Professional Documents

Culture Documents

Us4587423 PDF

Uploaded by

Ramanamurthy PalliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us4587423 PDF

Uploaded by

Ramanamurthy PalliCopyright:

Available Formats

United States Patent [191

[11]

[45]

Boyce

[54] METHOD FOR GRAVEL PACK

EVALUATION

[75] Inventor: James R. Boyce, Ridge?eld, Conn.

[73] Assignee: Schlumberger Technology

Patent Number;

Date of Patent:

4,587,423

May 6, 1986

publ. Journal of Petroleum Technology, Sep. 1983, pp.

1611-1616.

A Quantitative Approach to Gravel Pack Evalua

tion, Neal and Carroll, 6th SPE Formation Damage

Symposium, Feb. 13-14, 1984.

Corporation, New York, NY.

Primary Examiner-Carolyn E. Fields

Attorney, Agent, or Firm-Brumbaugh, Graves,

Donohue & Raymond

[21] Appl. No.: 636,307

[22] Filed:

Jul. 31, 1984

[51]

Int. Cl.4 ............................................. .. G01V 5/12

[52]

[58]

U.S, Cl. ............................ .. 250/269; 250/262

Field of Search ..................... .. 250/269, 262, 256;

364/422

[56]

References Cited

... ...

. . . . . . . . . ..

ABSTRACT

sion for the determination of percent packing as a func

tion of known or measurable borehole quantities is de

US. PATENT DOCUMENTS

4,340,934

[57]

Based on Monte Carlo modeling of gravel pack condi

tions in a completed borehole, a straightforward expres

7/1982

Scgesman

364/422

4,436,996

3/1984

Arnold et a1. .

4,442,701

4/1984

Cowherd et a1. ................. .. 250/269

..... .. 250/256

OTHER PUBLICATIONS

Gravel Pack Evaluation, Marvin R. Neal, presented

57th Annual Fall Technical Conf., SPE, Sep. 1982,

rived, from which an accurate quantitative gravel pack

log may be obtained for purposes of evaluating gravel

pack quality. The method includes using a logging tool

with a gamma source and gamma detector.

4 Claims, 5 Drawing Figures

OIL - BEARING

SAND FORMATION

U.S. Patent May6,1986

Sheetl0f4

4,587,423

S5

UEC\RLK[M\ETatg8

\

s

TM

ACEA.R

1%

w

PHm

D UPIE.U}

A!5_

T

8

.

mP

m

m

N

w

\.S 6T|lk

Wu;

S142

20

OIL- BEARING

SAND FORMATION

23

FIG. /

US. Patent May6, 1986

Sheet2of4

4,587,423

Formation

(22a)

Cement

(20a)

F/6.2

US. Patent May6,19v86

Sheet40f4

4,587,423

4,587,423

deriving a measurement (NT,5') of the number of

gamma rays detected by said detector over a predeter

mined time interval; and

METHOD FOR GRAVEL PACK EVALUATION

determining the percent packing (P) of the gravel

DESCRIPTION

pack at the depth of measurement in accordance with

1. Technical Field

the relationship:

The present invention relates to gravel pack logging

and, more particularly, to an improved method for

providing a reliable quantitative evaluation of gravel

pack quality.

10

2. Background Art

Many oil wells are completed with internal gravel

pack assemblies to prevent sand in?ltration into the

production tubing. A reliable method of evaluating the

quality of the gravel pack in situ, at the time of its con

struction, is needed in order to improve the effective

(T1,?) X14 )]

N75 is the measured count rate for the condition of

blank tubing (denoted by subscript T) or gravel pack

screen (denoted by the subscript S), whichever is pres

ent at the depth of measurement, and a, pf, B15 and

A735 are known parameters or constants of the bore

ness of the gravel pack and to reduce the chances that a

hole conditions as described hereinafter.

workover will be required later.

Prior investigations of this problem have indicated

By a straightforward solution of the foregoing rela

the applicability of wireline logging techniques to the 20 tionship, an accurate quantitative determination of per

cent packing in completed wells can readily be ob

tained. Because of the simplicity of the calculation, the

percent packing determination may be made on-line at

the 57th Annual Fall Technical Conference and Exhibi

the well site to provide immediate information on

tion of the Society of Petroleum Engineers of AIME,

New Orleans, LA, September, 1982, published Journal 25 gravel pack quality to the operator, or, if desired, it may

evaluation of qravel packs. In a paper entitled Gravel

Pack Evaluation, ?rst presented (Paper SPE 11232) at

be carried out later at a central processing site based on

the recorded tool response. In either case, a reliable

of Petroleum Technology, September, 1983, pp.

1611-1616, M. R. Neal described the responses of three

well logging tools, the compensated neutron tool (neu

gravel pack log can be obtained with the resulting ad

and two detectors), to various gravel pack situations

and showed that each tool responded well to changes in

density of the material in the annulus between the

well logging tool and associated surface processing

vantages of avoiding sand production and subsequent

tron source and two detectors), the nuclear ?uid density

meter tool (gamma ray source and one detector), and 0 gravel pack workovers.

the dual-spacing gamma ray tool (gamma ray source

BRIEF DESCRIPTION OF THE DRAWINGS

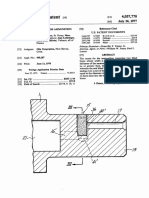

FIG. 1 is a schematic view of one embodiment of a

components for implementing the improved gravel

screen (of the gravel pack hardware) and the casing. 35 pack evaluation technique of the present invention;

Although Neals work provided useful qualitative infor

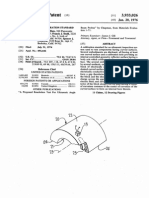

FIG. 2 is a horizontal cross section of an MCNP

mation concerning gravel pack quality, it did not pro

model of FIG. 1;

vide a procedure by which a quantitative evaluation

could be made.

Further research by M. R. Neal and J. F. Carroll, as

reported in a paper entitled A Quantitative Approach

to Gravel Pack Evaluation, 6th SPE of AIME Forma=

FIG. 3 graphically illustrates the results of MCNP

calculations compared with experimental values for a

7-inch casing and a 2i-inchtubing;

FIG. 4 graphically illustrates the results of MCNP

calculations compared with experimental values

tion Damage Symposium, Bakers?eld, CA, Feb. 13-14,

1984, demonstrated that tool response (count rate)

could be directly related to the percent void space in the

for a 7-inch casing and a 2%-inch screen; and

45

gravel pack, and led to the development of interpretive

procedures for determining percent packing when ?eld

FIG. 5 illustrates the application of the percent pack

ing determination (P) of the invention to an actual log,

showing percent packing plotted on the left grid and the

gamma ray count rate (i.e., N51) of the tool plotted on

hardware is the same as that used for laboratory calibra

the right grid, both as a function of depth, with a sche

tion measurements and for making a quick-look quanti

tative approximation when the well hardware differs

from laboratory hardware. A computer-assisted tech

matic representation of the tubing, screen and gravel

pack interposed between the two grids of the log for

illustrative purposes.

MODE FOR CARRYING OUT THE INVENTION

An illustrative embodiment of a gravel pack logging

tool useful in practicing the present invention is shown

nique for visualizing the quality of the gravel pack at

the well site was also developed and described.

It is desirabie, however, both to simplify quantitative

gravel pack evaluation techniques and to extend the

applicability thereof to borehole and gravel pack condi

tions other than those speci?cally measured in the labo

ratory.

DISCLOSURE OF THE INVENTION

There is provided, according to the present inven

tion, a method for investigating a gravel pack located in

the annulus between the tubing/screen and the casing of

65

a borehole, comprising the steps of:

moving a logging tool, including a gamma ray source

and at least one gamma ray detector, through the tu

bing/screen over the depth region of the gravel pack;

in FIG. 1. The tool includes a temperature-and-pressure

resistant sonde 10 that is adapted to be suspended in and

moved through a production tubing string 12 located

within a borehole 14. The tubing includes a gravel pack

screen, which is indicated schematically at 16 and

which may be conventional. Holes 17 are formed in the

tubing 12 inside of the screen to admit oil to the tubing.

The borehole is shown as completed, i.e., a casing 18

has been cemented 20 to the surrounding formations 22

and a gravel pack 24 has been constructed over the

region of the screen 16. The casing 18 and cement annu

lus 20 have been perforated, as at 23, opposite the screen

4,587,423

The tool 10, which may, for example, comprise the

(simulating) histories of the individual paths for a large

number of particles (photons in the present model). The

problem is speci?ed for the code by subdividing the

geometry into small cells and characterizing the mate

rial in each cell. The history of each energetic photon as

aforementioned ?uid density meter tool, includes an

omnidirectional gamma ray source 30 and at least one

mined by using the known interaction cross sections of

16 to permit oil ?ow from the formations 22 to the

tubing 12. Both the tubing 12 and the annulus between

the tubing 12 and the casing 18 are shown as ?uid-?lled,

as at 26 and 28, respectively.

gamma ray detector 32 spaced therefrom and shielded,

as at 34, against direct irradiation along the tool axis.

The source 30 may comprise any suitable gamma ray

emitter, such as cesium 137, and the detector 32 may

also be conventional, such as a NaI scintillation detec

tor. Gamma rays from the source 30 interact with the

materials in the borehole environment and are in part

scattered back to the detector 32. The resulting detector

signals are applied to downhole electronic circuits 34

for ampli?cation, coding or the like for transmission to

the earths surface over an armored cable 36.

it leaves the source and traverses a given cell is deter

the material in that cell. By tracking large numbers of

photons in this manner, MCNP generates the radiation

?ux anywhere in the geometry under study. In the

gravel pack problem, the primary interest is the ?ux in

the detector cells.

FIG. 2 shows a horizontal cross section of the gravel

pack model developed for the MCNP model. The ge

ometry is symmetrical about the borehole axis which is

in the center of the ?gure. Each section of the ?gure

represents a three-dimensional cylindrical cell, having

?nite vertical and horizontal dimensions. Thus, al

though not shown, it will be understood that the verti

At the surface, the detector signals are received by

electronic circuits 38, where they are decoded or other 20 cal cross section of the model is also divided into a

plurality of sections to de?ne the upper and lower

wise converted and restored as required for further

processing. Thereafter they are applied to the data pro

cessin g system 40, which may comprise a digital appara

bounds of each cell. Proceeding radially from the bore

tus such as a PDP 11/34 manufactured by the Digital

cells for the pressure housing and, at the appropriate

Equipment Corp. and specially modi?ed, as by stored

elevations in the model, for the source 30, the detector

32 and other internal components of the tool), the cells

instructions, to carry out the present invention. As de

hole axis in FIG. 2 are the tool cells 101: (which include

260 for the volume (shown ?uid?lled in FIG. 1) be=

tween the tool 10 and the tubing 12, the cells 12a for the

blank tubing 12, the cells 160 for the screen 16, the cells

output N735 which are applied to a plotter/recorder 42

for recording as a function of depth in the bore hole. 30 24a for the gravel pack region 24, the cells 18a for the

casing, the cells 201: for the cement bonding, and the

The usual winch and depth-recording linkage, indicated

cells 22a for the formation. The distribution of the mate

schematically at 44, is provided for this purpose.

rial within each cell is assumed to be uniform both radi

If desired, the derivation of percent packing may be

ally and circumferentially.

carried out remotely, as would be the case, for instance,

scribed hereinafter, the data processing system 40 gen

erates a percent packing output P and a tool count rate

when a computer is not available at the well site. In that 35

After de?ning the appropriate geometry of the cells,

case, the detector signals from the circuits 38 could be

applied directly to the recorder 42, as indicated by the

line 45, and recorded on magnetic tape for subsequent

the characteristics of the material in each cell are speci

?ed in terms of elemental content and density. For

example, the tubing 12 is assumed to be iron whose

transmission to the remote site.

density is determined from its weight per foot and its

The number of gamma rays returning to the detector 40 dimensions. In the case of the gravel pack region, two

32 is an indication of the density of the material through

conditions are considered, 0% packing, i.e., no gravel

pack, in which case only the ?uid 28 and its density are

which they traveled. High density materials cause more

used, and 100% packing, in which case the assumption

gamma rays to be slowed down and absorbed, while

is made that the cell volume is sandstone having a po

lower density materials allow more gamma rays to be

rosity of 40 p.u. (porosity units). 0% packing corre

returned to the detector. In a gravel packed well every=

sponds to 100 p.u.

thing remains constant except the annular space be

In one form of commercially available gravel pack

tween the casing and the screen or tubing. This space

screen, which is illustrated schematically in FIG. 1, the

can be totally ?lled with gravel, partially ?lled with

screen 16 is wrapped around the outside of the tubing 12

gravel, or have void spaces containing no gravel. In

and the tubing inside the screen is formed with holes 17.

each of these cases, the volume that is not ?lled with

The tubing size inside of the screen 16 is typically the

gravel is ?lled with some type of ?uid of a known den

sity. Since the density of the gravel is different from the

density of the ?uid, it is possible quantitatively to corre

same as the blank tubing with no screen. The blank.

tubing, however, has no holes.

In the model, the screen 16 (including the interior

late gamma ray count rates to percent pack.

In accordance with the present invention, an im 55 perforated tubing) is assumed to be made of uniformly

distributed iron having a density determined by its

proved technique for the quantitative evaluation of

weight per foot and its dimensions. Using this informa

gravel packs has been developed. The technique has

tion and assuming an iron density, e.g., 7.87 g/cc, the

been veri?ed by the application of mathematical model

volume fraction for the iron is calculated. The remain

ing of a logging tool of the con?guration illustrated in

ing volume of the cell 16a (FIG. 2) is assumed to be

FIG. 1 and by experimentation. The modeling approach

?lled with the borehole ?uid 26. The borehole fluid

uses MCNP, a generalized random sampling technique

typically might be fresh water, salt water or oil.

for simulating the transport of neutrons and photons in

The elemental contents and densities of the remaining

a three-dimensional geometry, as described in MCNP

cells are similarly determined based on the identity and

A General Monte Carlo Code for Neutron and Pho

ton Transport, Los Alamos National Laboratory, Los 65 quantity of the materials known or assumed to be pres

ent in the respective cells. Once the geometry and mate

Alamos, NM. 87545.

The MCNP code calculates an estimate of radiation

?ux anywhere in a speci?ed problem by generating

rial of each cell are de?ned, an importance value is

determined for each cell. As will be understood, such

4,587,423

importance values are used in the MCNP variance re

sandstone at 40 p.u. porosity. The diamond indicates a

duction techniques to reduce the computational time

and the uncertainty of the calculations.

Using the foregoing approach, the response of the

gravel pack logging tool of FIG. 1 was modeled. The

modeling result and the circle directly below it indi

cates an experimental data point. The dashed line 48 is

a ?t to the modeling results for 0% packing and 100%

photon ?ux across the detector cell was integrated over

Here, again, the same form of equation ?ts the results:

packing in this con?guration.

all energies of interest, and the resulting ?ux calculation

N'T=A1 exp(B'r><p')

was normalized to calibration counts previously deter

mined from experimental data taken with an actual

logging tool. In this manner, the resulting modeled

counts can be directly compared with the count rate

from the logging tool.

For purposes of the model of the gravel pack tool, the

(3)

where the prime indicates gravel packing. The slope

B'T of the line 48 represents the sensitivity of the tool to

density changes in the gravel pack region, i.e., the re

gion in FIG. 1 between the blank tubing 12 and the

casing 18. The values of AT, A'T, Br and BT are depen

dent on the downhole con?guration, i.e., the size and

calibration con?guration was for a 7-inch diameter

casing with a Zi-inch diameter blank tubing, with fresh

water as the borehole ?uid and no gravel pack (0%

packing). The counts for this con?guration were com

pared to the corresponding Monte Carlo calculations to

type of tubing and easing.

As may be seen from FIG. 3, the slope B'T (gravel

packing) is less than the slope BT(no gravel packing).

determine a normalization factor:

This results because the volume in which the density is

(1)

changing in the former case, i.e., the gravel packing

region between the tubing 12 and the casing 18, is less

which was then applied to the calculations for other

than the volume in which the ?uid density is changing

in the latter case, i.e., the region between the tool 10 and

20

f,,=counts/?ux

con?gurations.

the casing 18. Consequently, the density sensitivity BT

Comparisons between model and measured results 25 for the gravel packing region is less than that BTfor the

from a simulated laboratory well were made in order to

non-packed condition.

verify the mathematical model. The laboratory mea

It is also to be noted that the sensitivity B'r of the tool

surements were made for a variety of casing, tubing,

to density changes in the gravel pack region is not a

screen and ?uid types, sizes and densities, all in a labora

function of density. Thus for any given ?uid the counts

tory simulation of the downhole environment. The

N may be described as a function of the degree of

experimental data thus acquired were reported by Neal

gravel packing by drawing a line parallel to the dashed

and Carroll in the aforementioned paper A Quantita

line

48 in FIG. 3 and intersecting the 0% packing-?uid

tive Approach to Gravel Pack Evaluation presented at

line 46 at the ?uid density.

the 6th SPE of AIME Formation Damage Symposium.

FIGS. 3 and 4 illustrate exemplary comparisons of the 35 FIG. 4 shows data for a con?guration similar to that

of FIG. 3 except that a Z?-inch screen was used instead

model results with the experimental (Lab.) data.

of blank tubing. The same symbols are used in FIG. 4 as

in FIG. 3 to denote the experimental (Lab.) data and the

The results of the Monte Carlo calculations for the

case of a 7-inch casing with a 25-inch blank tubing are

shown in FIG. 3. The counts N are plotted vs. the den

Monte Carlo calculations for the 0% and 100% packed

conditions. Again, the solid line ?t 50 to the Monte

Carlo calculations for 0% packing is best described by:

sity pfof the borehole ?uid. The squares are experimen

tal data points and the triangles are the Monte Carlo

modeling results, for the con?guration of 0% packing.

(The bars (I) indicate the range of statistical uncertainty

for the individual points, and is approximately :4% for

Ns=AseXp(Bs><P?

where the subscript S denotes screen. And, similarly to

the calculated points. Not shown in FIG. 3 is an uncer

Eq. (3), the calculations for the 100% gravel pack con

dition, represented by the dashed line 52, are described

tainty in the experimental densities of approximately

i006 g/cc.)

by:

The solid straight line 46 in FIG. 3 represents a least

squares ?t to the modeling results, and is described by}

the following equation:

N1=A1eXp(BTXP/)

(4)

N'5=A's exp(B's><p')

(5)

50

where the prime denotes gravel packing and the sub

(2)

script S denotes screen.

The constants As and A's represent the y-axis inter

cepts of the lines 50 and 52, respectively, and the con

where

NTis the modeled number of counts;

ATis a constant given by the y-axis intercept;

BTis a constant given by the slope of the line 46; and

PflS the ?uid density.

The subscript T denotes blank tubing.

55

stants BS and B's represent the respective slopes of those

lines. These constants are dependent on the downhole

con?guration in like manner to the constants A T, etc., as

discussed above. p is the electron density of the packed

As is apparent from FIG. 3, the agreement between

the experimental data points and the calculated data 60

region.

points is quite good. The slope BT of the line 46 repre

can be expressed as:

The manner in which p is determined is as follows: It

sents the sensitivity of the tool to changes in ?uid den

sity for the particular con?guration of casing and blank

tubing modeled.

pl=vjpf+vmpm

(6)

Also shown in FIG. 3 are points for the con?guration 65 where vfand vm are the volume fractions of ?uid and

of 7-inch casing and 2%-inch blank tubing with 100%

gravel packing and oil (diesel fuel) as the borehole ?uid.

As previously mentioned, 100% packing is taken as

matrix material (gravel on sand), respectively, and

pf and Pm are the respective densities of those materials.

This equation can be written as:

4,587,423

centered within the casing, and the amount of gravel

pack is shown by the dotted regions 54 between the

tubing or screen and the casing.

In visualizing the gravel pack in FIG. 5 as a function

where

of percent packing P, it is assumed that the gravel pack

_W

100

(8)

a _

P is the percent packing expressed in percent and V] is

the volume fraction of the ?uid for 100% pack; e.g.,

v_'f=O.4 if 100% pack is assumed to be equivalent to 40

starts at the casing wall and extends inwardly from

there. Thus where there is less than 100% packing, the

voids are shown as being adjacent the tubing 12 or the

screen 16. This is done for illustrative purposes, how

ever, and may not be the case in actual fact. That is to

say, the voids may be distributed other than adjacent

p.u.

the tubing string. Also, the gravel pack is shown in

In order to solve for percent packing P in terms of

FIG. 5 as being uniformly distributed circumferentially

known quantities, it is necessary ?rst to derive expres

sions for the two constants AT and A's (hereinafter 5 of the casing, again for illustrative purposes, which

likewise may not be the case in actual practice. Eq. (12)

referred to collectively as A'T, s), where subscript T

affords an accurate determination of percent packing at

designates the value of the constant A for blank tubing

and subscript S designates the value of the constant A

for screen.

At the intersection of the percent packing line and the

0% packing line, the following equations hold:

any given depth, but does not indicate the uniformity of

distribution of the gravel pack, either radially or cir=

cumferentially, within the casing. It is, however, rea

sonable to expect that the distribution of the gravel pack

will be generally as depicted in FIG. 5 for any given

percent packing.

The log of FIG. 5 shows the quality of the gravel

N5=N's

25 pack to be better over the upper region 56 of the screen

16 than over the lower region 58, with a very good pack

in the region 60 immediately above the top of the

or, in collective notation:

NT. s =Nr. s

(9)

screen. Such a log would indicate the need to repair or

rework the gravel pack over at least the lower region

58.

and

PFP'

(1)

Solving for AS,T in terms of the other quantities, yields

the expression:

In producing a log such as that shown in FIG. 5 by

use of the tool of FIG. 1, the computer in the data pro

cessing system 40 is of course pre-programmed to solve

Eq. (12) based on the measured and known inputs for

35 the various terms of that equation. As the values of Vf,

pfand pm are known from samples of the ?uid and the

matrix material in the gravel pack region, these values

may be stored in the computer for the calculation of a

The derivation of percent packing P in terms of

known quantities can then be carried out by substituting

Eqs. (7), (8) and (l 1) into Eqs. (3) and (5) and solving for

P. This gives the expression:

N'Tys

A'TYS

from Eq. (8) and for the input of PflIllIO the solution of

Eq. (12). The values of 3'1 5 will likewise be known

from the slope of the model curves 50 and 52, and the

values of AT, s can be calculated from Eq. (ll), inas

much as all of the terms of that equation are known and

(12) 45 can be stored beforehand in the computer. It is to be

noted that the constants B'T, s and A'T, s will each have

two values, one for blank tubing and one gravel pack=

The foregoing illustrative comparisons of FIGS. 3

and 4 show excellent agreement between the model

results and the experimental data, giving a high level of

con?dence to the model and to the accuracy of Eq. (12)

as a quantitative measure of the degree of gravel pack

ing. It therefore provides a technique by which tool

responses can be obtained for a variety of borehole and

ing. The value to be used in solving Eq. ( 12) will depend

upon whether the sonde 10 is located opposite the blank

tubing 12 or the screen 16. As the depth of the screen is

known, the computer can be programmed automati

cally to select the correct values of the constants as a

function of depth as the sonde moves through the bore

hole.

The programs required to solve Eq. (12) and to calcu=

late the necessary inputs thereto, e.g. and A'T, s, are

quite straightforward and therefore need not be de

scribed in detail here. They are well within the skill of

gravel-pack conditions not measured in the laboratory,

and thus permits gravel packing percentage to be accu

rately predicted as a function of tool response (count

the average programmer in this art.

rate) and other known borehole parameters.

The tool count rate NT, 5 is generated, either down

FIG. 5 shows the results of applying Eq. (12) to an 60

hole

or at the surface, by accumulating the detector

actual log. The tool response NT, 5 is plotted on the

pulses over a predetermined time interval, which typi

right hand graph and percent packing P (from Eq. (12))

cally would correspond to a desired depth interval of

is plotted on the left hand graph, both as a function of

measurement. The count rate value N'T, s is then input

depth. The region between the graphs is a schematic

visualization of the packing in the borehole. In this 65 into Eq. (12) and the equation is solved for P. The value

of P thus obtained for the measurement depth in ques

region, the casing is the left side and the right side,

tion is applied to the plotter/recorder 42 to produce the

respectively, of the counts graph and the percent pack

graph. The tubing 12 and the screen 16 are shown as

visual log. Preferably, the tool count rate NT, 5 is also

4,587,423

10

depth of measurement is opposite the tubing or

plotted alongside the percent packing log for compara

the screen.

tive purposes.

2. The method of claim 1 further comprising the step

Although the invention has been described herein

of recording the percent packing determination as a

with reference to a specific embodiment thereof, it will

be understood that such embodiment is susceptible of 5 function of depth within the borehole.

3. A method for investigating a gravel pack located in

variation and modi?cation without departing from the

the annulus between the tubing/screen and the casing of

inventive concepts disclosed. All such variations and

a borehole, comprising the steps of:

modi?cations, therefore, are intended to be included

deriving a measurement (NT, 5) of the number of

within the spirit and scope of the appended claims.

gamma rays detected in a predetermined time inter

1O

I claim:

val by a gamma ray detector located within the

1. A method for investigating a gravel pack located in

tubing/screen as a result of irradiation of the bore

the annulus between the tubing/screen and the casing of

hole by a gamma ray source located within the

a borehole, comprising the steps of:

tubing/screen; and

moving a logging tool, including a gamma ray source

determining the percent packing (P) of the gravel

and at least one gamma ray detector, through the 15

pack at the depth of measurement in accordance

tubing/screen over the depth region of the gravel

with the relationship:

pack;

deriving a measurement (N'r. s) of the number of

gamma rays detected by said detector over a prede=

termined time interval; and

determining the percent packing (P) of the gravel

pack at the depth of measurement in accordance

with the relationship:

where

25

where

30

pfand pm are the density of the ?uid and the mate

rial, respectively, in the annulus between the

tubing/screen and the casing of the borehole;

v; is the volume fraction of the ?uid in the annulus

between the tubing/screen and the casing of the

borehole;

A'T, s is a previously determined constant Ar or

pfand pm are the density of the ?uid and the mate

rial, respectively, in the annulus between the

tubing/screen and the casing of the borehole;

v) is the volume fraction of the ?uid in the annulus

between the tubing/screen and the casing of the

'5 depending upon whether the depth of mea

surement is opposite the tubing or the screen;

B'1,S is a previously determined constant B'T or B's

depending upon whether the depth of measure

ment is opposite the tubing or the screen; and

N'T, s is said measured number of detected gamma

rays N'T or N's depending upon whether the

depth of measurement is opposite the tubing or

borehole;

A'T, s is a previously determined constant A'T or

A's depending upon whether the depth of mea

surement is opposite the tubing or the screen;

the screen.

BE, 5 is a previously determined constant B'T or B's

depending upon whether the depth of measure 45 4. The method of claim 3 further comprising the step

of recording the percent packing determination as a

ment is opposite the tubing or the screen; and

function of the depth within the borehole.

N'T, s is said measured number of detected gamma

*

*

*

*

*

rays NT or N's depending upon whether the

50

60

65

UNITED STATES PATENT AND TRADEMARK OFFICE

CERTIFICATE OF CORRECTION

PATENT ND. :

4,587,423

DATED

May 6, 1986

INVENTUFHS) :

Page 1 Of 2

James R. Boyce

It is certified that error appears in the above-identified patent and that said Letters Patent is hereby

corrected asshown below:

Col.1 , line 21, "qravel" should read -gravel;

Col.2z line 1, "(NT 8')" should read -N' T,S )--;

I

Col.2, line 13, "NT,S'" should read -N'T,S--;

Col.2, line 16, "BT'S'" should read --B'T,S--;

Col.2, line 17, "ATIS'" should read -A'T'S ;

Col.2, line 41, "inchtubing" should read -inch tubing--;

.

NS'T

I ll

should read -N ST--,

NT,S

| n

should read --N T,S-m,

Col.2z llne 48,

Col.3z llne 29,

'

Col.6, line 49, "N's=A'lsexp(-B'sx p) " should read

S

Col.6Z line 53, "As and A's" should read --AS and A'S--;

Col.6, line 55, "BS and B's" should read BS and B'sCol.7Z line 1 ,

" p

pf+ [3 x P" should read -- p

pf + a x P--;

UNITED STATES PATENT AND TRADEMARK OFFICE

- CERTIFICATE OF CORRECTION

PATENT N0. :

DATED

:

4,587,423

May 6, 1986

Page 2 of 2

INVENTUMS) 2

James RI Boyce

It is certified that error appears in the above-identi?ed patent and that said Letters Patent is hereby

corrected as shown below:

Col.7l llne 24,

.

Ns-N 8

||

NTIS-NTIS

Col.7z llne 28,

__

should read

II

__

should read

NS N S

=

___

'

__

'

__

Col.8l line 56, after "e.g." insert oz-.

Signed and Sealed this

Twenty-fifth Day of November, 1986

Arrest:

DONALD J. QUIGG

Arresting O?icer

Comrnisxiolmr of Parents and Trademarks

You might also like

- BS 6717 Part 1 1986 Standards for paving blocksDocument8 pagesBS 6717 Part 1 1986 Standards for paving blocksGita PrestalitaNo ratings yet

- Grit Blasting and Surface FinishDocument29 pagesGrit Blasting and Surface FinishhaiqalNo ratings yet

- March 19, 1968 H. W. Alter 3,373,683: Visual Imaging 0F - Track - Etched Patterns Filed Oct. 20, 1966Document3 pagesMarch 19, 1968 H. W. Alter 3,373,683: Visual Imaging 0F - Track - Etched Patterns Filed Oct. 20, 1966ulfah nur khikmahNo ratings yet

- SMN 09Document34 pagesSMN 09Siwadol DejphumeeNo ratings yet

- Triaxial Compression Test 1978Document5 pagesTriaxial Compression Test 1978Alejandro425No ratings yet

- Dyna,+04 2022.05.12.C.FINALDocument9 pagesDyna,+04 2022.05.12.C.FINALChristian HidalgoNo ratings yet

- Sand Corn TestDocument27 pagesSand Corn TestTinaaTinyNo ratings yet

- Estimation of Petrophysical Properties of Tar Sands Using MicrotomographyDocument12 pagesEstimation of Petrophysical Properties of Tar Sands Using MicrotomographyRosa K Chang HNo ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- Ited States Patent: Inventor: Raymond G. Voss, Bartlesville, OklaDocument5 pagesIted States Patent: Inventor: Raymond G. Voss, Bartlesville, OklazgregzNo ratings yet

- Oil Well CementDocument41 pagesOil Well CementadarshkalladayilNo ratings yet

- DETERMINATION OF THE BEARING CAPACITY OF PILES ON THE BASIS OF CPT SOUNDING TESTS by József PUSZTAIDocument8 pagesDETERMINATION OF THE BEARING CAPACITY OF PILES ON THE BASIS OF CPT SOUNDING TESTS by József PUSZTAIhedyNo ratings yet

- TEPZZ - 489 B - T: European Patent SpecificationDocument23 pagesTEPZZ - 489 B - T: European Patent Specificationzweisteine777No ratings yet

- Segmented Bond LoggingDocument15 pagesSegmented Bond LoggingMohd Nabeel100% (1)

- Us 4037770Document3 pagesUs 4037770ererNo ratings yet

- Process Distillation Tower DiagnosticsDocument8 pagesProcess Distillation Tower Diagnostics徐孝民No ratings yet

- Geophysical Diffraction Tomography: Theory and Field ResultsDocument94 pagesGeophysical Diffraction Tomography: Theory and Field Resultsttstanescu4506No ratings yet

- Erosion of Choke Valves Using CFD and ExperimentDocument8 pagesErosion of Choke Valves Using CFD and ExperimentHeath HoughtonNo ratings yet

- Stress Calculations for Sucker Rod Pumping SystemsDocument32 pagesStress Calculations for Sucker Rod Pumping SystemsPresident PCNo ratings yet

- Determining The Density and Unit Weight of Soil in Place by Nuclear Methods (Shallow Depth)Document16 pagesDetermining The Density and Unit Weight of Soil in Place by Nuclear Methods (Shallow Depth)crycodNo ratings yet

- United States Patent (19) : B JornstadDocument4 pagesUnited States Patent (19) : B JornstadlfilippiniNo ratings yet

- Stress Calculations For Sucker Rod Pumping SystemsDocument32 pagesStress Calculations For Sucker Rod Pumping Systemsboy.r.indrawanNo ratings yet

- United States Patent (191: Ham Et AlDocument7 pagesUnited States Patent (191: Ham Et Alguna1985sNo ratings yet

- Compaction Test Sand Cone MethodDocument27 pagesCompaction Test Sand Cone MethodAlex PandiazNo ratings yet

- Bardiya Soil ReportDocument50 pagesBardiya Soil ReportSubash BastolaNo ratings yet

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- SPT Soil TestingDocument40 pagesSPT Soil TestingHafiz Ur RehmanNo ratings yet

- Canadian Foundation ManualDocument10 pagesCanadian Foundation Manualbenchowdry9615No ratings yet

- A Method For Measuring In-Situ Capillary Pressures at Different Wettabilities Using Live Crude Oil at Reservoir ConditionsDocument12 pagesA Method For Measuring In-Situ Capillary Pressures at Different Wettabilities Using Live Crude Oil at Reservoir Conditionsari_si100% (1)

- Buat Surface AreaDocument11 pagesBuat Surface AreaRebecca FrancisNo ratings yet

- Innovative Data Acquisition For The Fall Cone Test in Teaching and ResearchDocument28 pagesInnovative Data Acquisition For The Fall Cone Test in Teaching and ResearchSumeet Kumar SinhaNo ratings yet

- Penetrómetro PANDADocument4 pagesPenetrómetro PANDAOctavio Castro Camacho0% (1)

- United States Patent: Odell (451 Sept. 26, 1972Document12 pagesUnited States Patent: Odell (451 Sept. 26, 1972Thiago Souza da RosaNo ratings yet

- United States PatentDocument8 pagesUnited States PatentManjul KothariNo ratings yet

- BS 812-Part 113-90Document10 pagesBS 812-Part 113-90anish_am2005No ratings yet

- CPT On Pile DesignDocument9 pagesCPT On Pile DesignBalamurugan KyNo ratings yet

- Smooth Wall Blasting Technique for Rock ExcavationDocument5 pagesSmooth Wall Blasting Technique for Rock ExcavationДүвчинмичид БалбийгомбоNo ratings yet

- CPT FieldDocument22 pagesCPT FieldAisha RianaNo ratings yet

- Use of Pressuremeter Tests For Land Reclamation Projects in Singapore SingaporeDocument54 pagesUse of Pressuremeter Tests For Land Reclamation Projects in Singapore SingaporeSeif EddineNo ratings yet

- KIRK - Falling Head Permeability Test (100%)Document16 pagesKIRK - Falling Head Permeability Test (100%)Kirk Woo ChongNo ratings yet

- Interpretation of Signals From An Acoustic Cone PenetrometerDocument6 pagesInterpretation of Signals From An Acoustic Cone PenetrometerLTE002No ratings yet

- Module 3. Pipe Scanning: 3.1. PrinciplesDocument8 pagesModule 3. Pipe Scanning: 3.1. PrinciplesWillykateKairuNo ratings yet

- 02-SM For in Situ Stress Measurement Using The Compact Conical-Ended Borehole Overcoring (CCBO) Technique - 1999Document16 pages02-SM For in Situ Stress Measurement Using The Compact Conical-Ended Borehole Overcoring (CCBO) Technique - 1999Beatriz Nuñez TapiaNo ratings yet

- Paper Mud Logging UnitDocument11 pagesPaper Mud Logging Unitdimas williamNo ratings yet

- A Novel Cased-Hole Density-Neutron Log Interpretation and CharacteristicsDocument7 pagesA Novel Cased-Hole Density-Neutron Log Interpretation and CharacteristicsCAlexPereiraNo ratings yet

- UT 7 Displaying Ultrasonic Indications Angle Beam Inspection WithDocument21 pagesUT 7 Displaying Ultrasonic Indications Angle Beam Inspection WithAZAZ AHMADNo ratings yet

- Instruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsFrom EverandInstruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsNo ratings yet

- Optimization of Twin Screw Extrusion Using CFD For Polymer/nanoclay CompositesDocument6 pagesOptimization of Twin Screw Extrusion Using CFD For Polymer/nanoclay Compositesgiovan ganandyNo ratings yet

- Project Standards and Specifications Piping Steam Tracing Rev01Document3 pagesProject Standards and Specifications Piping Steam Tracing Rev01hiyeonNo ratings yet

- Sieve Analysis Lab ReportDocument5 pagesSieve Analysis Lab ReportUsama Rao100% (1)

- Patents: Strain Gauge Data Reduction Apparatus and MethodsDocument8 pagesPatents: Strain Gauge Data Reduction Apparatus and MethodsvigneshwarimahamuniNo ratings yet

- Field Density Testing with Nuclear GaugeDocument10 pagesField Density Testing with Nuclear GaugedavethiyaguNo ratings yet

- Acoustic Logging Methods and Applications: Understanding Sonic Log Presentation and LimitationsDocument36 pagesAcoustic Logging Methods and Applications: Understanding Sonic Log Presentation and LimitationsbijupiraNo ratings yet

- Bearing Capacity Determination using Plate Load TestDocument7 pagesBearing Capacity Determination using Plate Load TestShubham ArondekarNo ratings yet

- Improving Particle Dispersion Characteristics With A Novel Cleaning Screen: Parameter Design and Numerical SimulationDocument56 pagesImproving Particle Dispersion Characteristics With A Novel Cleaning Screen: Parameter Design and Numerical SimulationArman HoseiniNo ratings yet

- Method 2E - Determination of Landfill Gas Production Flow RateDocument15 pagesMethod 2E - Determination of Landfill Gas Production Flow RateOrwah malkawiNo ratings yet

- 371 HW 07 SDocument4 pages371 HW 07 SSugumar Panneer SelvamNo ratings yet

- Us4587423 PDFDocument12 pagesUs4587423 PDFRamanamurthy PalliNo ratings yet

- SPE-171001-MS Frictional Pressure Losses of Slurries in Straight and Coiled Tubing - Part I: Model Statistical AnalysisDocument9 pagesSPE-171001-MS Frictional Pressure Losses of Slurries in Straight and Coiled Tubing - Part I: Model Statistical AnalysisRamanamurthy PalliNo ratings yet

- Us4587423 PDFDocument12 pagesUs4587423 PDFRamanamurthy PalliNo ratings yet

- Us4587423 PDFDocument12 pagesUs4587423 PDFRamanamurthy PalliNo ratings yet

- Spe 11012 PaDocument10 pagesSpe 11012 PaRamanamurthy PalliNo ratings yet

- Help Frac Pack 01Document9 pagesHelp Frac Pack 01Ramanamurthy PalliNo ratings yet

- Solids-Free Invert Gravel Pack (US-English)Document2 pagesSolids-Free Invert Gravel Pack (US-English)Ramanamurthy PalliNo ratings yet

- Us4587423 PDFDocument12 pagesUs4587423 PDFRamanamurthy PalliNo ratings yet

- GP in Depleted ReservoirsDocument14 pagesGP in Depleted ReservoirsRamanamurthy PalliNo ratings yet

- New Fracpack Design - Accurate Tip ScreenoutDocument11 pagesNew Fracpack Design - Accurate Tip ScreenoutRamanamurthy PalliNo ratings yet

- Lessons Learned From Using VESDocument8 pagesLessons Learned From Using VESRamanamurthy PalliNo ratings yet

- Spe 68639 MSDocument8 pagesSpe 68639 MSRamanamurthy PalliNo ratings yet

- Section 2 - CalculationsDocument34 pagesSection 2 - CalculationsIllimination Illuminated Minisatan100% (1)

- Us4587423 PDFDocument12 pagesUs4587423 PDFRamanamurthy PalliNo ratings yet

- Application of Tip Screen-Out Fracturing TechniqueDocument11 pagesApplication of Tip Screen-Out Fracturing TechniqueZhiyong Huang100% (1)

- Gravel Pack LitDocument1 pageGravel Pack LitRamanamurthy PalliNo ratings yet

- Fracpack Tool Erosion Qualifiaction TestingDocument11 pagesFracpack Tool Erosion Qualifiaction TestingRamanamurthy PalliNo ratings yet

- SPE 84218 Modeling Fracture Tip Screenout and Application For Fracture Height Growth ControlDocument6 pagesSPE 84218 Modeling Fracture Tip Screenout and Application For Fracture Height Growth ControlRamanamurthy PalliNo ratings yet

- Spe 103184 MSDocument7 pagesSpe 103184 MSRamanamurthy PalliNo ratings yet

- Spe 37735 MSDocument7 pagesSpe 37735 MSRamanamurthy PalliNo ratings yet

- SC-2 GP PackerDocument12 pagesSC-2 GP PackerRamanamurthy Palli100% (1)

- Spe 56589 MSDocument10 pagesSpe 56589 MSRamanamurthy PalliNo ratings yet

- Spe 0802 0049 JPTDocument2 pagesSpe 0802 0049 JPTRamanamurthy PalliNo ratings yet

- OTC 7891 New Tool Designs For High Rate Gravel Pack OperationsDocument12 pagesOTC 7891 New Tool Designs For High Rate Gravel Pack OperationsRamanamurthy PalliNo ratings yet

- TechTips Mini Frac DFITDocument1 pageTechTips Mini Frac DFITRamanamurthy PalliNo ratings yet

- EPA HF Study Technical Workshop: Chemical and Analytical Methods for Fracturing FluidsDocument11 pagesEPA HF Study Technical Workshop: Chemical and Analytical Methods for Fracturing FluidsrodrigoayresNo ratings yet

- Aldehyde C 16Document4 pagesAldehyde C 16Ramanamurthy PalliNo ratings yet

- 7 Inch GP Packer DetailsDocument1 page7 Inch GP Packer DetailsRamanamurthy PalliNo ratings yet

- Mechanical-Engineering Gate2016.InfoDocument3 pagesMechanical-Engineering Gate2016.InfoHenryNo ratings yet