Professional Documents

Culture Documents

FIVE-AXIS MACHINING ERROR CORRECTION

Uploaded by

hungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FIVE-AXIS MACHINING ERROR CORRECTION

Uploaded by

hungCopyright:

Available Formats

FIVE-AXIS MACHINING FUNCTION

26

26-4 Workpiece Setup Error Correction: G54.4P0, G54.4P1 to G54.4P7 (Option)

1.

Function outline

This function is provided to compensate for the error in setting a workpiece easily, without

having to rewrite the program section for describing the machining contour, by modifying the

workpiece coordinate system according to the error in question.

Coordinate system to be referred to

Automatic renovation of coordinate system

to compensate for setup error

Workpiece

Workpiece

Workpiece setup error

D740PB0104

2.

Programming format

G54.4 Pn;

n: Number of the data set for workpiece setup error correction (1 to 7)

Enter zero with P (G54.4 P0) to cancel the correction function.

- Be sure to enter the G54.4 command (for selection as well as for cancellation) independently.

If a block of G54.4 should contain any other commands, an alarm is caused (1815 CANNOT

USE G54.4).

- Omission of argument P will lead to an alarm (807 ILLEGAL FORMAT).

Alarm 809 ILLEGAL NUMBER INPUT occurs if argument P is of any other value than 0 to 7.

3.

Definition of workpiece setup coordinate system

The workpiece setup coordinate system is defined by using the following three types of

externally provided data on the setup error.

1.

Linear errors on the orthogonal axes X, Y, and Z (x, y, z)

Specify the origin of the workpiece setup coordinate system with its absolute values in the

current workpiece coordinate system.

2.

Angular errors in rotation around the orthogonal axes (a, b, c)

Specify those angles (a, b, and c) of rotations around the axes X, Y, and Z of the

current workpiece coordinate system, in that order, by which the same orientation as that of

the workpiece setup coordinate system can be obtained.

Positive values of angle refer to the rotation by which a right-handed screw moves in the

positive direction of the third orthogonal axis.

3.

Coordinate of the axis of table rotation during error measurement

Set the machine coordinate of the axis of table rotation during measurement of errors x,

y, z and a, b, c. No setting is required for machines without the controlled axis of

table rotation, while setting for two axes is necessary for five-axis control machines of table

rotating type.

26-59

26

FIVE-AXIS MACHINING FUNCTION

Workpiece with

setup errors

Y

Workpiece in the correct

mounting position

X

Workpiece coordinate

system (X, Y, Z)

Workpiece setup

coordinate system

(X, Y, Z)

y

X

4.

D740PB0105

Setting workpiece setup errors

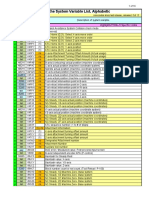

Seven data sets (No. 1 to No. 7) of workpiece setup errors can be set or prepared for the

designation by argument P in a G54.4 block.

It is possible, moreover, to prepare a special set of data to be added commonly to each of the

numbered data sets. Values for the linear errors (x, y, z) and the tables angular position

during measurement can be set as common data, but not for the angular errors (a, b, c).

The number of available data items for the tables angular position and their names depend

upon the specifications of the machine in question.

A.

WORK POSITION ERROR COMP. display

Use the WORK POSITION ERROR COMP. display to prepare the data for workpiece setup

error correction. See the relevant section in PART 3 of the Operating Manual.

Common data

B.

No. 1 to No. 7

5.

0.

3.

10.

0.

0.

0.

45.

0.

45.

15.

0.

90.

Set linear errors on the orthogonal axes X, Y, and Z.

Set angular errors in rotation around the orthogonal axes.

No common data can be provided for this type of data items.

Set the coordinate of the axis of table rotation during error

measurement.

System variables

Using variables tabulated below, it is possible to read and write the values used for workpiece

setup error correction.

Common

No. 1

No. 2

No. 3

No. 4

No. 5

No. 6

No. 7

#5801

#5811

#5821

#5831

#5841

#5851

#5861

#5871

#5802

#5812

#5822

#5832

#5842

#5852

#5862

#5872

#5803

#5813

#5823

#5833

#5843

#5853

#5863

#5873

#5814

#5824

#5834

#5844

#5854

#5864

#5874

#5815

#5825

#5835

#5845

#5855

#5865

#5875

#5816

#5826

#5836

#5846

#5856

#5866

#5876

Rotat. axis coord. 1

#5807

#5817

#5827

#5837

#5847

#5857

#5867

#5877

Rotat. axis coord. 2

#5808

#5818

#5828

#5838

#5848

#5858

#5868

#5878

Use #5800 to read the number (1 to 7) of the currently selected data set for workpiece setup

error correction.

26-60

FIVE-AXIS MACHINING FUNCTION

Note:

5.

26

An attempt to overwrite the system variable #5800 will only lead to an alarm (1821

UNWRITABLE SYSTEM VARIABLE).

Operation description

A.

Operation in the mode of workpiece setup error correction

A block of G54.4 Pn (n = 1 to 7) selects the mode of workpiece setup error correction, and

causes a workpiece setup coordinate system to be established according to the data set of No.

n as well as to the current positions on the rotational axes concerned, with the positional

indication (POSITION values) on the display with respect to the currently valid coordinate

system being changed accordingly.

Axis motion commands in the G54.4 Pn mode are processed in general with respect to the

workpiece setup coordinate system.

A block of G54.4 P0 cancels the mode of workpiece setup error correction. The workpiece setup

coordinate system will be replaced by the original workpiece coordinate system with reference

to which the G54.4 Pn command was given, and the POSITION values on the display will be

changed accordingly.

Y

X

c

y

X

Tool path in the workpiece setup

coordinate system (X Y Z)

Tool path in the workpiece

coordinate system (X, Y, Z)

D740PB0106

In the mode of workpiece setup error correction (G54.4), the NC unit controls the tool path by

including the program-externally provided data of workpiece setup errors.

Note 1: Resetting the NC-unit includes cancellation of the mode of workpiece setup error correction (G54.4).

Note 2: Selection and cancellation of the mode of workpiece setup error correction (with

G54.4) causes the POSITION values on the display to be changed as mentioned

above, indeed, but no actual movements occur on the machine.

26-61

26

FIVE-AXIS MACHINING FUNCTION

B.

Precautions for the selection and cancellation with G54.4

A block of G54.4 does not cause any actual movements on the machine. Use the method of

absolute data input, therefore, for the first block of axis movement after the selection of the

mode of workpiece setup error correction (with G54.4). Use of incremental data could not move

the tool to the expected position. This also applies to the cancellation, and the first motion

command after G54.4P0 must be given with absolute data.

Movements for a correctly mounted workpiece

Movement command with incremental data after G54.4

Y

Y

Y

20

N2

N2

5

N1

N1

X

X

X

For incremental data input

G54.4 P1

N1 G91 G0 X5.Y5.

N2 G91 G1 Y15.F500

N1 G91 G0 X5.Y5.

N2 G91 G1 Y15.F500

For absolute data input

Movement command with absolute data after G54.4

N1 G90 G0 X5.Y5.

N2 G90 G1 Y20.F500

Y

Y

N2

N1

X

X

G54.4 P1

N1 G90 G0 X5.Y5.

N2 G90 G1 Y20.F500

D740PB0107

26-62

FIVE-AXIS MACHINING FUNCTION

C.

26

Correction of the tool-axis direction

In addition to the translating correction in the XYZ space, an angular correction can be achieved

on five-axis control machines, according to the inclination on the rotational axis, in order to set

the tool-axis direction (tool attitude) normal to the surface to be machined.

Workpiece setup

error correction ON

D740PB0108

26-63

26

FIVE-AXIS MACHINING FUNCTION

6.

Relationship to other functions

A.

Commands available in the mode of workpiece setup error correction

Function

Code

Positioning

G00

Linear interpolation

G01

Dwell

G04

High-speed machining mode

G05

Exact-stop

G09

Programmed data setting ON/OFF

G10/G11

Plane selection

G17/G18/G19

Return to zero point

G28/G30

Nose radius/Tool radius compensation OFF

G40

Tool radius compensation for five-axis machining (to the right/left)

G41.2/G42.2

Remarks

G41.4/G42.4

G41.5/G42.5

Tool length offset (+/)

G43/G44

Tool tip point control type 1/2

G43.4/G43.5

Tool position offset ext./red./double ext./double red.

G45/G46/G47/G48

Tool length offset OFF

G49

Scaling ON/OFF

G50/G51

Mirror image ON/OFF

G50.1/G51.1

Machine coordinate system selection

G53

Tool-axis direction control

G53.1

High-accuracy control mode (Geometry compensation)

G61.1

Cutting mode

G64

Macro call

G65/G66/G66.1/G67

Inclined-plane machining

G68.2

Fixed cycle

G71.1-G89/G280-G289

Programmed coordinate rotation OFF

G69

Absolute data input

G90

Incremental data input

G91

Feed per minute

G94

Feed per revolution

G95

Constant surface speed control OFF

G97

Return to Initial point level in hole-machining fixed cycles

G98

Return to R-point level in hole-machining fixed cycles

G99

Subprogram call/End of subprogram

M98/M99

Feed function

M, S, T, B function

MSTB

Local variables, Common variables, Operation commands (arithmetic operations, trigonometric functions, square root, etc), Control

commands (IF GOTO , WHILE DO )

Macro instructions

Note:

Giving any other command than those enumerated above in the mode of workpiece

setup error correction will lead to an alarm (1814 ILLEGAL CMD IN G54.4 MODE).

26-64

FIVE-AXIS MACHINING FUNCTION

B.

26

Modes in which workpiece setup error correction is selectable

Function

Code

Positioning

Linear interpolation

G01

Polar coordinate interpolation OFF

G13.1

Polar coordinate input OFF

G15

Plane selection

G17/G18/G19

Inch/Metric data input

G20/G21

Pre-move stroke check OFF

G23

Return to zero point

G28/G30

Nose radius/Tool radius compensation OFF

G40

Shaping function OFF

G40.1

Tool length offset (+/)

G43/G44

Tool length offset OFF

G49

Scaling OFF

G50

Mirror image OFF

G50.1

Local coordinate system setting

G52

Selection of workpiece coordinate system

G54-G59/G54.1

Dynamic offsetting OFF

G54.2P0

High-accuracy control mode (Geometry compensation)

G61.1

Cutting mode

G64

Modal macro call OFF

G67

Programmed coordinate rotation OFF

G69

Fixed cycle OFF

G80

Absolute data input

G90

Incremental data input

G91

Inverse time feed

G93

Feed per minute

G94

Feed per revolution

G95

Constant surface speed control OFF

G97

Return to Initial point level in hole-machining fixed cycles

G98

Return to R-point level in hole-machining fixed cycles

G99

Note:

Remarks

G00

Selecting the mode of workpiece setup error correction in a mode other than those

enumerated above will lead to an alarm (1815 CANNOT USE G54.4).

26-65

26

FIVE-AXIS MACHINING FUNCTION

C.

Restrictions

1.

Be sure to enter the G54.4 command (for selection as well as for cancellation) independently. If a block of G54.4 should contain any other commands, an alarm is caused (1815

CANNOT USE G54.4).

2.

In the mode of workpiece setup error correction, system variables #5001 to #5116 for

reading positional information refer to the workpiece setup coordinate system, while system

variables #5021 to #5036 always denote the current position with respect to the machine

coordinate system.

3.

Resetting the NC-unit includes cancellation of the mode of workpiece setup error

correction.

4.

Tool radius compensation, tool length offset, tool tip point control, mirroring by G-code,

scaling, inclined-plane machining, and fixed cycle must be selected and cancelled within

the mode of workpiece setup error correction (between G54.4P_ and G54.4P0), as shown

in the example below for the use of tool radius compensation.

G54.4P2 (Workpiece setup error correction ON)

:

:

G41D3 (Tool radius compensation ON)

Mode of setup error correction

:

:

Mode of radius compensation

G40 (Tool radius compensation OFF)

:

:

G54.4P0 (Workpiece setup error correction OFF)

5.

Do not give any tool change command in the mode of workpiece setup error correction;

otherwise an alarm will be caused (1814 ILLEGAL CMD IN G54.4 MODE).

6.

Manual interruption is always performed on the basis of the machine coordinate system

(without any coordinate conversion). After manual interruption of workpiece setup error

correction (by or without using the TPS function) do not resume automatic operation

without returning the machine components concerned to the original positions on the

controlled axes; otherwise an alarm will be caused (184 ILLEGAL OPER IN G54.4

MODE).

7.

During interruption of workpiece setup error correction, an attempt to perform manual

movements on a rotational axis, or to use the manual pulse handle will only lead to an

alarm (184 ILLEGAL OPER IN G54.4 MODE).

8.

Tool path check can only be performed on the basis of the original workpiece coordinate

system (without coordinate conversion taken into consideration).

9.

Tracing in the mode of workpiece setup error correction is displayed with reference to the

machine coordinate system.

10. Do not use corner chamfering or rounding commands in the mode of workpiece setup error

correction; otherwise an alarm will be caused (1814 ILLEGAL CMD IN G54.4 MODE).

11. Restarting operation from a block in the mode of workpiece setup error correction begins

with a movement to the accordingly corrected position and to the position without

correction, respectively, in the case of using the [RESTART] and the [RESTART 2

NONMODAL] menu function.

26-66

FIVE-AXIS MACHINING FUNCTION

26

12. Do not specify a MAZATROL program as a subprogram to be called up in the mode of

workpiece setup error correction; otherwise an alarm will be caused (1814 ILLEGAL CMD

IN G54.4 MODE).

13. Do not enter a block of motion command which requires an angular movement through

more than 180; otherwise an alarm will be caused (1820 ILLEGAL COMMD IN G54.4).

7.

Related alarms

No.

Message

Description

Remedy

184

ILLEGAL OPER IN

G54.4 MODE

The operation attempted is not allowed in

the mode of workpiece setup error correction.

Do not attempt such an operation.

1813

G54.4 OPTION NOT

FOUND

The system of machining is not equipped

with the optional function for workpiece setup error correction.

G54.4 is not usable for a machine

without the optional function.

1814

ILLEGAL CMD IN

G54.4 MODE

The command given (G-code, T-code, etc.)

is not compatible with the mode of workpiece setup error correction.

Delete the incompatible command,

or cancel the error correction mode

beforehand to give the command.

1815

CANNOT USE G54.4

The mode of workpiece setup error correction is not selectable under the current

modal conditions.

Modify the program so as to

establish correct modal conditions for

workpiece setup error correction.

1820

ILLEGAL COMMD IN

G54.4

A block of motion command requires an

angular movement through more than 180.

Divide the command so that the

amount of angular movement of any

block does not exceed 180.

26-67

26

FIVE-AXIS MACHINING FUNCTION

- NOTE -

26-68 E

You might also like

- Doosan Puma MX Series PDFDocument68 pagesDoosan Puma MX Series PDFGuillermo RamirezNo ratings yet

- NTX 10006600 Post Manual 20120601Document197 pagesNTX 10006600 Post Manual 20120601Cristian VegaNo ratings yet

- Fanuc Lathe Programming GuideDocument93 pagesFanuc Lathe Programming GuidenguyenanhsoNo ratings yet

- HaasLiveToolOpProgram - W - DS Manual PDFDocument70 pagesHaasLiveToolOpProgram - W - DS Manual PDFGuillermo RamirezNo ratings yet

- Mori Seiki GM CodeDocument10 pagesMori Seiki GM CodevusvusNo ratings yet

- Doosan-Fanuc High Speed ModeDocument2 pagesDoosan-Fanuc High Speed Modemarkoskitp100% (1)

- Makino STL Cam PDFDocument98 pagesMakino STL Cam PDFberri23No ratings yet

- SystemVarsAlpha List OkumaDocument16 pagesSystemVarsAlpha List Okumaseb_dominique100% (2)

- DMG MillPlusV521 ProgManualDocument649 pagesDMG MillPlusV521 ProgManuallastowlNo ratings yet

- Doosan Puma-ADVANCED 30 Series TC PROGRAMMING Rev4 With 31i AddendumDocument114 pagesDoosan Puma-ADVANCED 30 Series TC PROGRAMMING Rev4 With 31i AddendumCasey GroomsNo ratings yet

- Mazatrol Basic EIA, IsO G Code Programming Class For Mazak Machining Centers OutlineDocument3 pagesMazatrol Basic EIA, IsO G Code Programming Class For Mazak Machining Centers OutlineAlberto SabasNo ratings yet

- Doosan Infracore EZ Guide-I Programming For Lathe.Document108 pagesDoosan Infracore EZ Guide-I Programming For Lathe.JohnPaulSmith1100% (1)

- Live Tool Drill TapDocument25 pagesLive Tool Drill TapRA Javier100% (1)

- Fanuc Alarms Fanuc Series 15 Alarm CodesDocument11 pagesFanuc Alarms Fanuc Series 15 Alarm CodesRevolusiSoekarno100% (1)

- M Ang G Code Mesin CNC Mori SeikiDocument13 pagesM Ang G Code Mesin CNC Mori SeikiWirdiIanNo ratings yet

- Okuma OSP 5 Axis TrainingDocument49 pagesOkuma OSP 5 Axis TrainingRick WilliamsNo ratings yet

- Puma Work Ejector Tip ReplacementDocument3 pagesPuma Work Ejector Tip ReplacementpaulNo ratings yet

- Accuracy Test of Five-Axis CNC Machine Tool With 3D Probe-Ball PartIIDocument8 pagesAccuracy Test of Five-Axis CNC Machine Tool With 3D Probe-Ball PartIIwang guanming100% (1)

- MazakDocument74 pagesMazakphuongdx100% (1)

- Fanuc Macro Program Examples and Programming GuideDocument2 pagesFanuc Macro Program Examples and Programming Guidedvt0% (1)

- Programming Fanuc OtDocument13 pagesProgramming Fanuc OtsaminziNo ratings yet

- Doosan Servo Driven Tail Stock MANUAL - ENGDocument5 pagesDoosan Servo Driven Tail Stock MANUAL - ENGmarkoskitp100% (1)

- Doosan TT Series CNCDocument7 pagesDoosan TT Series CNCRevolusiSoekarnoNo ratings yet

- Fanuc G68 Tilted Work Plane OperationDocument11 pagesFanuc G68 Tilted Work Plane OperationRelu ChiruNo ratings yet

- Fanuc MacroDocument3 pagesFanuc MacroGopi Nath0% (1)

- G M Codes All CNCDocument24 pagesG M Codes All CNCParveen Kumar0% (1)

- FANUC Macro Program ProgrammingDocument16 pagesFANUC Macro Program ProgrammingVinsensius Herdani Agung Nugroho50% (4)

- CNC Programming Guide: Functions & CommandsDocument540 pagesCNC Programming Guide: Functions & CommandsRicardoPagésMarínNo ratings yet

- Fanuc 21i Alarm CodesDocument14 pagesFanuc 21i Alarm CodesRevolusiSoekarnoNo ratings yet

- Citizen M16Document64 pagesCitizen M16Favoreel Patrick100% (1)

- M32 OpcenitoDocument14 pagesM32 OpcenitoDilhet NadarevicNo ratings yet

- DX-32 Start Up Procedures PDFDocument18 pagesDX-32 Start Up Procedures PDFkenNo ratings yet

- GE Fanuc 18i Installation ManualDocument81 pagesGE Fanuc 18i Installation Manualapi-3771584No ratings yet

- Direct Input Offset Value 2-Spindle LatheDocument14 pagesDirect Input Offset Value 2-Spindle Lathemahdi elmayNo ratings yet

- English Rotary RevRDocument114 pagesEnglish Rotary RevRssenn02No ratings yet

- Machining Simulation Software User ManualDocument89 pagesMachining Simulation Software User ManualJesus Alberto RIVERA /CALVEK AUTOMATIONNo ratings yet

- Tool Load For MC-APP2008-003Document16 pagesTool Load For MC-APP2008-003jon doughNo ratings yet

- Citizen M16 - 2Document112 pagesCitizen M16 - 2Favoreel Patrick50% (2)

- Fanuc Alpha Axis and Spindle Alarm CodesDocument10 pagesFanuc Alpha Axis and Spindle Alarm CodesEldglay Da Silva DomingosNo ratings yet

- N MV Post Processor Manual EngDocument36 pagesN MV Post Processor Manual EnglastowlNo ratings yet

- Yasnac MX-1Document252 pagesYasnac MX-1DOBJANNo ratings yet

- Kia SKT210SYDocument94 pagesKia SKT210SYrastaeggNo ratings yet

- Delcam - PowerMILL 9.0 FiveAxis Training Course en - 2008Document148 pagesDelcam - PowerMILL 9.0 FiveAxis Training Course en - 2008भागराज राज100% (1)

- 5 Axis Generic PostDocument68 pages5 Axis Generic Postwidya90% (10)

- Makino 3Document90 pagesMakino 3maneesh100% (1)

- Mori SeikiDocument7 pagesMori SeikimachineCanNo ratings yet

- Ponz Controller Fanuc Oi PF ManualDocument89 pagesPonz Controller Fanuc Oi PF ManualRose Ann C. RofuliNo ratings yet

- HE00HA0014EDocument640 pagesHE00HA0014EAdmir TalicNo ratings yet

- Daewoo Lathe Training Manual-FANUC O-TDocument104 pagesDaewoo Lathe Training Manual-FANUC O-TJAMES JUDY100% (1)

- Operation Manual for CNC Lathe Models ZL-153, ZL-153S, ZL-153MC, ZL-153SMC, ZL-203, ZL-203S, ZL-203MC, ZL-203SMC, ZL-253, ZL-253S, ZL-253MC and ZL-253SMC with MSG-501 NC UnitDocument561 pagesOperation Manual for CNC Lathe Models ZL-153, ZL-153S, ZL-153MC, ZL-153SMC, ZL-203, ZL-203S, ZL-203MC, ZL-203SMC, ZL-253, ZL-253S, ZL-253MC and ZL-253SMC with MSG-501 NC UnitБојан Јањић50% (2)

- EN - Complete Sinumerik Operate Milling - v26Document690 pagesEN - Complete Sinumerik Operate Milling - v26Hieu Nguyen100% (1)

- ATC M Functions and VariablesDocument3 pagesATC M Functions and Variablescmgankl75% (4)

- Lathe M-Code: Code Functional Explanation Ref ManDocument21 pagesLathe M-Code: Code Functional Explanation Ref ManRobotNo ratings yet

- Custom MacroDocument31 pagesCustom Macroshiva d100% (1)

- Doosan BMT65 ToolingDocument28 pagesDoosan BMT65 Toolingmarcos lemosNo ratings yet

- Setup 5-Axis Transformation TRAORI: Configuration of Machine DataDocument11 pagesSetup 5-Axis Transformation TRAORI: Configuration of Machine DataNaveen KumarNo ratings yet

- CNC Machining Center Programming ManualDocument106 pagesCNC Machining Center Programming ManualLight House50% (2)

- Servo Short Bar Feeder ManualDocument86 pagesServo Short Bar Feeder Manualhung100% (1)

- RS232 DNCDocument21 pagesRS232 DNChungNo ratings yet

- Minimaster Cutting ConditionDocument3 pagesMinimaster Cutting ConditionhungNo ratings yet

- Hobbing Example ProgramDocument1 pageHobbing Example ProgramhungNo ratings yet

- Rs232 DocumentationDocument10 pagesRs232 Documentationandan44No ratings yet

- Cable of Data Communication 181Document12 pagesCable of Data Communication 181hungNo ratings yet

- Mazak m2Document3 pagesMazak m2hungNo ratings yet

- Mazak t2Document3 pagesMazak t2hungNo ratings yet

- Guide BF ENDocument1 pageGuide BF ENhungNo ratings yet

- Hello HuangDocument2 pagesHello HuanghungNo ratings yet

- X Input AddressesDocument1 pageX Input AddresseshungNo ratings yet

- Ordering PCBsDocument1 pageOrdering PCBsDenis Villanueva PerezNo ratings yet

- Roundness SieveDocument9 pagesRoundness SievehungNo ratings yet

- STANDARD CHUCKS Technical SpecificationsDocument8 pagesSTANDARD CHUCKS Technical SpecificationshungNo ratings yet

- Ordering PCBsDocument1 pageOrdering PCBsDenis Villanueva PerezNo ratings yet

- Media Release: Australian Engineer Wins S$1,000,000 at Changi Airport's Millionaire Grand DrawDocument5 pagesMedia Release: Australian Engineer Wins S$1,000,000 at Changi Airport's Millionaire Grand DrawhungNo ratings yet

- Lecture 4Document20 pagesLecture 4Akshay KakoriyaNo ratings yet

- Infraworks 360 Pro QADocument7 pagesInfraworks 360 Pro QAdoradodoradoNo ratings yet

- Introduction To Product Design (PD) : Prof. Ganesh D. BhutkarDocument12 pagesIntroduction To Product Design (PD) : Prof. Ganesh D. BhutkarSwapnil KothawadeNo ratings yet

- Magnetrol 48-635Document36 pagesMagnetrol 48-635João LuizNo ratings yet

- Introduction To Software Engineering: N. L. Sarda I.I.T. BombayDocument58 pagesIntroduction To Software Engineering: N. L. Sarda I.I.T. BombayChandeep AroraNo ratings yet

- Anderson 4e PPT 07Document12 pagesAnderson 4e PPT 07Syaz AmriNo ratings yet

- The Expenditure Cycle Part II: Payroll Processing and Fixed Asset ProceduresDocument33 pagesThe Expenditure Cycle Part II: Payroll Processing and Fixed Asset ProceduresontykerlsNo ratings yet

- Labureader Plus 2: Semi-Automated Urine Chemistry AnalyzerDocument2 pagesLabureader Plus 2: Semi-Automated Urine Chemistry AnalyzerCARLOSNo ratings yet

- Oracle Taleo Recruiting: Requisition Management Training Guide - Section 2Document50 pagesOracle Taleo Recruiting: Requisition Management Training Guide - Section 2krishnaNo ratings yet

- Cleanup ProcessDocument3 pagesCleanup ProcessVinay ChauhanNo ratings yet

- SQLDocument41 pagesSQLSubhadip Das SarmaNo ratings yet

- Wet DesignDocument1 pageWet DesigncharathNo ratings yet

- BMW Coding Esys PDFDocument2 pagesBMW Coding Esys PDFZakaria El100% (1)

- TwistedDocument521 pagesTwistedEseosa MusaNo ratings yet

- Strategic Analysis Decisions in The Next Five YearsDocument3 pagesStrategic Analysis Decisions in The Next Five YearsGeofrey Nyaga100% (5)

- Oracle Approvals ManagementDocument22 pagesOracle Approvals Managementvinnisharma0% (1)

- HEC-RAS Reference ManualDocument0 pagesHEC-RAS Reference ManualJuan LineroNo ratings yet

- AntConc ReadmeDocument26 pagesAntConc ReadmeAmira GhonimNo ratings yet

- Eee-V-modern Control Theory (10ee55) - Question PaperDocument5 pagesEee-V-modern Control Theory (10ee55) - Question PaperKarthikeyanNo ratings yet

- C# - Loops: Loop Control StatementsDocument2 pagesC# - Loops: Loop Control Statementspbc3199No ratings yet

- Dimage MasterLite ManualDocument31 pagesDimage MasterLite ManualchrispittmanNo ratings yet

- How To Create Newswrap Server (Main Server)Document34 pagesHow To Create Newswrap Server (Main Server)Naveen PandeyNo ratings yet

- A Note On Zagreb Indices: Bo ZhouDocument10 pagesA Note On Zagreb Indices: Bo Zhoudragance106No ratings yet

- Linux Kernel Slides PDFDocument479 pagesLinux Kernel Slides PDFShripad Shivaji TawadeNo ratings yet

- PG Diploma in Software Technology (PG-DST) at C-DAC MumbaiDocument2 pagesPG Diploma in Software Technology (PG-DST) at C-DAC MumbaimunnagnekarNo ratings yet

- Pemasaran Syariah Di Lembaga Keuangan Mikro IslamDocument20 pagesPemasaran Syariah Di Lembaga Keuangan Mikro Islamnur azizatul ulyaNo ratings yet

- XDVD 600Document34 pagesXDVD 600Emanuel EscamillaNo ratings yet

- Isolation ForestDocument11 pagesIsolation ForestVarun NakraNo ratings yet

- Banqeut Hall MumbaiDocument237 pagesBanqeut Hall MumbaiKristie GarciaNo ratings yet

- Call and Delay InstructionsDocument7 pagesCall and Delay Instructionsnawazish_nehalNo ratings yet