ratings yet

- AS DSM Guide 2011 EN PDFDocument90 pagesAS DSM Guide 2011 EN PDFAnonymous qEPNPwANo ratings yet

- Plan - 400x400 Plan - 450x450 Plan - 700x350 Area in AbeyanceDocument1 pagePlan - 400x400 Plan - 450x450 Plan - 700x350 Area in AbeyanceAnonymous qEPNPwANo ratings yet

- Pages From 4170FinRep - Rev1 Final ReportDocument17 pagesPages From 4170FinRep - Rev1 Final ReportAnonymous qEPNPwANo ratings yet

- FJ56 Flat Jack: Isolation Valve 512 560Document1 pageFJ56 Flat Jack: Isolation Valve 512 560Anonymous qEPNPwANo ratings yet

- CBR Test Results for Clay SoilDocument7 pagesCBR Test Results for Clay SoilAnonymous qEPNPwANo ratings yet

- Iss 161125 Issue SheetDocument2 pagesIss 161125 Issue SheetAnonymous qEPNPwANo ratings yet

- Rep 170106 Structural Statement Addendum p1Document28 pagesRep 170106 Structural Statement Addendum p1Anonymous qEPNPwANo ratings yet