Professional Documents

Culture Documents

HRD C Frame Anchor TDS

Uploaded by

ronyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HRD C Frame Anchor TDS

Uploaded by

ronyCopyright:

Available Formats

HRD Frame anchor

Redundant fastening

HRD Frame anchor, Redundant fastening

Anchor version

Benefits

HRD-C 8x

HRD CR 8x

Innovative screw design for better hold

Suitable on practically all base materials

HRDHRDHRDHRDHRDHRDHRDHRDHRDHRDHRDHRDHRD-

Concrete

Tensile

zone*)

Solid brick

Hollow brick

Autoclaved

aerated

concrete

Flexible embedment depth (approved at

50mm and 70mm)

Suitable for fastening thicknesses up to

260mm

Available in 4 different materials for

optimum suitability in all

corrosive environments

Pre-assembled for optimum handling

and fastening quality

Prestressed

hollow core

slabs

Window

frame

Fire

resistance

European

Technical

Approval

CE

conformity

a)

Redundant fastening only

Approvals / certificates

Description

a)

European technical approval

Fire test report

b)

Window frame report

Authority / Laboratory

DIBt, Berlin

MFPA, Leipzig

Ift, Rosenheim

No. / date of issue

ETA-07/0219 / 2012-09-18

GS 3.2/10-157-1/ 2010-09-02

Ift report 105 33035 / 2007-07-09

a)

All data given in this section according ETA-07/0219, issue 2012-09-18. The anchor is to be used only for

redundant fastening for non-structural applications.

b)

only available for HRD 8

c)

only valid for HRD 10

370

09 / 2014

HRD Frame anchor

Redundant fastening

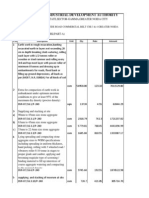

Basic loading data according ETAG 020

All data in this section applies to

- Correct setting (See setting instruction)

- No edge distance and spacing influence

- Base material as specified in the table

Minimum base material thickness

- Steel failure

- Shear without lever arm

- Anchors in redundant fastening

- The data that are highlighted in light grey are additional Hilti recommended data and not part of the approval

09 / 2014

371

HRD Frame anchor

Redundant fastening

Characteristic resistance

Anchor size

HRD 8

NRk

Concrete C 12/15

Concrete C 16/20 C 50/60

Solid clay brick

Mz 2,0

DIN V 105-100 / EN 771-1

Solid sand-lime brick

KS 2,0

DIN V 106 / EN 771-2

Lightweight solid block

Vbl 0,9

DIN V 18151-100 / EN 771-3

Vertically perforated clay brick

Hlz 1,2-2DF

brick

e)

F

Vertically perforated clay brick

Hlz 1,0-2DF

brick

e)

G

Vertically perforated clay brick

Poroton T8

brick

e)

M

Vertically perforated clay brick

Hlz 1,0-9DF

brick

e)

L

372

NRk

[kN]

2,0

3,0

6,9 / 6,6

b)

3,0

fb

FRk

[kN]

1,5

fb

FRk

[kN]

1,2

fb

FRk

[kN]

2,5

fb

FRk

[kN]

2,0

fb

FRk

[kN]

fb

FRk

[kN]

FRk

[kN]

0,50

FRk

[kN]

1,4

FRk

[kN]

fb

FRk

fb

6,9 / 6,6

10,6 / 10,1

b)

4,5

b)

10,6 / 10,1

3,0

d)

4,5

2,0

d)

3,0

3,0

d)

4,5

2,0

d)

3,0

3,5

d)

6,0

2,5

d)

4,5

-

hnom

=70mm

hnom

=90mm

6,0

/ 11,1

c)

8,5

b)

/ 11,1

c)

f)

f)

f)

f)

f)

f)

0,50

[kN]

1,5

FRk

[kN]

2,0

fb

FRk

[kN]

2,0

fb

FRk

[kN]

0,4

0,75

fb

FRk

[kN]

0,5

0,9

fb

FRk

[kN]

0,6

0,9

FRk

[kN]

0,9

1,5

fb

FRk

[kN]

2,0

2,5

fb

FRk

[kN]

3,0

3,5

fb

FRk

[kN]

0,75

1,5

fb

FRk

[kN]

1,2

1,5

fb

FRk

[kN]

1,5

1,5

fb

FRk

[kN]

1,5

2,0

fb

FRk

[kN]

2,0

3,0

fb

fb

Vertically perforated clay brick

e)

VHlz 1,6-2DF brick H

[kN]

hnom

=50mm

[kN]

fb

brick

VRk

hnom

=50mm

VRk

fb

Ital. solid brick

Tufo

Hollow clay brick

Hlz B 12/1,2

e)

A

[kN]

HRD 10

N/mm

09 / 2014

HRD Frame anchor

Redundant fastening

Characteristic resistance

Anchor size

Hollow sand-lime brick

KSL 12/1,4

brick

e)

O

HRD 8

HRD 10

hnom

=50mm

hnom

=50mm

hnom

=70mm

hnom

=90mm

FRk

[kN]

0,75

f

Vertically perforated sand-lime b

brick

fb

e)

KSL 1,6-2DF brick P

fb

FRk

[kN]

1,5

FRk

[kN]

1,5

FRk

[kN]

2,0

f

Vertically perforated sand-lime b

brick

fb

e)

KSL 1,4-3DF brick Q

fb

FRk

[kN]

2,0

FRk

[kN]

2,5

FRk

[kN]

3,0

fb

Vertically perforated sand-lime

fb

brick

KSL R 1,6-16DF

brick

fb

e)

R

fb

Lightweight hollow brick

Hbl 2/0,8

brick

fb

e)

S

Lightweight concrete hollow

fb

block

e)

fb

Hbl 1,2-12DF brick T

FRk

[kN]

0,9

1,2

FRk

[kN]

1,2

1,5

FRk

[kN]

1,5

2,0

FRk

[kN]

2,0

2,5

FRk

[kN]

0,30

FRk

[kN]

0,5

0,75

FRk

[kN]

1,2

2,0

fb

FRk

[kN]

1,5

fb

FRk

[kN]

0,6

fb

FRk

[kN]

0,9 (C)

1,5 (I)

fb

FRk

[kN]

0,60

fb

FRk

[kN]

1,5

2,0

fb

FRk

[kN]

1,5

fb

FRk

[kN]

0,50

AAC 2

FRk

[kN]

0,9

0,9

AAC 4

FRk

[kN]

2,0

2,5

FRk

[kN]

2,0

2,5

Ital. Hollow brick

Mattone

brick

e)

E

Ital. Hollow brick

e)

Poroton P700 brick N

Ital. Hollow brick

Doppio Uni

brick

e)

C+I

Span. Hollow brick

Rojo hydrofugano

brick

e)

D

Span. Hollow brick

Ladrillo perforado

brick

e)

J

Span. Hollow brick

e)

Clinker mediterraneo brick K

French Hollow brick

e)

Brique Creuse brick B

Autoclaved aerated concrete

AAC

09 / 2014

fb

AAC 6

FRk

[kN]

3,5

d)

4,5

d)

373

HRD Frame anchor

Redundant fastening

Design resistance

Anchor size

HRD 8

NRd

Concrete C 12/15

Concrete C 16/20 C 50/60

Solid clay brick

Mz 2,0

DIN V 105-100 / EN 771-1

Solid sand-lime brick

KS 2,0

DIN V 106 / EN 771-2

Lightweight solid block

Vbl 0,9

DIN V 18151-100 / EN 771-3

b)

1,7

0,6

5,5 / 5,2

fb

FRd

[kN]

0,48

fb

FRd

[kN]

1,0

fb

FRd

[kN]

0,8

fb

FRd

[kN]

fb

FRd

[kN]

FRd

[kN]

0,2

FRd

[kN]

0,56

FRd

[kN]

fb

FRd

fb

8,5 / 8,1

b)

2,5

b)

8,5 / 8,1

1,2

d)

1,8

0,8

d)

1,2

1,2

d)

1,8

0,8

d)

1,2

1,4

d)

2,4

1,0

d)

1,8

-

hnom

=70mm

hnom

=90mm

3,3

/ 8,5

c)

4,7

b)

/ 8,5

c)

f)

f)

f)

f)

f)

f)

0,2

[kN]

0,6

FRd

[kN]

0,8

fb

FRd

[kN]

0,8

fb

FRd

[kN]

0,16

0,3

fb

FRd

[kN]

0,2

0,36

fb

FRd

[kN]

0,24

0,36

FRd

[kN]

0,36

0,6

fb

FRd

[kN]

0,8

1,0

fb

FRd

[kN]

1,2

1,4

fb

FRd

[kN]

0,3

0,6

fb

FRd

[kN]

0,48

0,6

fb

FRd

[kN]

0,6

0,6

fb

FRd

[kN]

0,6

0,8

fb

FRd

[kN]

0,8

1,2

fb

374

5,5 / 5,2

[kN]

fb

Vertically perforated clay brick

e)

Hlz 1,0-9DF

brick L

[kN]

1,7

FRd

Hollow clay brick

e)

Hlz B 12/1,2

brick A

Vertically perforated clay brick

e)

Poroton T8

brick M

NRd

1,1

fb

fb

Vertically perforated clay brick

e)

VHlz 1,6-2DF brick H

[kN]

hnom

=50mm

[kN]

Ital. solid brick

Tufo

Vertically perforated clay brick

e)

Hlz 1,0-2DF

brick G

VRd

hnom

=50mm

VRd

fb

Vertically perforated clay brick

e)

Hlz 1,2-2DF

brick F

[kN]

HRD 10

N/mm

09 / 2014

HRD Frame anchor

Redundant fastening

Design resistance

Anchor size

Hollow sand-lime brick

KSL 12/1,4

brick

e)

O

HRD 8

fb

HRD 10

hnom

=50mm

hnom

=50mm

hnom

=70mm

hnom

=90mm

FRd

[kN]

0,3

FRd

[kN]

0,6

FRd

[kN]

0,6

FRd

[kN]

0,8

f

Vertically perforated sand-lime b

brick

fb

e)

KSL 1,4-3DF brick Q

fb

FRd

[kN]

0,8

FRd

[kN]

1,0

FRd

[kN]

1,2

fb

Vertically perforated sand-lime fb

brick

e)

fb

KSL R 1,6-16DF brick R

fb

Lightweight hollow brick

fb

e)

Hbl 2/0,8

brick S

FRd

[kN]

0,36

0,48

FRd

[kN]

0,48

0,6

FRd

[kN]

0,6

0,8

FRd

[kN]

0,8

1,0

FRd

[kN]

0,12

fb

FRd

[kN]

0,2

0,3

fb

FRd

[kN]

0,48

0,8

fb

FRk

[kN]

0,6

fb

FRd

[kN]

0,24

FRd

[kN]

0,36 (C)

0,6 (I)

fb

FRd

[kN]

0,24

fb

FRd

[kN]

0,6

0,8

fb

FRd

[kN]

0,6

fb

FRd

[kN]

0,20

AAC 2

FRd

[kN]

0,45

0,45

AAC 4

FRd

[kN]

0,21

1,0

1,25

FRd

[kN]

1,0

f

Vertically perforated sand-lime b

brick

fb

e)

KSL 1,6-2DF brick P

fb

Lightweight concrete hollow

block

e)

Hbl 1,2-12DF brick T

Ital. Hollow brick

e)

Mattone

brick E

Ital. Hollow brick

e)

Poroton P700 brick N

12 N/mm

Ital. Hollow brick

e)

Doppio Uni

brick C+I

Span. Hollow brick

e)

Rojo hydrofugano brick D

Span. Hollow brick

e)

Ladrillo perforado brick J

Span. Hollow brick

e)

Clinker mediterraneo brick K

French Hollow brick

e)

Brique Creuse brick B

Autoclaved aerated concrete

AAC

EN 771-4

09 / 2014

AAC 6

FRd

[kN]

0,21

1,75

1,25

d)

2,25

d)

375

HRD Frame anchor

Redundant fastening

Recommended loads a)

Anchor size

HRD 8

Nrec

Concrete C 12/15

Concrete C 16/20 C 50/60

Solid clay brick

Mz 2,0

DIN V 105-100 / EN 771-1

Solid sand-lime brick

KS 2,0

DIN V 106 / EN 771-2

Lightweight solid block

Vbl 0,9

DIN V 18151-100 / EN 771-3

Hollow clay brick

Hlz B 12/1,2

e)

A

Vertically perforated clay brick

Hlz 1,2-2DF

brick

e)

F

Vertically perforated clay brick

Hlz 1,0-2DF

brick

e)

G

Vertically perforated clay brick

e)

VHlz 1,6-2DF brick H

Vertically perforated clay brick

Poroton T8

brick

e)

M

Vertically perforated clay brick

Hlz 1,0-9DF

brick

e)

L

376

[kN]

Nrec

[kN]

hnom

=50mm

0,8

1,2

3,9 / 3,7

b)

1,2

[kN]

fb

Frec

[kN]

0,42

3,9 / 3,7

fb

Frec

[kN]

0,34

fb

Frec

[kN]

0,7

fb

Frec

[kN]

0,57

fb

Frec

[kN]

fb

Frec

[kN]

Frec

[kN]

0,14

Frec

[kN]

0,4

Frec

[kN]

fb

Frec

fb

6,1 / 5,8

b)

1,8

b)

6,1 / 5,8

0,85

d)

1,28

0,57

d)

0,85

0,85

d)

1,28

0,57

d)

0,85

1,0

d)

1,71

0,71

d)

1,28

-

hnom

=70mm

hnom

=90mm

2,4

/ 6,1

c)

3,4

b)

/ 6,1

c)

f)

f)

f)

f)

f)

f)

0,14

[kN]

0,42

Frec

[kN]

0,57

fb

Frec

[kN]

0,57

fb

Frec

[kN]

0,11

0,21

fb

Frec

[kN]

0,14

0,25

fb

Frec

[kN]

0,17

0,25

fb

Frec

[kN]

0,25

0,42

fb

Frec

[kN]

0,57

0,71

fb

Frec

[kN]

0,85

1,0

Frec

[kN]

0,21

0,42

fb

Frec

[kN]

0,34

0,42

fb

Frec

[kN]

0,42

0,42

fb

Frec

[kN]

0,42

0,57

fb

Frec

[kN]

0,57

0,85

fb

brick

Vrec

hnom

=50mm

Vrec

fb

Ital. solid brick

Tufo

[kN]

HRD 10

fb

fb

N/mm

09 / 2014

HRD Frame anchor

Redundant fastening

Recommended loads a)

Anchor size

Hollow sand-lime brick

e)

KSL 12/1,4

brick O

HRD 8

hnom

=50mm

hnom

=50mm

hnom

=70mm

hnom

=90mm

Frec

[kN]

0,21

f

Vertically perforated sand-lime b

brick

fb

e)

KSL 1,6-2DF brick P

fb

Frec

[kN]

0,42

Frec

[kN]

0,42

Frec

[kN]

0,57

f

Vertically perforated sand-lime b

brick

fb

e)

KSL 1,4-3DF brick Q

fb

Frec

[kN]

0,57

Frec

[kN]

0,71

Frec

[kN]

0,85

fb

Vertically perforated sand-lime fb

brick

e)

fb

KSL R 1,6-16DF brick R

fb

Lightweight hollow brick

fb

e)

Hbl 2/0,8

brick S

Frec

[kN]

0,25

0,34

Frec

[kN]

0,34

0,42

Frec

[kN]

0,42

0,57

Frec

[kN]

0,57

0,71

Frec

[kN]

0,09

fb

Frec

[kN]

0,14

0,21

fb

Frec

[kN]

0,34

0,57

Lightweight concrete hollow

block

e)

Hbl 1,2-12DF brick T

fb

HRD 10

Ital. Hollow brick

e)

Mattone

brick E

Ital. Hollow brick

e)

Poroton P700 brick N

fb

Frec

[kN]

0,43

fb

Frec

[kN]

0,17

Ital. Hollow brick

e)

Doppio Uni

brick C+I

fb

Frec

[kN]

0,25 (C)

0,42 (I)

fb

Frec

[kN]

0,17

fb

Frec

[kN]

0,42

0,57

fb

Frec

[kN]

0,42

fb

Frec

[kN]

0,14

AAC 2

Frec

[kN]

0,32

0,32

AAC 4

Frec

[kN]

0,15

0,71

0,89

Frec

[kN]

0,71

0,89

Span. Hollow brick

e)

Rojo hydrofugano brick D

Span. Hollow brick

e)

Ladrillo perforado brick J

Span. Hollow brick

e)

Clinker mediterraneo brick K

French Hollow brick

e)

Brique Creuse brick B

Autoclaved aerated concrete

AAC

EN 771-4

a)

b)

c)

d)

e)

f)

AAC 6

Frec

[kN]

0,15

1,25

d)

1,6

d)

With overall partial safety factor for action = 1,4. The partial safety factors for action depend on the type of

loading and shall be taken from national regulations.

Values for hot-dip galanized carbon steel

Values for stainless steel

Valid for edge distance c 150mm, intermediate values can be interpolated

Specification of hollow base material brick types see separate table below

Data can be determined by job-site testing, data for h nom = 50mm can be applied.

09 / 2014

377

HRD Frame anchor

Redundant fastening

Characteristic resistance for pull-out failure (plastic sleeve) for use in concrete

Anchor type

HRD 8

HRD 10

Pull-out failure in standard concrete slabs

Embedment depth

Characteristic resistance

Partial safety factor

hnom

NRk,p

C12/15 NRk,p

Mc

[mm]

[kN]

[kN]

50

3,0

2,0

50

4,5

3,0

1,8

70

8,5

6,0

50

3,5

2,5

1,8

50

0,6

1,5

2,5

3,5

1,8

a)

Pull-out failure in thin skins (weather resistant skins of external wall panels)

Embedment depth

Characteristic

resistance

h = 40mm

to 100mm

Partial safety factor

hnom

NRk,p

C12/15 NRk,p

Mc

[mm]

[kN]

[kN]

a)

Pull-out failure in precast prestressed hollow core slabs

Embedment depth

db

Characteristic db

resistance

db

db

Partial safety factor

mm

hnom

NRk,p

NRk,p

NRk,p

NRk,p

Mc

a)

[mm]

[kN]

[kN]

[kN]

[kN]

a) In absence of other national regulations

378

09 / 2014

HRD Frame anchor

Redundant fastening

Specification of hollow base material brick types

Specification

Picture / drilling method

Hollow clay bricks according EN 771-1

brick A

Hlz B 12/1,2

LxWxH [mm]: 300x240x248

hmin [mm]: 240

Specification

Picture / drilling method

brick B

Brique Creuse

Rotary

drilling hmin [mm]: 210

Rotary

drilling

brick C

Doppio Uni

LxWxH [mm]: 230x120x100

hmin [mm]: 120

brick E

Mattone

LxWxH [mm]: 240x180x100

hmin [mm]: 180

brick G

Hlz 1,0-2DF

LxWxH [mm]: 240x115x113

hmin [mm]: 110

brick D

Rotary Rojo hydrofugano

drilling LxWxH [mm]: 240x115x50

hmin [mm]: 115

brick F

Rotary Hlz 1,2-2DF

drilling LxWxH [mm]: 240x115x113

hmin [mm]: 115

brick H

Hammer VHlz 1,6-2DF

drilling LxWxH [mm]: 240x115x113

hmin [mm]: 115

brick I

Doppio Uni

LxWxH [mm]: 250x120x190

hmin [mm]: 120

brick K

Clinker mediterraneo

LxWxH [mm]: 240x113x50

hmin [mm]: 113

brick J

Rotary Ladrillo perforado

drilling LxWxH [mm]: 240x110x100

hmin [mm]: 110

brick L

Hlz 1,0-9DF

Hammer LxWxH [mm]: 372x175x238

drilling hmin [mm]: 175

brick M

Poroton T8

LxWxH [mm]: 248x365x249

hmin [mm]: 365

brick N

Poroton P700

Rotary LxWxH [mm]: 225x300x190

drilling hmin [mm]: 300

Rotary

drilling

Hollow sand-lime bricks according EN 771-2

brick P

brick O

KSL 12/1,4

KS L 1,6-2DF

Hammer LxWxH [mm]: 240x115x113

LxWxH [mm]: 240x248x248

drilling hmin [mm]: 115

hmin [mm]: 240

Hammer

drilling

brick Q

KS L 1,4-3DF

LxWxH [mm]: 240x175x113

hmin [mm]: 175

Rotary

drilling

Hammer

drilling

Hammer

drilling

Rotary

drilling

Rotary

drilling

brick R

KS L R 1,6-16DF

Hammer LxWxH [mm]: 480x240x248

drilling hmin [mm]: 240

Rotary

drilling

Lightweight concrete hollow block according EN 771-3

brick S

brick T

Hbl 2/0,8

Hbl 1,2-12DF

LxWxH [mm]: 497x240x248

LxWxH [mm]: 497x175x238

hmin [mm]: 240

hmin [mm]: 175

Hammer drilling

09 / 2014

Rotary drilling

379

HRD Frame anchor

Redundant fastening

Requirements for redundant fastening

The definition of redundant fastening according to Member States is given in the ETAG 020. In Absence of a

definition by a Member State the following default values may be taken

a)

Minimum number

of fixing points

Minimum number

of anchors per fixing point

Maximum design load of action

a)

NSd per fixing point

3 kN

4,5 kN

The value for maximum design load of actions per fastening point N Sd is valid in general that means all

fastening points are considered in the design of the redundant structural system.

Service temperature range

Hilti HRD frame anchors may be applied in the temperature range given below.

Temperature range

Base material

temperature

Temperature range

-40 C to +80 C

Maximum long term

base material

temperature

+50 C

Maximum short term

base material

temperature

+80 C

Max short term base material temperature

Short-term elevated base material temperatures are those that occur over brief intervals, e.g. as a result of

diurnal cycling.

Max long term base material temperature

Long-term elevated base material temperatures are roughly constant over significant periods of time.

Materials

Mechanical properties

Anchor size

Nominal tensile strength fuk

Yield strength fyk

Stressed cross-section As

Moment of resistance W

0

Char. bending resistance M Rk,s

HRD 8

[N/mm]

[N/mm]

[mm]

[mm]

[Nm]

HRD 10

Galv. steel

Stainless steel

Galv. steel

Hot-dip

galvanised

Stainless steel

600

480

22,9

15,5

11,1

580

450

22,9

15,5

10,8

600

480

35,3

29,5

21,3

600

480

33,7

27,6

19,9

630

480

35,3

29,5

22,3

Material quality

Part

Sleeve

Screw

380

HRD-C, -H, -K, -P

HRD-HF

HRD-CR2, -HR2, -KR2, -PR2

HRD-CR, -HR, -KR, -PR

Material

Polyamide, colour red

Carbon steel, galvanised to min. 5 m

Carbon steel, hot-dip galvanized to min. 65 m

Stainless steel, corrosion class II: 1.4301 / 1.4567

Stainless steel, corrosion class III: 1.4362 / 1.4401 / 1.4404 / 1.4571

09 / 2014

HRD Frame anchor

Redundant fastening

Anchor dimensions

Anchor size

HRD 8

HRD 10

Minimum thickness of fixture

tfix,min

[mm]

Maximum thickness of fixture

tfix,max

[mm]

90

260

Diameter of the sleeve

dnom

[mm]

10

Minimum length of the sleeve

l1,min

[mm]

60

60

Maximum length of the sleeve

l1,max

[mm]

140

310

Diameter of plastic washer

dpw

[mm]

17,5

Thickness of plastic washer

tpw

[mm]

Diameter of the screw

dS

[mm]

Minimum length of the screw

l2,min

[mm]

65

65

Maximum length of the screw

l2,max

[mm]

145

315

Head diameter of countersunk screw

dsc

[mm]

11

14

Head diameter of hexhead screw

dsw

[mm]

17,5

Anchor sleeve

dnom

dpw

tpw

Special screw

dsc

ds

2

dsw

dsw

09 / 2014

381

HRD Frame anchor

Redundant fastening

Setting

Installation equipment

Anchor size

Rotary hammer

Other tools

hammer, screw driver

Setting instruction

Additional preparation in case of application in precast prestressed hollow core slabs

After drilling follow the main instruction above

For detailed information on installation see instruction for use given with the package of the product.

382

09 / 2014

HRD Frame anchor

Redundant fastening

Setting details: depth of drill hole h1 and nominal anchorage depth hnom

hnom,1

ttol

h1,1

hmin

tfix

hnom,2

ttol

h1,2

tfix

hmin

Application with hnom,3 = 90mm analogue

Setting details HRD

HRD 8

HRD 10

Drill hole diameter

do

[mm]

10

Cutting diameter of drill bit

dcut

[mm]

8,45

10,45

Depth of drilled hole to deepest point

h1,1

[mm]

60

60

h1,2

[mm]

80

h1,3

[mm]

100

hnom,1

[mm]

50

50

hnom,2

[mm]

70

hnom,3

[mm]

Countersunk screw

df

[mm]

8,5

11

Hexhead screw

df

[mm]

12

Overall plastic anchor embedment depth in base

material

Diameter of clearance

hole in the fixture

Installation temperature

a)

[C]

90

a)

a)

-10 - +40

for use in AAC

09 / 2014

383

HRD Frame anchor

Redundant fastening

Setting parameters

Anchor size

Minimum base

material thickness

Minimum spacing

Concrete

Concrete thin skin

Masonry (depending on

brick type, see specification

of brick types above)

Concrete C12/15

Masonry and AAC

Masonry and AAC

Minimum edge

distance

Concrete C12/15

Masonry and AAC

Critical spacing in

a)

concrete

Concrete C12/15

Critical edge distance

b)

in concrete

Concrete C12/15

HRD 8

HRD 10

hnom =50mm

hnom

hnom

=50mm =70mm

100

120

hmin

hmin

hmin

[mm]

[mm]

[mm]

100

smin

[mm]

100

50

for c

smin

for c

amin

smin1

smin2

cmin

for s

cmin

for s

cmin

scr,N

scr,N

ccr,N

ccr,N

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

50

140

70

250

d)

200 (120 )

d)

400 (240 )

50

100

70

140

d)

100 (60 )

62

68

100

140

100

70

c)

140

250

100

100

50

c)

150

70

c)

210

100

40

115 - 300

c)

80

90

125

135

100

140

s2

a

s1

a)

b)

c)

d)

384

For spacing larger than the critical spacing each anchor in a group can be considered in design.

For edge distance smaller than critical edge distance the design loads have to be reduced.

Linear interpolation allowed

09 / 2014

HRD Frame anchor

Redundant fastening

Admissible anchor positions, minimum spacing and edge distance of anchors and

distance between anchor groups in precast prestressed hollow core slabs

Anchor type

Overall plasic anchor embedment depth

in the base material

Bottom flange thickness

HRD 8

HRD 10

hnom

[mm]

50

db

[mm]

25

Core distance

[mm]

100

Prestressing steel distance

[mm]

100

[mm]

50

[mm]

[mm]

[mm]

100

100

100

Distance between anchor position and

prestressing steel

Minimum edge distance

Minimum anchor spacing

Minimum distance between anchor groups

ap

cmin

smin

amin

Schemes of distances and spacing

Admissible anchor

position

Hollow core

hnom

db

ap

ap

ap

ap

Prestressing

steel

09 / 2014

c1, c2 edge distances

s1, s2 anchor spacings

a1, a2 distances between

anchor groups

385

HRD Frame anchor

Redundant fastening

Design method

Design method according ETAG 020, Annex C. Design resistance according data given in ETA-07/0219, issue

2012-09-18.

Valid for a group of two anchors

Influence of edge distance

The design method is based on the following simplifications:

Minimum base material thickness hmin

All data for concrete C16/20 C50/60

No different loads are acting on individual anchors (no eccentricity)

Shear without lever arm

The values are valid for a single anchor or a anchor group with spacing < s cr,N

scr,N each anchor can be considered as acting like a single anchor).

Tension loading in concrete

The design tensile resistance is the lower value of

- Steel resistance:

NRd,s

- Concrete pull-out resistance:

NRd,p

- Concrete cone resistance:

NRd,c = NRd,p (c/ccr,N)

Basic design tensile resistance

Design steel resistance NRd,s

Anchor size

NRd,s

HRD 8

Carbon steel [kN]

Stainless steel [kN]

HRD 10

hnom =50mm

hnom

=50mm

hnom

70mm

7,3

6,8

11,7

11,6

11,7

11,6

Design pull-out resistance NRd,p

Design concrete cone NRd,c = NRd,p (c/ccr,N)

Anchor size

NRd,p

386

HRD 8

Carbon steel [kN]

Stainless steel [kN]

HRD 10

hnom =50mm

hnom

=50mm

hnom

70mm

1,7

1,7

2,5

2,5

4,7

4,7

09 / 2014

HRD Frame anchor

Redundant fastening

Shear loading in concrete

The design shear resistance is the lower value of

- Steel resistance:

VRd,s

- Concrete edge resistance:

VRd,c = V

0

Rd,c

fB fc

Basic design shear resistance

Design steel resistance VRd,s

Anchor size

HRD 8

hnom =50mm

Carbon steel [kN]

Stainless steel [kN]

VRd,s

5,5

5,2

HRD 10

hnom

hnom

=50mm 70mm

8,5

8,5

8,5

8,5

Design concrete edge resistancea) VRd,c = V0Rd,c fB fc

Anchor type

HRD 8

hnom =50mm

V0Rd,c

[kN]

a) For anchor groups only the anchors close to the edge must be considered

5,1

HRD 10

hnom

hnom

=50mm 70mm

5,5

5,8

Influencing factors

Influence of concrete strength

Concrete strength designation

C 16/20 C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 C 50/60

(ENV 206)

1/2 a)

fB =

(fck,cube/25N/mm)

0,89

1

1,1

1,22

1,34

1,41

1,48

1,55

a) fck,cube = concrete compressive strength, measured on cubes with 150 mm side length

Influence of edge distance for different base material thickness a)

c [mm]

50

60

70

80

90 100 120 140 160 180

h = 100 mm

0,35 0,46 0,57 0,65 0,73 0,82 0,98 1,14 1,31 1,47

h = 120 mm

0,35 0,46 0,59 0,72 0,80 0,89 1,07 1,25 1,43 1,61

fc =

h = 150 mm

0,35 0,46 0,59 0,72 0,85 1,00 1,20 1,40 1,60 1,80

h = 180 mm

0,35 0,46 0,59 0,72 0,85 1,00 1,31 1,53 1,75 1,97

a) The edge distance shall not be smaller than the minimum edge distance c min.

The base material thickness shall not be smaller than the minimum base material thickness h min.

200

1,63

1,79

2,00

2,19

220

1,80

1,97

2,20

2,41

Combined TENSION and SHEAR loading in masonry

The design resistance in masonry and AAC FRd (see basic loading data) shall be used in

each load direction for single anchors and anchor groups.

09 / 2014

387

You might also like

- Steel Roof Truss BOQDocument2 pagesSteel Roof Truss BOQMuhammad Azanuddin Abdul Jalil100% (6)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Truss DesignDocument52 pagesTruss DesignDonna96% (27)

- Workshop Manual - 20-26 - 7748841Document350 pagesWorkshop Manual - 20-26 - 7748841Wayne Sharkett100% (1)

- Detailing of Concrete Masonry Cavity Walls 240 to 290Document64 pagesDetailing of Concrete Masonry Cavity Walls 240 to 290Sean KrieglerNo ratings yet

- Bills of Quantities KMTC For 4no Classrooms PDFDocument18 pagesBills of Quantities KMTC For 4no Classrooms PDFabdul100% (1)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Bolt Bearing AreaDocument1 pageBolt Bearing ArearonyNo ratings yet

- Asce Wind Load Examples PDFDocument126 pagesAsce Wind Load Examples PDFbrionkettler100% (3)

- Style 28 Coupling: Applied Vic-Ring SystemDocument4 pagesStyle 28 Coupling: Applied Vic-Ring SystemMina MagdyNo ratings yet

- Simplex Mech Manual PSSDocument29 pagesSimplex Mech Manual PSSSantrupta PandaNo ratings yet

- MOSCAD L Owners Manual PDFDocument126 pagesMOSCAD L Owners Manual PDFJesús Valdés100% (1)

- 160.48-RP2 2-97 YDTL 131 & 144 Centrifugal Compressors Style F 131Document14 pages160.48-RP2 2-97 YDTL 131 & 144 Centrifugal Compressors Style F 131Atma RobertsNo ratings yet

- HRD Frame Anchor Redundant FasteningDocument18 pagesHRD Frame Anchor Redundant FasteningFarrukh KhanNo ratings yet

- Hilti HIT HY 70 Injection Mortar For MasonryDocument26 pagesHilti HIT HY 70 Injection Mortar For MasonryVenkatesh PadmanabhanNo ratings yet

- Hilti Hit Hy 150 Max Con Barra CorrugadaDocument20 pagesHilti Hit Hy 150 Max Con Barra Corrugadalandsv01No ratings yet

- Item Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkDocument15 pagesItem Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkAmr M. AbdallahNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- Hilti HIT-HY 150 MAX anchor systemDocument12 pagesHilti HIT-HY 150 MAX anchor systemMihnea-Bogdan NicolaescuNo ratings yet

- Hilti HIT-HY 150 With Rebar PDFDocument16 pagesHilti HIT-HY 150 With Rebar PDFMuzammil HawaNo ratings yet

- Hilti HIT HY 150 MAX With RebarDocument14 pagesHilti HIT HY 150 MAX With RebarNelly BuquironNo ratings yet

- FTM HIT-RE 100 Rebar As AnchorDocument8 pagesFTM HIT-RE 100 Rebar As AnchorNyein ZawNo ratings yet

- FTM '12 HKD Push-In AnchorDocument14 pagesFTM '12 HKD Push-In AnchorShankerNo ratings yet

- HVZ adhesive anchor installation and design guideDocument13 pagesHVZ adhesive anchor installation and design guideMihnea-Bogdan NicolaescuNo ratings yet

- Concrete works for drainage structuresDocument4 pagesConcrete works for drainage structuresVikram DesaiNo ratings yet

- Standards and Specifications OverviewDocument38 pagesStandards and Specifications OverviewJorge Casero RoyoNo ratings yet

- Bill No. 5 - Cluster B, D & FDocument204 pagesBill No. 5 - Cluster B, D & FmimrusfanNo ratings yet

- PROPOSED CONSTRUCTIONDocument5 pagesPROPOSED CONSTRUCTIONAkshay SavvasheriNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDIonut SavaNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDTiago Cunha100% (1)

- Hilti Hit Hy70 System DS GBDocument9 pagesHilti Hit Hy70 System DS GBikirby77No ratings yet

- TAYTAY BID FORM - OdsDocument42 pagesTAYTAY BID FORM - OdsDavid Raphael CaÑaresNo ratings yet

- 44 - HVZ Adhesive AnchorDocument14 pages44 - HVZ Adhesive AnchorHuan VoNo ratings yet

- Hilti HST 1Document11 pagesHilti HST 1Mihnea-Bogdan NicolaescuNo ratings yet

- Concrete TechnologyDocument5 pagesConcrete TechnologyAh RashedNo ratings yet

- Anchor Fastening Technology ManualDocument152 pagesAnchor Fastening Technology ManualfdsafsadfNo ratings yet

- Technical Data Sheet For The HST2 Metal Expansion Anchor Technical Information ASSET DOC 5498557Document11 pagesTechnical Data Sheet For The HST2 Metal Expansion Anchor Technical Information ASSET DOC 5498557farid bashaNo ratings yet

- Interim Payment For Concrete WorksDocument52 pagesInterim Payment For Concrete Worksarchie_728No ratings yet

- Company Name: Calculation SheetDocument7 pagesCompany Name: Calculation SheetVenkatesha HebbarNo ratings yet

- Hilti HIT-HY 70 injection mortar systemDocument26 pagesHilti HIT-HY 70 injection mortar systemfkh3dNo ratings yet

- Fijaciones Químicas 2012 PDFDocument0 pagesFijaciones Químicas 2012 PDFMarcelo AlbeNo ratings yet

- Technical Data Sheet For HST Stud Anchor Technical Information ASSET DOC 2331133Document14 pagesTechnical Data Sheet For HST Stud Anchor Technical Information ASSET DOC 2331133giovanni perozziNo ratings yet

- B-Civil Works BOQ Phase 1Document28 pagesB-Civil Works BOQ Phase 1Abi DemeNo ratings yet

- HIGH PERFORMANCE STEEL ANCHORSDocument23 pagesHIGH PERFORMANCE STEEL ANCHORSIstván SzékelyNo ratings yet

- RE100 With HAS RodsDocument8 pagesRE100 With HAS RodssahanNo ratings yet

- FTM '12 DBZ Wedge AnchorDocument4 pagesFTM '12 DBZ Wedge AnchorshankerNo ratings yet

- Ref. Title No.: 10.1 Piling: GeneralDocument9 pagesRef. Title No.: 10.1 Piling: GeneralJithesh.k.sNo ratings yet

- Ce-424 Structure-V R.C.C DesignDocument38 pagesCe-424 Structure-V R.C.C Designstudio VIINo ratings yet

- Heavy-Duty Mechanical AnchorsDocument3 pagesHeavy-Duty Mechanical AnchorsCristian RezNo ratings yet

- Design Formula For EC2Document35 pagesDesign Formula For EC2Azim MuizNo ratings yet

- Sika Concrete HandbookDocument151 pagesSika Concrete Handbooksmartman35No ratings yet

- Petroleum Development Oman L.L.C. Schedule D' - Unit Rates For Alterations & Day Works C-5Document10 pagesPetroleum Development Oman L.L.C. Schedule D' - Unit Rates For Alterations & Day Works C-5Nadim JilaniNo ratings yet

- Concrete Masonry Vol3 Cavity Walls 240 290Document64 pagesConcrete Masonry Vol3 Cavity Walls 240 290wearplayNo ratings yet

- HIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, MixerDocument11 pagesHIT-TZ Injection Adhesive Anchor: HIT-HY 150 Foil Pack, Mixerlael00No ratings yet

- Bill No. 4 - Cluster A, C & EDocument183 pagesBill No. 4 - Cluster A, C & EmimrusfanNo ratings yet

- Dynabolt Zinc Coated Steel Design GuideDocument4 pagesDynabolt Zinc Coated Steel Design GuideMuhammad SarajevoNo ratings yet

- Estimate of Material and LaborDocument12 pagesEstimate of Material and LabornkureshiNo ratings yet

- Design Formula For EC2Document35 pagesDesign Formula For EC2sfowi100% (3)

- Sector 16CDocument87 pagesSector 16CPerkresht PawarNo ratings yet

- BASEMENT COST ESTIMATEDocument645 pagesBASEMENT COST ESTIMATEHuynh Khuong DuyNo ratings yet

- Roofing Materials and Installation GuideDocument7 pagesRoofing Materials and Installation GuidecjalwrdNo ratings yet

- High-performance hybrid mortar for chemical fixingsDocument4 pagesHigh-performance hybrid mortar for chemical fixingsanwarali1975No ratings yet

- Muro de Contencion en CantiliverDocument14 pagesMuro de Contencion en CantiliverJosé Alberto Garcia CordovaNo ratings yet

- Appendix 2 Final BoqDocument50 pagesAppendix 2 Final BoqPatrick SipatelaNo ratings yet

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesFrom EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesRating: 3.5 out of 5 stars3.5/5 (13)

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Foundation DesignDocument2 pagesFoundation DesignrabzihNo ratings yet

- 12m Octagonal Pole Design Column Base CalculationsDocument5 pages12m Octagonal Pole Design Column Base CalculationsJohn G Jose100% (1)

- Torsion Check in Steel Beam 02Document1 pageTorsion Check in Steel Beam 02ronyNo ratings yet

- Bolt-to-Rectangular HSS Wall Connections DesignDocument1 pageBolt-to-Rectangular HSS Wall Connections DesignronyNo ratings yet

- C FIX Report2Document7 pagesC FIX Report2ronyNo ratings yet

- Monorail Crane Girder CalculationDocument4 pagesMonorail Crane Girder Calculationrony100% (1)

- Wind Load EnclosedDocument1 pageWind Load EnclosedronyNo ratings yet

- ReportDocument11 pagesReportDhina karanNo ratings yet

- Flat Plate Stresses-Fixed All SidesDocument2 pagesFlat Plate Stresses-Fixed All SidesronyNo ratings yet

- Torsion Check in Steel Beam 04Document1 pageTorsion Check in Steel Beam 04ronyNo ratings yet

- Torsion Check in Steel Beam 01Document1 pageTorsion Check in Steel Beam 01ronyNo ratings yet

- Torsion Check in Steel Beam 03Document1 pageTorsion Check in Steel Beam 03ronyNo ratings yet

- Design and Structural Analysis of An Elliptical SkylightDocument64 pagesDesign and Structural Analysis of An Elliptical SkylightronyNo ratings yet

- Scale Factor in RSA - ETABS - Computers and Structures, IncDocument1 pageScale Factor in RSA - ETABS - Computers and Structures, IncronyNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- C1 ENGINEERING PRINCIPLES AND PRACTICES for Retrofitting Flood-Prone HomesDocument37 pagesC1 ENGINEERING PRINCIPLES AND PRACTICES for Retrofitting Flood-Prone HomesAnonymous mcHqIfbnV1No ratings yet

- Wind Force CalculationDocument2 pagesWind Force CalculationronyNo ratings yet

- ASCE7-10 Example Wind Chapter 5 PDFDocument12 pagesASCE7-10 Example Wind Chapter 5 PDFronyNo ratings yet

- Wind Euro CodeDocument2 pagesWind Euro CoderonyNo ratings yet

- Oasis Metal Manufacturing LLCDocument27 pagesOasis Metal Manufacturing LLCEric SimonsNo ratings yet

- ScanDocument1 pageScanronyNo ratings yet

- StairsDocument21 pagesStairstomnubiNo ratings yet

- Local Axes Frames - EtabsDocument3 pagesLocal Axes Frames - EtabsronyNo ratings yet

- DeflectionDocument4 pagesDeflectionronyNo ratings yet

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDocument4 pagesColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNo ratings yet

- Surface Water DrainageDocument8 pagesSurface Water DrainageronyNo ratings yet

- Boeing Distribution Services Discount Part ListDocument12 pagesBoeing Distribution Services Discount Part ListHasan RazaNo ratings yet

- Screen Operation and Service Manual and Parts Book: Jci Oval Motion Screen 6203-32LP S/N S102431Document42 pagesScreen Operation and Service Manual and Parts Book: Jci Oval Motion Screen 6203-32LP S/N S102431Jorge YaipenNo ratings yet

- SN200-8 - 2016-05 - Calculo de Cantidad Gel SilicaDocument25 pagesSN200-8 - 2016-05 - Calculo de Cantidad Gel SilicaUnidos Con PuerresNo ratings yet

- EZGO 5 PersonDocument100 pagesEZGO 5 PersonErnNo ratings yet

- Commercial Building SpecsDocument15 pagesCommercial Building SpecsGeeryl TayoneNo ratings yet

- Section Title: 25 OCT 2010 R66 Maintenance ManualDocument12 pagesSection Title: 25 OCT 2010 R66 Maintenance ManualpedroescorciaNo ratings yet

- Besam SW200i-IG ADDENDUM For Swing Door Operator Installation and Service Manual InstructionsDocument54 pagesBesam SW200i-IG ADDENDUM For Swing Door Operator Installation and Service Manual InstructionsXavierNo ratings yet

- 4.1.7 Engine ConnectionDocument2 pages4.1.7 Engine ConnectionThylaneNo ratings yet

- Maintain EOT Crane ManualDocument36 pagesMaintain EOT Crane ManualNikki ChauhanNo ratings yet

- Parts Catalog - Option DetailDocument3 pagesParts Catalog - Option DetailmunhNo ratings yet

- @ Toyota: Repair ManualDocument495 pages@ Toyota: Repair ManualPedro Martinez MorenoNo ratings yet

- Skid Steer Radiator and Cooling System PartsDocument886 pagesSkid Steer Radiator and Cooling System Partsomar suazoNo ratings yet

- Container Dome: Installation ManualDocument9 pagesContainer Dome: Installation ManualLance Zhengling YinNo ratings yet

- G 962 1188 - BomDocument8 pagesG 962 1188 - BomDibyendu ChakrabortyNo ratings yet

- Voltas VVE BOPT 2T (AC)Document82 pagesVoltas VVE BOPT 2T (AC)Johnson James100% (2)

- Haldex Disc Brake DB22 Service Manual: Innovative Vehicle TechnologyDocument93 pagesHaldex Disc Brake DB22 Service Manual: Innovative Vehicle TechnologyВЛАДИМИРNo ratings yet

- Lodge & Shipley Lathes: A Legacy of Quality Machine ToolsDocument8 pagesLodge & Shipley Lathes: A Legacy of Quality Machine ToolsRey SantanaNo ratings yet

- Erix Tool Catalog English Metric Print-2Document32 pagesErix Tool Catalog English Metric Print-2RupertNo ratings yet

- New and Revised Code (2009)Document1 pageNew and Revised Code (2009)danielsu87No ratings yet

- Boltec E: Fully Mechanized Rock Bolting Rig For Bolt Lengths From 2.4-6 Meters, Effective in Roof Heights Up To 13 MetersDocument5 pagesBoltec E: Fully Mechanized Rock Bolting Rig For Bolt Lengths From 2.4-6 Meters, Effective in Roof Heights Up To 13 MetersPaola ArtosNo ratings yet

- YK系列振动筛 XZUM 0700 0202Document15 pagesYK系列振动筛 XZUM 0700 0202Carlos Eugenio LoveraNo ratings yet

- Expamet Plastering AccessoriesDocument20 pagesExpamet Plastering Accessoriesapi-27549425100% (3)

- Get 8va EdicionDocument820 pagesGet 8va EdicionPlaneamiento MecanicoNo ratings yet

- Industrial Fasteners, Nuts & BoltsDocument79 pagesIndustrial Fasteners, Nuts & BoltsMudduKrishna shettyNo ratings yet

- Design and Compliance Control of A Robotic Gripper For Orange HarvestingDocument5 pagesDesign and Compliance Control of A Robotic Gripper For Orange HarvestingLeonardoGrandiniAdamiNo ratings yet