Professional Documents

Culture Documents

Project On Pressure Vessel

Uploaded by

fanusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project On Pressure Vessel

Uploaded by

fanusCopyright:

Available Formats

PRESSURE VESSEL DESIGN

By Network-6

Section 1

COLLEGE OF ENGINEERING AND TECHNOLOGY

DEPARTEMENT OF CHEMICAL ENGINEERING

PROJECT ON CHEMICAL ENGINEERING

APPARATUS DESIGN

Course code: (ChEg4191)

PROJECT TITLE:- PRESSURE VESSEL DESIGN

PREPARED BY:-NETWORK -6SECTION -1Year -4th

List Name of Network Members

ID

1) Fanus Alemu.............RET 0485/06

2) Letebrhan Bahta............................................RET 0963/06

3) Rgbey Kiday.............................................RET 1242/06

4) Teame Gebretsadik.......RET 1406/06

5) Teklehaimanot Abraha.............RET 1443/06

6) Wasie Kebire................................................RET 1578/06

Submitted to Instructor

Submission Date

Zinabu H.

December 12/2016 G.C

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Declaration

We hereby declare that the report submitted are entirely our own work and have not been

Copied from any other student or past year reports. Relevant work was referred to and

Appropriate citations were made to acknowledge the author of such a work. . We also declare

that wehave adhered to all principles of academic honesty and integrity and have not

misrepresented orfalsified any idea, source in our submission.

Page | 1

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Acknowledgment

We would like to extend our deepest appreciation to our remarkable instructor Zinabu H.

We have made it possible to write a project. In particular, we sincerely thank our god and the

Network six members, who help to develop ideas. Who have completed this project all of us

and We apologies for any errors and omissions.

Page | 2

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Executive summary

This technical paper can teach the concept of design, and analysis of pressure vessel. High

pressure rise is developed in the pressure vessel and pressure vessel has to withstand severe

forces. In the design of pressure vessel safety is the primary consideration, due the potential

impact of possible accident. Analyses were carried out on head, shell, nozzle and saddle. The

input parameters are type of material, pressure, temperature, diameter, and corrosion

allowance. Analysis performed the calculations of internal and external pressure, weight of

the element, allowable stresses, vessel longitudinal stress check, nozzle check and saddle

check.

Page | 3

PRESSURE VESSEL DESIGN

By Network-6

Section 1

TABLE CONTENT

Contents

Page

Declaration............................................................................................................. i

Acknowledgment................................................................................................... ii

Executive summary............................................................................................... iii

List of Figures........................................................................................................ vi

List of Tables........................................................................................................ vii

Acronyms............................................................................................................ viii

Chapter -1.............................................................................................................. 1

Introduction........................................................................................................... 1

1.1. Back ground.................................................................................................... 1

1.2 Statement of Problem...................................................................................... 3

1.3 Significant of studies....................................................................................... 3

1.4 Objectives........................................................................................................ 4

1.4.1 General objective.......................................................................................... 4

1.4.2 Specific objectives........................................................................................ 4

Chapter -2.............................................................................................................. 5

Literature review.................................................................................................... 5

2.1. NATURE OF DESIGN........................................................................................ 5

2.1.1. Pressure vessel............................................................................................ 5

2.1.2. DESIGN PARAMETER OF PRESSURE VESSEL.................................................6

2.2. Skirt and Base............................................................................................... 10

Chapter -3............................................................................................................ 12

Materials and Methods......................................................................................... 12

3.1. Materials....................................................................................................... 12

3.1.1 Assumptions............................................................................................... 12

Page | 4

PRESSURE VESSEL DESIGN

By Network-6

Section 1

3.2 METHODOLOGY.............................................................................................. 12

3.2.1. Sieve Plate Column Design Specifications.................................................12

Chapter -4............................................................................................................ 25

Result and discussion.......................................................................................... 25

4.1. Calculation.................................................................................................... 26

4.2. Reinforcement of Openings..........................................................................32

4.2.1. Required Area of Reinforcement................................................................32

4.3. Nozzles and flanges...................................................................................... 36

4.4. Discussion..................................................................................................... 49

Chapter -5............................................................................................................ 50

CONCLUSION AND RECOMMENDATION................................................................50

5.1 CONCLUSION................................................................................................. 50

5.2. Recommendation.......................................................................................... 50

References........................................................................................................... 51

Appendix.............................................................................................................. 52

Appendix B.......................................................................................................... 52

Appendix C Typical design stress for plate...........................................................53

Page | 5

PRESSURE VESSEL DESIGN

By Network-6

Section 1

List of Figures

Figures

Page

Figure4.1. Selected standard flange.25

Figure4.2. Standard ellipsoidal head26

Figure4.3. Schematic pressure vessel diagram.34

Page | 6

PRESSURE VESSEL DESIGN

By Network-6

Section 1

List of Tables

Lists

Page

Table3.1. Column specification..8

Table3.2. Nozzles specifications.9

Table3.3. Other sieve plate column.9

Table4.1. Standard flange...................25

Table4.2. Final results of the data sheet..33

Page | 7

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Acronyms

1. ASME.American society mechanical engineering

2. BPVCBoiler and pressure vessel code

3. D.P....Design Pressure

4. D.TDesign Temperature

5. MAWP.Maximum allowable working pressure

6. MDMT.....Maximum and Minimum design temperatures

7. PsiPound square inch

Page | 8

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Page | 9

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Chapter -1

Introduction

Pressure vessels are leak proof containers, as the name implies, their main purpose is to

contain a given medium under pressure and temperature. Pressure vessels are commonly used

in industry to carry both liquid and gases under required pressure and temperature limit. This

pressure and temperature comes from an external source or by the application of heat from a

direct or indirect source or any combination of them. Pressure vessels; commonly have the

cylindrical, spherical, ellipsoidal, conical or a combination of these shapes. However, some

pressure vessels are named after the type of function they required to perform. For example,

the distillation column is a vessel used in oil and petroleum refining process. The heat

exchanger used in many types of industries to transfer heat from one fluid to another fluid.

Also, reactor is a vessel, which is used for chemical reaction of contained substance. The

material comprising the vessel is subjected to pressure loading and hence stresses from all

direction. The normal stresses resulting from this pressure are functions of diameter of the

elements under consideration, the shape of the pressure vessel as well as the applied pressure.

Pressure vessels are usually spherical or cylindrical with dome end. The cylindrical vessels

are generally preferred because of they represent simple manufacturing problem and make

better use of the available space. Boiler, heat exchanger, chemical reactor and so on, are

generally cylindrical.

1.1. Back ground

The earliest design of pressure vessels is described by Leonardo da Vinci, in 1495, where

containers of pressurized air were theorized to lift heavy weights underwater. However

vessels resembling what are used today did not come about until the 1800s where steam was

generated in boilers helping to spur the However, with poor material quality and

manufacturing techniques along with improper knowledge of design, operation and

maintenance there was a large number of damaging and often fatal explosions associated with

these boilers and pressure vessels, with a death occurring on a nearly daily basis in the United

States Sieve plate column is one of the distillation columns with cross-flow trays, which is

widely used in various mass transfer operations, for instance, modern industrial nitric acid

plant. Sieve plates offer high capacity and efficiency, low pressure drop, ease of cleaning and

therefore, low capital cost.

Page | 1

PRESSURE VESSEL DESIGN

By Network-6

Section 1

A column should be designed with a specific wall thickness to ensure it has sufficient rigidity

to be able to cope with the maximum amount of pressure which it is expected to be

susceptible to in operation. The minimum column wall thickness needed to withstand the

vessel weight itself as well as other incidental loads such as internal pressure is calculated

and shown in the following calculation section The design pressure for vessels under internal

pressure is conventionally taken as the pressure where the relief device is set. This is usually

about 5-10 % above the regular working pressure. This is done to avoid spurious operation

during minor process upsets. A cylindrical pressure vessel shell must be enclosed at both ends

by heads. Flat plates, formed flatheads, hemispherical heads, torispherical heads and

ellipsoidal heads are several principal types of heads used . Hemispherical, torispherical and

ellipsoidal are categorised as domed heads where the formation is by pressing or spinning

with large diameters fabricated from formed sections.Torispherical heads, on the other hand

also referred to as dished ends. Pressure vessels can theoretically be almost any shape, but

shapes made of sections of spheres, cylinders and cones are usually employed. More

complicated shapes have historically been much harder to analyse for safe operation and are

usually far harder to construct. Theoretically a sphere would be the optimal shape of a

pressure vessel. Unfortunately the sphere shape is difficult to manufacture, therefore more

expensive, so most of the pressure vessels are cylindrical shape with 2:1 semi elliptical heads

or end caps on each end. Smaller pressure vessels are arranged from a pipe and two covers.

Disadvantage of these vessels is the fact that larger diameters make them relatively more

expensive. Many pressure vessels are made of steel. To manufacture a spherical pressure

vessel, forged parts would have to be welded together. The design of pressure vessels is an

important and practical topic which has been explored for decades. Optimization techniques

have been extensively applied to design structures in general; few pieces of work can be

found which are directly related to optimal pressure vessel design. These few references are

mainly related to the design optimization of homogeneous and composite pressure vessels.

The pressure vessel meets international safety standards, carefully selected steel with a high

impact resistance & corrosion resistant material.

1.2 Statement of Problem

Vessels failure can be grouped into the following major categories, which describe why a

vessel failure occurs. Failures also grouped into types of failures, which describe how the

Page | 2

PRESSURE VESSEL DESIGN

By Network-6

Section 1

failure occurs mean each failure contains its failure history, why and how it occurs. There are

many reasons of vessels failure such as:

Improper material selection, defected material.

Incorrect design data, incorrect or inaccurate design method or process, inadequate shop

testing.

Improper fabrication process, poor quality control, insufficient fabrication process

including welding, heat treatment and forming methods. In order to meet a safe design, a

designer must be familiar with the above mentioned failure and its causes. There have a few

main factors to design safe pressure vessel. This study is focusing on analysing the safety

parameters for allowable working pressure.

1.3 Significant of studies

For design of pressure vessel the selection of Code are important as a reference guide to

achieve the safety pressure vessel. The primary purpose of the preliminary column design,

materials of construction, fabrication, inspection, and testing. Improper vessel design and

maintenance increase the risk of vessel failure and may lead to serious safety hazard. Thus a

mechanical design of the column is highly important in essence of keeping the safety hazard

and maintenance cost at minimum. The significance of the study is not only the calculation of

the detailed dimensions of a member but rather is an all-inclusive term, incorporating:

1. The selection of pressure vessel orientation.

2. The selection of pressure vessel end closers.

3. The selection of suitable flanges.

4. The selection of suitable pressure vessel support.

5. The method of stress analysis employed and significance of results.

6. The selection of materials type and its environmental behaviour.

7. Understanding the application of the pressure vessel in different industry.

1.4 Objectives

1.4.1 General objective

To design pressure vessel according to input data and analyse the safety parameters of each

component for its allowable working pressure.

1.4.2 Specific objectives

i. To build an interactive system using auto cad design system to design pressure vessel.

ii. To compare results of design analysis in the system of design pressure calculation.

Page | 3

PRESSURE VESSEL DESIGN

By Network-6

Section 1

iii. To validate the results in the system using theoretical calculation.

Chapter -2

Literature review

2.1. NATURE OF DESIGN

Design is a creative activity, and as such can be one of the most rewarding and satisfying

activities undertaken by an engineer. It is the synthesis, the putting together, of ideas to

achieve a desired purpose. The design does not exist at the commencement of the project. The

designer starts with a specific objective in mind, a need, and by developing and evaluating

possible designs, arrives at what he considers the best way of achieving that objective; be it a

better chair, a new bridge, or for the chemical engineer, a new chemical product or a stage in

the design of a production process.

Page | 4

PRESSURE VESSEL DESIGN

By Network-6

Section 1

2.1.1. Pressure vessel

The term pressure vessel referred to those reservoirs or containers, which are subjected to

internal or external Pressure. The pressure vessels are used to store fluids under pressure.

The fluid being stored may undergo a change of state inside vessels as in case of steam

boilers or it may combine with other reagents as in chemical plants. High pressure is

developed in pressure vessel so pressure vessel has to withstand several forces developed due

to internal pressure, so selection of pressure vessel is most critical. ASME is most widely

used code for design & construction of pressure vessel. It does not consider harmonic

analysis. Consider biaxial state of stress combined in accordance with maximum stress

theory. When pressure of operating fluid increases, increase in thickness of vessel. These

Increases in thickness beyond a certain value possess fabrication difficulties and stronger

material for vessel construction.

The material of pressure vessel may be brittle such as cast iron or ductile such as mild steel.

Failure in Pressure vessel occurs due to improper selection of material, defects in material,

incorrect design data, design method, shop testing, improper or insufficient fabrication

process including welding. To obtain safety of pressure vessel and to design Pressure vessel

the selection of code is important. Corrosion allowance is the main consideration in vessel

design. Corrosion occurring over the life of the vessel.

During service, pressure vessel may be subjected to cyclic or repeated stresses. Fatigue in

pressure vessel occurs due to:

a) Fluctuation of pressure

b) Temperature transients,

c) Restriction of expansion or contraction during normal temperature variations,

d) Forced vibrations,

e) Variation in external load

2.1.2. DESIGN PARAMETER OF PRESSURE VESSEL

The following are design parameters of pressure vessel;

1. Design temperature

Page | 5

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Design temperature is the temperature that will be maintained in the metal of the part of the

vessel being considered for the specified operation of the vessel. The strength of metals

decreases with increasing temperature so the maximum allowable design stress will depend

on the material temperature. For most vessels, it is the temperature that corresponds to the

design pressure. However, there is a maximum design temperature and a minimum design

temperature (MDMT) for any given vessel. The MDMT shall be the lowest temperature

expected in service or the lowest allowable temperature as calculated or the individual parts.

Design temperature for vessels under external pressure shall not exceed the maximum

temperatures.

2. Design pressure

In the pressure vessels, three terms related to pressure are commonly used

Maximum working pressure is the maximum pressure to which the pressure vessel is

Subjected.

Design pressure is the pressure for which the pressure vessel designed.

Hydrostatic test pressure is the pressure at which the vessel is tested. The pressure vessel is

finally tested by the hydrostatic test before it is put into operation.

The pressure use in the design of a vessel is called design pressure. It is recommended to

design a vessel and its parts for a higher pressure than the operating pressure.

A design pressure higher than the operating pressure with 10%, whichever is the greater, will

satisfy the requirement. The pressure of the fluid will also be considering. The maximum

allowable working pressure (MAWP) for a vessel is the permissible pressure at the top of the

vessel in its normal operating position at a specific temperature. This pressure is based on

calculations for every element of the vessel using nominal thicknesses exclusive of corrosion

allowance. It is the basis for establishing the set pressures of any pressure relieving devices

protecting the vessel.

3. Corrosion Allowance

Page | 6

PRESSURE VESSEL DESIGN

By Network-6

Section 1

The corrosion allowance is the additional thickness of metal added to allow for material

lost by corrosion and erosion, or scaling. The allowance to be used should be agreed between

the customer and manufacturer. The walls of the pressure vessel are subjected to thinning due

to corrosion which reduces the life of the pressure vessel. The corrosion in pressure vessel is

due to the following reasons:

Chemical attack by reagents on the inner wall surface of the vessel.

Rusting due to atmospheric air and moisture.

High temperature oxidation.

Erosion due to flow of reagent over the wall surface at high velocities.

Every attempt should be made avoid the corrosion. However, this may not be always

possible. An allowance is, therefore, required to be made by suitable increase in wall

thickness to compensate for the thinning due to corrosion. Corrosion allowance is an

additional thickness of the pressure vessel wall over and above that required to withstand the

internal pressure.

4. Materials

Several of materials have been use in pressure vessel fabrication. The selection of material is

based on the appropriateness of the design requirement. The materials used in the

manufacture of the receivers shall comply with the requirements of the relevant design code,

and be identifiable with mill sheets.

The selection of materials of the shell shall take into account the suitability of the materials

with the maximum working pressure and fabrication process.

Pressure vessels are constructed from plain carbon steels, low and high alloy steels, other

alloys, clad plate, and reinforced plastics. Selection of a suitable material must take into

account the suitability of the material for fabrication (particularly welding) as well as the

compatibility of the material with the process environment. The pressure vessel design codes

and standards include lists of acceptable materials; in accordance with the appropriate

material standards.

Page | 7

PRESSURE VESSEL DESIGN

By Network-6

Section 1

5. Design stress (nominal design strength)

For design purposes it is necessary to decide a value for the maximum allowable stress

(nominal design strength) that can be accepted in the material of construction. This is

determined by applying a suitable design stress factor (factor of safety) to the maximum

stress that the material could be expected to withstand without failure under standard test

conditions. The design stress factor allows for any uncertainty in the design methods, the

loading, the quality of the materials, and the workmanship.

6. Welded joint efficiency, and construction categories

The strength of a welded joint will depend on the type of joint and the quality of the welding.

The soundness of welds is checked by visual inspection and by non-destructive testing

(radiography).

The possible lower strength of a welded joint compared with the virgin plate is usually

allowed for in design by multiplying the allowable design stress for the material by a welded

joint factor J. The value of the joint factor used in design will depend on the type of joint

and amount of radiography required by the design code. The use of lower joint factors in

design, though saving costs on radiography, will result in a thicker, heavier, vessel, and the

designer must balance any cost savings on inspection and fabrication against the increased

cost of materials. The standard specifies three construction categories.

Category 1: the highest class requires 100 per cent non-destructive testing of the welds; and

allows the use of all materials covered by the standard, with no restriction on the plate

thickness.

Category 2: requires less non-destructive testing but places some limitations on the materials

which can be used and the maximum plate thickness.

Category 3: the lowest class, requires only visual inspection of the welds, but is restricted to

carbon and carbon-manganese steels, and austenitic stainless steel; and limits are placed on

the plate thickness and the nominal design stress.

Page | 8

PRESSURE VESSEL DESIGN

By Network-6

Section 1

7. Design loads

A structure must be designed to resist gross plastic deformation and collapse under all the

conditions of loading. The loads to which a process vessel will be subject in service are listed

below. They can be classified as major loads that must always be considered in vessel design

and subsidiary loads. Formal stress analysis to determine the effect of the subsidiary loads is

only required in the codes and standards where it is not possible to demonstrate the adequacy

of the proposed design by other means; such as by comparison with the known behaviour of

existing vessels.

A. Major loads

1. Design pressure: including any significant static head of liquid.

2. Maximum weight of the vessel and contents, under operating conditions.

3. Maximum weight of the vessel and contents under the hydraulic test conditions.

4. Wind loads.

5. Earthquake (seismic) loads.

6. Loads supported by, or reacting on, the vessel.

B. Subsidiary loads

1. Local stresses caused by supports, internal structures and connecting pipes.

2. Shock loads caused by water hammer, or by surging of the vessel contents.

3. Bending moments caused by eccentricity of the centre of the working pressure relative to

the neutral axis of the vessel.

4. Stresses due to temperature differences and differences in the coefficient expansion of

materials.

5. Loads caused by fluctuations in temperature and pressure. A vessel will not be subject to

all these loads simultaneously. The designer must determine what combination of possible

loads gives the worst situation, and design for that loading condition.

8. Minimum practical wall thickness

There will be a minimum wall thickness required to ensure that any vessel is sufficiently rigid

to withstand its own weight, and any incidental loads. As a general guide the wall thickness

of any vessel should not be less than the values given below; the values include a corrosion

allowance of 2 mm:

Page | 9

PRESSURE VESSEL DESIGN

By Network-6

Section 1

2.2. Skirt and Base

Column supporting skirt and base ring

One of the most essential components of a distillation column would be its supports. By

convention, there are four types of vessel support structures which are typically used as

saddle supports for heat exchangers, skirt support for vertical columns, leg support for

spherical vessels, and lug/bracket support for other applications. These supporting columns

would have to be designed to handle the weight of the pressure vessel and its contents,

superimposed loads such as pressure and temperature as

well as wind loads while taking into account practicality factors like size and dimensions,

location and setup, attachments of fittings and flanges, as well as ease of access for inspection

and maintenance. This assignment demonstrates the guidelines required to design a skirt

support for a vertical column which was welded in place to the bottom of the pressure vessel,

taking into account the design of the skirt itself, base ring and the anchoring bolts.

Skirt supports

In this design, it was assumed that the skirt support used would consist of a conical shell

welded to the bottom dome of the pressure vessel. The flange, which was located at the

bottom of the skirt, transmits forces from the skirt itself to the foundation. Openings in the

skirt made with the purpose of creating access and pipe connections that would later be

reinforced.

To ensure a safe design of the skirt, it was important to take into account the load per unit

length, bending moment, bending stress, and dead weight loading stress without water.

Base ring/flange and anchor bolt design

The bottom of the skirt must be anchored to a concrete foundation by the means of anchor

bolts embedded in the concrete that help to prevent overturning from any sort of bending

moment that might induced by either wind and seismic loads. When either a compressive or

tensile load is applied to the anchor bolts, the load would be dispersed from the steel through

its bond to the concrete the materials used for the skirt was made entirely of carbon steel,

Page | 10

PRESSURE VESSEL DESIGN

By Network-6

Section 1

silicon killed. Meaning, the anchor bolt formed from the steel rounds should be clean and free

of oil; ensuring that it will bond to the embedded surface of steel.

Chapter -3

Materials and Methods

3.1. Materials

Materials that used to design this project are;

Stainless steel vessel, unsterilized (304).

Stainless steel nozzle, unsterilized (304).

Carbon Steel skirt support, silicon killed.

50 sieve plate

Access ladder with plat form.

Page | 11

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Insulation mineral wool.

3.1.1 Assumptions

In order to develop a preliminary design, some assumptions are made and listed below.

No significant loading from piping and external equipment.

Plates and plate supports design is negligible.

Material is double welded butt or equivalent and fully radiographed.

Assume flanges are standard flanges.

Earth quake loading need not be considered.

3.2 METHODOLOGY

3.2.1. Sieve Plate Column Design Specifications

The design specifications and requirements for column, nozzle, material of construction and

other specification are specified in Table below;

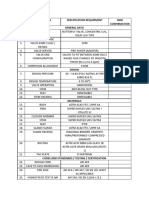

Required Specifications

The specification to calculate the column wall thickness is tabulated in Table 3.1below;

Table 3.1 Column Specification

Properties

Specifications

Length of cylindrical section, L

Internal diameter, Di

Heads

Number of sieve plates, n

Design temperature, T

Design pressure, Pi

Corrosion allowance, C

37 m

1.5 m

Standard ellipsoidal

50

150 0C

1200 KN/m2

2 mm

Page | 12

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Table3.2. Nozzles Specification

Properties

Feed

Vapor out

Specifications

At mid-point

At 0.7 m below top of cylindrical

200 mm inside diameter

Bottom

Section

At Centre of vessel head

250 mm inside diameter

200 mm inside diameter

Product

At 1.0 m below top of cylindrical 200 mm inside diameter

section

Table 3.3 other sieve plate column specification

Properties

Specifications

At 1.0 m above the

Diameter of Access ports

0.6 m

(manhole)

bottom

At 1.5 m below the top

of the

Column

Height of support skirt

Thickness of insulation

2.5 m

50 mm thick

Design Procedures

The minimum plate thickness to resist the internal pressure.

Page | 13

PRESSURE VESSEL DESIGN

e=

By Network-6

Section 1

PiDi

2 fjPi ...

(1)

Where,

e = minimum plate thickness (mm)

N

Pi = design pressure ( mm2 )

Di = internal diameter (mm)

J = joint efficient factor

N

f = maximum allowable working or design stress ( mm2 )

minimum wall thickness of torispherical and ellipsoidal heads

For

ellipsoidal;

PiDi

2 fj0.2 Pi

......................................................................................(2)

Torispherical;

e=

Pi R c C s

2 fj+Pi (Cs0.2)

.(3)

Where,

( )

1

Rc

Cs is stress concentration factor for torispherical heads Cs 4 3+ Rk

(4)

Rc =crown radius,

Page | 14

PRESSURE VESSEL DESIGN

Rk

By Network-6

Section 1

= knuckle radius.

J=joint factor

f=maximum allowable design stress

e=minimum wall thickness torispherical head

Dead Weight

For a steel vessel

Wv = 240 CvDm (Hv + 0.8 Dm)t..(5)

Dead weight of the plate

Pw

n plate A plate P liquid ,loading

....(6)

Where,

Pw = Weight of the plate, kN

n plate = Number of plate

A plate = Area of the plate m2

Pliquid ,loading = Pressure of liquid loading, kN/m2

Dead weight of the insulation materials

The weight of the insulation can be calculate by,

W I =insulation V insulation g

Whereby,

W I = Weight of the insulation material, kN

Page | 15

PRESSURE VESSEL DESIGN

insulation

= Density of insulation materials,

By Network-6

Section 1

kg

3

m

V insulation =Volume of the insulation materials, m3

m

g=gravitational force, s 2

Wind Loading Per linear, F x and the bending moment

w= Pw D eff

(7)

F

Mx

Where

Fw X

2

Mx

(8)

= Bending moment (Nm)

Pw = Wind Pressure(N/m2)

X = Length of cylindrical section (m)

Deff = Effective column diameter (m)

Stress Analysis

In the stress analysis of the column, , direct stress due to weight of vessel and bending

stress are considered. The resultant longitudinal stress and direct stress of cylindrical

vessel with water are also calculated. Coulson & Richardsons CHEMICAL

ENGINEERING VOLUME 6 Book was used as reference for the formula used in this

section.

Longitudinal and circumferential stress:

At bottom tangent line, the pressure stresses are given by:

Page | 16

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Pi

Longitudinal stress, L= 4 t (N/mm2) .

(9)

where,

L = Longitudinal stress,

Pi

=Design Pressure(N/mm2)

i=

D Internal Diameter, mm

w t = Wall thickness, mm

Pi

Circumferentialstresh= 2 t (N/mm2)

.(10)

Stress due to dead weight

Wv

w =

( Di+t b ) t b .....................................................................................(11)

Bending Stresses,

Di

+t

2 b

).................(12)

M

b = x

Iv

D o=Di +2 t b

I v=

...............(13)

( Do4 D4i ) ....................(14)

64

Where

Page | 17

PRESSURE VESSEL DESIGN

b

Mx

By Network-6

Section 1

N

=Bending stress ( mm2 )

=The bending moment (N.m)

i=

D Internal Diameter(mm)

t b =Bottom Tangent line thickness (mm)

Iv

= Second moment of area ( mm

I v=

( Do4 D4i )

64

i=

D Internal Diameter in mm

Do = Outer Diameter in mm

Resultant longitudinal stress is given by,

Z = L + W b .........................(15)

Critical buckling stress can be calculated as:

C =2 104 (

tb

)

Do

(16)

The maximum resultant compressive stress will occur when the vessel is not under pressure

given by,

Z = W + b (17)

Page | 18

PRESSURE VESSEL DESIGN

By Network-6

Section 1

The bending moment, in skirt.

The effect of bending moment of skirt, Ms, can be calculated as follow.

M s=

Fw 2

x ..................(18)

2

x=H s + H v .....................(19)

Where,

MS = Bending moment at the base of the skirt

FW = Load per unit length

HS = Height of skirt

H V = Height of the vessel

The bending stress in the skirt.

The bending stress in the skirt is given by;

bs=

4 Ms

( Ds +ts ) Ds ts .....(20)

Where, Ds =Internal column diameter,

ts = Thickness of the skirt

bs=

Bending stress in the skirt

The dead weight stress for the test and operating conditions.

For test condition,

ws

Is given by,

ws (test )=

W water

( Ds+ts ) ts ......

(21)

Where,

Page | 19

PRESSURE VESSEL DESIGN

ws (test )=

By Network-6

Section 1

Dead weight stress in the skirt for test condition

W water = Total weight of the vessel with contents (water).

For operating condition , ws (operating) : is given by;

ws (operating)=

W operating

( Ds+ ts ) ts ........(22)

Where,

ws (operating)= Dead weight stress in the skirt for operating condition

W vessel = Total dead weight of vessel with heads.

The resultant bending stress in the skirt.

For maximum

s ( compresive ) =

test

) ..(23)

bs +

For minimum

operating

(

ws tensile )= bs + w )(24)

Number of bolts required N bolts given by the formula:

N

bolts=

Where;

D P

600

(25)

Ds

= Internal column diameter

D P = Pitch circle diameter

Page | 20

PRESSURE VESSEL DESIGN

The new required bolt area,

A b ,=

1

N bolts f

Ab,

By Network-6

Section 1

is given by :

vessel

4 MS

(

W ...

Dp

(26)

Where,

N bolts= Number of bolts required

f b= Bolt design stress

M S= Bending moment in skirt

W vessel = Total dead weight of vessel with heads

D p= Pitch circle diameter

The bolt root diameter

Dbolt

Is given by the formula;

D bolt =

4 Ab

.....(27)

The total compressive load on each base ring per unit length,

Fbolt

is Given by:

Page | 21

PRESSURE VESSEL DESIGN

4 MS

By Network-6

Section 1

W vessel

D

D

).(28)

F bolt =

2

s

Where,

Wvessel= Total dead weight of vessel with heads

Ms= Bending moment in skirt

Ds= Internal column diameter

The minimum width of base ring, Lb

L

Given by the formula:

b=

F bolt

fc

..............(29)

Where

Fbolt = Total compressive load on the base ring per unit length

f c =maximum allowable bearing pressure on the concrete foundation pad

The skirt base angle: s .

Skirt base angle, s given by,

s=tan 1 (

D 's

0.5 ( D' s Ds )

.............(30)

The bolt spacing.

Page | 22

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Bolt spacing is given by the formula:

bolt specing=

D bolt '

N bolt ' (31)

Where,

D bolt' = Bolt circle diameter

N bolt ' = Number of bolts

The total compressive load on each base ring per unit length, Fbolt.

Given the formula:

Fbolt =(

4 Ms

W

W vessel vessel ) ..(32)

D ' s

D 's

2

Where,

W vessel = Total dead weight of vessel with heads

M s=

Bending moment in skirt

D' s = Flared skirt bottom diameter

The actual bearing pressure on the concrete foundation,

Given the formula:

Page | 23

PRESSURE VESSEL DESIGN

f ' c=

By Network-6

Section 1

F bolt '

Actual width (33)

Actual width =Lr + ts + ti(34)

Where,

ts = Skirt thickness

ti = Insulation thickness

Fbolt = Total compressive load on the base ring per unit length

Lr =Distance from the edge of the skirt to the outer edge of the ring = 178 mm (Sinnott.,

Coulson & Richardson's Chemical Engineering 1999) : Using Bolt size 70 (BS 4190:1967)

The base ring thickness, tb.

The base ring thickness given by the formula:

t b=Lr

3f'c

f r ..(35)

Where,

Lr=Distance from the edge of the skirt to the outer edge of the ring = 127 mm (Sinnott.,

Coulson & Richardson's Chemical Engineering 1999) : Using Bolt size 70 (BS 4190:1967)

f r = Allowable design stress in the ring material = 140 N/mm2 (Typically)

f 'c

= Actual bearing pressure on the concrete foundation

Effective Column Diameter

To find the effective column diameter,

Page | 24

PRESSURE VESSEL DESIGN

D eff

By Network-6

Section 1

= D s +2(t ave ,wall +t i) .(36)

Where, Deff = Effective column diameter (m)

Ds= Diameter (m)

t ave, wall = Average thickness of cylinder vessel wall (m)

t i = Thickness of insulation (m)

compensation area required

design skirt support

2

( Di H V ) W g

Approximate weight = 4

).......(37)

Total weight=

W V + Approximate weight

..............................(38)

Bending moment at the base of skirt

1

M S= F w (H v + H skirt ) (39)

,

2

Where

M s=bending moment the skirt

s

D s+ t D S

.(40)

4 MS

bs=

bs=bending stressthe skirt

Where

t s=skirt thickness

Dead weight stress in the skirt

s

D s +t t s

..

Approximate weight

ws (test )=

(41)

Page | 25

PRESSURE VESSEL DESIGN

Where

ws

By Network-6

Section 1

= dead weight stress in the skirt

v

W

...(42)

weight of vessels

ws ( operating )=

Required Area of Reinforcement

1f r 1

A=dt r f +2 t n t r f )...........................(43)

A '1

r

1

=d(

(44)

1F r

E1 tF t 2 t n ( E 1 t F t r )

where:

A = total cross-sectional area of reinforcement required in the plane under consideration

A1 = area in excess thickness in the vessel wall available for reinforcement

A2 = area in excess thickness in the nozzle wall available for reinforcement

A3 = area available for reinforcement when the nozzle extends inside the vessel wall

S = design stress at design temperature

d = finished diameter of circular opening under consideration

E = joint efficiency factor

F = correction factor that compensates for the variation of in internal pressure stresses on

different planes with respect to the axis of the vessel

t = specified vessel wall thickness

ti = nominal thickness of internal projection of the nozzle wall

Page | 26

PRESSURE VESSEL DESIGN

By Network-6

Section 1

tn = nozzle wall thickness

tr = required thickness of seamless shell based on circumferential stress

Chapter -4

Result and discussion

Mechanical design of the sieve plate column with;

Inner diameter of the column, Di = 1.5 m = 1500 mm

Design temperature = 150

Design stress of the material at 150 = 130 N/mm2

Material of construction = stainless steel 18Cr/8Ni unestablished (304).

2

Design stress of the material = 130 N/ mm

2

Youngs modulus = 200000 N/ mm

2

Design pressure = 1.2 N/ mm

Corrosion allowance = 2 mm

Inner diameter of the column = 1500 mm

Height of the column between the two tangent lines = 37000 mm

Skirt height = 2500 mm

No of plates = 50

Insulation = 50 mm thick

Mineral wool density = 130 kg/m3

Maximum wind velocity = 160KM/h

2

Access ladder with platforms = 1.7 k N/ m area,

1

2

3

4

Thickness calculation for the cylindrical shell

Selection and sizing calculation

Pressure calculation for the ellipsoidal shell and torispherical heads

Calculation for nozzle

Page | 27

PRESSURE VESSEL DESIGN

5

By Network-6

Section 1

Calculation for legs and supports

4.1. Calculation

Thickness of Heads

Step1, determine Calculation of the minimum thickness

the column wall thickness to resist internal pressure

then Calculated using

e=

PiDi

2 fjPi

1.2 1500

=

6.955mm

2 130 11.2

Rounding off to 7 mm Take into consideration of 2 mm of corrosion allowance.

Therefore the final thickness is,

T 7mm +2 mm=9mm

Domed head

Step2, determine Calculation of the minimum thickness of the ellipsoidal and

torispherical head

Most standard ellipsoidal heads are manufactured with a major and minor axis ratio of 2:1.

For this ratio, the following equation can be used to calculate the minimum thickness

required:

e

PiDi

2 fj0.2 Pi

Page | 28

PRESSURE VESSEL DESIGN

e

By Network-6

Section 1

1.2 1500

=

6.93mm

2 130 10.2 1.2

e=

PiRcCs

2 fj+Pi (Cs0.2)

( )

1

Rc

Where, Cs is stress concentration factor for torispherical heads Cs 4 3+ Rk

Rc

=crown radius,

Rk

= knuckle radius.

The ratio of the knuckle to crown radii should not be less than 0.06, to avoid buckling;and the

crown radius should not be greater than the diameter of the cylindrical section.

Crown radius,

Rc =

Knuckle radius

, Rk =

Di 1.5 m

6%

Rc =

0.09 m

A head of this size would be formed by pressing: no joints, so J 1.

( )

1

1.5

Cs 4 3+ 0.09 = 1.77m

1.2 1500 1.77

=

12.1657mm

2 130 1+1.2(1.770.2)

So an ellipsoidal head would probably be the most economical.

Step3,

Select the ellipsoidal head because it has minimum wall thickness.

Page | 29

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Mean Thickness of Column Wall

Since a vessel needs to withstand design loads such as wind and the dead weight loads, the

column wall has to be gradually thicker from the top to the bottom Thus, the pressure at the

vessel base is maintained at maximum and this requires greater thickness of the column wall

and also larger diameter for the column. This is crucial to prevent the vessel from collapsing

as well as to increase its capability to endure wind loading and dead weight of vessel and

content that contributed to the high stress from increase in pressure.Therefore, For stability of

the shell the column wall is divided into 5 sections with an increase of 2mm for each section

going downwards. The column wall thickness from top to bottom of the shell is 7mm , 9

mm, 11 mm, 13 mm and 15mm respectively. The mean thickness of Column wall can then

be calculated.

t s=

7+9+11 +13+15

=11 mm

5

For all other calculations, the average thickness is used.

Step4:Dead weight of vessel

For a steel vessel

Take Cv = 1.15, vessel with plates

Dm = 1.5 + 11 x 10-3 = 1.511m

Hv = 37 m

t = 11 mm

Wv = 240 CvDm (Hv + 0.8 Dm) t

Wv = 240 X 1.15 X 1.511 (37 + 0.8 X 1.511) 11

= 175,279 N

= 175.279kN

Page | 30

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Step5: Weight of plates

Plates area = /4 X 1.52 = 1.77 m2

Access ladder with platforms=1.7kN/m2 X 1.77 m2 = 3.009kN

50 plates = 50 X 3.009KN = 150.45kN

Step6: Weight of insulation

Mineral wool density = 130 kg/m3

Approximate volume of insulation = x 1.5 x 37 x 50 x 10-3 = 8.72 m3

Weight = 8.72 m3 x 130 kg/m3 x 9.81 m/s2 = 11,121 N

Double this to allow for fitting, etc. = 22.241 kN

Total weight:

Shell

Plates & contents

Insulation

175.279kN

150.45kN

22.241kN

Total

347.97kN

Step7:Wind loading

Take dynamic wind pressure as 1280 N/m2,corresponding to 160kph (100 mph) for

preliminary design studies.

Mean diameter including thickness and insulation

Dm

= Di + 2(ts +tins) x 10-3

= 1.5 + 2(11+50) x 10-3 =1.622 m

Loading (per linear meter),

Fw

= 1280 N/m2 x 1.622 m = 2076.16 N/m

Page | 31

PRESSURE VESSEL DESIGN

Bending moment at bottom tangent line = Mx =

By Network-6

W

x Hv

2

Section 1

37 m

= 1421131.52Nm

2

2076.16 N /m

Step8: Analysis of stress

Longitudinal and circumferential stress:

At bottom tangent line, the pressure stresses are given by:

Longitudinal stress,

Pi

L= 4 t (N/mm2) =

1.2 1500

(N/mm2) = 30N/mm2

4 15

Circumferential stress,

Pi

h= 2 t (N/mm2) =

1.2 1500

(N/mm2) = 60N/mm2

2 15

Stresduetodeadweight,

w =

Wv

( Di+t b ) t b

Do = Di + 2 t = 1500 mm + 2 (15 mm) = 1530 mm = outer diameter of the column

Page | 32

PRESSURE VESSEL DESIGN

Bending Stresses,

b =

By Network-6

Section 1

M x Di

( +t )

Iv 2 b

D o=Di +2 t b

I v=

4

4

( Do Di )

64

I v=

(15304 15004 )

64

b =

10

= 2.048 10 mm

1421131520 Nm 1500 mm

(

+15 mm)

= 53.084N/mm2

2

2.048 1010 mm

Resultantlongitudinal

Z = L + W b W

stress

is

given

by,

Is compressive therefore it is negative.

Z (up wind) = 30+ (2.455 ) +53.084=80.63 N /mm2

Z (down wind) = 30+ (2.455 )53.084=25.535 N /mm2

(Upwind)

Page | 33

PRESSURE VESSEL DESIGN

By Network-6

80.63 N/mm2

60 N/mm2

Section 1

25.535 N/mm2

60N/mm2

(Downwind)

The greatest the difference between the principal stress will be on the down -wind side

60 (25.535)=85.535 N/mm2

Since both upwind (80.63 N/mm2) and downwind stress (25.535 N/mm2) are much more less

than the maximum allowable stress, S = 130 N/mm 2 this design with metal thickness of 15

mm is okay and satisfactory.

Step9: Check elastic stability (buckling).

Critical buckling stress can be calculated as:

C =2 104 (

tb

)

Do

C =2 104 (

15

)

2

1530 = 196.078 N/mm

The maximum resultant compressive stress will occur when the vessel is not under pressure

given by,

Z = W + b

Z =2.455+53.084= 55.539N/mm2

Page | 34

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Since the maximum resultant compressive resultant stress (55.539 N/mm 2) less than that of

critical buckling stress(196.078 N/mm2). So the design of the vessel is satisfactory.

4.2. Reinforcement of Openings

4.2.1. Required Area of Reinforcement

Pressure Vessel, for design of internal pressure, the total cross-sectional area of reinforcement

A required in any given plane through the opening for a shell or formed head under internal

pressure shall not be less than

A=dt r f +2 t n t r f (1f r 1 )

n

Preliminary Calculations for thickness ( t r ,t rn , t , t i , t distance (h)

A) The minimum required thickness under circumferential stress, tr, for seamless shell or

head is determined by:

t r=

PR

pk 1 D

=

SE0.6 P

SE0.6 P

Given

S = 130 N/mm2

E=1

P = 1.2 N/mm2

D = 600 mm = 0.6 m

K1 = 0.90

t r=

1.2 0.9 600

130 10.6 1.2 =5.012mm

B) a nozzle wall thickness of:

t n=50 mm

C) For the vessel wall thickness, t, it is determined as;

Page | 35

PRESSURE VESSEL DESIGN

By Network-6

Section 1

D

1500

R= 2 =

= 750mm

2

1500

1.2

PR

2

t=

= 6.96 7 mm+2=9 mm

+ c=

sE0.6 p

1300.6 1.2

D) For the nominal thickness of internal projection of nozzle wall,

ti ,

it is determined

as follows:

t i =t

n2 c

= 50 2 2=46 mm

D) Distance nozzle projects beyond the inner surface of the vessel wall is as determined:

H = min(2.5t,

2.5 t i

t = 7mm

ti = 46 mm=min(2.5 9 ,2.5 46 )

=min(22.5,115)

E) The diameter of the finished opening, d, is determined as,

d=D +C=600+2=602mm

Note: The opening is in a corroded condition. Thus, a corrosion allowance is added to the

diameter of the opening.

Calculations of Area Required for Reinforcement

Given

d = D = 600 mm

t = 9 mm

Page | 36

PRESSURE VESSEL DESIGN

ti

By Network-6

Section 1

= 46 mm

t r = 5.0123 mm

t n = 50mm

t r ,n = 7 mm

h = 12.5 mm

Assuming correction factor, F = 1 and d=D,

A=dt r f +2 t n t r f (1f r ) =600 5.0123 1 +2 50 5 ( 11 ) =3007.38 mm2

To determine whether additional reinforcement is necessary for the manhole, the actual area

available for reinforcement must be calculated and compare with the area required for

reinforcement.

The following condition must be satisfied if no additional reinforcement is required:

A Ai

Where,

Ai

A 1 + A 2 + A3 + A 41 + A 43

Thus, the following area (A1, A2, A3, A41, A43) is calculated as follows.

A1 (largest):

A '1

r

1

=d(

1F r

E1 tF t 2 t n (E 1 tF t r )

N

F

mm 2

,

F

r

=

=

=1

1

where

F

N

130

mm 2

130

Page | 37

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Since both the nozzle and the vessel are made up of the same material, Then the term

1

1F r

will be cancel out.

2t n ( E1 tF t r )

A ' 1=

A ' 1=

r

d ( E1 tF t ,

E1=F=1=E

r

d( tt =602 ( 95 )=2408 mm2

1

1F r

1

1F r

t+t n ( E1 tF t r )(2t n E 1 tF t r )

A ' ' 1=2

t+t n ( E1 tF t r )=2 ( 9+50 )( 95 )=472 mm

A ' ' 1=2

Since A<A, then A=

A '1

= 2408 mm

A 2 (Smallest)

A ' 2 :First of all , assuming , Fr 2=Fr 1 since they both have the same formula(

Sn

)

SV

A ' 2=5 ( t nt rn ) Fr 2 t=5 ( 507 ) ( 1 9 )=1935 mm2

Page | 38

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Then substituting the values,

A ' ' 2=5 ( t nt rn ) Fr 2 t n=5 ( 507 )=10750 mm 2

Since

'

''

'

A 2< A 2 ,Then , A2= A 2 =1935 mm2

A 3 (Smallest )

A ' 3=5 t(t i Fr 2)=( 5 9 )( 46 1 )=2070mm

Substituting the values,

A ' ' 3=5 t i (t i Fr2 )=( 5 46 ) ( 46 1 ) =10,580 mm

A ' ' ' 3=2h (t i Fr 2)=2 17.5 ( 46 1 )=1,610 mm2

Since A ' ' ' 3 < A ' 3< A ' ' 3

For areas

A 43

and

, Then,

A 41

A 3= A ' ' ' 3=1,610 mm2

they are not considered since the welds vary from fillet to

butt weld type

A 41= A 43=0

by adding of A 1 A3

Ai=2,408+1935+1,610=5953 mm 2

By comparing both the required area for reinforcement, A and the area available for

reinforcement,

Page | 39

PRESSURE VESSEL DESIGN

By Network-6

Section 1

2

A=3007.38 mm

Ai=

2

5953 mm The condition Ai > A is satisfied

Then there is no additional reinforcement will be required.

4.3. Nozzles and flanges

Nozzles and flanges can be categorized into several categories depending on their sizes, types

and other attachments to vessels. A nozzle is a relatively simple device, a cylindrical

component that penetrates the shell or heads of a pressure vessel. The main function of

nozzles on the plates is to transport fluids and allow the liquids and gas to disperse

throughout the towers as the fluids flow through the nozzles. On the other hand, flanges

improve the strength of a structure and also apply as a guide for keeping a particular object in

place. Different column design requires different standards and designs of the nozzles and

flanges. Flanges are used for connecting pipe and instruments to vessels, for removable

vessel heads and manhole covers. For this particular design, then nozzle and flanges design is

strictly based on specification of nozzles provided in the project specification sheet. The

nozzles connecting the feed to column at the midpoint has a 200mm inside diameter and

vapour outlet diameter of 250 mm. The bottom product and reflux return have inside

diameter of 200mm.

Table4.1. Standard flanges

Pipe

Nominal

bolting

Flange

Raised

Output

Size

drilling

boss

face

diameter(mm)

D

d4

No

d2

Page | 40

d3

PRESSURE VESSEL DESIGN

By Network-6

76.1

Section 1

M12

65

160

14

32

110

130

100

20

18

335

295

M12

20

273

375

22

44

312

Typical Standard Flanges;

Figure4.1. Selected Standard flange

4.3. Design of skirt support for the vessel

The height of the vessel including height of each ellipsoidal head.

Height of the vessel,

Hv

Given:

o Length of cylindrical section = 37 m

o Internal column diameter = 1.5 m

Height of each ellipsoidal head, h

Since the ellipsoidal heads used for this design are a standard measurement as shown below

in Figure 4.2, it is safe to assume that the heads are manufactured with a major and minor

axis ratio of 2:1(Coulson and Richardsons chemical engineering Vol.6).

Page | 41

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Figure4.2. Standard ellipsoidal head

The height of each ellipsoidal head, h =

The height of vessel,

Hv

D

4

1.5

=0.375 m=375 mm

4

Hv

= (Length of cylindrical section) + (Height of the two ellipsoidal heads)

=37+2(0.375)= 37.75m

Height of the vessel, Hv =length of cylindrical section + height of the two ellipsoidal head

37 m +20.375 m =37.75 m

Approximate weight =

Total weight=

( 4 1.5 m 37.75 m) 1000 Kgm 9.81 ms =654.42 K

2

175.279+654.42=829.72 K N

Page | 42

PRESSURE VESSEL DESIGN

By Network-6

Section 1

As a first trial, take the skirt thickness as the same as that of the bottom of section

of the vessel,

t s=15 mm

Step1: The bending moment, in skirt.

The effect of bending moment of skirt, Ms, can be calculated as follow.

M s=

Fw 2

x

2

x=H s + H v

Where,

MS = Bending moment at the base of the skirt

FW = Load per unit length

HS = Height of skirt

H V = Height of the vessel

x=37.75+2.5=40.25 m

Ms=

2.076

( 40.252 )=1681.63 KNm

2

Step2: The bending stress in the skirt.

The bending stress in the skirt is given by;

bs=

4 Ms

( Ds +ts ) Ds ts

Assume as a first trial, take the skirt thickness as the same as that of the bottom

section of the vessel, 15 mm.

Where, Ds =Internal column diameter, =1.5m

ts = Thickness of the skirt = Thickness of the bottom section, =15mm

Page | 43

PRESSURE VESSEL DESIGN

By Network-6

Section 1

bs = Bending stress in the skirt

Thus,

bs=

4 1681.63 106 mm

= 62.812N/mm2

( 1500+15 ) 1500 15

Step3: The dead weight stress for the test and operating conditions.

For test condition,

ws

ws (test )=

Is given by,

W water

( Ds+ts ) ts

Where,

ws (test )=

Dead weight stress in the skirt for test condition

W wat er = Total weight of the vessel with contents (water).

Thus,

ws (test )=

654422.7 N

=

9.166N/mm2

( 1500+15 ) 15

For operating condition , ws (operating) : is given b

ws (operating)=

W operating

( Ds+ ts ) ts

Where,

ws (operating)= Dead weight stress in the skirt for operating condition

W vessel = Total dead weight of vessel with heads.

3

Thus,

ws (operating)=

175.3 10

= 2.455 N/mm2

( 1500+15 ) 15

Page | 44

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Step4: The resultant bending stress in the skirt.

test

For maximum: s ( compresive ) = )

bs +

s ( compresive )=62.812+9.166= 71.978N/mm2 72 N /mm 2

For minimum:

operating

ws (tensile )= bs + w )

ws (tensile )=62.8122.455= 60.357N/mm2

Step5: Design criteria:

A straight type skirt support is selected, where = 90 Material of construction used is

plain carbon steel maximum allowable design stress, S =115 N/mm 2 and Youngs modulus,

E=200,000N/mm2

at

ambient

temperature.

The

welding

efficiency,

=0.85.

Maximum dead-weight load on the skirt will occur when the vessel is full of water.

Since hydrocarbon materials have density that is lower than water, then we use density of

water to complete our calculations.

For the maximum:

Given the formula,

71.978

s ( compresive ) 0.125 E(

ts

)sin s

Ds

N

15

0.125 200,000

sin 90

2

1500

mm

Page | 45

PRESSURE VESSEL DESIGN

71.978

By Network-6

Section 1

N

250 N /mm2

2

(correct)

mm

For minimum:

Given the formula,

ws (tensile ) fsJ sin s

60.357

N

115 1 sin 90

mm2

60.357

N

N

115

2

mm

mm 2 (correct)

Since all the calculations and comparison above shows that all design criteria were

correct,add 2 mm for corrosion allowance, gives a design thickness of new skirt thickness,

ts

New skirt thickness,

ts =

ts

(Old thickness of the skirt) + (Corrosion allowance)

=15mm + 2mm = 17mm

Step6: Design Base ring/flange and anchor bolt

For

D' s

1.5 m

Determine the number of bolts required, N bolts

Since the measurements for the pitch diameter were not given, it was assumed that the

measurement of column diameter would be used to make an assumption for the pitch

diameter. An estimation of 10% allowance was then added to the pitch circle diameter

column.

Page | 46

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Number of bolts required N bolts given by the formula:

N

bolts=

Ds

D P

600

Where,

= Internal column diameter = 1.5 m

D P = Pitch circle diameter

Ds

+ (10

of D s

= 1.5 + 0.1 x 1.5 = 1.65 m = 1,650 mm

N bolts=

Thus,

1,650

=8.635 mm

600

By taking the closest multiple of 4, 12 is the nearest value to the number of bolts required,

N bolts

Determine the required bolt area,

Ab,

This is given by:

A b ,=

Where,

f b=

1

N bolts f

vessel

4 MS

(

W

Dp

N bolts=

Number of bolts required = 12 Bolts

N

Bolt design stress = 125 mm2

M S= Bending moment in skirt = 1681.63KNm

W vessel = Total dead weight of vessel with heads = 175.3KN

Page | 47

PRESSURE VESSEL DESIGN

By Network-6

Section 1

D p= Pitch circle diameter = 1.6 5m = 1650 mm

A b ,=

1

N bolts f

vessel

4 MS

(

W

Dp

1

4 1681.63 106

(

175300) =2600.9mm2

12 125

1650

Dbolt ,

The bolt root diameter

Is given by the formula:

D bolt =

4 2600.9

D bolt =

4 Ab

=57.546 mm

With the addition of base rings, the bolt should be sufficient enough to distribute the total

compressive load to the foundation.

The total compressive load on each base ring per unit length,

Fbolt

4 MS

Is Given by:

Where,

W vessel

D

Ds

)

F bolt =

Wvessel= Total dead weight of vessel with heads = 175.3KN

Ms= Bending moment in skirt = 1681.63 103 Nm

Ds= Internal column diameter = 1.5m

Page | 48

PRESSURE VESSEL DESIGN

Fbolt =(

Fbolt =

4 MS

D

2

s

By Network-6

Section 1

W vessel

)

D

s

4 1681.63 10 175300

2

( 1500 )

( 1500 )

=988.878N/mm

The minimum width of base ring, Lb

Given by the formula:

b=

F bolt

fc

Fbolt = Total compressive load on the base ring per unit length = 988878N/m

f c =maximum allowable bearing pressure on the concrete foundation pad bearing pressure

5N

b=

F bolt

3

f c 10

Lb=

988878

=

3

5 10

197.8 mm=0.1978m

Due to the large base ring width, a flared skirt shall be used as an alternative to the design.

Therefore, the requirements and assumptions for the new skirt are:

Flared skirt bottom diameter,

D s = 2.5 m

Bolt circle diameter, Dolt =

D s + (10% of

Ds )

Page | 49

PRESSURE VESSEL DESIGN

By Network-6

Section 1

= 2.5 m + (1. 0.1)

= 2.5 m + 0.15 m = 2.65 m = 2650 mm

Number of bolt,

N ' bolts=

D ' p

600

D' p=D ' s+ ( 10 of D ' s )

D' p=2.5+ (10 of 2.5 )

= 2.75 m = 2750mm

(2,750)

N ' bolts=

= 14.39 14.4

600

The skirt base angle, s .

D' s

Skirt base angle, s (With

s=tan 1 (

s=tan (

=2.5 m) given by,

D 's

)

0.5 ( D' s Ds )

2.5

)=

78.69 0

0.5 ( 2.51.5 )

The bolt spacing.

Bolt spacing is given by the formula:

bolt specing=

D bolt '

N bolt '

Where,

D bolt' = Bolt circle diameter = 2650 mm

Page | 50

PRESSURE VESSEL DESIGN

By Network-6

Section 1

N bolt '= Number of bolts =14.39

bolt specing=

(2,650)

= 578.542 mm (satisfactory)

14.39

The required bolt area,

Is given by the formula:

Ab

f

4 Ms

N bolt ' ( b)(

W vessel )

D bolt '

1

Ab=

W vessel = Total dead weight of vessel with heads = 175.3KN

M s=

N bolt ' =

Bending moment in skirt

Number of bolts required = 14.39

D bolt' = Bolt circle diameter = 2.650m = 2650 mm

f b= Bolt design stress = 125 N/mm2

Ab=

4 ( 1681630 103 )

1

175300 = 256mm2

2,650

14.39 ( 125 )

The total compressive load on each base ring per unit length, Fbolt.

Given the formula:

Fbolt =(

4 Ms

W

W vessel vessel )

D ' s

D 's

2

Where,

W vessel = Total dead weight of vessel with heads =175.3KN

Page | 51

PRESSURE VESSEL DESIGN

M s=

By Network-6

Section 1

Bending moment in skirt = 1681.63kNm

D' s = Flared skirt bottom diameter =2.5m =2500mm

Fbolt =

4 1681.63 106 175300

+

= 364.89 N/mm=364890N/m

2

2500

( 2,500 )

The minimum width of base ring,

Given the formula:

fc=

Lb =

Lb

F ' bolt

fc

Maximum allowable bearing pressure on the concrete foundation pad Bearing

pressure = 5 N/mm2

Lb =

364890

= 72.978mm 73 mm

5

The actual bearing pressure on the concrete foundation,

Given the formula:

f ' c=

F bolt '

Actual width

Actual width =Lr + ts + ti

Where,

ts

= Skirt thickness = 17mm,

ti = Insulation thickness = 50mm

Fbolt = Total compressive load on the base ring per unit length

Lr =Distance from the edge of the skirt to the outer edge of the ring = 178 mm (Sinnott.,

Coulson & Richardson's Chemical Engineering 1999) : Using Bolt size 70 (BS 4190:1967)

Actual width = 178 + 17 +50 = 245 mm

Page | 52

PRESSURE VESSEL DESIGN

f ' c=

By Network-6

Section 1

364.89

= 1.4893 N/mm2

245

The base ring thickness, tb.

The base ring thickness given by the formula:

3 (1.4893)

=

140

31.798mm 32 m

3f'c

t b=Lr

t =178

fr b

Equipment No

Data sheet

Tag pv-1

Fun. sieve plate column

Sheet No.1

Customer: ADU

Shell

Heads

torispherical

ellipsoidal

12.17mm

7mm

supports

Flanges

17mm

25mm

1200

10bar

Thickness

9mm

KN

D. pressure

1200 mm2

1200

KN

mm2

KN

1200 mm2

KN

mm2

Page | 53

PRESSURE VESSEL DESIGN

D.

temperature

By Network-6

Section 1

150 c

150 c

150 c

150 c

150 c

ASME

ASME

ASME

ASME

Stainless

steel

Stainless steel

carbon

Stainless

steel

Design code

ASME

Material

construction

Stainless

steel

unestablished

(304)

Process

material

Water

Water

Water

Water

Water

Diameter

1500mm

1500mm

1500mm

1500mm

395mm

Length

37000mm

0.75mm

Design by: Network 6

Nozzle

Skirt carbon

Silicon killed

ID No:(0485,0963,1242,1406,1443,1578)/06

Section: 1

2mm

Corrosion

Date: 12/12/2016

Checked by: ____________?

allowance

Page | 54

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Distil ate

Feed

Bottom

Figure4.3. Schematic Pressure vessel diagram

Page | 55

PRESSURE VESSEL DESIGN

By Network-6

Section 1

4.4. Discussion

Since a vessel needs to withstand design loads such as wind and the dead weight loads, the

column wall has to be gradually thicker from the top to the bottom Thus, the pressure at the

vessel base is maintained at maximum and this requires greater thickness of the column wall

and also larger diameter for the column. This is crucial to prevent the vessel from collapsing

as well as to increase its capability to endure wind loading and dead weight of vessel and

content that contributed to the high stress from increase in pressure.

The ellipsoidal head is chosen to satisfy the specifications mentioned earlier. However, there

were also other factors considered when chosen the vessel head. Essentially, the best vessel

head should be able to withstand maximum stress with the least materials and economically

feasible (Sinott 2008) .From the calculated thickness of both heads previously, Ellipsoidal

head with smaller thickness compared to that of torispherical Head may suggested an

economically feasible head. The head resembles an ellipse with its radius varying

continuously in its cross section. The varying radius results in a smooth transition between

the dome and cylindrical section of the vessel. Its head is deeper than a comparable

torispherical head. When an opening and its reinforcement are in an ellipsoidal head, and

located entirely within a circle, the centre of which coincides with head. The diameter of the

circle is equal to 80% of the shell diameter. tr is the thickness required for a seamless sphere

of radius K1D, where D is the shell internal diameter and K1 is 0.9 (Steward and Lewis

2013). Assume no weld is used in the nozzle. The required reinforcement area is needed to

compare with the total area of nozzle in feed, vapour out, bottom product, 1 m above the

bottom of the column and 1.5 m below the top of the column to ensure the nozzle got

reinforcement. To obtain the total area, the area of excess thickness in shell or head, area

available in nozzle projecting outward and area available in nozzle projecting inward are

determined. If,

Ai A

.Opening is adequately reinforced; if

Ai< A .

Therefore ,

there will no additional reinforcements needed.

Page | 56

PRESSURE VESSEL DESIGN

By Network-6

Section 1

Chapter -5

CONCLUSION AND RECOMMENDATION

5.1 CONCLUSION

Generally, The design of pressure vessel is initialized with the specification requirements in

terms of standard technical specifications along with numerous requirements that lay hidden

from the market. The design of a pressure vessel is more of a selection procedure, selection of

its components to be more precise rather designing each and every component. Regarding

storage of fluid for a pressure vessel system should be preferred due to its simplicity, better

sensitivity, higher reliability, low maintenance, compactness for the same capacity. The

storage of fluid at high pressure in the pressure vessel is at the heart of its performance and is

the first step towards the design.

For pressure vessels, finite element analysis provides an additional tool for use in analysis.

However, it must be compared to other available data, not taken as being correct just because

it looks right. Used with this understanding, finite element analysis offers great insight into

the complex interactions found in pressure vessel design. With the help of finite element

analysis, we can study the actual maximum stress distributions in the different components of

pressure vessel and the actual behavior of pressure vessel.

5.2. Recommendation

To do this project many problems have been occurred. Those are the courses which are

related to AutoCAD, project writing, shortage of materials such as computer, shortage of

knowledge about how can we design, it takes many times to practice and understand.

So for next it should be given the courses of introduction to project, AutoCAD and more

practice of the course of chemical apparatus design before such big project is given and

simple projects must be given before doing such it.

Page | 57

PRESSURE VESSEL DESIGN

By Network-6

Section 1

References

Vessel Design Handbook, AZBEL, D. S. and CHEREMISINOFF, N. P. (1982)

Chemical and Process Equipment Design: vessel design and selection (Ann Arbor

Science).

BEDNAR, H. H. (1990) Pressure 2nd edn (Krieger).

BHATTACHARYYA, B. C. (1976) Introduction to Chemical Equipment Design,

Mechanical Aspects (Indian Institute of Technology).

BERGMAN, D. J. (1963) Trans. Am. Soc. Mech. Eng. (J. Eng. for Ind.) 85, 219.

Temperature gradients for skirt supports of hot vessels.

BIRCHALL, H. and LAKE, G. F. (1947) Proc. Inst. Mech. Eng. 56, 349. An

alternative form of pressure vessel of novel construction.

MyChemE. Types of Vessel Head. 4 March, 2013. http://www.mycheme.com/types-ofvessel-head/ (accessed 29 October, 2015).

http://www.inspection-for-industry.com/pressure-vessel-heads.html

Sinnott, R.K. 2008. Coulson & Richardsons Chemical Engineering Volume 6:

Chemical Engineering Design, 3rd ed. Burlington, MA: Butterworth-Heinemann

Publications.