Professional Documents

Culture Documents

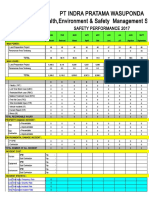

HSE Statistics

Uploaded by

giri943Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE Statistics

Uploaded by

giri943Copyright:

Available Formats

Revision No:

Initial Issue Date

KEY PERFORMANCE INDICATORS (KPI)

Revision Date:

Preparation: Safety Mgr

Authority: President

Issuing Dept: Safety

Page:

Initial Version

Page 1 of 5

KEY PERFORMANCE INDICATOR

Purpose

The ATP Key Performance Indicators (KPI) initiative is an education, observation and tracking process used to

improve safety and reduce risk in the workplace for our Canadian operations. This process uses a proactive

approach and is intended to track & correct trends, communicate to employees the procedures of Key

Performance Indicators procedures that will assist in reducing at risk behaviors which in turn reduces injuries in

our workplaces.

Scope

The ATP KPI applies to all staff. Employees are requested to participate in Key Performance Indicators (KPI)

process by reporting all incidents & near misses no matter how insignificant they think they are.

Requirements

Individual Health and Safety Performance Evaluation

All workers, including management, will have their individual health and safety performance evaluated. Criteria

will include consideration of positive and negative behaviour. Examples include:

Adherence to or violation of health and safety requirements.

Participation in voluntary programs.

Positive contributions to the safety management process.

Methods of evaluation include individual performance appraisal, disciplinary process, complimentary letters of

appreciation, etc.

Monitoring Statistics

ATP maintains an ongoing system for recording events in order to compare statistics over a period of time. Leading

indicators measure the activities used by the organization to reduce the likelihood of an incident. Lagging

indicators analyze the frequency, severity, and type of incidents.

ATP will maintain and analyse statistics to help identify trends in both leading and lagging indicators. Leading

indicators that can tell if systems are working as expected could include:

Records of inspections - Are inspections being performed as required?

Maintenance Records records indicate all maintenance & repairs completed on each machine, vehicle,

etc as indicated on the unit registry.

Meeting minutes - Are safety meetings are being held according to the schedule?

Investigation reports - Are appropriate causes being identified? Are corrections being made in a timely

manner?

Maintaining statistics over time will allow the identification of trends which can be useful in determining where

system changes may be needed.

Health and Safety Key Performance Indicators (KPI)

KPIs are used to determine what changes need to be made, to review individual project management success

towards compliance and to track progress towards published goals and objectives. KPI results are supplied to

Revision No:

Initial Issue Date

KEY PERFORMANCE INDICATORS (KPI)

Revision Date:

Preparation: Safety Mgr

Authority: President

Issuing Dept: Safety

Page:

Initial Version

Page 2 of 5

COMPANY management on a monthly basis. Health and Safety KPIs are tracked for each project managers

responsible area and include:

Injuries

Days Away From Work Cases

Restricted Work Cases; Recordable Medical Cases

Total Recordable Injuries/Illness and Incident Rate

First Aid Cases

Reportable spills

Workers compensation data

Total Hours Worked

Total Kilometers Driven

Vehicle incidents and property damage or loss

Audit System

Whether completed by internal or external auditors, annual audits give COMPANY a means of identifying how its

system measures against a recognized standard. Audit results communicate program successes as well as identify

areas in need of improvement and will form the basis of action plans designed to make specified individuals

accountable for corrective action within set timelines.

Management will follow up on the status of the action plan on a regular basis to ensure action items are being

completed. The Safety Manager maintains a record of the audit. Results of the annual audit are incorporated into

changes to the COMPANY Health and Safety Management System, site specific HSE plans or appropriate safety

procedures.

Requirements:

The health and safety system will be evaluated at least annually through the use of an audit process.

An action plan will be developed and implemented as a result of any internal or external audit.

Injuries shall be classified as follows:

FIRST AID

Dressing on a minor cut, removal of a splinter, typically treatment for household type injuries.

LOST WORK DAY CASE (LWDC)

An injury that results in an employee being unfit to perform any work on any day after the occurrence of

an occupational injury.

NUMBER OF LOST OR RESTRICTED WORK DAYS

The number of days, other than the day of occupational injury and the day of return, missed from

scheduled work due to being unfit for work or medically restricted to the point that the essential

functions of a position cannot be worked.

OCCUPATIONAL INJURY

An injury which results from a work related activity.

OCCUPATIONAL ILLNESS

Any abnormal condition or disorder caused by exposure to environmental factors while performing work

that resulted in medical treatment by a physician for a skin disorder, respiratory condition, poisoning,

hearing loss or other disease (frostbite, heatstroke, sunstroke, welding flash, diseases caused by parasites,

etc.). Do not include minor treatments (first aid) for illnesses.

Revision No:

Initial Issue Date

KEY PERFORMANCE INDICATORS (KPI)

Revision Date:

Preparation: Safety Mgr

Authority: President

Issuing Dept: Safety

Page:

Initial Version

Page 3 of 5

RECORDABLE MEDICAL CASE (RMC)

An occupational injury more severe than first aid that requires advanced treatment (such as fractures,

more than one stitch, prescription medication of more than one dose, unconsciousness, removal of

foreign body embedded in eye (not flushing), admission to a hospital for more than observation purposes)

and yet results in no lost work time beyond the day of injury.

RESTRICTED WORK DAY CASE (RWDC)

An occupational injury which results in a person being unfit for essential functions of the regular job on

any day after the injury but where there is no time lost beyond the day of injury. An example would

include an injured associate is kept at work but not performing within the essential functions of their

regular job.

WORK OR WORK RELATED ACTIVITY

All incidents that occur in work related activities during work hours, field visits, etc. are reportable and are

to be included if the occupational injury or illness is more serious than requiring simple first aid. Incidents

occurring during off hours and incidents while in transit to or from locations that are not considered an

employees primary work are not reportable.

The following are examples of incidents that will not be considered as recordable:

The injury or illness involves signs or symptoms that surface at work but result solely from a non-work

related event or exposure that occurs outside the work environment.

The injury or illness results solely from voluntary participation in a wellness program or in flu shot,

exercise class, racquetball, or baseball.

The injury or illness is solely the result of an employee eating, drinking, or preparing food or drink for

personal consumption (whether bought on the employer's premises or brought in). The injury or illness is

solely the result of an employee doing personal tasks (unrelated to their employment) at the

establishment

outside

of

the

employee's

assigned

working

hours.

Revision No.

KEY PERFORMANCE INDICATORS (KPI)

Initial Issue Date

Revision Date:

Preparation: Safety Mgr

Authority: President

Issuing Dept: Safety

Initial Version

Page 4 of 5

Page:

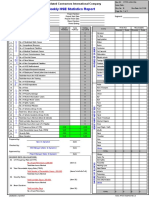

HSE STATISTICS

WORK INCIDENT STATS

Total Hours Worked/Quarter

LWDC

LTI

RWDC

MAI

16,200

7,200

7,200

7,200

7,200

7,200

7,200

7,200

7,200

Total Hours

Worked

1Q

2Q

3Q

2014

22

87,840

26,620

28,820

32400

2013

15

64,800

15,200

17,200

16,200

2012

10

28,800

7,200

7,200

2011

10

28,800

7,200

2010

10

28,800

7,200

4Q

DA

Total Number

of Employees

NM

Recordable

Injuries

Year

Report Completed By: AC Ramirez

Incident Type /Number

# Vehicle

Incidents

Total Km

Driven

1800

Reviewed By: G. Belli

Revision No.

KEY PERFORMANCE INDICATORS (KPI)

Revision Date:

Preparation: Safety Mgr

Authority: President

Initial Issue Date

Issuing Dept: Safety

Page:

Initial Version

Page 5 of 5

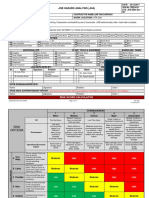

2014 STAT UPDATES

Completed By: AC Ramirez

st

1 quarter 2014

Stats

Average Number of Employees

Number of Employee Work Hours

Reviewed By: M Fiorespino

nd

2 quarter 2014

rd

3 quarter 2014

15

22

11,880

15,324

22

15,324

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

2180

0

0

0

63

2020

0

0

0

63

2240

0

0

0

63

Commercial Transportation ONLY

Out of Service Violations

Total Company Owned trucks

Total Company Owned Trailers

# Plated trucks

# Plated trailers

0

3

0

3

0

0

3

0

3

0

0

3

0

3

0

# Subcontractor trucks

# Subcontractor Trailers

0

0

0

0

0

0

Number of Fatalities

Number of Lost Workday Cases

Number of Lost Time Injuries

Number of Modified/Restricted Duty Incidents

Number of Medical Aid Incidents

Number of First Aid Incidents

Number of Near Misses

KMs Driven

Number of Auto Incidents

Number of Company Drivers

# of subcontractors

# Transportation Inspections (GOV)

Date: 08/09/2014

th

4 quarter 2014

You might also like

- HSE Statistics PDFDocument5 pagesHSE Statistics PDFRashid100% (1)

- Monthly HSE Report April .2013Document8 pagesMonthly HSE Report April .2013sakthivelNo ratings yet

- Weekly HSE Report Feb .2013Document12 pagesWeekly HSE Report Feb .2013sakthivelNo ratings yet

- HSE Program Schedule and TargetsDocument1 pageHSE Program Schedule and Targetsimhayt1370% (1)

- Sshe Performance Monthly Report: Project: PeriodDocument1 pageSshe Performance Monthly Report: Project: PeriodYudi Arkananta100% (1)

- Incident Accident RegisterDocument2 pagesIncident Accident RegisterMuruganNo ratings yet

- HSE Monthly ReportDocument11 pagesHSE Monthly ReportAlfredo Medina Cano100% (7)

- Brief HSE Procedures ContentsDocument2 pagesBrief HSE Procedures Contentsarifayee-1No ratings yet

- HSE Monthly Statisctical Report February 2016Document2 pagesHSE Monthly Statisctical Report February 2016naveed566100% (2)

- Hse Statistics Report Pp701 Hse f04 Rev.bDocument1 pageHse Statistics Report Pp701 Hse f04 Rev.bMohamed Mouner100% (1)

- Hse Activity Plan 2010: NO Objek Month January February March April MAYDocument4 pagesHse Activity Plan 2010: NO Objek Month January February March April MAYImanuel MantiriNo ratings yet

- Annexure - IV - Contractor HSE Capability Assessment Sheet - Rev 00 - VibrantDocument4 pagesAnnexure - IV - Contractor HSE Capability Assessment Sheet - Rev 00 - VibrantGovindKrishnanNo ratings yet

- HSE Observation Card LogDocument1 pageHSE Observation Card Logramod100% (1)

- Monthly HSE Performance Report Form DTLP FEB-21Document2 pagesMonthly HSE Performance Report Form DTLP FEB-21Muhammad Khan100% (1)

- Occupational Health, Safety & Environment Management System: Hse Biweekly ReportDocument3 pagesOccupational Health, Safety & Environment Management System: Hse Biweekly ReportAhmed Hassan SabryNo ratings yet

- Sample HSE KPI Report - Doc2Document6 pagesSample HSE KPI Report - Doc2Edo-Abasi EkereNo ratings yet

- Hse Close Out Report PresentationDocument31 pagesHse Close Out Report PresentationLuqman Osman100% (10)

- CHINA HARBOUR ENGINEERING LFTZ HSE REPORTDocument21 pagesCHINA HARBOUR ENGINEERING LFTZ HSE REPORTWealth OSIOBE100% (1)

- Hse StatisticsDocument1 pageHse Statisticskrissregion100% (1)

- Monthly HSE report summaryDocument5 pagesMonthly HSE report summaryNiraNo ratings yet

- HSE KPI Data Collection Tool BriefingsDocument20 pagesHSE KPI Data Collection Tool Briefingstnsv222No ratings yet

- HSE Training MatrixDocument5 pagesHSE Training Matrixfrancis100% (8)

- HSE Statistics (Monthly) - Package I November-2016Document182 pagesHSE Statistics (Monthly) - Package I November-2016makdelNo ratings yet

- Hse Goals and TargetsDocument4 pagesHse Goals and TargetsVICTOR100% (1)

- ALSA VAPOUR RECOVERY COMPRESSOR MODIFICATION AND PLANT UPGRADESDocument2 pagesALSA VAPOUR RECOVERY COMPRESSOR MODIFICATION AND PLANT UPGRADESsauspy100% (1)

- Hse Monthly ReportDocument2 pagesHse Monthly Reportshubham dabasNo ratings yet

- Hse Monthly ReportDocument1 pageHse Monthly Reportpunnyakumar100% (1)

- Hse StatisticsDocument1 pageHse StatisticsPaul Uwaya100% (5)

- HSE Training MatrixDocument1 pageHSE Training MatrixAmer Y K100% (4)

- HSE Monthly Report Mei 2020Document19 pagesHSE Monthly Report Mei 2020Rendi SeptiansyahNo ratings yet

- Report Flowchart GuideDocument1 pageReport Flowchart GuideTXsafetymasters12100% (1)

- HSE Evaluation Form PDFDocument4 pagesHSE Evaluation Form PDFFaizal ENRANo ratings yet

- Health Safety Committee Meeting MinutesDocument3 pagesHealth Safety Committee Meeting MinutesMuhammad Iqbal NiyaziNo ratings yet

- WDC 2013-14 Health & Safety ReportDocument18 pagesWDC 2013-14 Health & Safety ReportSarah WalkerNo ratings yet

- Example COSHH Risk Assessment - Warehouse - COSHHDocument2 pagesExample COSHH Risk Assessment - Warehouse - COSHHWisnu KertaningnagoroNo ratings yet

- 06-June Monthly QHSE PerformanceDocument11 pages06-June Monthly QHSE Performancemknkjbk kkjkNo ratings yet

- HSE Pre-Qualification ChecklistDocument11 pagesHSE Pre-Qualification ChecklistSri Dharan74% (39)

- 2013 OH&S Strategic Plan ScorecardDocument6 pages2013 OH&S Strategic Plan Scorecardrodrigo_gon57100% (1)

- Kpi HseDocument6 pagesKpi HseAnonymous p2VYG0100% (2)

- Noise Monitoring Record FormDocument2 pagesNoise Monitoring Record FormMalefane Cortez TlatlaneNo ratings yet

- HSE Procedure For Planning & AuditingDocument4 pagesHSE Procedure For Planning & AuditingKhuda Buksh100% (1)

- Observation Reg Feb 2016Document10 pagesObservation Reg Feb 2016Sarmad Hussain100% (1)

- HSE Performance MonitoringDocument6 pagesHSE Performance MonitoringmarvinNo ratings yet

- Monthly HSE Performance Report April 2018-AD 540Document70 pagesMonthly HSE Performance Report April 2018-AD 540Mohamed ThowfeekNo ratings yet

- Non-Turnaround Daily HSE ReportDocument66 pagesNon-Turnaround Daily HSE Reportabdulfro100% (1)

- Legislation Register - ExampleDocument10 pagesLegislation Register - ExampleKingsley AhanonuNo ratings yet

- HSE Action PlanDocument3 pagesHSE Action PlanELANCHELIYANNo ratings yet

- Hse Plan EngDocument45 pagesHse Plan EngSayed DarwishNo ratings yet

- HSE Inspection Report 2nd Week April 2015Document5 pagesHSE Inspection Report 2nd Week April 2015adi50% (2)

- Machine excavation hazard analysisDocument7 pagesMachine excavation hazard analysisVenkadesh Periathambi100% (1)

- List of Elements of HSE PlanDocument3 pagesList of Elements of HSE PlanSRIRAM D100% (1)

- Company Safety Audit ChecklistDocument7 pagesCompany Safety Audit ChecklistSaddem HadfiNo ratings yet

- BGPI - HSSE - 013 Weekly HSE Report FormDocument10 pagesBGPI - HSSE - 013 Weekly HSE Report Formtimisite2470% (2)

- + Contractor Safety Weekly Statistic Report FormDocument1 page+ Contractor Safety Weekly Statistic Report FormNathaniel Kwek100% (2)

- Corporate Hse AuditDocument21 pagesCorporate Hse AuditKukuh Widodo100% (3)

- New HSE Monthly Report Statistic 2015Document47 pagesNew HSE Monthly Report Statistic 2015IchsanNo ratings yet

- Career Technical Education at Abu Dhabi PolytechnicDocument27 pagesCareer Technical Education at Abu Dhabi PolytechnicAhmed AlamriNo ratings yet

- QMS Audit Report 2019Document16 pagesQMS Audit Report 2019Dr. Mir Iqbal Faheem75% (4)

- Method Statement at JLT b3Document24 pagesMethod Statement at JLT b3giri943No ratings yet

- CV - AmalshaDocument4 pagesCV - Amalshagiri943No ratings yet

- Method Statement For Leak Rectification WorksDocument7 pagesMethod Statement For Leak Rectification Worksgiri943No ratings yet

- Method Statement For Leak Rectification WorksDocument7 pagesMethod Statement For Leak Rectification Worksgiri943No ratings yet

- Job Safety Analysis for Hydro-TestingDocument1 pageJob Safety Analysis for Hydro-TestingZeyad RezkNo ratings yet

- Fire Risk AssesmentDocument25 pagesFire Risk Assesmentgiri943No ratings yet

- Chemical Risk Assessment PDFDocument8 pagesChemical Risk Assessment PDFS.h. RippendeepNo ratings yet

- OTE Maintenance Inspection For Grinding Eng Web PDFDocument2 pagesOTE Maintenance Inspection For Grinding Eng Web PDFgiri943No ratings yet

- Qhse Amended 3.1Document257 pagesQhse Amended 3.1midhunNo ratings yet

- Iso 14000Document7 pagesIso 14000anu_acharyaNo ratings yet

- Audco Ball Valve - Full Bore1Document2 pagesAudco Ball Valve - Full Bore1giri943No ratings yet

- Qhse Amended 3.1Document257 pagesQhse Amended 3.1midhunNo ratings yet

- Qhse Amended 3.1Document257 pagesQhse Amended 3.1midhunNo ratings yet

- Qhse Amended 3.1Document257 pagesQhse Amended 3.1midhunNo ratings yet

- HR Audit SMU MU0013Document8 pagesHR Audit SMU MU0013Abdullah AzadNo ratings yet

- Assignment HRM Meligy Last Update Friday 5 MayDocument23 pagesAssignment HRM Meligy Last Update Friday 5 MayMohamed MeligyNo ratings yet

- Appraising and Rewarding Performance June 13Document27 pagesAppraising and Rewarding Performance June 13Roselyn Alegre LedamoNo ratings yet

- Performance Appraisal EbookDocument15 pagesPerformance Appraisal Ebookshashidhar_chittela100% (1)

- Performance Management ProcessDocument26 pagesPerformance Management ProcesssnehaarpiNo ratings yet

- How Apple Manages Productivity-1Document3 pagesHow Apple Manages Productivity-1Shamitha NaikNo ratings yet

- Wildcraft Welfare PDFDocument6 pagesWildcraft Welfare PDFDinesh NarasimhanNo ratings yet

- Forbes Marshall - All in The FamilyDocument5 pagesForbes Marshall - All in The FamilyMeenu ChaudharyNo ratings yet

- Library ScienceDocument139 pagesLibrary SciencePaul GeorgeNo ratings yet

- Palm Beach FinalDocument67 pagesPalm Beach FinalvinayNo ratings yet

- Wave InfraDocument62 pagesWave Infratanya013No ratings yet

- A Study On Performance Appraisal System at BYJU's in Lucknow CityDocument44 pagesA Study On Performance Appraisal System at BYJU's in Lucknow CityChandan SrivastavaNo ratings yet

- MCQs POMDocument72 pagesMCQs POMAbdul SamadNo ratings yet

- Managing Workforce Diversity in a Dynamic EnvironmentDocument70 pagesManaging Workforce Diversity in a Dynamic EnvironmentshubhamNo ratings yet

- The Models Exploring The "Black Box" Between HRM and Organizational PerformanceDocument9 pagesThe Models Exploring The "Black Box" Between HRM and Organizational PerformanceBrent NoraNo ratings yet

- Learning and Development ProgramsDocument9 pagesLearning and Development ProgramsShahzad SaifNo ratings yet

- Performance appraisal at Springs International SchoolDocument71 pagesPerformance appraisal at Springs International SchoolAysha LukmanNo ratings yet

- Internship Report: On HRM Practices in Babylon Group LimitedDocument89 pagesInternship Report: On HRM Practices in Babylon Group LimitedFahimNo ratings yet

- Performance Appraisal at CCIDocument68 pagesPerformance Appraisal at CCIRashmi VaishyaNo ratings yet

- 2ndprelims OrgDocument3 pages2ndprelims OrgParEngJhomAr50% (2)

- Your Employee Handbook - MG (HB) 500Document60 pagesYour Employee Handbook - MG (HB) 500stonedtech100% (3)

- Organizational Structure and CultureDocument32 pagesOrganizational Structure and Cultureamr369100% (1)

- Project Identifies Relationship Between Work Pressure and PerformanceDocument19 pagesProject Identifies Relationship Between Work Pressure and PerformanceYousefkicNo ratings yet

- Report On Industrial VisitDocument20 pagesReport On Industrial Visitprazgna100% (2)

- Quality Executive Job DescriptionDocument8 pagesQuality Executive Job Descriptionqualitymanagement246No ratings yet

- AppendicesDocument26 pagesAppendicesapi-3816638100% (1)

- J.K. TyresDocument10 pagesJ.K. Tyresaman27jaiswalNo ratings yet

- 203 Richa Ghosalkar - 203Document68 pages203 Richa Ghosalkar - 203Anu stephie NadarNo ratings yet

- Effective Performance Feedback for Organizational LearningDocument5 pagesEffective Performance Feedback for Organizational Learningfahim_iub_2012No ratings yet

- Training Procedure OP 10Document8 pagesTraining Procedure OP 10cristhianNo ratings yet