Professional Documents

Culture Documents

Material PDF

Uploaded by

keyur1109Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material PDF

Uploaded by

keyur1109Copyright:

Available Formats

RANGE OF MANUFACTURED MATERIALS - FOUNDRY

Material

Standard Designations

Standard Designations

DIN

ASTM

UNS

Others

1.4034

1.4034

Ferrite / Martensite

1.4027

SEW410-14027

Ferrite / Martensite

1301

10283 - 1.4008

A743 - (CA15)

J91150

(AISI 414)

Ferrite / Martensite

1304

10283 - 1.4317

A743 - CA6NM

J91540

(AISI 1.4313)

Ferrite / Martensite

1604CuNB

10283-1.4527

A747 - CB7Cu-1

J92180

-1.454

Mart. - hardened through precipitation

1810

17445 - 1.4308

A743 - CF8

J92600

(1.4301)(AISI 304)

Austenite + Ferrite(0 - 15%)

1810LN

10283 - 1.4306

A743 - CF8

D92500

(1.4306) (AISI 304L)

Austenite + Ferrite(0 - 15%)

1810Nb

10583 - 1.4552

A743 - CF8C

D92M10

(1.4550) (AISI 347)

Austenite + Ferrite(0 - 15%)

1711/2.5

10283 - 1.4408

A743 - CF8M

J92900

(1.4401)(AISI 316)

Austenite + Ferrite(0 - 15%)

1711/2.5LN

10283 - 1.4404

A743 - CF3M

J92800

(1.4404)(AISI 316L)

Austenite + Ferrite(0 - 15%)

1711/2.5Nb

10283 - 1.4581

A351 - (CF10MC)

J92971

(AISI 318)(1.4580)

Austenite + Ferrite(0 - 15%)

1711/2.5N

10283 - 1.4446

A743 - CG3M

(J92999)

(AISI 317LN)(1.4439)

Austenite + Ferrite(0 - 15%)

2512

10295 - 1.4837

A297 - HH

J93503

(AISI 309)

Austenite

2520

10295 - 1.4848

A297 - HK

J94224

(AISI 310)

Austenite

1.4361

-1.4361

Super - Austenitic High Si

1.4529

-1.4529

J94651

Super - Austenitic

2025/4.5Cu

-1.4539

10283 - 1.4584

J94650

(1.4539)(AISI 904L)

Super - Austenitic

1.45

1.45

Super - Austenitic

2606N

10283 - 1.4347

Duplex (Aust+Ferrite)

2205/3N

10283 - 1.4470

A890 - CD3MN

D92205 (1.4462)

Duplex (Aust+Ferrite)

2604.5/1.5N

-1.446

A890 - (CD6MN)

J93371

(AISI 329)

Duplex (Aust+Ferrite)

2408/2

1.4463

A890 - (CE8MN)

(J93345)

Duplex (Aust+Ferrite)

2705/2

SEW410 - 1.4464

Duplex (Aust+Ferrite) + Carb.

2606/2.5CuN

10283 - 1.4517

A890 - (CD4MCuN)

J93372

Duplex (Aust+Ferrite)

2.466

-2.466

N08020

(ALLOY 20)

Austenite + Phase Intermetal.

2.4602

-2.4602

A494 - CX2MW

N26022

(HASTELLOY C22)

Austenite + Phase Intermetal.

2.4686

-2.4686

A494 - CW2M

N26455

(HASTELLOY C4)

Austenite + Phase Intermetal.

2.481

-2.481

A494 - N12MV

N30012

(HASTELLOY B)

Austenite + Phase Intermetal.

2.4856

-2.4856

A494 - CW6MC

N26625

(INCONNEL 625)

Austenite + Phase Intermetal.

( ) = Inside the parenthesis, similar materials.

NOTE: We produce other materials, according to standards or client's specifications.

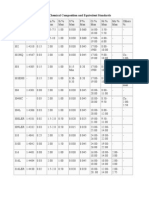

CHARACTERISTICS OF PRODUCED MATERIALS - FOUNDRY

Material

Chemical Composition (%) (1)

Shrinkage - Density

Cr

Ni

Mo

Outros

(%) - (g/cm3)

1.4034

0.42-0.50

12.5-14.5

2.0 - 7.70

1.4037

0.16-0.23

12.5-14.5

1.0 MAX

2.0 - 7.70

1301

0.1

12.0-13.5

1.00-2.00

0.20-0.50

2.0 - 7.73

1304

0.06

12.0-13.5

3.50-4.50

0.40-0.70

2.0 - 7.77

1604CuNb

0.017

15.5-17.0

3.60-4.60

Cu=2.50-3.20 Nb=0.15-0.35

2.0 - 7.77

1810

0.07

18.0-19.0

8.00-11.0

2.5 - 7.77

1810LN

0.03

18.0-20.0

9.00-12.0

N=0.10-0.20

2.5 - 7.74

1810Nb

0.07

18.0-20.0

9.00-12.0

Nb=8xC-1.00

2.5 - 7.78

1711/2.5

0.07

18.0-20.0

9.0-12.0

2.00-2.50

2.5 - 7.84

1711/2.5LN

0.03

18.0-20.0

9.0-12.0

2.00-2.50

N=0.10-0.20

2.5 - 7.81

1711/2.5Nb

0.07

18.0-20.0

9.0-12.0

2.00-2.50

Nb=8xC-1.00

2.5 - 7.84

1711/2.5N

0.03

16.5-18.5

12.5-14.5

4.00-4.50

N=0.12-0.22

2.5 - 7.91

2512

0.30-0.50

24.0-26.0

11.0-14.0

2.5 - 7.71

2520

0.30-0.50

24.0-26.0

19.0-22.0

2.5 - 7.79

1.4361

0.03

17.0-18.5

14.5-15.5

Si=3.8-4.5 N=0.10-0.15

2.5 - 7.65

1.4529

0.03

19.0-21.0

24.0-26.0

5.50-7.00

Cu=1.0-2.0 N=0.05-0.10

2.5 - 8.10

2025/4.5Cu

0.025

19.0-21.0

24.0-26.0

4.00-5.00

Cu=1.00-3.00

2.5 - 8.04

1.45

0.06

19.0-21.0

24.0-25.0

2.50-3.50

Cu=1.50-2.50 Nb>8xC

2.5 - 8.02

2606N

0.08

25.0-27.0

5.5-7.5

N=0.10-0.20

2.0 - 7.70

2205/3N

0.03

21.0-23.0

4.5-6.5

2.5-3.5

N=0.12-0.20

2.0 - 7.77

2604.5/1.5N

0.05

25.0-27.0

4.50-6.00

1.75-2.00

N=0.15-0.20

2.0 - 7.72

2408/2

0.07

23.0-25.0

7.00-8.50

2.00-2.50

2.0 - 7.77

2705/2

0.30-0.50

26.0-28.0

4.00-6.00

2.00-2.50

2.0 - 7.67

2606/2.5CuN

0.03

24.5-26.5

5.00-7.00

2.50-3.50

Cu=2.75-3.50 N=0.12-0.22

2.0 - 7.79

2.466

0.05

19.0-21.0

36.0-38.0

2.0-3.0

Cu=3.0-4.0 Nb=8xC-1.0

2.5 - 8.10

2.4602

0.02

20.0-22.5

Base

12.5-14.5

W=2.5-3.5 Fe=2.0-6.0

2.5 - 8.67

2.4686

0.02

15.5-17.5

Base

15.0-17.5

2.5 - 8.79

2.481

0.12

1.0 MAX

Base

26.0-30.0

V=0.2-0.6 Fe=4.0-6.0

2.5 - 9.11

2.4856

0.06

20.0-23.0

Base

8.0-10.0

Nb=3.15-4.15

2.5 - 8.58

(1) = Maximum concentrations, unless indicated limits.

PROPERTIES OF MANUFACTURED MATERIALS - FOUNDRY

Mechanical Properties (2)

Material

Heat Treatment

Yiels 0.2%

Strength

Elongation

Impact ISO-V

Hardness

MPa

MPa

Joule

HB

1.4034

[<=800]

[<=275]

Annealed

1.4027

440

590-790

12

180-240

Annealed

1301

440

590-790

15

27

170-240

Annealed + Quenched + Tempered

1304

500/830*

700-920*

12/16*

35/50*

<285

Annealed + Quenched + Tempered

1604CuNb

750/1000*

900/1100*

5/12*

0/20*

269/375*

Annealed + Quenched

1810

205

485-640

35

60

130-200

Solution Annealed

1810LN

205

485

35

80

Solution Annealed

1810Nb

205

485

30

40

130-200

Solution Annealed

1711/2.5

205

485-640

30

60

130-200

Solution Annealed

1711/2.5LN

205

485

30

80

Solution Annealed

1711/2.5Nb

185

440

25

40

130-200

Solution Annealed

1711/2.5N

240

515

25

50

130-200

Solution Annealed

2512

240

515

10

"As Casting"

2520

240

450

10

"As Casting"

1.4361

200

500

20

60

130-200

Solution Annealed

1.4529

[270]

[600-800]

[30]

[90]

Solution Annealed

2025/4.5Cu

185

450

30

60

Solution Annealed

1.45

200

450

30

65

130-200

Solution Annealed

2606N

420

590

20

30

[190-230]

Solution Annealed

2205/3N

420

620

25

30

Solution Annealed

2604.5/1.5N

450

655

25

190-230

Solution Annealed

2408/2

390

590-790

20

170-200

Solution Annealed

2705/2

230-300

Annealed

2606/2.5CuN

480

650-850

22

50

Solution Annealed

2.466

[270]

[590]

[30]

Solution Annealed

2.4602

310

550

30

Solution Annealed

2.4686

275

495

20

Solution Annealed

2.481

275

525

Solution Annealed

2.4856

275

485

25

Solution Annealed

(2) = Minimum values, unless indicated limits.

[ ] = For orientation only - values for rolled products.

(*) = Minimum values, depending on quenched/tempered temperatures.

You might also like

- Hot Rolled and Structural Steel Grades (40Document4 pagesHot Rolled and Structural Steel Grades (40sudeponnaniNo ratings yet

- Dunaferr Cold Rolled Product catalogueDocument12 pagesDunaferr Cold Rolled Product catalogueMihály PálffyNo ratings yet

- Star Steels A PDFDocument24 pagesStar Steels A PDFsocomenin2013No ratings yet

- Tool Steel Grade and Property GuideDocument2 pagesTool Steel Grade and Property GuideDuy NguyenNo ratings yet

- Astm A493 16Document2 pagesAstm A493 16wongNo ratings yet

- BSC Legirani Celici Za Kotrljajne LezajeveDocument12 pagesBSC Legirani Celici Za Kotrljajne LezajeveradankezNo ratings yet

- TV 100x100x5#S235JRDocument5 pagesTV 100x100x5#S235JRRazvan CristeaNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Material PropertiesDocument4 pagesMaterial Propertiesbratkp100% (1)

- Centravis - Product Catalogue - HEX TubesDocument22 pagesCentravis - Product Catalogue - HEX TubesVictor PomboNo ratings yet

- 4.2.2 Material Grade Tables: 4.2 Manufactured MaterialsDocument10 pages4.2.2 Material Grade Tables: 4.2 Manufactured Materialstamson19071978No ratings yet

- WS410Document7 pagesWS410Martin OusephNo ratings yet

- Cold Rolled2Document9 pagesCold Rolled2exinno888No ratings yet

- 1319 3 Guidelines For WeldingDocument64 pages1319 3 Guidelines For Weldingg_sanchetiNo ratings yet

- Werkstoffe E PDFDocument12 pagesWerkstoffe E PDFirajfarji2481No ratings yet

- Ferritic and Martensitic Casting Materials SpecificationsDocument2 pagesFerritic and Martensitic Casting Materials SpecificationsSinan YıldızNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- Chemical Properties & Compositions of Stainless Steel GradesDocument4 pagesChemical Properties & Compositions of Stainless Steel GradesPrabhakar KattulaNo ratings yet

- High Strength Steel Tubes For Structural and Engineering ApplicationsDocument12 pagesHigh Strength Steel Tubes For Structural and Engineering ApplicationsA LettristeNo ratings yet

- A582 - A582m - 2005 PDFDocument4 pagesA582 - A582m - 2005 PDFPatricio Altavilla100% (1)

- Steel GradesDocument12 pagesSteel GradesDidar Singh Thethi100% (1)

- Technical Data Sheet Product CatalogueDocument16 pagesTechnical Data Sheet Product CatalogueKamalNo ratings yet

- Friction and Wear Behavior of ABS - 2014, INDIADocument5 pagesFriction and Wear Behavior of ABS - 2014, INDIAvaxevNo ratings yet

- Comp SteelsDocument8 pagesComp Steelskgupta27No ratings yet

- ASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingDocument6 pagesASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingJose TorresNo ratings yet

- Tubular Silicon Iron Anodes Technical DataDocument2 pagesTubular Silicon Iron Anodes Technical DataAhmed MagdiNo ratings yet

- WS412Document7 pagesWS412Martin OusephNo ratings yet

- Stainless Steel PropertiesDocument3 pagesStainless Steel Propertieskiwanis_lamNo ratings yet

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiNo ratings yet

- Columbus Stainless Pocket GuideDocument29 pagesColumbus Stainless Pocket Guidebruteforce2000No ratings yet

- EN Series Steels Characterization and Burnishing Process OptimizationDocument18 pagesEN Series Steels Characterization and Burnishing Process OptimizationRebekah WilsonNo ratings yet

- Material delivery specificationsDocument2 pagesMaterial delivery specificationsviyfNo ratings yet

- EN6114Document14 pagesEN6114akayirNo ratings yet

- AL1717x Acer LCD Display PDFDocument15 pagesAL1717x Acer LCD Display PDFsylvan_No ratings yet

- 04Cr18Ni10 PDFDocument3 pages04Cr18Ni10 PDFAvishekNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- CastMaterials E00510Document6 pagesCastMaterials E00510samir basuniNo ratings yet

- Weld Consumable SelectionDocument25 pagesWeld Consumable SelectionNisarg PandyaNo ratings yet

- Acer AL1717 Service Manual 3Document11 pagesAcer AL1717 Service Manual 3Daniel DragoevNo ratings yet

- A 582Document3 pagesA 582Gustavo SuarezNo ratings yet

- Low-Carbon Steel Specs and Mechanical PropertiesDocument9 pagesLow-Carbon Steel Specs and Mechanical PropertiescharssxNo ratings yet

- Chemical Composition & Mechanical Properties: e (Min.)Document4 pagesChemical Composition & Mechanical Properties: e (Min.)Joby GeorgeNo ratings yet

- Low-Carbon Steel Strip: Cold-Rolled: Chemical CompositionDocument9 pagesLow-Carbon Steel Strip: Cold-Rolled: Chemical CompositionSachin JawaleNo ratings yet

- A 249 - A 249m - 03 Qti0os9bmjq5ts1sruqDocument11 pagesA 249 - A 249m - 03 Qti0os9bmjq5ts1sruqAntonio ChangNo ratings yet

- (TSC) ss32-ss315Document2 pages(TSC) ss32-ss315Gut Besser WasserNo ratings yet

- Stainless Steel Data PDFDocument4 pagesStainless Steel Data PDFRobert SumińskiNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringNo ratings yet

- Techinfo WorkpieceDocument1 pageTechinfo Workpiecesototo90No ratings yet

- Cold-Rolled Steel Strips for Springs StandardsDocument10 pagesCold-Rolled Steel Strips for Springs StandardsPaviter SinghNo ratings yet

- C45e - Propriedades 2Document1 pageC45e - Propriedades 2engenharia metalicaNo ratings yet

- Bab IiDocument8 pagesBab Iibeni firiyaNo ratings yet

- BUTTING Duplex PipesDocument20 pagesBUTTING Duplex PipeswenigmaNo ratings yet

- 4130, 75 Ksi (517 Mpa), Forging/Barstock, H2S Compatible: Doc No: M21509 Rev: O Page 1 of 3Document3 pages4130, 75 Ksi (517 Mpa), Forging/Barstock, H2S Compatible: Doc No: M21509 Rev: O Page 1 of 3Anonymous ZSne5ChQNo ratings yet

- Vulcan steel alloy specificationsDocument4 pagesVulcan steel alloy specificationsk koradiaNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- C P P Total SeriesDocument1 pageC P P Total Serieskeyur1109No ratings yet

- C P P Total SeriesDocument18 pagesC P P Total Serieskeyur1109No ratings yet

- Detailed Advertisement of OM Manpower RecruitmentDocument15 pagesDetailed Advertisement of OM Manpower Recruitmentkeyur1109No ratings yet

- GET - Safety Presentation 2009Document27 pagesGET - Safety Presentation 2009keyur1109No ratings yet

- Ball BearingDocument70 pagesBall Bearingpatrik710No ratings yet

- Aniline PFDDocument1 pageAniline PFDkeyur11090% (1)

- Bearing Electro PittingDocument19 pagesBearing Electro PittinglyanagustNo ratings yet

- 1c225 General Merit List BiotechnologyDocument10 pages1c225 General Merit List Biotechnologykeyur1109No ratings yet

- NB ReactionDocument1 pageNB Reactionkeyur1109No ratings yet

- CPP History BoardDocument3 pagesCPP History Boardkeyur1109No ratings yet

- Course M-3041Document44 pagesCourse M-3041Satya NarayananNo ratings yet

- Ball Bearing Prefixes and SuffixesDocument6 pagesBall Bearing Prefixes and Suffixeskeyur1109No ratings yet

- Aniline Process DescriptionDocument13 pagesAniline Process Descriptionkeyur1109100% (3)

- 4417 Self Aligning Bearing SystemDocument22 pages4417 Self Aligning Bearing SystemSayed KassarNo ratings yet

- Influence of Tilting Pad Bearing Clearance On Rotor Response of Steam Turbine PDFDocument20 pagesInfluence of Tilting Pad Bearing Clearance On Rotor Response of Steam Turbine PDFAhtsham AhmadNo ratings yet

- 2005 Seal and Its FunctionDocument1 page2005 Seal and Its FunctionHaseeb BokhariNo ratings yet

- State Bank of IndiaDocument1 pageState Bank of Indiakeyur1109No ratings yet

- Bearing Tolerances PDFDocument13 pagesBearing Tolerances PDFkeyur1109No ratings yet

- Angular Contact Ball Bearing Universal Matching - Back To BackDocument2 pagesAngular Contact Ball Bearing Universal Matching - Back To Backkeyur1109No ratings yet

- Thermosiphon seal supply system overviewDocument4 pagesThermosiphon seal supply system overviewkeyur1109No ratings yet

- 2015-3 CE ArticleDocument1 page2015-3 CE Articlekeyur1109No ratings yet

- Finned TubeDocument6 pagesFinned Tubekeyur1109No ratings yet

- B-7901cd Seal Flushing SystemDocument2 pagesB-7901cd Seal Flushing Systemkeyur1109No ratings yet

- EagleBurgmann TS4000 enDocument3 pagesEagleBurgmann TS4000 enkeyur1109No ratings yet

- EagleBurgmann - Statotherm V Cover Seal V901 - ENDocument1 pageEagleBurgmann - Statotherm V Cover Seal V901 - ENkeyur1109No ratings yet

- EagleBurgmann - Statotherm R Profile Rings R901 - B.. - ENDocument1 pageEagleBurgmann - Statotherm R Profile Rings R901 - B.. - ENkeyur1109No ratings yet

- EagleBurgmann Burachem Brown 9655 R enDocument1 pageEagleBurgmann Burachem Brown 9655 R enkeyur1109No ratings yet

- EagleBurgmann - Statotherm V Cover Seal V881 - ENDocument1 pageEagleBurgmann - Statotherm V Cover Seal V881 - ENkeyur1109No ratings yet

- EagleBurgmann Statotherm P Foil 9591 P enDocument1 pageEagleBurgmann Statotherm P Foil 9591 P enkeyur1109No ratings yet

- EagleBurgmann Buratherm N 9544 N enDocument1 pageEagleBurgmann Buratherm N 9544 N enkeyur1109No ratings yet

- The Dynamics of BreathingDocument5 pagesThe Dynamics of BreathingChris McCulloch100% (1)

- Capstone PresentationDocument19 pagesCapstone PresentationArun BalachandranNo ratings yet

- Zara Restaurant and Lounge Business PlanDocument54 pagesZara Restaurant and Lounge Business Plankira572992% (12)

- Thermocold AWC PROZONE Tech PDFDocument44 pagesThermocold AWC PROZONE Tech PDFAlexNo ratings yet

- Elo TecDocument2 pagesElo TecMimi MimiNo ratings yet

- Sahara ModularDocument12 pagesSahara ModularDonnarose DiBenedettoNo ratings yet

- Shipping Instructions For US ImportsDocument7 pagesShipping Instructions For US ImportsRichard LimNo ratings yet

- TRILOGY Product BrochureDocument8 pagesTRILOGY Product BrochureMarina JankovicNo ratings yet

- Govt. of Andhra Pradesh: (A.P.T.C HR Bill)Document3 pagesGovt. of Andhra Pradesh: (A.P.T.C HR Bill)Sri KrishnaNo ratings yet

- 2007 MCQDocument67 pages2007 MCQTiffani Gutierrez100% (1)

- Isc BUX82/83: Isc Silicon NPN Power TransistorsDocument2 pagesIsc BUX82/83: Isc Silicon NPN Power TransistorsCarlos HCNo ratings yet

- Advanced GeomorphologyDocument30 pagesAdvanced GeomorphologyCarlos Letras100% (3)

- CHEMIST LICENSURE EXAM TABLEDocument8 pagesCHEMIST LICENSURE EXAM TABLEJasmin NewNo ratings yet

- Life Skills Unit PlanDocument15 pagesLife Skills Unit PlanLindy McBratneyNo ratings yet

- 3G3EV Installation ManualDocument55 pages3G3EV Installation ManualHajrudin SinanovićNo ratings yet

- HVAC Control ModuleDocument2 pagesHVAC Control ModuleData TécnicaNo ratings yet

- Shoplifting's Impact on Consumer BehaviorDocument3 pagesShoplifting's Impact on Consumer BehaviorJerico M. MagponNo ratings yet

- Concept Paper For Stuck Garbages in Our BarangayDocument2 pagesConcept Paper For Stuck Garbages in Our BarangayJhonemar TejanoNo ratings yet

- sm2000 GBDocument4 pagessm2000 GBRikky ChaniagoNo ratings yet

- Gregg Perkin QualificationsDocument10 pagesGregg Perkin QualificationsOSDocs2012No ratings yet

- All India Test Series (2023-24)Document22 pagesAll India Test Series (2023-24)Anil KumarNo ratings yet

- A Safety Alert Maintenance 1 IADCDocument10 pagesA Safety Alert Maintenance 1 IADCVeeramuthu SundararajuNo ratings yet

- Complete Your Summer Sculpt Calendar WorkoutsDocument1 pageComplete Your Summer Sculpt Calendar WorkoutsSmarauza TinyNo ratings yet

- RPH Finals Quiz BeeDocument29 pagesRPH Finals Quiz BeeJoshua Liann EscalanteNo ratings yet

- Event Details Report - Algoma SteelDocument66 pagesEvent Details Report - Algoma SteelThe NarwhalNo ratings yet

- Importance of WaterDocument3 pagesImportance of WaternicNo ratings yet

- Crude Palm Oil MSDS Provides Safety InformationDocument3 pagesCrude Palm Oil MSDS Provides Safety InformationCarlos MontanoNo ratings yet

- Power Quality SolutionDocument40 pagesPower Quality Solutionshankar ammantryNo ratings yet

- Weapons of Mass DestructionDocument41 pagesWeapons of Mass DestructionRexchel Nicole P. AlvarezNo ratings yet

- Learning Strand I - EnglishDocument19 pagesLearning Strand I - EnglishMaricel MaapoyNo ratings yet