Professional Documents

Culture Documents

HAZARD IDENTIFICATION PLAN FOR PIPELINE DEMOLITION

Uploaded by

princeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAZARD IDENTIFICATION PLAN FOR PIPELINE DEMOLITION

Uploaded by

princeCopyright:

Available Formats

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

CATEGORY

HSE PROCEDURE

TITLE

HAZARD IDENTIFICATION PLAN (STM Area)

DOCUMENT

REFERENCE

NSH-SAOMPP-HSE-GE-11

Page 1 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

HAZARD IDENTIFICATION PLAN FOR STM

AREA

NSH-SAOMPP-HSEGE-006

Rev-00

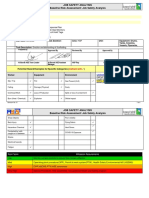

00

Revisin

15TH Feb 2015

Date

Date: 15th FEB-2015

For Review

Description

PRINCE JOSE

Prepared By

MOHAN PILLAI

Reviewed By

BOBBY PAUL

Approved By

REVISION HISTORY

Index

1. Background

2. Objective

3. Assignment of Responsibility

4. Types of Hazards and Controls

4.1 Process safety related hazards

4.2 Survey

4.3 Demolition

4.4 Civil Work/ Concreting

4.5 Erections Pipe and Structure

4.6 Electrical

4.7 Welding

4.8 Trust boring

4.9 Controlled Blasted

4.10

Flow Line Tie In

4.11

Hydro testing

4.12

Final Inspection.

4.13

General Health and Safety Related Hazards.

4.14

Loss of Amenity to Workforce and Community

Page 2 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

4.15

Other Risk to The Biophysical Environment

4.16

Training

5. Program Review

6. Attachments

Appendix A: Risk Survey

Appendix B: Safety Checklist

HAZARD IDENTIFICATION PLAN DEMOLITION OF PIPELINE

General Information

NSH is contracted for installation of all phases of well sites, flow lines,

trunk lines, laterals, headers, manifolds, transfer lines and any other

pipelines with all associated facilities, such as instrumentation,

communication, fencing, site preparation, civil work, and mechanical

work in Northern Area as requested by SAUDI ARAMCO.

The contract comprises of installation of all phases of well tie-in piping,

which includes but is not limited to communications, Electrical &

Instrumentation, Civil/structural, flow lines, water injection lines, trunk

lines, test lines, production and test headers, and any other pipelines

directed by SAUDI ARAMCO in the Onshore Oil and Gas fields.

1.

BACKGROUND

Page 3 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Nasser S Al-Hajri Corporation is committed to provide safe work environment to its

workforce and keep them trained and informed of the same to empower and equip them to

act with the full knowledge of the safety systems available to them at their disposal in case

of emergency. Towards this Nasser S Al-Hajri Corporation complies with all applicable Laws

and encourage its workforce to discharge their duties bounded within the confines of the

rules and regulations which are operable at work site. This Hazard Identification Plan

identifies the hazards and its control measure during demolition constructions phase of the

pipelines which would serve to reduce the risk Health Safety and Environment in the

following ways.

Identifies the hazards that would be encountered during the processes involved till

the completion of the Project.

Identifies the hazards that are prevalent all throughout the phase generally.

Identifies the hazards that can be of concern to the community and environment.

Arrives at the control measures to be put in place to effectively reduce or nullify the

threats of the hazards.

Identifies the persons responsible for control, monitor and report on the hazards and

its control measures.

Plan the training for the workforce and staff engaged in this activity.

2.

OBJECTIVE:This Hazard Identification Plan identifies and assesses hazards associated with the

following activities while carrying out the job stated in STM Area of the contract:

Survey

Demolition

Civil work/concreting

Page 4 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Erections pipe and structure

Electrical

Welding

Trust boring

Controlled blasting

Flow line tie in

Hydro testing

Final Inspection

It also provides employees with information and guidelines that will assist them in

recognizing, reporting, and controlling fire hazards.

3.

ASSIGNMENT OF RESPONSIBILITY

Safety is everyone's responsibility. All employees should be aware of the hazards present

at the work site and how to respond in emergency situations.

3.1 Management

Management states the policies of Nasser S Al Hajri Corporation regarding

Occupation Health and environmental protection. They would also in turn identify

the procedures to be followed during the different phases of the project.

Management will also provide adequate resources in the form of man-hours and

material to ensure effective training is imparted to all personnel before entering

work site regarding the safety requirements and connected rules and regulations.

3.2 HSE Manager

Page 5 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Project HSE manager would implement all management decisions without any

dilution and also execute the plans and procedures made for the purpose. He

shall also be responsible for the communication, documentation and training on

the matter.

Develop and administer the Nasser S Al Hajri Corporation training

program.

Ensure that all equipments and materials required for the safety

measures are in working order and available at site.

Monitor the daily HSE supervision activities at site to provide sufficient

HSE coverage.

Act on any observation/ suggestion/ feedback from any person entering

the site regarding potential Hazards and its control measures.

3.3 Supervisors

Supervisors are responsible for ensuring that employees receive appropriate

training, and for notifying, when changes in operation increase the existing.

Supervisors are also responsible for enforcing Nasser S Al Hajri Corporation

control measures put in place to contain the Hazards identified for the demolition

of pipeline activity,

3.4 Employees

All employees shall:-

Page 6 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Complete all required training before working with supervision.

Conduct operations safely to limit the risk.

Report potential safety hazards to their supervisors.

Follow an emergency procedures.

4.

4.1

TYPES OF HAZARDS AND CONTROLS

A list of hazards associated with the demolition and constructions work is listed in

the table given below

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH SURVEYING

01

Heat Stress

02

Fatigue and dehydration

03

Reptiles and harmful insects

04

Exposure to prolonged sun glare

05

Exposure to dust and hostile environmental conditions like dust storm, rain etc.

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH DEMOLITION

06

Damage to adjacent plant or equipment due to uncontrolled and/or unplanned falling

of structure, object or crane collapse.

07

Damage to live pipe work during removal or inadvertent cutting into live pipe or

08

09

10

Pipeline.

Failure to isolate process equipment.

Damage to underground cables and/ or oily water sewer

Introduction of ignition sources into area classified as Hazardous Area

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH CONCRETING/ CIVIL

WORK

Page 7 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

11

12

13

14

15

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Exposure to cement dust

Cement debris accumulation

Waste management issues related to wasted cement

Material handling injuries and health issues(Skin Allergy)

Exposed Rebar

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH ERECTIONS

16

Crane Collapse

17

Striking against equipment

18

Overloading of crane/Sling belt

19

Unstable ground/Un compacted ground

20

Proximity to overhead Power lines

21

Heavy wind/Sand Strom

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH ELECTRICAL

WORK

22

Electrical Shock

23

Fall from heights

24

Short Circuits

25

Fire Hazard

26

Entanglement due to poor cable management

4.1 PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH WELDING

27

Fire & Explosion

28

UV radiation

30

Welding fumes

31

Poor earthling system

32

Electric shock

33

Excessive Glare due to welding arc

Page 8 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH THRUST BORING

34

Flying Debris

35

Bore Hole giving in

36

Damage to underground Utility Services

37

Sparks

38

Dust

39

Property loss due to equipment overload

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH CONTROLLED

BLASTING

40

Exposure to pressure wave of blasting

41

Exposure to Sudden high decibel sound blast

42

Exposure to flying splinters/ debris

43

Exposure to high intensity flash

44

Exposure to dust cloud

45

Exposure to heavy reverberation/vibrations

46

Caving in of earth

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH FLOW LINE TIE-IN

Accidental Spillage

47

Fluid Jetting Out/Leakage/splash

48

Flying Objects in the event of joints giving away making fitments flying away

49

Exposure to paint vapour during painting

50

Exposure to harmful radiation while radiography

PROCESS SAFETY RELATED HAZARDS ASSOCIATED WITH HYDROSTATIC TESTING

51

Accidental Spillage

52

Fluid Jetting Out through faulty joints

53

Flying Objects in the event of joints giving away making fitments flying away

Page 9 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

54

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Pressure blasts due to inadequate material strength

General Health and Safety Related Hazards

55

Crushing or impact Injuries

56

Fall from heights

57

Worker trapped (inside confined space)

58

Subsidence and Collapse/Fall into excavation

59

Public and traffic hazardous interaction on public roads or foot path

60

Loss of material in transit leading to traffic incident and potential injury

61

Exposure to airborne hazardous material, or skin contact with such materially metals

62

Heavy, chemicals etc)

Contact with live overhead power lines.

Loss of Amenity to Workforce and Community

63

Discomfort from odour associated with removal and disposal of cooling water

64

65

66

67

pipelines (Smell- No Health Hazard)

Offensive odour and community complaints from mercaptan

Noise generation

Dust Cloud from various activities

Flying splinters/debris from the blasting activities

Other Risk to the Biophysical Environment

68

Incorrect classification of waste leading to contamination of trucks and potential

69

70

71

72

delivery to wrong landfill location

Re-Contamination of opened pipe work.

Dust cloud giving rise to atmosphere pollution

Noise Pollution generated from the activities

Waste generation due to the project activities

Control Activities

SNO

Activity

Control Measures

Page 10 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

01

Survey

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Work only at bright light

Barricade around existing pits / trench if any.

Legs of the tripod shall be well secured into ground.

No activity at the time of heavy wind, sand storm.

Provide certified flagman and control vehicle

Safety Helmet

Safety Boot

Safety Coverall/Pant shirt with full sleeves.

Safety Gloves

Face Mask

Safety glass

Reflective Jacket

02

Demolition

Training

Safety signs/boards/ posters

Safety Helmet

Safety Boot

Safety Coverall

Safety Gloves

Face Mask

Safety glass

Reflective Jacket

03

Civil Work/

Hard Barricading

Concreting

Training

Page 11 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

FIRE watch

Warning signs

Safety posters

Safety Helmet

Safety Boot

Safety Coverall

Face Mask

Eye Wash/ Face/Hand Wash

Rest Breaks

04

Erections

Hard Barricading

Protective Barriers for the stalked pipes

Training

FIRE watch

Aramco Certified rigger

Measurement of wind speed using anemometer

Safety signs/boards/ posters

Safety Helmet

Safety Boot

Safety Coverall/Reflective Jacket

Safety Glass

05

Electrical

Safety Gloves

Hard Barricading

Circuit Breaks and ELCBs.

Conduit Cables for transmission cables

Page 12 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Training

DCP/CO2 Fire Extinguisher

FIRE watch

Competent person

LOTO

Warning signs, messages boards and posters

Safety Helmet

Safety Boot/ Rubber Boots

Safety Coverall/Reflective Jacket

Face Mask

Electrical Gloves

06

Welding

Ventilator

Fabrication of Welding Booth / Welding wind shields

Carrying trolley for compressed Gas Cylinders

Cable conduit

Flash back arrestor

Training

FIRE watch

Safety signs/boards/ posters

Good Housekeeping

Welding Goggles

Welding Apron

Welding Helmet

Welding Gloves

Page 13 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Safety Boot

Safety Coverall/Reflective Jacket

07

THRUST BORING

Face Mask

Cooling Jet to Cool of the drilling bit

Training

FIRE watch

Safety signs/boards/ posters

Safety Helmet

Safety Boot

Safety Coverall/Reflective Jacket

Face Mask

Safety Gloves

08

CONTROLLED

Safety Glass

Hard Barricading

BLASTING

Erecting Screens as a means of protection

Safety signs/boards/ posters

Training

FIRE watch

Safety Helmet

Safety Boot

Safety Coverall/Reflective Jacket

Face Mask

FLOW LINE TIE-IN

Safety Glass

Hard Barricading

Carrying trolley for compressed Gas Cylinders

Page 14 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Training

FIRE watch

Safety signs/ boards/ posters

Safety Helmet

Safety Boot

Safety Coverall/Reflective Jacket

Safety Glass

HYDROSTATIC

Face Mask

Usage of break Tanks for storage or check tanks for slow water

TESTING

dissipation.

Whip Lash Arrestor

Training

Safety signs/boards/ posters

Good House keeping

Safety Helmet

Safety Boot

Safety Coverall/Reflective Jacket

Safety Gloves

Face Mask

Safety Glass

5.

TRAINING

Responsible Person shall impart training to all concerned covering all the relevant safety

topics for the activity. He also shall prepare and maintain documentation of the training,

which includes:

Page 15 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Review of CFR 1926: Subpart T, 1926.21(a) and how to incorporate the

relevant sections into the safety procedure.

The Hazard Identification Plan and how it will be made accessible to the

work force.

Maintain documentation of feedbacks to be incorporated into the training

sessions.

Impart training and awareness on Emergency response plan at demolition

site.

Plan and assist in conducting mock drills

Recognition of potential hazards through interviews and feedbacks.

Supervisors shall train employees about the hazards associated with the demolition

activities and will maintain documentation of the training. Employees will receive this

training:

On their initial assignment.

Annually and

When changes in work processes necessitate additional training.

6.

PROGRAM REVIEW

Responsible Person shall review this Hazard Identification plan according to the following: Annually

In the event of an incident occurring at site wherein the mitigation measures to

contain its repetition in future should be wedged into the HIP.

In the event of observation/comments from the external auditors

Page 16 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

HAZARD IDENTIFICATION PLAN FOR STM

AREA

NSH-SAOMPP-HSEGE-006

Rev-00

Date: 15th FEB-2015

In the event of advice from competent authority.

6.

Attachments

Appendix A

Risk Survey:

Company Name:

Location:

Type of Hazard

Location

Emergency Actions

Required PPE

Page 17 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Page 18 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Completed by: __________________________

Date:

__________________Appendix B

SAFETY CHECKLIST

PART ONE - INITIAL CLEARANCES and APPROVALS

Conducted site visits/inspections to verify the location and identification of Hazards-

Yes/No

Prepared documentation - photos, drawings check list etc.

Yes/No

Statutory Checklist made for the site and activities

Yes/No

Environmental Assessment carried out for the site and the activities.

Yes/No

Environmental testing for possible contaminants by authorized third party

Yes/No

Putting up warnings, signs and posters carried out

Yes/No

Utility Disconnections and Clearance taken: (Water/Gas/fuel/ Electricity)

Yes/No

PART TWO - ACTUAL DEMOLITION:

Necessary Work Permit is obtained

Yes/No

Has a competent supervisor, experienced in demolition work, been appointed?

Yes/No

Are all onsite employees sufficiently trained and competent to complete their

tasks and duties safely?

Yes/No

Are all site personnel wearing the correct personal protective clothing and equipment

for the work at all times, and is the clothing/equipment being maintained effectively?

Yes/No

Is the site properly enclosed and are protective screens erected?

Yes/No

Have danger notices been erected? Is all access to the site regulated?

Yes/No

Are all ladders and other equipment in good order?

Yes/No

Is sufficient watering taking place to keep down dust?

Yes/No

Are there sufficient fire extinguishers or other fire-fighting equipment onsite, and are

they readily accessible?

Yes/No

Page 19 of 17

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL

PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-HSEGE-006

Rev-00

HAZARD IDENTIFICATION PLAN FOR STM

AREA

Date: 15th FEB-2015

Are good housekeeping practices being maintained?

Yes/No

Does all electrical equipment have been colour code to verify safety for use?

Yes/No

Page 20 of 17

You might also like

- MIP17 - HSE - PP - 023 Hazardous Waste Storage-Handling REV 1Document13 pagesMIP17 - HSE - PP - 023 Hazardous Waste Storage-Handling REV 1AmeerHamzaWarraichNo ratings yet

- MIP17 - HSE - PP - 011 PPE Needs Analysis REV 1Document20 pagesMIP17 - HSE - PP - 011 PPE Needs Analysis REV 1AmeerHamzaWarraichNo ratings yet

- Preparation and Mobilization SafetyDocument14 pagesPreparation and Mobilization SafetyGurumoorthy Rajavijayan100% (2)

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Document31 pages14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- HSE Plan for Saudi Power ProjectDocument29 pagesHSE Plan for Saudi Power ProjectAsif Khanzada63% (8)

- Jsa & Hip PlanDocument7 pagesJsa & Hip Plansaquib_jamadar100% (1)

- P. Hazard Identification ProgramDocument23 pagesP. Hazard Identification ProgramYounis Khan100% (1)

- 001 - JSA For Back Filling - TCF AreaDocument5 pages001 - JSA For Back Filling - TCF AreaSalah Abd Eldayem100% (2)

- Man-Machine Interface Program (Revised)Document11 pagesMan-Machine Interface Program (Revised)Arjun Satheesan50% (2)

- Aramco HSE Roles & RespDocument16 pagesAramco HSE Roles & RespArshad Mahmood0% (1)

- Jsa - Hot TappingDocument15 pagesJsa - Hot TappingAmadeo Sabanal0% (1)

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Document27 pages20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- Contractors Safety ObservationsDocument3 pagesContractors Safety ObservationsFarrukh JavedNo ratings yet

- HIP For AramcoDocument6 pagesHIP For Aramcoahsanhasan84No ratings yet

- 73 SP-JSA-Mandrel Test in Ductbank Inside ManholeDocument7 pages73 SP-JSA-Mandrel Test in Ductbank Inside Manholeabrahmanjazbi100% (2)

- Job Safety Analysis Work SheetDocument10 pagesJob Safety Analysis Work SheetJayvee Baradas ValdezNo ratings yet

- Pre-Qualification Safety Requirements of RC JubailDocument6 pagesPre-Qualification Safety Requirements of RC JubailRenatoNo ratings yet

- Ete Hse Plan and DocumentsDocument20 pagesEte Hse Plan and DocumentsREMYANo ratings yet

- Hip Plan - Hvac WorkDocument30 pagesHip Plan - Hvac WorksrisetNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdDocument3 pagesJob Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdTeodoro EsquilloNo ratings yet

- Permit To Work ProcedureDocument5 pagesPermit To Work ProceduresinghajitbNo ratings yet

- ARK JSA 0 Rev 00 Crane LiftingDocument6 pagesARK JSA 0 Rev 00 Crane LiftingREMYANo ratings yet

- ADCO Approved HSE EquipmentDocument71 pagesADCO Approved HSE EquipmentManikandan VijayanarayananNo ratings yet

- Marafiq Risk Assessment 02Document5 pagesMarafiq Risk Assessment 02Arshad Mahmood50% (2)

- 340AJ Risk AssessmentDocument7 pages340AJ Risk AssessmentMyaIdzaharNo ratings yet

- Job Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityDocument7 pagesJob Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityMuhammad TariqNo ratings yet

- Hse Action Plan 2019 Marafiq JubailDocument17 pagesHse Action Plan 2019 Marafiq Jubailjonathan camba100% (5)

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Minhaj60% (5)

- Confined Space Entry PlanDocument2 pagesConfined Space Entry PlanAmeerHamzaWarraichNo ratings yet

- Job Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisDocument7 pagesJob Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisSKH CultureNo ratings yet

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocument6 pagesSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaNo ratings yet

- Confined Space Entry PlanDocument12 pagesConfined Space Entry PlanMansoor BabarNo ratings yet

- Safety Talk On-Safety During ShutdownDocument10 pagesSafety Talk On-Safety During Shutdownchakri4all100% (1)

- DOR-HSE Observations-Zone 01-04nov19Document27 pagesDOR-HSE Observations-Zone 01-04nov19Aravindhan Ganesan100% (1)

- Contractor Pre-Job Safety Explanation Meetings Guide 07-003-2012Document46 pagesContractor Pre-Job Safety Explanation Meetings Guide 07-003-2012LAWRENCE100% (2)

- Chemical Handling ProcedureDocument15 pagesChemical Handling ProcedureGHULAM MOHYUDDINNo ratings yet

- Risk Assessment Chemical CleaningDocument1 pageRisk Assessment Chemical CleaningJohn Vem Bansag100% (2)

- SA 924 4 Green PrintDocument2 pagesSA 924 4 Green PrintAbdus SamadNo ratings yet

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- Revised JHA HDDDocument12 pagesRevised JHA HDDHariharan RajaramanNo ratings yet

- JSA 02-03 Vertical Borehole and Anode Bed InstallationDocument5 pagesJSA 02-03 Vertical Borehole and Anode Bed InstallationHaleemUrRashidBangash100% (1)

- TR 167-01-061 01 Contractors ES H Program PlanDocument138 pagesTR 167-01-061 01 Contractors ES H Program PlanErnesto SerranoNo ratings yet

- JHA of Painting PDFDocument3 pagesJHA of Painting PDFTanver Ali100% (1)

- Night PlanDocument5 pagesNight PlanSyed Ali Hassan100% (1)

- Jsa 035Document10 pagesJsa 035Mohammad Anwar Hossain100% (1)

- Chemical Hazard Bulletin No. 0188: OxygenDocument2 pagesChemical Hazard Bulletin No. 0188: Oxygenshinto LawrenceNo ratings yet

- Attachment A3 Contractor Pre-Qualification Safety Evaluation Inquiry and Submittal ContentsDocument8 pagesAttachment A3 Contractor Pre-Qualification Safety Evaluation Inquiry and Submittal ContentsSathi sh100% (1)

- Hydro Jetting and Sludge RemovalDocument18 pagesHydro Jetting and Sludge Removalmarvin100% (1)

- Emergency Response PlanDocument10 pagesEmergency Response PlanJaseelKanhirathinkal100% (1)

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocument23 pagesJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDNo ratings yet

- Life Saving RulesDocument19 pagesLife Saving RulesKARTHIKBALUNo ratings yet

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- Confined Space EntryDocument15 pagesConfined Space EntryEnginnering Section100% (1)

- JSA Sump CleaningDocument2 pagesJSA Sump CleaningPanchdev Kumar100% (1)

- Saudi Aramco Safe Fueling ProcedureDocument16 pagesSaudi Aramco Safe Fueling Procedurerana qamarNo ratings yet

- DOCUMENT Job Hazard AnalysisDocument11 pagesDOCUMENT Job Hazard AnalysisFrancis Enriquez Tan0% (1)

- Job Safety Analysis Work SheetDocument7 pagesJob Safety Analysis Work SheetTomNo ratings yet

- Part II - 08 Abrasive BlastingDocument5 pagesPart II - 08 Abrasive Blastingsalah abddayemNo ratings yet

- Proposed Tia 1325 Nfpa 5000 CH 21Document3 pagesProposed Tia 1325 Nfpa 5000 CH 21princeNo ratings yet

- Gas monitoring checklist for ISO standards complianceDocument1 pageGas monitoring checklist for ISO standards complianceprinceNo ratings yet

- CFPA E Guideline No 26 2010 FDocument30 pagesCFPA E Guideline No 26 2010 Fdvs99No ratings yet

- Ra For EarthingDocument5 pagesRa For EarthingprinceNo ratings yet

- Inspection Checklist Chain BlockDocument2 pagesInspection Checklist Chain Blockprince100% (3)

- List of Mandatory Documents - IMSDocument1 pageList of Mandatory Documents - IMSprince100% (1)

- Ra For EarthingDocument5 pagesRa For EarthingprinceNo ratings yet

- RA For Equipment InstallationDocument2 pagesRA For Equipment InstallationprinceNo ratings yet

- Gas Monitoring Checklist: Integrated Management System (ISO 9001:2015, ISO 14001:2015 & OHSAS 18001:2007)Document1 pageGas Monitoring Checklist: Integrated Management System (ISO 9001:2015, ISO 14001:2015 & OHSAS 18001:2007)princeNo ratings yet

- RA For Fire Detection SystemDocument4 pagesRA For Fire Detection SystemprinceNo ratings yet

- Ra For Fire Protection Piping Installation WorksDocument7 pagesRa For Fire Protection Piping Installation WorksprinceNo ratings yet

- RA For Equipment InstallationDocument2 pagesRA For Equipment InstallationprinceNo ratings yet

- Excavation Checklist Pocket CardDocument2 pagesExcavation Checklist Pocket CardprinceNo ratings yet

- Fire Protection Plan - 1Document11 pagesFire Protection Plan - 1princeNo ratings yet

- MAB-Emergency Evacuation Plan Rev OA (Repaired)Document20 pagesMAB-Emergency Evacuation Plan Rev OA (Repaired)princeNo ratings yet

- Constr. Safety JeopardyDocument25 pagesConstr. Safety JeopardyprinceNo ratings yet

- Daeling With Hazards and RisksDocument121 pagesDaeling With Hazards and RisksprinceNo ratings yet

- Saudi Hse LAWS and Its ChecklistDocument19 pagesSaudi Hse LAWS and Its ChecklistprinceNo ratings yet

- Excavation Checklist Pocket CardDocument2 pagesExcavation Checklist Pocket CardprinceNo ratings yet

- Excavation CollapseDocument3 pagesExcavation CollapseprinceNo ratings yet

- Hip Oil WellsDocument30 pagesHip Oil WellsprinceNo ratings yet

- Concrete Pipe Installation Guide-CPMDocument17 pagesConcrete Pipe Installation Guide-CPMSankar CdmNo ratings yet

- Oil and Gas Cyber Security From SAP To ICSDocument49 pagesOil and Gas Cyber Security From SAP To ICSmmagdiNo ratings yet

- Piping EngineerDocument4 pagesPiping EngineerMasoodMiyanNo ratings yet

- Midstream Applications For Oil and GasDocument8 pagesMidstream Applications For Oil and Gasjhon berez223344No ratings yet

- Chapter VI-0623c3a873ca902.59818737Document10 pagesChapter VI-0623c3a873ca902.59818737Ali NasseriNo ratings yet

- Hasbah Offshore Gas Facilities Increment-II: Project at A Glance Field InformationDocument2 pagesHasbah Offshore Gas Facilities Increment-II: Project at A Glance Field InformationAltamas RehanNo ratings yet

- The Approximate Equation in My KnowledgeDocument3 pagesThe Approximate Equation in My KnowledgeOvaid Mehmood100% (1)

- Iso 3171 1988Document13 pagesIso 3171 1988Yagmur SimsekNo ratings yet

- Service Intakes Outfalls Marine Pipelines SDocument2 pagesService Intakes Outfalls Marine Pipelines SJusron MasjhudaNo ratings yet

- PTS Index To PTSDocument47 pagesPTS Index To PTSDandy Harris FirdiandaNo ratings yet

- Pertemuan 9-10 PPPKDocument74 pagesPertemuan 9-10 PPPKEKO PRIBADINo ratings yet

- Vol II of II 20181203 120035 PDFDocument259 pagesVol II of II 20181203 120035 PDFGilberto YoshidaNo ratings yet

- 5 Pipe Loops Versus Compression: 2785 - C005.fm Page 177 Friday, April 1, 2005 3:30 PMDocument24 pages5 Pipe Loops Versus Compression: 2785 - C005.fm Page 177 Friday, April 1, 2005 3:30 PMMMMOH200No ratings yet

- AAVANTIKA GAS LTD CNG AND CITY GAS DISTRIBUTION PROJECT LAST MILE CONNECTIVITY (LMC) WORK AT GWALIOR GA VOL II TECHNICALDocument385 pagesAAVANTIKA GAS LTD CNG AND CITY GAS DISTRIBUTION PROJECT LAST MILE CONNECTIVITY (LMC) WORK AT GWALIOR GA VOL II TECHNICALBorislav VulićNo ratings yet

- Modeling Pipeline HydraulicsDocument14 pagesModeling Pipeline Hydraulicsac2475100% (1)

- Subsea Umbilical, Riser Flowline Installation: National Unversity of SingaporeDocument39 pagesSubsea Umbilical, Riser Flowline Installation: National Unversity of SingaporeYohanest ChandraNo ratings yet

- Basics Water Supply Systems Local Management TrainingDocument65 pagesBasics Water Supply Systems Local Management TrainingJeraldine AgarpaoNo ratings yet

- Measuring Water in Crude OilDocument4 pagesMeasuring Water in Crude OilEryl YeongNo ratings yet

- 353.FoamglassAssamblyDocument12 pages353.FoamglassAssamblyCeratita ClarkNo ratings yet

- Outdoor Unit and Installation (T1)Document92 pagesOutdoor Unit and Installation (T1)Diêm Công ViệtNo ratings yet

- Instruction Manual: LKH Centrifugal PumpDocument70 pagesInstruction Manual: LKH Centrifugal PumpService CTANo ratings yet

- Saep 306Document13 pagesSaep 306brecht1980No ratings yet

- DBNPP MDM1 ASYYY 07 342001 0001 - Rev03Document31 pagesDBNPP MDM1 ASYYY 07 342001 0001 - Rev03Krishnan KrishNo ratings yet

- CV ERWAN NOOR 18 Mar 2011Document5 pagesCV ERWAN NOOR 18 Mar 2011Erwan NoorNo ratings yet

- IPTC-20219-MS A Systematic Approach To Increase Banyu Urip Crude OilDocument15 pagesIPTC-20219-MS A Systematic Approach To Increase Banyu Urip Crude OilGilbert OmittaNo ratings yet

- New Shale - Final.031213 PDFDocument8 pagesNew Shale - Final.031213 PDFmaveryqNo ratings yet

- Pipeline System DesignDocument75 pagesPipeline System Designjoreli50% (2)

- E Ds K7 K Mab HVJ6 Xxqxi PK 1601153088Document8 pagesE Ds K7 K Mab HVJ6 Xxqxi PK 1601153088Fernando Emmanuel BenitezNo ratings yet

- 08572-Trht-Egcb-Qc-Aq-012 Itp - Pipeline Construction Rev1 PDFDocument33 pages08572-Trht-Egcb-Qc-Aq-012 Itp - Pipeline Construction Rev1 PDFbelhaskaNo ratings yet

- 3.0. - 230004 - Section 3 - Itt - Technical PackageDocument111 pages3.0. - 230004 - Section 3 - Itt - Technical PackageleftkarthikeyanNo ratings yet