Professional Documents

Culture Documents

Prequalified Minimum Preheat and Interpass Temperature

Uploaded by

Anonymous wJGQDTH0pCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prequalified Minimum Preheat and Interpass Temperature

Uploaded by

Anonymous wJGQDTH0pCopyright:

Available Formats

AWS D1.1/D1.

1M:2015

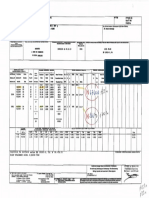

CLAUSE 3. PREQUALIFICATION OF WPSs

Table 3.3

Prequalified Minimum Preheat and Interpass Temperature (see 3.5)

C

a

t

e

g

o

r

y

Thickness of

Thickest Part at

Point of Welding

ASTM A36

ASTM A53

ASTM A106

ASTM A131

ASTM A139

ASTM A381

ASTM A500

ASTM A501

ASTM A516

ASTM A524

ASTM A573

ASTM A709

ASTM A1008 SS

A

ASTM A1011 SS

ASTM A1018 SS

API 5L

ABS

ASTM A36

ASTM A53

ASTM A106

ASTM A131

Welding

Process

Steel Specification

ASTM A139

ASTM A381

ASTM A441

ASTM A500

ASTM A501

ASTM A516

ASTM A524

ASTM A529

in

Minimum Preheat

and Interpass

Temperature

mm

Grade B

Grade B

Grades A, B, CS, D, DS, E

Grade B

Grade Y35

Grade A

Grade B

Grade C

Grade A

Grades I & II

Grade 65

Grade 36

Grade 30

Grade 33 Type 1

Grade 40 Type 1

Grade 30

Grade 33

Grade 36 Type 1

Grade 40

Grade 45

Grade 50

Grade 55

Grade 30

Grade 33

Grade 36

Grade 40

Grade B

Grade X42

Grades A, B, D, CS, DS

Grade E

Grade B

Grade B

Grades A, B,

CS, D, DS, E

AH 32 & 36

DH 32 & 36

EH 32 & 36

Grade B

Grade Y35

Grade A

Grade B

Grade C

Grades A and B

Grades 55 & 60

65 & 70

Grades I & II

Grades 50 & 55

SMAW

with other

than lowhydrogen

electrodes

SMAW

with lowhydrogen

electrodes,

SAW,

GMAW,

FCAW

(Continued)

57

1/8 to 3/4

incl.

3 to 20

incl.

a32a

a0a

Over 3/4

thru 1-1/2

incl.

Over 20

thru 38

incl.

150

65

Over 1-1/2

thru 2-1/2

incl.

Over 38

thru 65

incl.

225

110

Over 2-1/2

Over 65

300

150

1/8 to 3/4

incl.

3 to 20

incl.

Over 3/4

thru 1-1/2

incl.

32a

a0a

Over 20

thru 38

incl.

50

10

Over 1-1/2

thru 2-1/2

incl.

Over 38

thru 65

incl.

150

65

Over 2-1/2

Over 65

225

110

CLAUSE 3. PREQUALIFICATION OF WPSs

AWS D1.1/D1.1M:2015

Table 3.3 (Continued)

Prequalified Minimum Preheat and Interpass Temperature (see 3.5)

C

a

t

e

g

o

r

y

Thickness of

Thickest Part at

Point of Welding

Welding

Process

Steel Specification

ASTM A537

ASTM A572

ASTM A573

ASTM A588

ASTM A595

ASTM A606

ASTM A618

ASTM A633

ASTM A709

ASTM A710

ASTM A808

ASTM A913b

ASTM A992

ASTM A1008 HSLAS

ASTM A1008 HSLAS-F

ASTM A1011 HSLAS

B

(Contd)

ASTM A1011 HSLAS-F

ASTM A1018 HSLAS

ASTM A1018 HSLAS-F

ASTM A1018 SS

ASTM 1085

API 5L

API Spec. 2H

API 2MT1

API 2W

API 2Y

ABS

in

Minimum Preheat

and Interpass

Temperature

mm

Classes 1 & 2

Grades 42, 50, 55

Grade 65

Grades A, B, C

Grades Ib, II, III

Grades A, B

Grades C, D

Grades 36, 50, 50S, 50W,

HPS 50W

Grade A, Class 2

(>2 in [50 mm])

Grade 50

Grade 45 Class 1

Grade 45 Class 2

Grade 50 Class 1

Grade 50 Class 2

Grade 55 Class 1

Grade 55 Class 2

Grade 50

Grade 45 Class 1

Grade 45 Class 2

Grade 50 Class 1

Grade 50 Class 2

Grade 55 Class 1

Grade 55 Class 2

Grade 50

Grade 45 Class 1

Grade 45 Class 2

Grade 50 Class 1

Grade 50 Class 2

Grade 55 Class 1

Grade 55 Class 2

Grade 50

Grade 30

Grade 33

Grade 36

Grade 40

SMAW

with lowhydrogen

electrodes,

SAW,

GMAW,

FCAW

Grade B

Grade X42

Grades 42, 50

Grade 50

Grades 42, 50, 50T

Grades 42, 50, 50T

Grades AH 32 & 36

Grades DH 32 & 36

Grades EH 32 & 36

(Continued)

58

32a

a0a

Over 20

thru 38

incl.

50

10

Over 1-1/2

thru 2-1/2

incl.

Over 38

thru 65

incl.

150

65

Over 2-1/2

Over 65

225

110

1/8 to 3/4

incl.

3 to 20

incl.

Over 3/4

thru 1-1/2

incl.

AWS D1.1/D1.1M:2015

CLAUSE 3. PREQUALIFICATION OF WPSs

Table 3.3 (Continued)

Prequalified Minimum Preheat and Interpass Temperature (see 3.5)

C

a

t

e

g

o

r

y

Thickness of

Thickest Part at

Point of Welding

Steel Specification

ASTM A572

ASTM A633

ASTM A913b

ASTM A710

ASTM A710

ASTM A709c

ASTM A852c

ASTM A1018

HSLAS

ASTM A1018

HSLAS-F

API 2W

API 2Y

API 5L

ASTM A710

D

ASTM

A913b

Grades 60, 65

Grade E

Grades 60, 65, 70

Grade A, Class 2

(2 in [50 mm])

Grade A, Class 3

(>2 in [50 mm])

Grade HPS 70W

Grade 60 Class 2

Grade 70 Class 2

Grade 60 Class 2

Grade 70 Class 2

Grade 60

Grade 60

Grade X52

Grade A

(All classes)

Grades 50, 60, 65

Welding Process

SMAW with

low-hydrogen electrodes,

SAW, GMAW, FCAW

in

Minimum Preheat

and Interpass

Temperature

mm

1/8 to 3/4

incl.

3 to 20

incl.

50

10

Over 3/4

thru 1-1/2

incl.

Over 20

thru 38

incl.

150

65

Over 1-1/2

thru 2-1/2

incl.

Over 38

thru 65

incl.

225

110

Over 2-1/2

Over 65

300

150

SMAW, SAW, GMAW, and

FCAW with electrodes or electrode-flux combinations capable of depositing weld metal

with a maximum diffusible

hydrogen content of 8 ml/100 g

(H8), when tested according to

AWS A4.3.

All thicknesses

1/8 in [3 mm]

32a

a0a

When the base metal temperature is below 32F [0C], the base metal shall be preheated to a minimum of 70F [20C] and the minimum interpass

temperature shall be maintained during welding.

The heat input limitations of 5.7 shall not apply to ASTM A913.

c For ASTM A709 Grade HPS 70W and ASTM A852, the maximum preheat and interpass temperatures shall not exceed 400F [200C] for

thicknesses up to 1-1/2 in [40 mm], inclusive, and 450F [230C] for greater thicknesses.

b

Notes:

1. For modification of preheat requirements for SAW with parallel or multiple electrodes, see 3.5.2.

2. See 5.11.2 and 5.6 for ambient and base metal temperature requirements.

59

You might also like

- Sans 10137 2011Document107 pagesSans 10137 2011Pamps Mangampo50% (2)

- Work Instructions For Rolling of PlatesDocument3 pagesWork Instructions For Rolling of PlatesPravin Patil100% (1)

- Welder, Welding Operator Qualification Test ReportDocument2 pagesWelder, Welding Operator Qualification Test Reportkarthik sundaramNo ratings yet

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- Shell Rolling ProcedureDocument26 pagesShell Rolling ProcedureKingston Rivington100% (1)

- Vaccum Test MethodDocument4 pagesVaccum Test MethodMahmud AlamNo ratings yet

- WSI Corrosion Control by Weld Overlay (Boilers)Document11 pagesWSI Corrosion Control by Weld Overlay (Boilers)Claudia Mms100% (1)

- D1.1 D1.1M 2020 Errata 2qDocument19 pagesD1.1 D1.1M 2020 Errata 2qSleyda Munoz100% (1)

- Hele 6Document16 pagesHele 6Ella Mae Berro0% (1)

- As 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveDocument7 pagesAs 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveSAI Global - APAC50% (2)

- Imp-Comparison of SpecificationsDocument7 pagesImp-Comparison of SpecificationsKetan PatelNo ratings yet

- Weld ShrinkageDocument16 pagesWeld ShrinkageWeff JingNo ratings yet

- Preheat and Interpass TempDocument2 pagesPreheat and Interpass TempUche UrchNo ratings yet

- Electrode Handling Procedure - Simple - SMAWDocument7 pagesElectrode Handling Procedure - Simple - SMAWGalih Suksmono Adi0% (1)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Weld GaugesDocument15 pagesWeld Gaugesraobabar21100% (1)

- MS-C-013 Structural Steel Fabrication Method StatementDocument9 pagesMS-C-013 Structural Steel Fabrication Method StatementilliasuddinNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- AES-W-016 welding filler metalsDocument2 pagesAES-W-016 welding filler metalsmalika_00No ratings yet

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNo ratings yet

- Sample Heat Treatment ProcedureDocument13 pagesSample Heat Treatment ProcedureAnonymous uXdS9Y7100% (1)

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanNo ratings yet

- Flame Straightening S355Document9 pagesFlame Straightening S355Anonymous oI04sS100% (1)

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Duplex & Super Duplex InformationDocument7 pagesDuplex & Super Duplex InformationrajeshNo ratings yet

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocument5 pagesAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedNo ratings yet

- Hastelloy C-276 WeldingDocument4 pagesHastelloy C-276 WeldingClaudia MmsNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- Floating Head Heat Exchanger Hydrotest ProcedureDocument15 pagesFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezNo ratings yet

- Interpass Temperature WeldingDocument2 pagesInterpass Temperature Weldinghareesh13hNo ratings yet

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- Procedure for Flame Straightening Structural SteelDocument3 pagesProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- DistortionDocument62 pagesDistortionSharad AtraheNo ratings yet

- 8 Material ControlDocument8 pages8 Material ControlPrakash RajNo ratings yet

- Painting & Inspection FormatDocument1 pagePainting & Inspection FormatABEC Trombay siteNo ratings yet

- Weld Filler Metal SelectionDocument7 pagesWeld Filler Metal SelectionsusanwebNo ratings yet

- Repair Procedure For Super Heater Coil TubesDocument2 pagesRepair Procedure For Super Heater Coil Tubesbehzad mohammadiNo ratings yet

- Welding of Duplex Stainless SteelDocument7 pagesWelding of Duplex Stainless SteelAnthony YUNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Pneumatic Test Procedure DT 29112017 CompressDocument7 pagesPneumatic Test Procedure DT 29112017 Compressjamesvarghese2812No ratings yet

- Visual Inspection Report FormDocument8 pagesVisual Inspection Report FormfriyantoNo ratings yet

- Corrective and Preventive Action On High Rejection RateDocument1 pageCorrective and Preventive Action On High Rejection RateRakeshNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- ASME SECTION IX INTERPRETATIONSDocument95 pagesASME SECTION IX INTERPRETATIONSnizam1372No ratings yet

- Material Certificate Plate 16mmDocument1 pageMaterial Certificate Plate 16mmAdeoyeNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- 10 Procedure For PWHTDocument5 pages10 Procedure For PWHTSachin S. SalunkheNo ratings yet

- INSPECTION REPORT TITLEDocument7 pagesINSPECTION REPORT TITLEABEC Trombay siteNo ratings yet

- Brazing BPS 107-1 PDocument5 pagesBrazing BPS 107-1 Pmbe josephNo ratings yet

- Structural Steel and Pipe Work ProcedureDocument5 pagesStructural Steel and Pipe Work ProcedureMohamed100% (2)

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- PreheatDocument4 pagesPreheatShaikh IbrahimNo ratings yet

- AWS D1.1 structural welding code errataDocument8 pagesAWS D1.1 structural welding code erratadarren84No ratings yet

- Prequalified Minimum Preheat and Interpass Temperature (See 5.7)Document4 pagesPrequalified Minimum Preheat and Interpass Temperature (See 5.7)Nilton SantillanNo ratings yet

- AWS Errata Sheet CorrectionsDocument6 pagesAWS Errata Sheet CorrectionsDarwin EnriqueNo ratings yet

- 701 en Armox Workshop Recommendations V1 2020 WebDocument12 pages701 en Armox Workshop Recommendations V1 2020 WebMOHAC KILICASLANNo ratings yet

- Steel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Document2 pagesSteel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Akhi IsMailNo ratings yet

- Pressure Vessel Steels - Astm A516Document6 pagesPressure Vessel Steels - Astm A516septo982No ratings yet

- SSAB Armox Workshop Recommendations 701 ENDocument12 pagesSSAB Armox Workshop Recommendations 701 ENferminNo ratings yet

- TWI MSS FRM 008 00, Training Course Registration FormDocument1 pageTWI MSS FRM 008 00, Training Course Registration FormAnonymous wJGQDTH0pNo ratings yet

- Because You Have Shared inDocument1 pageBecause You Have Shared inAnonymous wJGQDTH0pNo ratings yet

- TWI MSS FRM 008 00, Training Course Registration FormDocument1 pageTWI MSS FRM 008 00, Training Course Registration FormAnonymous wJGQDTH0pNo ratings yet

- CSWIP WI UK Enrolment Rev 18 April 2013-IranDocument4 pagesCSWIP WI UK Enrolment Rev 18 April 2013-IranAnonymous wJGQDTH0pNo ratings yet

- VT Acceptance Criteria Vs ASMEDocument1 pageVT Acceptance Criteria Vs ASMEAnonymous EkfqSPNo ratings yet

- Because You Have Shared inDocument1 pageBecause You Have Shared inAnonymous wJGQDTH0pNo ratings yet

- Standard Test MethodDocument4 pagesStandard Test MethodAnonymous wJGQDTH0pNo ratings yet

- VT Acceptance Criteria Vs ASMEDocument1 pageVT Acceptance Criteria Vs ASMEAnonymous EkfqSPNo ratings yet

- Selective MediaDocument10 pagesSelective Mediaprincess_likemist4No ratings yet

- General Characteristics of Bacteria and MollicutesDocument13 pagesGeneral Characteristics of Bacteria and MollicutesPrincess Mehra0% (1)

- Qcs 2010 'Part 8.04 Pipeline InstallationDocument29 pagesQcs 2010 'Part 8.04 Pipeline InstallationRotsapNayrb100% (2)

- Expwb3ans eDocument67 pagesExpwb3ans eOlivia LinNo ratings yet

- Material Safety Data Sheet: Ephedrine HydrochlorideDocument6 pagesMaterial Safety Data Sheet: Ephedrine HydrochlorideTyaga MahardikaNo ratings yet

- COC-Dosing Skid - NalcoDocument11 pagesCOC-Dosing Skid - NalcodeyprasenNo ratings yet

- Index TO XV: ArsphenamineDocument7 pagesIndex TO XV: ArsphenamineAlex12No ratings yet

- Syntheses of Soap and DetergentDocument4 pagesSyntheses of Soap and DetergentChin Castro Zabat100% (2)

- Schunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFDocument2 pagesSchunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFMUHAMMAD ASYRAAF BIN ANUARNo ratings yet

- Class 10 science lab exam MCQ questionsDocument4 pagesClass 10 science lab exam MCQ questionsDonkeyNo ratings yet

- Low Temp Refrigeration Oil DataDocument1 pageLow Temp Refrigeration Oil DataGeorgiana DumitruNo ratings yet

- ASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire ApparatusDocument3 pagesASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire Apparatusalin2005No ratings yet

- Dalma Mall's Industrial Plastic Pipes and FittingsDocument24 pagesDalma Mall's Industrial Plastic Pipes and FittingsashishNo ratings yet

- Warna Daun Padi LCCDocument12 pagesWarna Daun Padi LCCM Hisyam NasrullohNo ratings yet

- JHP 8 69Document9 pagesJHP 8 69Khalil El BayadNo ratings yet

- Exporters: Index by CountryDocument113 pagesExporters: Index by CountrySyam WadiNo ratings yet

- 1 Auxilliary Equipment - US PricingDocument132 pages1 Auxilliary Equipment - US PricingOscar EspitiaNo ratings yet

- Dotaverine HCLDocument5 pagesDotaverine HCLalbertsmasudoNo ratings yet

- AVK Hydrants BrochureDocument11 pagesAVK Hydrants Brochuremubarak aliNo ratings yet

- Current Concepts in Orthopaedic Biomaterials and Implant FixationDocument24 pagesCurrent Concepts in Orthopaedic Biomaterials and Implant FixationS.ENo ratings yet

- Stainless Steel 304 FlangesDocument6 pagesStainless Steel 304 FlangesiSteelindiaNo ratings yet

- Validation and Verification of Cleanning ProcessDocument42 pagesValidation and Verification of Cleanning ProcessEva Pa'e ONo ratings yet

- Astm 1351 1 REPLICADocument6 pagesAstm 1351 1 REPLICAmaheshNo ratings yet

- A Review On Development of Stereolithography (SLA) 3D Printing in Additive Manufacturing For Biomedical IndustryDocument4 pagesA Review On Development of Stereolithography (SLA) 3D Printing in Additive Manufacturing For Biomedical IndustryFirdaus Mat SoibNo ratings yet

- Lightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiDocument6 pagesLightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiAfzalNo ratings yet

- TubingDocument6 pagesTubingkevin wongNo ratings yet

- Atracurium BesylateDocument4 pagesAtracurium BesylateStill DollNo ratings yet