Professional Documents

Culture Documents

Peppers - Catalogue - Approved - Accessories PDF

Uploaded by

pandiangvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Peppers - Catalogue - Approved - Accessories PDF

Uploaded by

pandiangvCopyright:

Available Formats

Peppers Cable Glands Accessories Catalogue

www.cableglands.com

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

Introduction to Peppers

For over 65 years, Peppers Cable Glands has been involved in the manufacture and

sale of Cable Glands, giving the company a wealth of experience and expertise

within the industry.

Operating from its UK base in Surrey, Peppers Cable Glands runs a

Peppers range of glands incorporate some unique engineering

satellite manufacturing system using group companies situated in

features. The CR gland for armoured cable features a single

the North of England. This provides an assured supply chain and

orientation clamping system, CROCLOCK allowing the clamping of

when paired with their global distribution network, results in on-time

all armour types with no mistakes being possible during installation.

deliveries. We believe quick deliveries are only part of the service. Its

The advertising slogan No reversible Components No Mistakes

all about the complete experience. We aim to give our customers

sums up this benefit. Due to ingenious design features Deluge is

excellent service not just in terms of our quick deliveries but from

achieved without the use of additional sealing devices.

when the initial contact is made throughout the quotation, ordering

and expediting process.

Peppers barrier glands incorporate unique features that reduce

installation times by using the Peppers T-1000 compound, which

Peppers customers can be sure that they are getting accurate advice,

enables the conductors to be terminated within the equipment after

and if we are unable to meet your requirements, we will inform you.

one hour. At four hours, the compound chamber may be inspected

We dont bend the truth to secure orders. Peppers simply does not

and the equipment can be energized. Our innovative barrier chamber

promise what it cannot deliver.

provides a cable acceptance that is on average 17% larger than other

Peppers operates a quality management system, approved to

ISO 9001:2008 and an Environmental System approved to

barrier gland designs allowing the use of smaller glands thereby

significantly reducing cost.

ISO 14001:2004. All new employees are trained to recognise what it

Glands can be supplied in various materials including brass,

takes to meet these standards and staff assessments are undertaken

aluminium, stainless steel and polyamide. We offer plating options

regularly to ensure that the highest levels of customer service are

for corrosion protection, including nickel, tin and zinc. Peppers also

maintained at all times.

supply accessories, which include a comprehensive range of certified

thread adaptors, reducers, stopping plugs and breather drains.

Peppers has an extensive range of

international approvals incorporating

Peppers Engineering Team are constantly striving to improve the

ATEX, IECEx, UL, CSA, GOST, INMETRO &

quality of our range whilst continually working to design and

NEPSI as well as marine type approvals by

develop new and innovative products.

ABS (American Bureau of Shipping), RMRS (Russian

Maritime) & Lloyds Register. Our range of approved

products are designed and tested for use in Ex d, Ex e, Ex nR

and Ex t hazardous area protection concepts.

Peppers ... a refreshing attitude to manufacturing

www.cableglands.com

Tel: +44 (0) 1276 64232 Fax: +44 (0) 1276 691752 Email: sales@peppers.co.uk

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

Table of Contents

AR Series Adaptors and Reducers

ARMM and ARFF Series Adaptors

AR Series Adaptors and Reducers Dimensional Data

AR Series Adaptors and Reducers Dimensional Data

SPMH Series Plugs (Dome / Mushroom Head)

SPHH Series (Hex Head) / Type A & B Series Blanking Plugs

ACDP Series Breather Drains

ARMR & ARFR Series 90 Degree Adaptors

CR-S*M Series Conduit Stopper Boxes

Other Products

Cable Glands

10

Locknuts - Earthtags - IP Washers - Serrated Washers - Shrouds

11

Technical Information

12

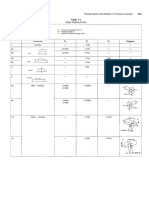

Type

Nickel Plating (NP)

Zinc Plating (ZP)

Series

Material: Brass (B)

Stainless (S)

Nylon (N)

Aluminium (A)

Exd/Exe (F)

Exd (D)

Exe (E)

Industrial (U)

Description / Type

Seal: None (0)

Nitrile (1)

Silicone (3)

Part Number Overview

Thread

Thread

Male x Female Adaptor/Reducer

AR

NP

M20

M20

Male x Male Adaptor

ARMM

M M

NP

M20

M20

Female x Female Adaptor

ARFF

NP

M20

M20

Right Angled Male/Female

ARMR

NP

M20

M20

Right Angled Female/Female

ARFR

NP

M20

M20

Domehead Stopping Plug

SPMH

NP

M20

Type A Stopping Plug

SPA

NP

M20

Type B Stopping Plug

SPB

NP

M20

Hex Head Stopping Plug

SPHH

NP

M20

Breather Drain

ACDP

NP

M20

x length

Notes:

Standard O-ring material is Nitrile

All Dome Head Stopping Plugs, Hex Head Stopping Plugs and Breather Drains are supplied with an O-ring

Type A & B plugs are not supplied with O-rings

Parallel Male Threads on adaptors and reducers are supplied with O-rings as standard

Tapered Male Threads on Adaptors & Reducers are not supplied with O-rings

Flat washers are supplied upon request

2012 Accessories Catalogue Issue 1

www.cableglands.com

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

AR Series Metallic Adaptors and Reducers

AR Series Certified Adaptors & Reducers provide a method of matching electrical thread forms on Ex equipment whilst maintaining Ex d, Ex e, Ex tb and

Ex nR methods of explosion protection. Approved for use in mining and surface installations they maintain IP66 & IP68 for IEC type applications and Class

I Division 1 and NEMA 4X for CEC type applications. All external parallel threads are fitted with a nitrile O-ring as standard.

Compliance

Standard:

EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-15, EN 60079-31

IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-15, IEC 60079-31 & 60529

Certification:

ATEX

GOST-R

LLOYDS

I M2 II 2GD Ex d I&IIC Mb Gb / Ex e I&IIC Mb Gb/ Ex tb IIIC Db

II 3GD Ex nR IIC Gc

Ex d I&IIC / Ex e I&IIC / Ex tb IIIC / Ex nR IIC

Class I, Division 1 Groups A, B, C & D

Class II, Groups E, F & G; Class III

Ex d I&IICU / Ex e I&IIU / Ex nRIIU

Enclosure Systems - Part 1B

RMRS

Part XI of Rules for sea-going ships (ed.2008)

ATEX

IECEx

CSA

GOST-R

LLOYDS

RMRS

SIRA 09ATEX1322X & SIRA 09ATEX4323X

SIR 09.0131X

2310046

POCC GB.06.B00853

10/00056

09.00784.011

IECEx

CSA

Marine

Approvals:

Certificate No.

IP Rating:

IP66 & IP68 (100 metres for 7 days) & NEMA 4X 6P

Impact Resistance:

20Nm (Aluminium 7Nm)

Operating

Temperature:

O-ring - None

O-ring - Nitrile

O-ring - Silicone

Materials:

Plating:

Brass, Stainless Steel or Aluminium

Nickel - Zinc

ARB:M25:M20

Reducer

ARB:M25:M20

Example Part Numbering

Always Quote Male Thread First

AR

1

B

F

NP

M20

M25

-100C to +400C

-30C to +100C

-60C to +200C

Optional

Accessories

Adaptor

ARB:M25:M32

ARB:M25:M32

AR1BF/NP/M20/M25

Thread converting Adaptor/Reduce

No IP O-ring (0) - Nitrile (1) - Silicone (3)

Brass (B) - Stainless Steel (S) - Aluminium (A)

Ex d & Ex e certification

Nickel Plated (NP) - Zinc Plated (ZP)

Male Entry Thread

Female Entry Thread

[N/V] IP Washers

[T] Earth Tag

[L] Locknut

[S] Serrated Washer

Nylon [N] (ACNSW) / Fibre [V] (ACFSW)

Brass (ACBET) / Stainless Steel (ACSET)

Brass (ACBLN) / Stainless Steel (ACSLN)

Stainless Steel (ACSSW)

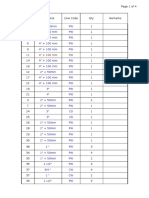

Thread Reference Tables

ISO Metric ISO 965-1, ISO 965-3, BS 3643, IEC 60423

Thread

Peppers

Reference

Standard

Pitch

TPI

M16

M20

M25

M32

M40

M50

M63

M75

M80

M85

M90

M100

M110

M120

M16

M20

M25

M32

M40

M50

M63

M75

M80

M85

M90

M100

M110

M120

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

2.00

2.00

2.00

2.00

2.00

2.00

16.93

16.93

16.93

16.93

16.93

16.93

16.93

16.93

12.70

12.70

12.70

12.70

12.70

12.70

Thread

Peppers

Reference

Pitch

TPI

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

3-1/2

4

050NPS

075NPS

100NPS

125NPS

150NPS

200NPS

250NPS

300NPS

350NPS

400NPS

1.81

1.81

2.20

2.20

2.20

2.20

3.18

3.18

3.18

3.18

14.0

14.0

11.5

11.5

11.5

11.5

8.0

8.0

8.0

8.0

Major Dia

Thread

Length

Bore

15.97

19.97

24.97

31.97

39.97

40.97

62.97

74.97

79.97

84.97

89.97

99.97

109.97

119.97

16.0

16.0

16.0

16.0

16.0

16.0

16.0

16.0

20.0

20.0

20.0

20.0

20.0

20.0

10.0

14.0

18.0

24.0

32.0

41.0

53.0

64.0

69.0

73.0

78.0

88.0

98.0

108.0

NPS ANSI B1.20.1

Major Dia

Thread

Length

Bore

20.90

26.26

32.84

41.61

47.67

59.72

72.16

88.06

100.78

113.43

19.9

20.1

25.0

25.6

26.0

26.9

39.9

41.5

42.8

44.0

14.1

19.0

25.0

32.0

38.0

49.0

60.0

75.0

88.0

100.0

Max

Clearance

Hole Dia

16.7

20.7

25.7

32.7

40.7

50.7

63.7

75.7

80.8

85.7

90.7

100.7

110.7

120.7

Max

Clearance

Hole Dia

21.60

26.96

33.54

42.31

48.37

60.42

72.86

88.76

101.48

114.13

NPT ANSI B1.20.1

Thread

Peppers

Reference

Pitch

TPI

Major Dia

Thread

Length

Bore

3/8

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

3-1/2

4

5

038NPT

050NPT

075NPT

100NPT

125NPT

150NPT

200NPT

250NPT

300NPT

350NPT

400NPT

500NPT

1.41

1.81

1.81

2.20

2.20

2.20

2.20

3.18

3.18

3.18

3.18

3.18

18.0

14.0

14.0

11.5

11.5

11.5

11.5

8.0

8.0

8.0

8.0

8.0

17.15

21.34

26.67

33.40

42.16

48.26

60.33

73.03

88.90

101.60

114.30

141.30

15.3

19.9

20.1

25.0

25.6

26.0

26.9

39.9

41.5

42.8

44.0

46.7

10.0

14.1

19.0

25.0

32.0

38.0

49.0

60.0

75.0

88.0

100.0

120.0

Thread

Peppers

Reference

Pitch

TPI

Major Dia

Thread

Length

Bore

PG7

PG9

PG11

PG13.5

PG16

PG21

PG29

PG36

PG42

PG48

PG7

PG9

PG11

PG13.5

PG16

PG21

PG29

PG36

PG42

PG48

1.27

1.41

1.41

1.41

1.41

1.59

1.59

1.59

1.59

1.59

20.0

18.0

18.0

18.0

18.0

16.0

16.0

16.0

16.0

16.0

12.50

15.20

18.60

20.40

22.50

28.30

37.00

47.00

54.00

59.30

16.0

16.0

16.0

16.0

16.0

16.0

16.0

16.0

16.0

16.0

8.0

10.0

13.5

14.0

16.0

21.0

29.0

38.0

45.0

50.0

PG DIN 40430

ISO Pipe Parallel ISO 228 BS2779 (BSPP, C, G, R, PF & Tpy 6)

ISO Pipe Taper ISO 7-1 BS21 (BSPT, Gc, Gk, Rk, PT & Kmpy 6)

Thread

Peppers

Reference

Pitch

TPI

Major Dia

Thread

Length

Bore

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

050BSP/BST

075BSP/BST

100BSP/BST

125BSP/BST

150BSP/BST

200BSP/BST

250BSP/BST

300BSP/BST

1.81

1.81

2.31

2.31

2.31

2.31

2.31

2.31

14.0

14.0

11.0

11.0

11.0

11.0

11.0

11.0

20.96

26.44

33.25

41.91

47.80

59.61

75.18

87.88

19.9

20.1

25.0

25.6

26.0

26.9

39.9

41.5

14.1

19.0

25.0

32.0

38.0

49.0

60.0

75.0

Notes:

Max

Clearance

Hole Dia

21.66

27.14

33.95

42.61

48.50

60.31

75.78

88.58

Max

Clearance

Hole Dia

17.85

22.04

27.37

34.10

42.86

48.96

61.03

73.73

89.60

102.30

115.00

142.00

Max

Clearance

Hole Dia

13.20

15.90

19.30

21.10

23.20

29.00

37.70

47.70

54.70

60.00

ET Imperial Conduit BS31

Thread

Peppers

Reference

Pitch

TPI

Major Dia

Thread

Length

Bore

5/8

3/4

1

1-1/4

1-1/2

2

2-1/2

3

058ET

075ET

100ET

125ET

150ET

200ET

250ET

300ET

1.41

1.59

1.59

1.59

1.81

1.81

1.81

1.81

18

16

16

16

14

14

14

14

15.88

19.05

25.40

31.75

38.10

50.80

63.50

76.20

16

16

16

16

16

16

16

16

10

14

18

24

32

41

53

64

Max

Clearance

Hole Dia

16.58

19.75

26.10

32.45

38.80

51.50

64.20

76.90

* Assembly instructions must be read prior to installation and adhered to in full.

* For Ex d applications female threads must comply with clause 5.3 of IEC 60079-1

* For Ex nR applications parallel entry threads must be installed with a suitable entry thread seal

* ATEX / IECEx versions are supplied as standard. If additional approvals are required they must be requested at time of order.

* Where applicable the standard O-ring material is nitrile. Other options are available upon request.

* Aluminium versions are not suitable for Group I Mining application.

Page 1

www.cableglands.com

2012 Accessories Catalogue Issue 1

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

ARMM Series Male x Male Adaptors

ARMM Series Certified Male x Male Adaptors provide a method of matching electrical thread forms on Ex equipment whilst maintaining Ex d, Ex e, Ex tb

and Ex nR methods of explosion protection. Approved for use in mining and surface installations they maintain IP66 & IP68 for IEC type applications and

Class I Division 1 and NEMA 4X for CEC type applications. All external parallel threads are fitted with a nitrile O-ring as standard.

Compliance

Standard:

EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-15, EN 60079-31

IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-15, IEC 60079-31 & 60529

Certification:

ATEX

GOST-R

I M2 II 2GD Ex d I&IIC Mb Gb / Ex e I&IIC Mb Gb/ Ex tb IIIC Db

II 3GD Ex nR IIC Gc

Ex d I&IIC / Ex e I&IIC / Ex tb IIIC / Ex nR IIC

Class I, Division 1 Groups A, B, C & D

Class II, Groups E, F & G; Class III

Ex d I&IICU / Ex e I&IIU / Ex nRIIU

Marine

Approvals:

LLOYDS

RMRS

Enclosure Systems - Part 1B

Part XI of Rules for sea-going ships (ed.2008)

Certificate No.

ATEX

IECEx

CSA

GOST-R

LLOYDS

RMRS

SIRA 09ATEX1322X & SIRA 09ATEX4323X

SIR 09.0131X

2310046

POCC GB.06.B00853

10/00056

09.00784.011

IECEx

CSA

IP Rating:

IP66 & IP68 (100 metres for 7 days) & NEMA 4X 6P

Impact Resistance:

20Nm (Aluminium 7Nm)

Operating

Temperature:

Materials:

Plating:

O-ring - None

O-ring - Nitrile

O-ring - Silicone

-100C to +400C

-30C to +100C

-60C to +200C

Brass, Stainless Steel or Aluminium

Nickel - Zinc

Example Part Numbering

(See below for details)

ARMM

ARMM1BF/NP/M20/M20

ARMM

Male to Male Adaptor

No IP O-ring (0) - Nitrile (1) - Silicone (3)

Brass (B) - Stainless Steel (S) - Aluminium (A)

Ex d & Ex e certification

NP

Nickel Plated (NP) - Zinc Plated (ZP)

M20

Male Entry Thread

M20

Male Entry Thread

Optional

Accessories

[N/V] IP Washers

Nylon [N] (ACNSW) / Fibre [V] (ACFSW)

[T] Earth Tag

Brass (ACBET) / Stainless Steel (ACSET)

[L] Locknut

Brass (ACBLN) / Stainless Steel (ACSLN)

[S] Serrated Washer

Stainless Steel (ACSSW)

ARFF Series Female x Female Adaptors

ARFF Series Certified Female x Female Adaptors provide a method of matching electrical thread forms on Ex equipment whilst maintaining Ex d, Ex e,

Ex tb and Ex nR methods of explosion protection. Approved for use in mining and surface installations they maintain IP66 & IP68 for IEC type applications

and Class I Division 1 and NEMA 4X for CEC type applications..

Compliance

Standard:

EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-15, EN 60079-31

Certification:

ATEX

IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-15, IEC 60079-31 & 60529

IECEx

CSA

I M2 II 2GD Ex d I&IIC Mb Gb / Ex e I&IIC Mb Gb/ Ex tb IIIC Db

II 3GD Ex nR IIC Gc

Ex d I&IIC / Ex e I&IIC / Ex tb IIIC / Ex nR IIC

GOST-R

Class I, Division 1 Groups A, B, C & D

Class II, Groups E, F & G; Class III

Ex d I&IICU / Ex e I&IIU / Ex nRIIU

Marine

Approvals:

LLOYDS

Enclosure Systems - Part 1B

RMRS

Part XI of Rules for sea-going ships (ed.2008)

Certificate No.

ATEX

SIRA 09ATEX1322X & SIRA 09ATEX4323X

IECEx

SIR 09.0131X

CSA

2310046

GOST-R

POCC GB.06.B00853

LLOYDS

10/00056

RMRS

09.00784.011

Example Part Numbering

(See below for details)

ARFF

ARFF

Peppers Type Code

No IP O-ring (0)

Brass (B) - Stainless Steel (S) - Aluminium (A)

Ex d & Ex e certification

NP

Nickel Plated (NP) - Zinc Plated (ZP)

IP Rating:

IP66 & IP68 (100 metres for 7 days) & NEMA 4X 6P

M20

Female Entry Thread

Impact Resistance:

20Nm (Aluminium 7Nm)

M20

Female Entry Thread

Materials:

Brass, Stainless Steel or Aluminium

Plating:

Nickel - Zinc

Notes:

ARFF0BF/NP/M20/M20

* Assembly instructions must be read prior to installation and adhered to in full.

* For Ex d applications female threads must comply with clause 5.3 of IEC 60079-1

* For Ex nR applications parallel entry threads must be installed with a suitable entry thread seal

* ATEX / IECEx versions are supplied as standard. If additional approvals are required they must be requested at time of order.

* Where applicable the standard O-ring material is nitrile. Other options are available upon request.

* Aluminium versions are not suitable for Group I Mining application.

2012 Accessories Catalogue Issue 1

www.cableglands.com

Page 2

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

AR Series Metallic Adaptor & Reducers

METRIC FEMALE SIZES

MALE SIZE

NPT FEMALE SIZES

Metric

M16

M20

M16

A01

A01

M20

R02

A02

A03

A05

M25

R05

R05

A04

A05

A06

M32

R07

R07

R07

A05

A06

A08

M40

R09

R09

R09

R09

A07

A08

A11

M50

R12

R12

R12

R12

R12

A09

A11

A12

M63

R14

R14

R14

R14

R14

R14

A11

A12

A13

A14

M75

R16

R16

R16

R16

R16

R16

R16

A12

A13

A14

A14

M80

R16

R16

R16

R16

R16

R16

R16

A12

A13

A14

M85

R17

R17

R17

R17

R17

R17

R17

R17

A13

M90

R17

R17

R17

R17

R17

R17

R17

R17

M100

R18

R18

R18

R18

R18

R18

R18

M110

R19

R19

R19

R19

R19

R19

M120

R20

R20

R20

R20

R20

R20

R01*

A01*

A03

A05

R03*

R03*

A03*

A05

A06

R06*

R06*

R06*

A05*

A06

A08

R08*

R08*

R08*

R08*

A06*

A08

A11

R10*

R10*

R10*

R10*

R10*

A08*

A11

A12

R13

R13

R13

R13

R13

R13

A11

A12

A13

A14

R15

R15

R15

R15

R15

R15

R15

A12

A13

A14

A14

R16*

R16*

R16*

R16*

R16*

R16*

R16*

R16*

A13*

A14

A14

A15

A16

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

A15

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

PG9

A01

A01

PG11

A01

A02

A03

PG13.5

R02

A02

A03

PG16

R04

A03

PG21

R07

PG29

M25

M32

M40

M50

M63

M75

M80

M85

M90

M100

M110

M120

3/4

2/

A19

A20

A22

R05

A21

A22

A23

R07

R07

A22

A23

A24

R09

R09

R09

A23

A24

A26

R12

R12

R12

R12

A24

A26

A27

R14

R14

R14

R14

R14

A26

A27

A15

R16

R16

R16

R16

R16

R16

A14

A15

R16

R16

R16

R16

R16

A14

A14

A15

R17

R17

R17

R17

R17

A14

A14

A15

A16

R17

R17

R17

R18

R18

R18

R18

A15

A16

A17

R18

R18

R19

R19

R19

R19

R19

R19

A16

A17

R19

R20

R20

R20

R20

R20

R20

R20

A17

A28

A29

A30

R16

R16

A29

A30

R17

R17

R17

A29

A30

R17

R17

R17

R17

A29

A30

A31

R18

R18

R18

R18

R18

R18

A30

A31

R19

R19

R19

R19

R19

R19

R19

R19

A31

A33

R20

R20

R20

R20

R20

R20

R20

R20

R20

A32

A33

A18*

A20

A22

R03*

A20*

A22

A23

R06*

R06*

A22*

A23

A24

R08*

R08*

R08*

A23*

A24

A26

R10*

R10*

R10*

R10*

A24*

A26

A27

R13

R13

R13

R13

R13

A26

A27

A29

R15

R15

R15

R15

R15

R15

A27

A29

A30

A17

R16*

R16*

R16*

R16*

R16*

R16*

R16*

A29

A30

A31

A16

A17

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

A30

A31

R19*

A16

A17

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

A31

A33

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

A33

A18

NPT

PG

A18

A19

A20

A05

A19

A20

A22

A03

A05

A20

A20

A22

R07

A05

A05

A06

R07

A22

A22

A23

R08

R08

R08

R08

A06

A08

R08

R08

A23

A23

A24

PG36

R11

R11

R11

R11

R11

A08

A11

R11

R11

R11

A24

A24

A26

PG42

R13

R13

R13

R13

R13

A10

A11

A12

R13

R13

R13

R13

R13

A26

A27

PG48

R14

R14

R14

R14

R14

R14

A11

A12

R14

R14

R14

R14

R14

A26

A27

Adaptor

Reducer

Page 3

* ADAPTORS AND REDUCERS WITH NPT MALE THREADS ARE DESIGNED TO BE USED IN THREADED ENTRIES. IF REQUIRED WITH A

SEALING WASHER FOR USE IN CLEARANCE HOLES WITH A LOCKNUT THESE ITEMS CAN BE MANUFACTURED FROM A LARGER

HEXAGON SIZE TO PROVIDE A SUITABLE SEALING FACE.

www.cableglands.com

2012 Accessories Catalogue Issue 1

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

AR Series Metallic Adaptor & Reducers

PG FEMALE SIZES

MALE SIZE

Metric

PG7

PG9

PG11

PG13.5

M16

R01

A01

A01

A01

M20

R02

R02

A02

M25

R05

R05

R05

M32

R07

R07

M40

R09

M50

PG16

PG21

PG29

PG36

PG42

PG48

A02

A02

A04

R05

A04

A04

A06

R07

R07

R07

A05

A06

A08

R09

R09

R09

R09

R09

A07

A08

A10

R12

R12

R12

R12

R12

R12

R12

A09

A10

A11

M63

R14

R14

R14

R14

R14

R14

R14

R14

R14

A11

M75

R16

R16

R16

R16

R16

R16

R16

R16

R16

R16

M80

R16

R16

R16

R16

R16

R16

R16

R16

R16

R16

M85

R17

R17

R17

R17

R17

R17

R17

R17

R17

R17

M90

R17

R17

R17

R17

R17

R17

R17

R17

R17

R17

M100

R18

R18

R18

R18

R18

R18

R18

R18

R18

R18

M110

R19

R19

R19

R19

R19

R19

R19

R19

R19

R19

M120

R20

R20

R20

R20

R20

R20

R20

R20

R20

R20

NPT

R01*

R01*

A01*

A01*

A02

A04

R03*

R03*

R03*

R03*

A03*

A04

A06

R06*

R06*

R06*

R06*

R06*

A05*

A06

A08

R08*

R08*

R08*

R08*

R08*

R08*

A06*

A08

A10

R10*

R10*

R10*

R10*

R10*

R10*

R10*

A08*

A10

A11

R13

R13

R13

R13

R13

R13

R13

R13

R13

A11

R15

R15

R15

R15

R15

R15

R15

R15

R15

R15

R16*

R16*

R16*

R16*

R16*

R16*

R16*

R16*

R16*

R16*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R17*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R19*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

R21*

PG

PG9

A01

A01

A01

A01

PG11

A01

A01

A01

A01

A02

A04

PG13.5

R02

R02

A02

A02

A02

A04

PG16

R04

R04

R04

A03

A03

A04

PG21

R07

R07

R07

R07

R07

A05

A06

PG29

R08

R08

R08

R08

R08

R08

A07

A08

PG36

R11

R11

R11

R11

R11

R11

R11

A08

A10

A11

PG42

R13

R13

R13

R13

R13

R13

R13

R13

A10

A11

PG48

R14

R14

R14

R14

R14

R14

R14

R14

R14

A11

ADAPTORS

Metric x Metric / Metric x PG / PG x Metric / PG x PG

AR Adaptor Details

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A/F Dim (Min)

23.4

27.0

30.0

31.8

37.6

44.5

47.2

55.9

57.2

61.2

69.9

90.2

104.8

104.8

114.3

120.7

140.0

A/C Dim (Min)

25.7

29.7

33.0

35.0

41.4

48.9

51.9

61.5

62.9

67.3

76.8

99.2

99.2

115.3

125.7

132.8

154.0

Nominal Protrusion Length *

22.5

22.5

22.5

22.5

22.5

22.5

22.5

23.5

23.5

23.5

23.5

23.5

29.0

29.0

29.0

29.0

29.0

AR Adaptor Details

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

A33

A/F Dim (Min)

23.4

27.0

30.0

31.8

37.6

47.2

55.9

57.2

69.9

80.0

90.2

104.8

114.3

127.0

133.0

160.0

Metric x NPT / NPT x NPT / PG x NPT

A/C Dim (Min)

25.7

29.7

33.0

35.0

41.4

51.9

61.5

62.9

76.9

88.0

99.2

115.3

125.7

139.7

146.3

176.0

Nominal Protrusion Length **

26.0

26.0

26.0

26.0

31.0

31.0

32.0

32.0

32.0

44.4

44.4

46.0

47.3

48.5

48.5

53.7

REDUCERS

Metric / NPT / PG

AR Reducer Details

R01

R02

R03

R04

R05

R06

R07

R08

R09

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R21

A/F Dim (Min)

23.4

27.0

27.9

30.0

31.8

34.9

37.6

44.5

47.2

52.1

55.9

57.2

61.2

69.9

80.0

90.2

104.8

114.3

120.7

133.4

146.0

A/C Dim (Min)

25.7

29.7

30.7

33.0

35.0

38.4

41.4

48.9

51.9

57.3

61.5

62.9

67.3

76.8

88.0

99.2

115.3

125.7

132.8

146.7

160.7

Nominal Protrusion Length **

12.0

10.0

10.0

10.0

10.0

10.0

10.0

10.0

10.0

10.0

11.0

11.0

11.0

11.0

11.0

11.0

11.0

11.0

11.0

12.0

12.0

* Stated nominal protrusion lengths do not take into account if any form of IP seal (o-ring / washer) is used in conjunction with the entry thread

** Due to the nature of tapered threads the nominal protrusion length may be further away from the enclosure wall than the stated figure

2012 Accessories Catalogue Issue 1

www.cableglands.com

Page 4

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

SPMH Series Metallic Plugs (Dome Head)

SPMH Series Certified Metallic Stopping (Blanking) Plugs provide a method of sealing unused entries in Ex equipment. They

maintain Ex d, Ex e, Ex tb and Ex nR methods of protection and IP66, IP68 for IEC type applications. They also maintain Class I,

Division 1 and NEMA 4X for CEC type applications.

Example Part Numbering

(See below for details)

SPMH/M20

SPMH

1

B

F

NP

M20

SPMH1BF/NP/M20

Stopping Plug with Mushroom/Dome head

No IP O-ring (0) - Nitrile (1) - Silicone (3)

Brass (B) - Stainless Steel (S) - Aluminium (A)

Ex d & Ex e certification

Nickel Plated (NP) - Zinc Plated (ZP)

Male Thread

Optional

Accessories

[N/V] IP Washers

[T] Earth tag

[L] Locknut

[S] Serrated Washer

Nylon [N] (ACNSW) / Fibre [V] (ACFSW)

Brass (ACBET) / Stainless Steel (ACSET)

Brass (ACBLN) / Stainless Steel (ACSLN)

Stainless Steel (ACSSW)

Compliance

Standard:

EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-15, EN 60079-31

IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-15, IEC 60079-31 & 60529

Certification:

ATEX

IECEx

CSA

GOST-R

I M2 II 2GD Ex d I&IIC Mb Gb / Ex e I&IIC Mb Gb/ Ex tb IIIC Db / II 3GD Ex nR IIC Gc

Ex d I&IIC / Ex e I&IIC / Ex tb IIIC / Ex nR IIC

Class I, Division 1 Groups A, B, C & D / Class II, Groups E, F & G; Class III

Ex d I&IICU / Ex e I&IIU / Ex nRIIU

Marine

Approvals:

LLOYDS

RMRS

Enclosure Systems - Part 1B

Part XI of Rules for sea-going ships (ed.2008)

Certificate No.

ATEX

IECEx

CSA

GOST-R

LLOYDS

RMRS

SIRA 09ATEX1320X & SIRA 09ATEX4323X

SIR 09.0131X

2310046

POCC GB.06.B00853

10/00056

09.00784.011

IP Rating:

Impact

Resistance:

ISO Thread

IP66 & IP68 (100 metres for 7 days) & NEMA 4X 6P

20Nm (Aluminium 7Nm)

Materials:

Brass, Stainless Steel or Aluminium

Plating:

Nickel - Zinc

Hex Socket

A/F

Overall

Length

Weight

NPT Thread

Hex Socket

A/F

Overall

Length

M16

8.0

21.5

0.032

1/2

10.0

25.4

M20

10.0

21.5

0.049

3/4

12.0

25.7

M25

12.0

21.5

0.078

12.0

30.5

M32

12.0

21.5

0.134

1-1/4

14.0

31.1

M40

14.0

21.5

0.218

1-1/2

17.0

31.5

M50

17.0

21.5

0.333

17.0

32.4

M63

17.0

21.5

0.544

2-1/2

19.0

45.4

M75

19.0

21.5

0.777

22.0

47.0

M80

22.0

25.5

1.050

3-1/2

22.0

48.3

M85

22.0

25.5

1.225

22.0

49.5

M90

22.0

25.5

1.326

M100

22.0

25.5

1.680

Head Diameter = Minimum 5.5mm

larger than the major thread diameter

All dimensions in mm / weight in kgs (for metric version)

Operating

Temperature:

Notes:

O-ring - None

O-ring - Silicone

-100C to +400C

-60C to +200C

* When used in an Ex nR application SPMH plugs must be fitted with an appropriate seal.

* Assembly instructions must be read prior to installation and adhered to in full.

* To maintain the specified IP rating, clearance holes must be in accordance with EN 50262 Table 1 and the entry device should be suitably secured.

* For Ex d applications female threads must comply with clause 5.3 of IEC 60079-1

* ATEX / IECEx versions are supplied as standard. If additional approvals are required they must be requested at time of order.

* The standard O-ring material is nitrile. Other options are available upon request.

* Aluminium versions are not suitable for Group I Mining application.

Page 5

www.cableglands.com

2012 Accessories Catalogue Issue 1

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

SPA / SPB Series Metallic Plugs

SPA & SPB Series Certified Metallic Stopping Plugs provide a method of sealing unused threaded entries in Ex equipment. They

maintain Exd and Ex tb methods of explosion protection and IP66 for IEC type applications. They also maintain Class I, Division 1 and

NEMA 4X for CEC type applications. SPA stopping plugs are installed from the outside of an enclosure and can be tightened with

an appropriate allen key. SPB stopping plugs are installed from the outside of an enclosure but the allen key recess for tightening is

located inside. Due to this design they are sometimes referred to as tamperproof stopping plugs.

Compliance

Standard:

Certification:

Marine

Approvals:

Certificate No.

IP Rating:

EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-31

IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-31 & 60529

ATEX

I M2 II 2GD Ex d I&IIC Mb Gb / Ex e I&IIC Mb Gb / Ex tb IIIC Db

IECEx

Ex d I&IIC / Ex e I&IIC / Ex tb IIIC

CSA

Class I, Division 1 & 2; Groups A, B, C & D

Class II, Groups E, F & G

GOST-R

Ex d I&IICU / Ex e I&IIU

LLOYDS

Enclosure Systems - Part 1B

RMRS

Part XI of Rules for sea-going ships (ed.2008)

ATEX

IECEx

CSA

GOST-R

LLOYDS

RMRS

IP66

20Nm (Aluminium 7Nm)

Materials:

Brass, Stainless Steel or Aluminium

Plating:

Nickel - Zinc

Operating

Temperature:

-100C to +400C

SPA

0

B

D

NP

M20

SPA0BD/NP/M20

Stopping Plug Flush Fitting [SPA] / Tamperproof [SPB]

No IP O-ring (0)

Brass (B) - Stainless Steel (S) - Aluminium (A)

Ex d certification

Nickel Plated (NP) - Zinc Plated (ZP)

Male Thread

ISO Thread Hex Socket

Dia

A/F

M16

8.0

M20

10.0

M25

12.0

M32

12.0

M40

14.0

M50

17.0

M63

17.0

M75

19.0

M80

22.0

M85

22.0

M90

22.0

M100

22.0

SIRA 09ATEX1320X

SIR 09.0131X

2310046

POCC GB.06.B00853

10/00056

09.00784.011

Impact

Resistance:

Example Part Numbering

(See below for details)

Overall

Length

17.0

17.0

17.0

17.0

17.0

17.0

17.0

17.0

22.0

22.0

22.0

22.0

Weight

0.019

0.032

0.052

0.095

0.153

0.244

0.406

0.583

NPT Thread Hex Socket

Dia

A/F

1/2

10.0

3/4

12.0

1

12.0

1-1/4

14.0

1-1/2

17.0

2

17.0

2-1/2

19.0

3

22.0

3-1/2

22.0

4

22.0

Overall

Length

14.5

14.8

18.5

19.1

19.5

20.5

30.5

32.1

33.4

34.7

Type A = External Fixing

Type B = Internal Fixing

All dimensions in mm / weight in kgs (for metric version)

Notes:

SPA & SPB plugs have been independently IP tested in representative threads of enclosures. In practice the interface between the stopping plug and associated equipment cannot be

defined, therefore it is the users responsibility to ensure that an appropriate IP seal is maintained.

* Assembly instructions must be read prior to installation and adhered to in full.

* For Ex d applications female threads must comply with clause 5.3 of IEC 60079-1

* ATEX / IECEx versions are supplied as standard. If additional approvals are required they must be requested at time of order.

SPHH Series Metallic Plugs (Hex Head)

SPHH Series Certified Metallic Stopping (Blanking) Plugs provide a method of sealing unused entries in Ex equipment. They

maintain Ex d, Ex e, Ex tb and Ex nR methods of protection and IP66, IP68 for IEC type applications. They also maintain Class

I, Division 2 and NEMA 4X for CEC type applications.

Compliance

Standard:

EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-15, EN 60079-31

Certification:

ATEX

IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-15, IEC 60079-31 & 60529

GOST-R

I M2 II 2GD Ex d I&IIC Mb Gb / Ex e I&IIC Mb Gb/ Ex tb IIIC Db

II 3GD Ex nR IIC Gc

Ex d I&IIC / Ex e I&IIC / Ex tb IIIC / Ex nR IIC

Class I, Division 1 Groups A, B, C & D

Class II, Groups E, F & G; Class III

Ex d I&IICU / Ex e I&IIU / Ex nRIIU

Marine

Approvals:

LLOYDS

RMRS

Enclosure Systems - Part 1B

Part XI of Rules for sea-going ships (ed.2008)

Certificate No.

ATEX

IECEx

CSA

GOST-R

LLOYDS

RMRS

SIRA 09ATEX1320X & SIRA 09ATEX4323X

SIR 09.0131X

2310046

POCC GB.06.B00853

10/00056

09.00784.011

IECEx

CSA

IP Rating:

IP66 & IP68 (100 metres for 7 days) & NEMA 4X 6P

Impact

Resistance:

20Nm (Aluminium 7Nm)

Materials:

Brass, Stainless Steel or Aluminium

Plating:

Nickel - Zinc

Operating

Temperature:

O-ring - Nitrile

-30oC to +100oC

O-ring - Silicone

-60oC to +200oC

Notes:

Example Part Numbering

(See below for details)

SPHH

1

B

F

NP

M20

SPHH1BF/NP/M20

Peppers Stopping Plug with Hexagon Head

No IP O-ring (0) - Nitrile (1) - Silicone (3)

Brass (B) - Stainless Steel (S) - Aluminium (A)

Ex d & Ex e certification

Nickel Plated (NP) - Zinc Plated (ZP)

Male Thread

[N/V] IP Washers

[T] Earth tag

[L] Locknut

[S] Serrated Washer

Optional

Accessories

ISO Thread

Min A/F

M16

M20

M25

M32

M40

M50

M63

M75

M80

M85

M90

M100

23.4

27.0

31.8

37.6

47.2

57.2

69.9

90.0

90.0

104.8

104.8

114.3

Overall

Length

20.5

21.0

21.0

21.0

21.5

21.5

22.0

22.0

28.0

28.0

28.0

28.0

Nylon [N] (ACNSW) / Fibre [V] (ACFSW)

Brass (ACBET) / Stainless Steel (ACSET)

Brass (ACBLN) / Stainless Steel (ACSLN)

Stainless Steel (ACSSW)

Weight

NPT Thread

Min A/F

Overall

0.040

0.063

0.096

0.150

0.246

0.377

0.610

0.890

1.210

1.410

1.530

1.930

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

3-1/2

4

27.9

33.0

41.2

50.0

57.2

69.9

90.0

104.8

114.3

127.0

24.4

24.7

30.0

31.1

31.5

32.9

46.4

49.5

50.8

52.0

All dimensions in mm / weight in kgs (for metric version)

* Assembly instructions must be read prior to installation and adhered to in full.

* When used in an Ex nR application SPHH plugs must be fitted with an appropriate seal.

* To maintain the specified IP rating, clearance holes must be in accordance with EN 50262 Table 1 and the entry device should be suitably secured.

* For Ex d applications female threads must comply with clause 5.3 of IEC 60079-1

* IECEx / ATEX versions are supplied as standard. If additional approvals are required they must be requested at time of order.

* Where applicable the standard O-ring material is nitrile. Other options are available upon request.

* Aluminium versions are not suitable for Group I Mining application

2012 Accessories Catalogue Issue 1

www.cableglands.com

Page 6

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

ACDP Series Metallic Breather Drains

ACDP Series Breather Drains allow the inside of the equipment to breathe with the outside atmosphere and provide a method of effectively draining any

moisture from within the equipment. ACDP series breather drains maintain Ex e method of protection and IP66 for IEC type applications. A Castellated

Locknut and O-ring is supplied with every Breather Drain.

Compliance

Standard:

EN 60079-0, EN 60079-7, EN 60079-31

IEC 60079-0, IEC 60079-7, IEC 60079-31 & 60529

Certification:

ATEX

IECEx

CSA

GOST-R

I M2 II 2GD Exe I&IIC Mb Gb / Ex tb IIIC Db

Ex e I&IIC / Ex tb IIIC

Ex e II

Ex e I&IIU

Marine

Approvals:

LLOYDS

RMRS

Enclosure Systems - Part 1B

Part XI of Rules for sea-going ships (ed.2008)

Certificate No.

ATEX

IECEx

CSA

GOST-R

LLOYDS

RMRS

SIRA 09ATEX3321U

SIR 09.0132U

2310046

POCC GB.06.B00853

10/00056

09.00784.011

Example Part Numbering

(See below for details)

ACDP

Breather Drain c/w Castellated Locknut

No IP O-ring (0) - Nitrile (1) - Silicone (3)

Brass (B) - Stainless Steel (S) - Aluminium (A)

Ex e certification

NP

IP Rating:

IP66

Impact

Resistance:

20Nm (Aluminium 7Nm)

Flow Rate:

0.25 Litres per Hour

Operating

Temperature:

O-ring - Nitrile

O-ring - Silicone

ACDP1BE/NP/M20/10

M20

10

Nickel Plated (NP) - Zinc Plated (ZP)

Male Entry Thread

Entry Thread Length 10mm or 15mm

Dimension Data

-30oC to +100oC

-60oC to +200oC

Thread Size

A/F

A/C [A]

Length [B]

Length [L]

Weight

M20 x 1.5

27.0

29.7

10 or 15

12.0

0.065

M25 x 1.5

31.8

34.9

10 or 15

12.0

0.097

37.6

41.3

10 or 15

12.0

0.107

Materials:

Brass, Stainless Steel or Aluminium

M32 x 1.5

Plating:

1/2NPT

28.6

31.4

15

12.0

0.075

Nickel - Zinc

3/4NPT

33.0

36.3

15

12.0

0.107

All dimensions in mm / weight in kgs (for 10mm metric versions)

Notes:

* Assembly instructions must be read prior to installation and adhered to in full.

* The ACDP flow rate was obtained from testing in an empty enclosure filled with water. The enclosure had no heat or pressure producing equipment inside. Flow rates in

the field may vary depending on operational parameters and surrounding environmental conditions.

* To maintain the specified IP rating, clearance holes must be in accordance with EN 50262 Table 1 and the entry device should be suitably secured.

* IECEx / ATEX versions are supplied as standard. If additional approvals are required they must be requested at time of order.

* The standard O-ring material is nitrile. Other options are available upon request.

* All Breather Drains are supplied with Castellated locknut as standard.

* Aluminium versions are not suitable for Group I Mining application.

Page 7

1.1.0

www.cableglands.com

2012 Accessories Catalogue Issue 1

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

ARMR & ARFR Series Metallic 90 Degree Adaptors

ARMR & ARFR Series Dual Certified Right Angled Adaptors are designed to protect cables when installed in confined spaces where the cable may

otherwise be subject to excessive bending and or stress. The Series is available with Male/Female or Female/Female connection threads. They are approved

for Ex d, Ex e, Ex tb and Ex nR methods of explosion protection whilst maintaining IP66, IP68 for IEC type applications and Class I Division 1, and NEMA 4X

for NEC/CEC type applications. All external parallel threads are fitted with a nitrile O-ring as standard.

Compliance

Standard:

EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-15, EN 60079-31

IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-15, IEC 60079-31 & 60529

Certification:

ATEX

I M2 II 2GD Ex d I&IIC Mb Gb / Ex e I&IIC Mb Gb/ Ex tb IIIC Db

II 3G Ex nR IIC Gc

IECEx

Ex d I&IIC / Ex e I&IIC / Ex tb IIIC / Ex nR IIC

CSA

Class I, Division 1 & 2; Groups A, B, C & D

Class II, Groups E, F & G

Certificate No.

ATEX

IECEx

CSA

SIRA 10ATEX1132U & SIRA 10ATEX4133U

SIR 10.0068U

2310046

IP Rating:

IP66 & IP68 (100 metres for 7 days) & NEMA 4X 6P

Impact

Resistance:

20Nm (Aluminium 7Nm)

Temperature:

O-ring - None

O-ring - Silicone

O-ring - Nitrile

Materials:

Brass, Stainless Steel or Aluminium

Plating:

Nickel - Zinc

-100oC to +400oC

-60oC to +200oC

-30oC to +100oC

Example Part Numbering

(See below for details)

ARMR

Dimensions:

Size

Bore

Height

Length

Width

M16 x M16

M20 x M20

M25 x M25

M32 x M32

M40 x M40

M50 x M50

M63 x M63

M75 x M75

10.0

14.0

18.0

24.0

32.0

41.0

53.0

64.0

38.1

38.1

44.4

50.8

63.5

72.0

90.0

102.0

27.0

27.0

37.0

45.0

52.0

67.0

83.0

94.0

25.4

25.4

31.8

38.1

50.8

60.0

75.0

88.0

All dimensions in mm

Notes:

ARMR1BF/NP/M20/M20

90 Degree Adaptor Male/Female (Right Angled)

OR

ARFR

90 Degree Adaptor Female/Female (Right Angled)

No IP O-ring (0) - Nitrile (1) - Silicone (3) (Only available on ARMR)

Brass (B) - Stainless Steel (S) - Aluminium (A)

Ex d & Ex e certification

NP

Nickel Plated (NP) - Zinc Plated (ZP)

M20

Male Entry Thread

M20

Female Entry Thread

* Differing threads and thread forms are avaible upon request

* 90 Degree Adaptors are approved and available up to size M100

* Aluminium versions are not suitable for Group I Mining application

* When used in an Ex nR application ARMR & ARFR adaptors must be fitted with an appropriate seal.

CR-S*M - A NEW CONCEPT

Connecting Ex d Junction Boxes

So how do you connect two Ex d Flameproof enclosures?

Most installations do not call for enclosures to be connected together but what do you do if you

need to connect two (or more) Ex d enclosures within a Zone 1 hazardous area?

Traditional practice has been to use a compound barrier gland mounted at the entry of both

enclosures with a length of cable or conduit. In the event of an ignition or explosion inside one

of the enclosures this practice prevents the transmission of the explosion to the other enclosure.

Whilst this will maintain the integrity of the installation it carries significant cost implications.

Peppers can now provide a substantially more cost effective solution for this type of

installation. Peppers CR-S*M range of barrier glands can now be installed directly

between two Ex d enclosures. Tested in accordance with IEC / EN

60079-1 the gland is capable of maintaining the integrity of the

installation having passed pressure and sealing tests from

both directions to simulate the event of an explosion

in either enclosure. Supplied with two male

threads, the gland allows conductors to pass

through the compound ensuring that a

flameproof seal is maintained for

each enclosure. In the event of an

explosion within one enclosure

the CR-S*M gland will

prevent any transmission to

the second enclosure or the

surrounding atmosphere.

2012 Accessories Catalogue Issue 1

www.cableglands.com

PagePage

1.1.0

8

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

Other Products

Male x Female Union

Male x Male Union

Earth Lead Adaptors

Male Bush Long Pattern

Female Bush

Male Bush Short Pattern

Coupler

Nipple

Round Adaptor / Reducer

HV Earth Glands

Customer Specific

Specials

Page 1.1.0

9

www.cableglands.com

2012 Accessories Catalogue Issue 1

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

Cable Glands

Double Compression

Type E

Exd/Exe Double Compression for Armoured Cables

IP66, IP67 & IP68 (35 metres for 7 days)

ATEX - IECEx - GOST - CSA - INMETRO - NEPSI LLOYDS - ABS

Dedicated Armour Locking Suitable for SWA (W)

SWB/STA (X)

Available with optional silicone seal for use at -60

to +180 C.

Brass or Stainless Steel

Type A

Single Compression

Exd/Exe Single Compression for Unarmoured or

Armoured Cables

IP66, IP68 (25 metres for 30 minutes) & Deluge Proof

ATEX-IECEx-GOST-CSA-INMETRO-NEPSI-LLOYDS-ABS

Double Compression and Conduit versions optional

Available with optional silicone seal for use at

-60 to +180 C.

Brass, Stainless Steel or Aluminium

Type CR

Universal Double Compression

Exd/Exe Double Compression Universal Clamping

IP66, IP68 (35 metres for 7 days) & Deluge Proof

ATEX-IECEx-GOST-CSA-INMETRO-LLOYDS-ABS

CROCLOCK - No Reversible Components

- No Mistakes

Optional silicone seal for use at -60 to +180 C.

Brass or Stainless Steel

Type CR-C

Universal Barrier

Exd/Exe Double Compression Barrier Gland

IP66, IP68 (100 metres for 7 days) & Deluge

ATEX-IECEx-GOST-CSA (CUS)-INMETRO-LLOYDS-ABS

Featuring Peppers T-1000 fast curing compound

Temperature rating -60 to +135 C.

Brass or Stainless Steel

2012 Accessories Catalogue Issue 1

www.cableglands.com

Page

Page

1.1.0

10

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

Installation Accessories

A complete range of locknuts, earthtags, IP washers, serrated washers and shrouds.

LOCKNUTS

Locknuts are recommended for securing external entry threads into equipment. They are

available in various materials such as brass, plated brass, stainless steel, aluminium

and nylon.

Order Code

Brass

Brass Nickel Plated

Stainless Steel

Aluminium

Nylon

Example

ACBLN/M20

ACBLN/NP/M20

ACSLN/M20

ACALN/M20

ACNLN/M20

Note: Dimensions shown are only applicable to metallic locknuts

Alternate thread pitches are available

EARTH TAGS

Earth tags are recommended for providing an earth bond connection for an entry component into

the equipment. Earth tags are available in brass, plated brass, stainless steel and aluminium.

Order Code

Brass

Brass Nickel Plated

Stainless Steel

Aluminium

Example

ACBET/M20

ACBET/NP/M20

ACSET/M20

ACAET/M20

Peppers Earth tags are compliant with the Category

B requirements of EN 50262: 1999

IP WASHERS

In order to maintain the integrity of an enclosure greater than IP54, washers are

recommended to be installed at the gland entry interface.

Order Code

Fibre

Nylon

PTFE

Example

ACFSW/M20

ACNSW/M20

ACPSW/M20

Temperature

-40oC to +95oC

-40oC to +135oC

-200oC to +260oC

Colour

Fibre

Nylon

PTFE

Metric = Red

Metric = Red

Metric = White

NPT = Red

NPT = White

NPT = White

SERRATED WASHERS

Minimum Minimum

Weight NPT Thread Minimum Minimum Minimum

A/F

A/C

(Kgs/100)

Dia

Thickness

A/F

A/C

22.0

24.2

0.772

1/2"

3.2

27.0

29.7

24.0

26.4

0.683

3/4"

4.0

30.5

33.5

30.0

33.0

1.027

1"

5.0

38.1

41.9

40.0

44.0

2.020

1-1/4"

5.5

50.0

55.0

50.0

55.0

3.435

1-1/2"

6.0

60.0

66.0

65.0

71.5

6.997

2"

7.0

75.0

82.5

75.0

82.5

9.369

2-1/2"

9.0

90.0

99.0

90.0

99.0

14.871

3"

9.0

104.8

115.3

90.0

99.0

15.140

3-1/2"

10.0

114.3

125.7

4"

10.0

140.0

152.4

104.8

115.3

27.518

104.8

115.3

23.256

Sizes M110 to M130, PG7 to PG48 and

BSPP / BSPT are available upon request

114.3

125.7

25.256

All dimensions in mm - Weights are based on metric versions

ISO Thread Minimum

Dia

Thickness

M16

1.5

M20

1.5

M25

1.5

M32

1.5

M40

1.5

M50

1.5

M63

1.5

M75

1.5

M80

1.5

M85

1.5

M90

1.5

M100

1.5

Nominal

Bolt Hole

Weight NPT Thread Minimum Nominal

Bolt Hole

Centres

Dia

(Kgs/100)

Dia

Thickness

Centres

Dia

31.8

6.9

0.746

1/2"

1.5

33.0

6.9

33.0

6.9

0.672

3/4"

1.5

36.5

6.9

36.5

6.9

0.797

1"

1.5

42.5

11.8

42.5

11.8

1.476

1-1/4"

1.5

45.4

13.5

45.4

13.5

2.089

1-1/2"

1.5

58.1

13.5

58.1

13.5

3.729

2"

1.5

66.8

13.5

66.8

13.5

4.898

2-1/2"

1.5

73.0

13.5

73.0

13.5

5.220

3"

1.5

90.0

13.5

73.0

13.5

4.647

3-1/2"

1.5

112.0

13.5

4"

1.5

120.0

13.5

90.0

13.5

7.658

90.0

13.5

6.669

Sizes M110 to M130, PG7 to PG48 and

BSPP / BSPT are available upon request

112.0

13.5

10.305

All dimensions in mm - Weights are based on metric versions

ISO Thread Thickness

Dia

Nylon

M16

2.00

M20

2.00

M25

2.00

M32

2.00

M40

2.00

M50

2.00

M63

2.00

M75

2.00

M80

2.00

M85

2.00

M90

2.00

M100

2.00

Thickness Outside

Weight NPT Thread Thickness Thickness

Outside

Fibre

Diameter (Kgs/100)

Dia

Nylon

Fibre

Diameter

1.50

25.0

0.116

1/2"

2.0

1.50

30.0

1.50

29.4

0.164

3/4"

2.0

1.50

38.0

1.50

38.1

0.257

1"

2.0

1.50

46.3

1.50

42.5

0.341

1-1/4"

2.0

1.50

55.5

1.50

52.0

0.386

1-1/2"

2.0

1.50

60.0

1.50

65.0

0.594

2"

2.0

1.50

79.4

1.50

79.4

0.794

2-1/2"

2.0

1.50

90.5

1.50

90.5

0.868

3"

2.0

1.50

114.3

1.50

104.8

0.839

3-1/2"

2.0

1.50

114.3

4"

2.0

1.50

146.0

1.50

104.8

0.698

1.50

114.3

0.913

Sizes M110 to M130, PG7 to PG48 and

BSPP / BSPT are available upon request

1.50

114.3

0.512

All dimensions in mm - Weights are based on metric versions

ISO Thread Dia

Serrated or "shake proof" washers act as an anti-vibration device to prevent the

cable gland, or other cable entry device and locknut arrangement from loosening.

It can also be used as an earth enhancing device on painted enclosures. They are only

available in Stainless Steel.

Order Code

Stainless Steel

ISO Thread Minimum

Dia

Thickness

M16 x 1.5

4.0

M20 x 1.5

4.0

M25 x 1.5

4.0

M32 x 1.5

4.0

M40 x 1.5

4.5

M50 x 1.5

5.0

M63 x 1.5

6.5

M75 x 1.5

7.0

M80 x 2

9.0

M85 x 2

9.0

M90 x 2

9.0

M100 x 2

9.0

Example

ACSSW/M20

M16

M20

M25

M32

M40

M50

M63

M75

M80

M85

M90

M100

Minimum

Outside

Minimum

Outside

Weight

NPT Thread Dia

Thickness

Diameter

Thickness

Diameter

(Kgs/100)

1.5

25.5

0.262

1/2"

1.5

35.4

1.5

32.4

0.560

3/4"

1.5

43.4

1.5

37.4

0.675

1"

1.5

52.0

1.5

48.0

1.042

1-1/4"

1.5

59.5

1.5

60.0

1.730

1-1/2"

1.5

71.0

1.5

71.0

2.154

2"

1.5

87.0

1.5

87.0

3.259

2-1/2"

1.5

102.0

1.5

102.0

4.189

3"

1.5

125.0

1.5

120.0

6.880

3-1/2"

1.5

140.0

4"

1.5

155.0

1.5

120.0

6.550

1.5

125.0

6.233

Sizes M110 to M130 are available upon request

1.5

140.0

7.985

All dimensions in mm - Weights are based on metric versions

SHROUDS

Peppers manufacture a range of shrouds in various materials to complement our

complete range of glands. Materials available are Polyvinylchloride (PVC),

Polychloroprene (PCP) & Low Smoke Halogen Free Silicone (LS0H). Please note that

the shrouds are manufactured to fit our glands and will not necessarily fit other

manufacturer's products.

The shroud sizes are detailed on each of the product pages.

Order Code

Example

Temperature

PVC

PCP

LS0H

ACSPVC/L24

ACSPCP/L24

ACSSIO/L24

-25oC to +70oC

-30oC to +100oC

-60oC to +200oC

Please note that glands with larger than standard entry threads will require a larger shroud in order to fit over the gland hexagon body section

Page 1.1.0

11

www.cableglands.com

2012 Accessories Catalogue Issue 1

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

Technical Information

Ingress Protection

Temperature Classification

It is essential when selecting cable glands and / or accessories to ensure that the products

will maintain the IP rating of the equipment and the integrity of the installation. All

Peppers products have been tested in accordance with the requirements of IEC 60529 and

as such the pressure applied during the IPX8 testing is a static pressure.

The equipment must be selected so that its maximum surface temperature will not reach

the ignition temperature of any gas or vapour that may be present.

Please note that clearance holes must be drilled in accordance with EN 50262 table 1 and

any gland without an integral O-ring must have a suitable IP washer fitted in order to

maintain greater than IP54. If in doubt about the installation please contact Peppers for

installation guidance.

INGRESS PROTECTION (IP)

CODE IEC 60529

First Numeral

Protection against solid objects

0 - No special protection

1 - Objects > 50mm diameter (e.g.

part of a hand)

2 - Objects > 12.5mm diameter

(e.g. finger)

3 - Objects > 2.5mm diameter

(e.g. tool)

4 - Objects >1.0mm diameter

(e.g. wire)

5 - Dust protected

6 - Dust tight

Second Numeral

Protection against water

0 - No special protection

1 - Vertically dripping water

2 - Vertically dripping water when

enclosure tilted by 15

3 - Sprayed water up to 60 from

the vertical

4 - Sprayed water from all directions

5 - Water jets

6 - Powerful water jets

7 - Temporary submersion to a

depth of 1m

8 - Extended submersion to a

depth >1m

NEMA TESTING

APPROXIMATE

EQUIVALENT TO IPXX

NEMA TYPE

Generally, T-class is based on fault conditions or, at the very least, worst case normal

operating conditions. When selecting equipment, the T-class must be below the autoignition temperature of the gas.

As glands do not generate heat they are classified as passive and not subject to a T rating.

TEMPERATURE CLASS (GROUP II)

IP

Maximum Surface Temperature

T Class

450C

T1

IP54

300C

T2

NEMA 3R

IP14

200C

T3

NEMA 3S

NEMA 4 and 4X

IP54

IP55

135C

T4

NEMA 5

IP52

100C

T5

NEMA 6 and 6P

IP67

85C

T6

NEMA 12 and 12K

IP52

NEMA 13

IP54

NEMA 1

IP10

NEMA 2

IP11

NEMA 3

This table cannot be used to convert IP codes to NEMA ratings

is a barrier gland required?

N.B. For Group I applications, apparatus has rigid 150C

(coal dust) and 450C (methane) limits rather than T classes.

INTEGRAL EARTH GLANDS

Selection chart for cable entry devices into

flameproof enclosures for cables complying

with item b) of Section 10.4.2.b.

On condition the cable gland is not certified

as part of the equipment but tested and

certified as a separate component and the

used cable is substantially compact and

circular the selection chart above taken from

section 10 of EN/IEC60079-1 can be used.

Cable Glands with an integral earth connection are recommended for use with high

voltage systems. The earth connection on these glands has been successfully tested in

accordance with the 43kA short-circuit test specified in BS 6121, Part 5, 1992.

Ex Standards do not cover the requirements of cable glands for HV cable. BS6121 Part

5 Section 4.6.2 for non integral earth connections suggests that if the short circuit for 1

second is more than 10.4 kA we then revert to section 4.6.3 Integral Earth Connection

where the short circuit rating for 1 second is between 26 & 43kA.

EMC

It has become a common problem that glands featuring an elastomeric Ex d seal are

used where a barrier gland is required. This is easy to understand, if you consider the

specification of a typical gland featuring an elastomeric Ex d seal it will confirm that the

gland is suitable for use in ATEX categories 2G (Zones 1 & 2), gas group IIC and as passive

components they have no temperature classification limitations. However when the

installation code: IEC 60079-14 Electrical Apparatus for Explosive Gas Atmospheres Part

14 Electrical Installations in Hazardous Areas (other than mines) 3rd Edition 2002-10, is

considered it is clear that a more detailed examination of the application should be made.

Our CR range of barrier glands have unique features that include, CROCLOCK, the

non reversible multi clamping system for armoured cables, Peppers T-1000, the sealing

compound that enables a quick and easy installation and an innovative barrier chamber

that provides a cable acceptance that is on average 17% greater than other designs.

2012 Accessories Catalogue Issue 1

Terminations suitable for EMC protection can be made using armoured cables with

our armour clamping glands. Following tests, Peppers has been informed by ERA

Technology Ltd that our glands do not significantly reduce the ability of an enclosure to

which they are attached to withstand electromagnetic interference . We conclude that

the effectiveness of a cable entry in EMC terms will generally be limited by the cable,

including the cable armour or screen. Braid screens are not necessarily the most effective

means of EMC protection. Tape armours can give the best results. Since a Peppers cable

gland makes a 360 clamp on cable armour, it will not inhibit the EMC protection of the

cable entry.

The cable gland standard BS EN 50262 states that cable glands are EMC neutral. This is

taken to mean that cable glands are neither affected by electro-magnetic radiation nor

will cause any electro-magnetic interference in other equipment.

www.cableglands.com

Page

Page

1.1.0

12

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT United Kingdom

Telephone: +44 (0) 1276 64232 Facsimile: +44 (0) 1276 691752

Email: sales@peppers.co.uk Website: www.cableglands.com

www.cableglands.com

ATEX IECEx GOST-R CSA(cus) UL INMETRO NEPSI ABS RMRS LLOYDS ISO9001: 2008 - ISO14001:2004

Your local agent or distributor

Peppers Cable Glands Limited

Stanhope Road, Camberley, Surrey, GU15 3BT, United Kingdom

Tel: +44 (0) 1276 64232 Fax: +44 (0) 1276 691752 Email: sales@peppers.co.uk

Page 1.1.0

www.cableglands.com

2012 Accessories Catalogue Issue 1

2012 Accessories Catalogue Issue 1

You might also like

- As Me Certificate Holder ReportDocument5 pagesAs Me Certificate Holder ReportpandiangvNo ratings yet

- Crosby Eye Bolt G 291Document1 pageCrosby Eye Bolt G 291pandiangvNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument6 pages06 Eurocodes Steel Workshop WALDpandiangvNo ratings yet

- Washer ThicknessDocument2 pagesWasher ThicknesspandiangvNo ratings yet

- Nut DetailsDocument1 pageNut DetailspandiangvNo ratings yet

- Ship Motion LoadDocument4 pagesShip Motion LoadpandiangvNo ratings yet

- CharttorqueswgDocument2 pagesCharttorqueswgYutana RuxnakNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Force and Moment Sketches ModelDocument1 pageForce and Moment Sketches ModelpandiangvNo ratings yet

- Xylan Offshore FlierDocument2 pagesXylan Offshore FlierpandiangvNo ratings yet

- Wind Load Calculation ReportDocument2 pagesWind Load Calculation ReportpandiangvNo ratings yet

- UBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffDocument4 pagesUBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffpandiangvNo ratings yet

- 999 Industrial Guide 2010Document42 pages999 Industrial Guide 2010kasosei100% (1)

- Peppers Catalogue Approved AccessoriesDocument16 pagesPeppers Catalogue Approved AccessoriespandiangvNo ratings yet

- Studding Outlets Dimensions & SpecificationsDocument2 pagesStudding Outlets Dimensions & SpecificationspandiangvNo ratings yet

- A Lok Tube FittingsDocument88 pagesA Lok Tube FittingsCesarNo ratings yet

- S2 - Jaw and Jaw-136Document1 pageS2 - Jaw and Jaw-136pandiangvNo ratings yet

- Design Base Plate ThicknessDocument6 pagesDesign Base Plate ThicknesspandiangvNo ratings yet

- Buoyancy: M. Bahrami Fluid Mechanics (S 09) Fluid Statics 9Document5 pagesBuoyancy: M. Bahrami Fluid Mechanics (S 09) Fluid Statics 9RonoNo ratings yet

- Guidance Notes RevisionDocument8 pagesGuidance Notes RevisionpandiangvNo ratings yet

- Design and Development PlanningDocument6 pagesDesign and Development PlanningpandiangvNo ratings yet