Professional Documents

Culture Documents

Numerical Simulation of Thin Layer Coffee Drying by Control Volumes Simulación Numérica de Secado de Café en Capa Delgada Usando Volúmenes de Control

Uploaded by

ปิยวุฒิ เอกพิพัฒน์เวชกุลOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Numerical Simulation of Thin Layer Coffee Drying by Control Volumes Simulación Numérica de Secado de Café en Capa Delgada Usando Volúmenes de Control

Uploaded by

ปิยวุฒิ เอกพิพัฒน์เวชกุลCopyright:

Available Formats

NUMERICALSIMULATIONOFTHINLAYERCOFFEE

DRYINGBYCONTROLVOLUMES

SIMULACINNUMRICADESECADODECAFENCAPA

DELGADAUSANDOVOLMENESDECONTROL

HCTORJ.CIROVELSQUEZ

DepartmentofAgriculturalandFoodEngineering,UNAL SedeMedelln,hjciro@unal.edu.co

LUISC.ABUDCANO

MechanicalEngineer,M.Sc,labud68@hotmail.com

LUIS.R.PREZALEGRA

DepartmentofAgriculturalandBiosystems Engineering,UniversityofPuertoRicoMayagezCampus, luisr.perez1@upr.edu

ReceivedforreviewMay21th,2009,acceptedSeptember8th,2009,finalversionSeptember,24th,2009

ABSTRACT:Thethinlayerdryingmodelproposed by SokhansanjandBruce(1987)wasimplementedtomodel

the drying process ofparchment coffee beans. A computationalmodel based on a control volume approach was

developed to simulate the drying process of parchment coffee. A one dimensional transient analysis was

implementedintheradialdirectionappliedtoasphericalcoffeebeanofequivalentradius.Theresultsfoundthat,

eventhoughthenumericalvalueforthemasstransfercoefficientisasmallnumber(aboutof107 m/sec),moisture

content predictions were sensitive to this value. The predicted drying curve compared favorably with published

results.

KEYWORDS:Coffee,drying, numericalsimulation,thinlayer.

RESUMEN:ElmodelodesecadoencapadelgadadesarrolladoporSokhansanjyBruce(1987)fueimplementado

parasimularelsecadodeungranodecafpergamino.Elmodelocomputacionalfuedefinidoenestadotransitorio

yunidimensional paraunaesferaderadioequivalente utilizandolatcnicadelvolumendecontrol.Losresultados

indicaron que el valor numrico del coeficiente de transferencia de masa es muy pequeo (orden de magnitud

alrededorde107 m/s) haciendoquelaprediccindelcontenidodehumedadseamuysensibleaestevalor.Adems,

losresultadosdelasimulacinmostraronquelaprediccindelmodelonumricofuefavorablementesimilaralos

datosexperimentalesdadosenlaliteratura.

PALABRASCLAVES: Caf,secado,simulacinnumrica,capadelgada.

1.INTRODUCTION

Worldwide, Colombia is the third coffee

producing country and the first coffee producer

of smooth coffees. To reach and maintain the

statusoftheColombiancoffee,understandingof

the impact of coffee drying and other stages of

postharvest managementhasbeenfundamental.

Drying of grains has been a researchintensive

area because of the complexity of the drying

phenomenon and, consequently, modeling and

simulation of the same needs the proper

definition of the governing equations with

boundaryconditions,useofappropriatematerial

properties and consideration of mechanical and

chemical effects, when necessary [13].

Dyna,year77,Nro.163,pp. 270278. Medellin,September,2010.ISSN00127353

271

Dyna163,2010

Dryingisthepartofthepostharvestprocessthat

isresponsiblefortheremovalofexcessmoisture

to a level that is safe for long time storage

withoutanyimpacttoaromaortasteofthefinal

beverage. Drying is a combination of heat and

masstransfersthatoccurssimultaneouslywhere

moisture is removed by evaporation from the

outer surface of the bean due to partial vapor

pressure differentialbetweenthebeans andthe

air mass that surrounds it [46]. Drying could

affect the physical appearance, the yield at

hulling and the taste of the beverage [7].

Actually, dry parchment coffee is sold at final

moisturecontentbetween10and12%wetbasis.

Coffee drying in deep beds is modeled using

thinlayermodels(thinlayeristhedepthofthree

layers of coffee beans), one in top of the next

until the depth of the bed is reached. Models

build this way are able to predict and simulate

the temperature and moisture profile under

constantairflow [810].Therefore,theaccuracy

of this modeling approach directly depends on

theaccuracyofthethinlayerdryingmodel[11

14].

This paper describes a new implemented coffee

drying simulation model based on heat

conduction equation [15]. Upon validation the

modelcanbeusedtodesignandoptimizationof

deep bed dryers forparchmentcoffee beans.

In convective drying, the grains surface

exchange heat with the surroundings as aresult

of convection, while the internal mass of the

grainis heatedbyheatconduction.Thegeneral

formofheatconductionequationthatappliesto

graindryingcanbewrittenas:

rCp

The general diffusion equation that describes

moisture mass transfer in the bean is given by

theequation:

M

= div( DM )

t

[1]

Initial and boundary conditions for equation (1)

are,respectively:

M=Mi ,

t 0

[2]

and

M

- D

= hm( M-Me ) ,r=R,t>0

r

[3]

[4]

Boundaryconditionsforeq.(4)areabasedon1)

liquid moisture in the grain moves from the

interior layer to the outer surface by diffusion

and 2) moisture evaporates from the outer

surface. The energy balance at the beans

surfacecanbewrittenas:

V

T

M

= h(T - Ta ) - k r[hfg + Cpv(Ta - T)]

r

Ak

t

-k

,

r=R,t > 0[5]

Eq.5implies that the energytransportedbythe

air is used to evaporate moisture in the beans

surfaceandtheresttoheattheinternallayersof

the bean. The initial condition for this process

is:

T=Ti,t 0

[6]

Usingthemasstransferconditionineq.(3),the

boundary condition for the beans temperature

(eq.5)canbesimplified [16]to:

-k

2. THEORETICAL ANALYSIS

T

= div( kT)

t

= h(T-Ta) + r[hfg +Cpv(Ta -T)]hm(M

- Me),

r

r=R,t > 0

[7]

The set of equations described above represent

heat and mass transfer in a coffee bean. These

equations are tight together by the use of the

derivative of the beans moisture content and

time (eq. 5) are solved to describe temperature

and moisture profiles inasinglecoffeebean.

The thin layer coffee drying model developed

hereusethefollowingassumptions:1)thecoffee

bean is homogeneousand isotropic,2)thebean

is represented by an equivalent sphere which is

definedas theratiobetweenbeans volumeand

surface area, 3) the bean is symmetrical with

respecttoitsprincipalaxisandtemperatureand

moisture depend on the radial distance, r and

time, t, 4) moisture evaporation takes place in

Ciroetal

the beans surface, 5) initial temperature and

moisturecontentareuniform,6)temperatureand

moisture profiles are symmetrical during the

drying process, 7) heat and mass transfer are

pure diffusion within the bean and outside the

bean are pure convection. There is not heat

radiation,8)beansvolumeisassumedconstant,

there is no shrinkage or expansion of the bean

during drying and 9) specific heat and thermal

conductivity depend on the beans moisture

content. Diffusion coefficient and latent heat of

vaporization depend on the beans temperature

andmoisturecontent.

2.1 Numer ical scheme

Under transient regime, heat and moisture

transfer equations are nonlinear. These

equationshavephysicalvariablesthatdependon

beans moisture and temperature [17]. The set

of equations were solved using the control

volume scheme [18]. In this scheme, each

controlvolume maintains mass conservation,

energyandmomentum.Toapplythistechnique,

thecomputationaldomainisdividedinaknown

number of controlvolumes that do not overlap

andthateachnodeofthegridisassociatedwith

one control volume. In each control volume,

energy or mass balances are performed.

Moisture and temperature variations follow a

linear profile with respect to radial distance, r.

The solution also uses an implicit scheme that

assumes that the new value of the dependent

variable (temperature or moisture) prevails

constantduringthetimeinterval.Asaresultof

this scheme, a set of algebraic equations are

generated.Theset ofalgebraicequations,one

for each control volume, are solved using an

iterative procedure. The coffee bean is

represented by a sphere with an equivalent

radius that is symmetrical with respect to the

azimuthal coordinate . The solution model

uses only an eighth of sphere. The model also

assumes symmetry with respect to the zenith

angle q. Therefore, the model offers solutions

with respect to the polar coordinates radial, r

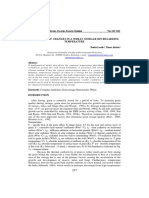

andtime,t.Figure1showsthesolutionscheme

foranyzenithangleofthesphere.Theplainin

Fig. 1 is divided in N number of subregions

withanodeinthemidradiusofeachsubregion,

exceptfornodes0andNthatarelocatedinthe

272

center and the outer surface of the sphere,

respectively. The energy and moisture mass

balanceforthecentral,intermediatesandsurface

nodes a set of N+1 simultaneous algebraic

equations aregeneratedforN+1Xsunknowns.

These set of equations are expressed in matrix

formas:

[AN ]{Xi+1} = {DN}

[8]

Where, X represents the beans temperature or

moisture, A and D are constants that depend

mainly on physical and thermal properties of

coffeebeansanditsgeometry.

q =

T/q=0

Control

volume

Tn+

[ Aq]

Tn

n+1

Dr

Tn

CV

[Aq]

n-1/

q =

n1/2

n n+1/2

T/q=0

q =

Mn+

Control

volume

M/q =0

Mn

[ Ah]

Dr

n +1

Mn

CV

[ Ah]

n -1/

q =

n1/2

n n+1/2

M/q =0

Figur e1. Controlvolumeforheatandmasstransfers

withinparchmentcoffeebeans

273

Dyna163,2010

The solution of the system of nonlinear

equations (eq. 8) gives the nodes temperature

and moisture content for each time interval

duringthe dryingprocess.Nonlinearity comes

from the fact that the thermal conductivity and

the beans specific heat depend on the grain

moisturecontentwhilethediffusioncoefficient

andthelatentheatofvaporizationdependonthe

beans temperature and moisture content.

Assuming that the beans density remains

constant, the mean temperature or mass

temperature and mean moisture content were

determined using the following equations:

T =

vT(r)dm

v dm

3.26raCpaVs

Pr2/3

Re-0.65

[11]

Initially, the mass transfer coefficient was

estimatedusingtheChiltonColburnanalogy:

hm =

hPr2/3

h

2/3 =

r aCpaSc

raCpaLe 2/3

[12]

3. RESULTSANDDISCUSSION

3.1Computational model

And

M =

h =

[9]

v dm

v M(r)dm

The heat transfer coefficient was calculated

using correlationforgrains[15]:

[10]

Thesolutionofthematrixsystemofequationat

eachstep was obtainedbysuccessive iterations.

The implicit method was chosen because it is

unconditionally stable. A banded matrix of

unknowns was thus formed with the solution

obtainedusingastandarditerativesolverforthe

matrix.Themoisturematrixwassolvedfirstand

the change in the moisture from one iteration

step to the next was substituted into the

temperature

boundary

condition.

This

information was then transferred to the D

matrix of the temperature equation and the

conduction equation was solved. The numerical

solutionwascodedinFortran.

2.2 Ther mophysicalPr oper tiesofCoffee

Thermal and physical properties of the coffee

bean were taken from the literature: Diffusion

coefficient [19], equilibrium moisture content

and latent heat of vaporization [20] equivalent

radius, real density, thermal conductivity and

specific heat [21]. Heat and mass transfer

coefficients were calculated in this study.

Convergence and stability of the models

solution scheme was studiedby discretizing the

domain(numberofnodes)andthetimestepand

measuring its effect on estate variables

(temperature and moisture). A robust model

offers solutions that are independent of the

discretizationusedandthetimeintervalselected.

3.2 Effectofthenodalgr id

The effect of the nodal grid in the solution was

measured by calculating coffee beans moisture

contentfora30hrdryingtimewithonesecond

timestep. Reference [22] gives the drying

operational conditions used in this study: Air

dryingtemperature(Ta=40C),relativehumidity

(RH=29%)andinitialmoisturecontent(Mi=0.65

decimal, d.b). Table 1 shows that the obtained

meanbeansmoistureislessthan0.5%between

a 40 and 80 nodes grid. Therefore, a 40 node

gridwasusedinthisstudy.

Table1. Influenceofmeshsizeonmodelsstability

Nodes

10

20

40

80

160

Mean

moisture

content

(dec,d.b)

0.111 0.108 0.108 0.107 0.107

Ciroetal

3.3 Effectoftimestep

Thesolutionmodelshowednosensitivity andno

significant differences of the beans moisture

whentheintegrationtimewasvariedfrom0.1to

60 seconds (Table 2). Therefore a 60sec

integration time was used for the solution.

Table2. Modelstabilityaccordingtocomputational

Drying

time

(h)

5

15

30

0.1s

0.364

0.172

0.108

Computationalsteptime

1

5

1s

10s

Min min

0.364 0.363 0.364 0.368

0.172 0.172 0.172 0.174

0.108 0.108 0.108 0.108

time stepfordifferentdryingtime

3.4

Modelsvalidation

Reference[22]presentstheexperimentaldataof

coffeedryingusedtovalidatethemodel.Beans

moisture results using the mass transfer

coefficient generated by the ChiltonColburn

analogy under predicts the beans moisture

during the entire drying process (Figure 2).

Thus, the drying process occurs at a faster rate

than observed therefore, the mass transfer

coefficientcalculatedusingChiltonColburn is

not appropriate forcoffee beans.

0.7

Ta =40C,RH =29%,Mi =0.65

Vair=12m/min

Exp.Jaramillo(1990)

0.5

Themasstransfercoefficientwasthencalculated

withtheexperimentaldata.Aconstantmoisture

loss is assumed for all phases of the drying

process.Duringdrying,moistureisonlylossat

thebeanssurfacetherefore,moisturemigration

withinthebeaniscontrolledbywaterlossatthe

beanssurface. Themathematicalexpressionfor

moisturelossis:

A

dM

=- hm k (M - Me )

dt

Vk

[13]

After integration and assuming hm a time

independentfunction,obtain:

M(t)-Me

Mi- Me

Ln

= - mt

[14]

Thus, the graph of beans moisture versus time

shouldproduceastraightlinewithslopem(Eq.

14). Hence, the mass transfer coefficient is

givenby:

R

V

hm = m= eq m

A

3

[15]

In Figure 3 the mass transfer coefficient was

varied to simulate the drying conditions. The

prediction of the model improves for the initial

600 min (10 hr) of drying when the coefficient

was reduced in 30% (hm=0.305x107 m/s) and

worsen when the coefficient was increased in

30%.Regardless ofthe value of hm the model

over estimates grain moistureat the finalstages

ofdrying.Although hm isasmallnumber(Table

3),itcontrolsthebeansmoistureduringdrying.

ChiltonColburn

0.4

0.7

Moisturecontent(dec,d.b)

Moisturecontent (dec,d.b)

0.6

274

0.3

0.2

0.1

0

0

300

600

900

1200

1500

1800

Ta =40C ,RH =29%,Mi =0.65

Vair=12m/min

0.6

hm =0.568e7m/s

0.5

hm =0.437e7m/s

hm =0.305e7m/s

0.4

Exp.Jaramillo(1990)

0.3

0.2

0.1

Time(min)

0

0

300

600

900

1200

1500

1800

Time(min)

Figur e2. Simulatedmeanmoisturecontentof

parchmentcoffeebeanusingtheChiltonColburn

analogy(hm =0.561x101m/s)

Figur e3. Simulatedmeanmoisturecontentof

parchmentcoffeebeantodifferent heatmasstransfer

coefficients

275

Dyna163,2010

Abetterestimateofthemasstransfercoefficient

was generated taking into account the time into

dryingandthereforethebeansmoisturecontent

withthefollowingeqs.:

Air

temperature

(C)

40

50

60

Rel.

Humidity

(%)

29

17

13

Initial

moisture

content(Mi)

hm

(m/s)107

(dec,d.b)

0.65

0.52

0.50

0.437

0.970

1.946

Ta=50C,RH=17%,Mi=0.52

Vair=12m/min

0.6

Moisturecontent(dec,d.b)

Table3. Masstransfercoefficientscalculated

accordingto dryingexperimentalconditions

0.7

0.5

0.4

Exp.Jaramillo

(1990)

Numerical

0.3

0.2

0.1

0

0

1

dM(t) Vk

dt Ak M(t)- Me

hm =-

300

[17]

Inthese eqs.,hm depend onthebeans moisture

content, equilibrium moisture content and

moisture ratio for every stage of the drying

process (temperature, relative humidity and

airflow velocity). Eq.(18) gives the final

expressionforhm accordingtodryingconditions

presentedinFigure4:

Req

[18]

- 0.0560+ 0.0102t0,5

hm =

3 3600 (0.650- 0.0560t+ 0.00681

t1,5) - Me

600

900

1200

Time(min)

[16]

Figur e4. Simulatedmeanmoisturecontentof

parchmentcoffeebeansusinganexperimentalmass

transfercoefficientchangingwiththedryingtimeand

dryingconditions:airtemperature(40C),relative

humidity(29%),initialmoisturecontent(0.65)and

airvelocity(12m/min)

0.7

Ta =40C,RH=29%,Mi=0.65

Vair=12m/min

0.6

Mositurecontent(dec,d.b)

A

dM (t)

=- hm k [M(t)- Me]

dt

Vk

0.5

0.4

Exp.Jaramillo

(1990)

0.3

Numerical

0.2

0.1

Updatinghm duringthedryingprocessimproved

significantly models predictions (Figures 4, 5

and 6). Further analysis of the results indicate

that the beans moisture equilibrium, Me

developed in reference [20] and used in this

study,isresponsibleforpredictinghigherbeans

moisture contents at the end of the drying

process[22].

0

0

300

600

900 1200 1500 1800

Time(min)

Figur e5. Simulatedmean moisturecontentof

parchmentcoffeebeansusinganexperimentalmass

transfercoefficientchangingwiththedryingtimeand

dryingconditions:airtemperature(50C),relative

humidity(17%),initialmoisturecontent(0.52)and

airvelocity(12m/min)

Ciroetal

276

0 .6

0 .4

Ex p .Ja r a millo

( 1 9 9 0 )

0 .3

Nu me r ic a l

0 .2

0 .1

0

0

3 0 0

6 0 0

T a = 40C , H R = 29% , Mi = 0. 65

V air = 12m / m in

45

9 0 0

Temperature(C)

Moisturecontent(dec,d.b)

directly improves modeling of deep coffee

drying. Thus, this paper provides a direct

contributiontorealapplicationofcoffeedrying.

Ta = 6 0 C , R H = 1 3 % , Mi = 0 . 5 0

V a ir = 1 2 m / m in

0 .5

T im e (m in )

35

25

A v e ra ge

S u rf ac e

15

0

Figur e6. Simulatedmean moisturecontentof

parchmentcoffeebeanusinganexperimentalmass

transfercoefficientchangingwiththedryingtimeand

dryingconditions:airtemperature(60C),relative

humidity(13%),initialmoisturecontent(0.50)and

airvelocity(12

Beans interior and surface temperature

increased during the first 15 min of simulation

time (Figures 7A, B, C). The beans mean and

surface temperatures reached equilibrium

temperature (air temperature) 20 min from

initiation of drying and then remained constant

duringtherestoftheprocess.

3 0

45

6 0

T im e(m in)

Ta = 5 0 C ,R H = 1 7 % ,Mi= 0 .5 2

Va ir=1 2 m /m i n

5 5

Temperature(C)

3.5 BeansTemper atur e

1 5

4 5

3 5

A v er ag e

S u rf a c e

2 5

1 5

0

1 5

3 0

4 5

6 0

Time ( min)

Ta = 60C ,H R = 13% , Mi = 0.50

V air= 12 m /m in

6 5

Temperature(C)

A sharp increase in the mass average

temperature prediction during the first few

minutesofdryingindicatesthepresenceoflarge

temperature gradients and therefore high levels

ofthermalstressduringthatperiod.Hence,rapid

stabilization of the mass average temperature

could have an effect on mass transfer [1]. The

short time required for equilibrium temperature

is documented [15, 2324] but due to lack of

temperature profile of coffee beans during

dryingthisstudycouldnotvalidatethisclaimfor

coffeebeans.

5 5

4 5

C

3 5

A v e ra g e

2 5

S ur f a c e

1 5

Practical application of thinlayer theory is

limited because rarely coffee is dried in thin

layersnowdays.Itsimportancelaysinthefact

that beans temperature and moisture transfer is

govern by thinlayer theory, therefore any

improvement to the modeling of thin layer

1 5

30

4 5

60

T im e(m in)

Figur e7. Simulatedtemperatureofparchmentcoffee

beansfordifferent experimentaldryingconditions

277

4.

Dyna163,2010

CONCLUSIONS

Thinlayer coffee drying was successfully

modeled using the equation proposed by

Sokhansanj and Bruce (1987). A key element

that affected the accuracy of the model is the

availability of relevant experimental data to

generate thermophysicals parameters of coffee

beans or any grain that are relevant to describe

thermal and mass diffusion within the drying

process.Itwasalsofoundthatthemasstransfer

coefficientisaverysmallnumberintheorderof

107 m s1 but highly significnt to describe the

process and verydependent onthetime elapsed

indrying process.

LISTOFSYMBOLS

Ak=Kernelsuperficialarea,m2.

AN=Numericalmatrix.

Cp=Specificheat,kJ/kgK.

Cpa=Airspecificheat,kJ/kgK.

Cpv=Vaporspecificheat,kJ/kgK.

D=Kerneldiffusivity,m2/s.

DN=Matrix

h=Airgrainconvectiveheattransfercoefficient,

W/m2 K.

hfg=Latentheatvaporizationofwater,kJ/kg.

hm=Convectivemasstransfercoefficient,m/s.

k=Kernelthermalconductivity,W/mK.

Le=Lewisnumber

M=Kernelmoisturecontent,decimald.b.

Me=Equilibriummoisturecontent,decimald.b.

Mi=Initialmoisturecontent,decimald.b.

Pr=Prandtlnumber.

r=radialcoordinates.

R=Radiusofthegrain,m.

Re=Reynoldsnumber.

Req=Equivalentradius,m.

RH=Relativehumidity,%.

Sc=Schmidtnumber.

t=dryingtime,h.

T=Kerneltemperature,C.

Ta=Airdryingtemperature,C.

Ti=Initialtemperature,C.

Vk=KernelVolume,m3.

Vs=Superficialairvelocity,m/s.

X=Variablesvector.

GreekSymbols

r=Kerneldensity,kg/m3.

ra=Airdensity,kg/m3.

REFERENCES

[1] IRUDAYARAJ, J., HAGHIGHI, K. AND

STROSHINE, R. L. Finite element analysis of

dryingwithapplicationtocerealgrains,J.Agric.

Eng.Res.,53,209229,1992.

[2] DUTTA, A. K. AND ZHANG. J. Porous

media approach to heat and mass transfer in

solid foods, ASAE Paper No. 993068. St.

Joseph,Mich.:ASAE,1999.

[3]RANJANR.,IRUDAYARAJ,J.ANDJUN,

S.Athreedimensionalcontrolvolumeapproach

to modeling heat and mass transfer in foods

materials, Transactions of the ASAE 33, 209

229,2001.

[4] SRIVASTAVA, V.K. AND JOHN, J. Deep

bed grain drying modeling, Energy Conversion

andManagement43,16891708,2002.

[5] ZIEGLER, TH. AND RICHTER, I.G.

Analyzing deepbed drying based on enthalpy

water content diagrams for air and grain,

Computers and Electronics in Agriculture 26,

105122,2000.

[6] YADOLLAHINIA, A.R., OMID, M. AND

RAFIEE, S. Design and fabrication of

experimental dryer for studying agricultural

products, International Journal of Agricultural

&Biology10,6165,2008.

[7] AREGBA, A.W., SEBASTIAN, P. AND

NADEAU, J.P. Stationary deepbed drying: A

comparativestudybetweenalogarithmic model

and a nonequilibrium model, Journal of Food

Engineering77,2740,2006.

[8] PABIS, S., JAYAS, D. S. AND

CENKOWSKI, S. Grain drying: Theory and

practice,JohnWiley&Sons,1998.

[9] FREIRE, F. B., BARROZO, M.A.,

SARTORI, D.ANDFREIRE,J.T.Study ofthe

drying kinetics in thin layer: fixed and moving

bed,DryingTechnology 23,14511464,2005.

Ciroetal

[10] American Society of Agricultural and

Biological Engineering (ASABE). Thin layer

equation ofagriculturalcrops:StandardS448.1,

ASABEStandards,2006.

[11] PARTI, M. Selection of mathematical

models for drying grain in thin layer,

J.Agric.Eng.Res.54,339352,1993.

[12] BROOKER, D. B., BAKKERARKEMA,

F.W. AND HALL, C.W. Drying and storage of

grainsandoilseeds,Springer,1992.

[13] BALA, B.K. Drying and storage of cereal

grains,SciencePublishers,1997.

[14] GARCAPREZ, J.A., CARCEL, J.V.,

GARCAALVARADO, M.A. AND MULET,

A. Simulation of grape stalk deepbed drying,

JournalofFoodEngineering 90,308314,2009.

[15]SOKHANSANJ,S.ANDBRUCE,D.M.A

conductionmodeltopredictgraintemperaturein

grain drying simulation, Transactions of the

ASAE30,11811184,1987.

[16] MIKETINAC, M. J., SOKHANSANJ, S.

AND TUTEK, Z. Determination of heat and

masstransfercoefficientsinthinlayerdryingof

grain,TransactionsoftheASAE35,18531858,

1992.

[17] SANDER, A. Thinlayer drying of porous

materials: Selection of the appropriate

mathematical model and relationships between

thinlayer models parameters, Chemical

Engineering and Processing 46, 13241331,

2007.

278

[18] PATANKAR, S. V. Numerical Heat

TransferandFluidFlow,HemispherePublishing

Corp,1980.

[19] MONTOYA E., OLIVEROS, C. AND

ROA, G. 1990. Optimizacin operacional del

secador intermitentede flujos concurrentes para

caf pergamino, Centro Nacional de

investigacionesdeCaf,CENICAFEColombia

41,1933,1990.

[20] TREJOS R., ROA, G. AND OLIVEROS,

C. Humedad de equilibrio y calor latente de

vaporizacin del caf pergamino y del caf

verde, Centro Nacional de investigaciones de

Caf,CENICAFEColombia40,515,1989.

[21] PEREZALEGRA, L.R., CIROV., H.J.

AND ABUD, L.C. Physical and thermal

properties of parchment coffee bean,

TransactionsoftheASAE44,17211726,2001.

[22] JARAMILLO B. G. Ecuacin de capa

delgada para caf pergamino, Centro Nacional

de investigaciones de Caf, CENICAFE

Colombia 41,103113,1990.

[23] FORTES, M. AND OKOS, M. R. A non

equilibrium thermodynamics approach to

transport phenomenon in capillary porous

bodies,Transactions ofthe ASAE24,756760,

1981.

[24]IRUDAYARAJ,J.ANDWU,Y.Numerical

modeling of heat and mass transfer in starch

systems, Transactions of the ASAE 42, 449

455,1999.

You might also like

- Holling, Goldberg - 1971 - Ecology and PlanningDocument11 pagesHolling, Goldberg - 1971 - Ecology and PlanningShreyas SrivatsaNo ratings yet

- EVS 1101 QuestionsDocument7 pagesEVS 1101 QuestionsJameson CongoNo ratings yet

- Mathematical Description of The Drying Rate of Fully Exposed CornDocument5 pagesMathematical Description of The Drying Rate of Fully Exposed CorngwodajeNo ratings yet

- 34 Mathematical Simulation of Corn DryingDocument5 pages34 Mathematical Simulation of Corn DryingNguyen Thu HaNo ratings yet

- CFD Drying SimulationDocument6 pagesCFD Drying SimulationAdonis A. ClosasNo ratings yet

- Article in Press: Heat and Mass Transfer in Apple Cubes in A Microwave-Assisted Uidized Bed DrierDocument9 pagesArticle in Press: Heat and Mass Transfer in Apple Cubes in A Microwave-Assisted Uidized Bed DrierJuan Camilo HenaoNo ratings yet

- Capacity Estimation of High-Temperature Grain Dryers - A Simplified Calculation MethodDocument17 pagesCapacity Estimation of High-Temperature Grain Dryers - A Simplified Calculation Methodmig26_peruNo ratings yet

- Model-Based Predictive Control of Greenhouse Climate For Reducing Energy and Water ConsumptionDocument22 pagesModel-Based Predictive Control of Greenhouse Climate For Reducing Energy and Water ConsumptionAyoubMoufidNo ratings yet

- Aic 11406Document18 pagesAic 11406haftomNo ratings yet

- Determination of Suitable Thin Layer Drying Curve Model For Some Vegetables and FruitsDocument10 pagesDetermination of Suitable Thin Layer Drying Curve Model For Some Vegetables and FruitsLe Quoc TuanNo ratings yet

- IOSR JournalsDocument7 pagesIOSR JournalsInternational Organization of Scientific Research (IOSR)No ratings yet

- Mathematical Modelling of Hot Air Drying of Sweet PotatoDocument11 pagesMathematical Modelling of Hot Air Drying of Sweet PotatoNEFTALI VAZQUEZ ESPINOSANo ratings yet

- Dialnet SimulacionDeUnSecadorContinuoDeLechoFluidizadoConF 5179451 PDFDocument10 pagesDialnet SimulacionDeUnSecadorContinuoDeLechoFluidizadoConF 5179451 PDFYusnita OniNo ratings yet

- Hybrid Solar-Gas-Electric Dryer Optimization With Genetic AlgorithmsDocument8 pagesHybrid Solar-Gas-Electric Dryer Optimization With Genetic Algorithmshicham El FeroualiNo ratings yet

- Vacuum Contact Drying of Crystals: Multi-Scale Modelling and ExperimentsDocument6 pagesVacuum Contact Drying of Crystals: Multi-Scale Modelling and ExperimentsNishant Kumar GuptaNo ratings yet

- A Model To Simulate Chopped Alfalfa Drying in Fixed Deep-BedDocument9 pagesA Model To Simulate Chopped Alfalfa Drying in Fixed Deep-BedobajemarthaNo ratings yet

- Design and CFD Analysis of Food Dryer UsDocument14 pagesDesign and CFD Analysis of Food Dryer UsShubham kumarNo ratings yet

- 38 Ijmperddec201838Document14 pages38 Ijmperddec201838TJPRC PublicationsNo ratings yet

- tmp4B41 TMPDocument7 pagestmp4B41 TMPFrontiersNo ratings yet

- Boundary Control Heat Exchanger3Document43 pagesBoundary Control Heat Exchanger3APRAJITA SRIVASTAVANo ratings yet

- Simulation Model For Heat Pump-Assisted Dehumidified Air Drying For Some HerbsDocument5 pagesSimulation Model For Heat Pump-Assisted Dehumidified Air Drying For Some HerbsRizki RahmadinNo ratings yet

- Science 6 (19) PDFDocument15 pagesScience 6 (19) PDFMaria Angélica Marques PedroNo ratings yet

- Ids 2022Document7 pagesIds 2022zhor El hallaouiNo ratings yet

- Batch Drying of Banana: Modelling and ExperimentsDocument6 pagesBatch Drying of Banana: Modelling and ExperimentsDaniel David ArangurenNo ratings yet

- Douglas Gomes-COBEM - Estendido - Rev - Com - 01Document8 pagesDouglas Gomes-COBEM - Estendido - Rev - Com - 01Douglas GomesNo ratings yet

- Comparison of On-Farm Forage-Dry-Matter Methods To Forced-Air Oven For Determining Forage Dry MatterDocument4 pagesComparison of On-Farm Forage-Dry-Matter Methods To Forced-Air Oven For Determining Forage Dry MatterStella CardosoNo ratings yet

- A037 With Cover Page v2Document6 pagesA037 With Cover Page v2Axel EspiiNo ratings yet

- J Buildenv 2006 04 027Document6 pagesJ Buildenv 2006 04 027Yetana WubnehNo ratings yet

- Experimental Study of Drying KineticsDocument10 pagesExperimental Study of Drying KineticsNguyễn Hoàng Minh TríNo ratings yet

- Solar DryerDocument5 pagesSolar DryersamadonyNo ratings yet

- Secado Con CFDDocument13 pagesSecado Con CFDCarlos CarinelliNo ratings yet

- Dynamic Discharge Simulation of Caves in Caes System-Huntorf Case StudyDocument8 pagesDynamic Discharge Simulation of Caves in Caes System-Huntorf Case StudyDouglas GomesNo ratings yet

- Heat and Mass Transfer Analysis of Banana Slices For Food Processing ApplicationsDocument6 pagesHeat and Mass Transfer Analysis of Banana Slices For Food Processing ApplicationsRahul HNo ratings yet

- A Mathematical Model of The Drying ProcessDocument4 pagesA Mathematical Model of The Drying Processlili&valiNo ratings yet

- Modeling and Control of A Mixed - Ow Rice Dryer With Emphasis On Breakage QualityDocument7 pagesModeling and Control of A Mixed - Ow Rice Dryer With Emphasis On Breakage QualityJason RichardsonNo ratings yet

- 2-Ruska LaszloözelikbuğdayDocument8 pages2-Ruska Laszloözelikbuğdayayşegül durmuşNo ratings yet

- International Journal of Engineering Research and Development (IJERD)Document6 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- A New Mathematical Method To Solve Highly Coupled Equations of Heat and Mass Transfer in Porous MediaDocument10 pagesA New Mathematical Method To Solve Highly Coupled Equations of Heat and Mass Transfer in Porous MediabrunoNo ratings yet

- Application of CFD Simulation in The Development of A New Generation Heating OvenDocument11 pagesApplication of CFD Simulation in The Development of A New Generation Heating OvenashwinsheriefNo ratings yet

- Exploitation of Artificial Neural Networks Approach To Predict The Thermal Conductivity of Food Products in NigeriaDocument8 pagesExploitation of Artificial Neural Networks Approach To Predict The Thermal Conductivity of Food Products in NigeriaAJER JOURNALNo ratings yet

- Current State of Automation Process of Convection Drying of Bulk MaterialsDocument6 pagesCurrent State of Automation Process of Convection Drying of Bulk MaterialsOpen Access JournalNo ratings yet

- Non-Linear Constrained MPC: Real-Time Implementation of Greenhouse Air Temperature ControlDocument12 pagesNon-Linear Constrained MPC: Real-Time Implementation of Greenhouse Air Temperature ControlenggsabiNo ratings yet

- Mathematical Simulation of Corn Drying - A New Model: T. L. Thompson, R. M. Peart and G. H. FosterDocument5 pagesMathematical Simulation of Corn Drying - A New Model: T. L. Thompson, R. M. Peart and G. H. FosterJuan Karlos Alberca AlfaroNo ratings yet

- Batch and Semibatch Reactor Performance For An ExothermicDocument8 pagesBatch and Semibatch Reactor Performance For An ExothermicGiorolongNo ratings yet

- 2005 - Identification of Human Gripping-Force Control From Electro-Encephalographic Signals by Artificial Neural NetworksDocument6 pages2005 - Identification of Human Gripping-Force Control From Electro-Encephalographic Signals by Artificial Neural NetworksademargcjuniorNo ratings yet

- Computational Analysis of Heat and Mass Transfer of Impinging Jet Onto Different Foods During The Drying Process at Low Reynolds NumbersDocument14 pagesComputational Analysis of Heat and Mass Transfer of Impinging Jet Onto Different Foods During The Drying Process at Low Reynolds NumbersShumaila RafiqueNo ratings yet

- Secado de SojaDocument4 pagesSecado de Sojayamid pismagNo ratings yet

- Evaluation of Compressed Air Adsorption Dryer WithDocument27 pagesEvaluation of Compressed Air Adsorption Dryer WithKarthikeyan VisvakNo ratings yet

- Dimensionless Mass Transfer CorrelationsDocument9 pagesDimensionless Mass Transfer CorrelationsLaura FrancoNo ratings yet

- Bixin DryingDocument7 pagesBixin DryingChristianWicaksonoNo ratings yet

- 2007 4026 Inagbi 11 01 3 EsDocument18 pages2007 4026 Inagbi 11 01 3 EsAlexandraOrtizRochaNo ratings yet

- An Experimental Analysis of A Solar Greenhouse Drier Computational Fluid Dynamics CFD ValidationDocument11 pagesAn Experimental Analysis of A Solar Greenhouse Drier Computational Fluid Dynamics CFD Validationkrunalgangawane85No ratings yet

- Compartment Model Approach: Mixing in Large Scale Aerated Reactors With Multiple ImpellersDocument12 pagesCompartment Model Approach: Mixing in Large Scale Aerated Reactors With Multiple ImpellersAngghisna Richard N.H.PNo ratings yet

- Mathematical Modeling and Simulation of Shrunk Cylindrical Material's Drying Kinetics-Approximation and Application To BananaDocument6 pagesMathematical Modeling and Simulation of Shrunk Cylindrical Material's Drying Kinetics-Approximation and Application To BananaNouha JhiderNo ratings yet

- PB2Document8 pagesPB2Thor L. LemmingerNo ratings yet

- PredictionDocument10 pagesPredictionlyncyberprintNo ratings yet

- Kinetics of Moisture Movement Air of Beet Root: SugarDocument11 pagesKinetics of Moisture Movement Air of Beet Root: SugarLê Minh Toàn SvdNo ratings yet

- Modelo MatematicoDocument8 pagesModelo MatematicodatinjacabNo ratings yet

- Anaerobic Digestion ManuscriptDocument17 pagesAnaerobic Digestion ManuscriptAaNo ratings yet

- Influence of Environmental Conditions On Drying Efficiency and Heat Pump Performance in Closed and Open Loop Drying of PaddyDocument15 pagesInfluence of Environmental Conditions On Drying Efficiency and Heat Pump Performance in Closed and Open Loop Drying of PaddyRackelyne UrbinoNo ratings yet

- Global Vegetation Dynamics: Concepts and Applications in the MC1 ModelFrom EverandGlobal Vegetation Dynamics: Concepts and Applications in the MC1 ModelDominique BacheletNo ratings yet

- Hydrothermal Analysis in Engineering Using Control Volume Finite Element MethodFrom EverandHydrothermal Analysis in Engineering Using Control Volume Finite Element MethodNo ratings yet

- WEP Energy Question BankDocument2 pagesWEP Energy Question BankAJ SkybornNo ratings yet

- TISE in One DimensionDocument5 pagesTISE in One DimensionJohnson LiuNo ratings yet

- FRP Ship RuleDocument103 pagesFRP Ship Rulereza84No ratings yet

- Westergaard Stress Solution Method PDFDocument2 pagesWestergaard Stress Solution Method PDFEmilia Elena MilutinoviciNo ratings yet

- Cebu City Department of ChemistryDocument7 pagesCebu City Department of ChemistryGeorgette RepunteNo ratings yet

- Chemtech GM Clear - English (Uk) - Issued.06.12.2007Document3 pagesChemtech GM Clear - English (Uk) - Issued.06.12.2007Mohamed Farag50% (2)

- SL No 2Document3 pagesSL No 2Chakravarthi NagaNo ratings yet

- Semiconductor ElectronicsDocument46 pagesSemiconductor Electronicspraveen2910No ratings yet

- Penetration Limits of Conventional Large Caliber Anti Tank - Kinetic Energy ProjectilesDocument9 pagesPenetration Limits of Conventional Large Caliber Anti Tank - Kinetic Energy ProjectilesSteve RothwellNo ratings yet

- Las Piñas Science High SchoolDocument2 pagesLas Piñas Science High Schooldeviehex0% (1)

- Sylgard HVIC Plus PDSDocument4 pagesSylgard HVIC Plus PDSProject Sales CorpNo ratings yet

- Introduction To Artificial Neural Network (ANN) Methods: What They Are and How To Use ThemDocument27 pagesIntroduction To Artificial Neural Network (ANN) Methods: What They Are and How To Use ThemavinashpatilNo ratings yet

- Tutorial On Scale UpDocument18 pagesTutorial On Scale Uphafizi naim IsmailNo ratings yet

- NSNSNSN SNJSJDocument53 pagesNSNSNSN SNJSJMayank VisalparaNo ratings yet

- Liste Des FiltresDocument6 pagesListe Des FiltresYacine MokhtariNo ratings yet

- Netzash BrochureDocument24 pagesNetzash BrochureYasin GençNo ratings yet

- Hummer's MethodDocument1 pageHummer's MethodPrajwal Bikram Thapa0% (1)

- Standards and ControlsDocument34 pagesStandards and ControlsamitbhmcNo ratings yet

- ACOUSTICS Enclosure Design OKDocument51 pagesACOUSTICS Enclosure Design OKcatanino100% (1)

- Latihan AmaliDocument14 pagesLatihan Amaliazman94No ratings yet

- Thesis Inter 1Document144 pagesThesis Inter 1Ayuni NirthiNo ratings yet

- Part 2 Microscopic World (I) LQ AnswersDocument17 pagesPart 2 Microscopic World (I) LQ AnswersWing LamNo ratings yet

- Termoplásticos Reforçados Usando Matérias Primas de Fontes Renováveis BiocompósitosDocument52 pagesTermoplásticos Reforçados Usando Matérias Primas de Fontes Renováveis BiocompósitosFERNANDO JOSE NOVAESNo ratings yet

- Thesis Title: "Designing of A Green Roof Engineering: Systems"Document7 pagesThesis Title: "Designing of A Green Roof Engineering: Systems"marlon moralesNo ratings yet

- Comparison of Standards For Cooling Water Pipes (IS3589 vs. API5L)Document17 pagesComparison of Standards For Cooling Water Pipes (IS3589 vs. API5L)Anonymous gr5Pr9AVNo ratings yet

- Q3 - GRADE 8 - Lesson Guide - 2023-2024Document4 pagesQ3 - GRADE 8 - Lesson Guide - 2023-2024Jasmine kNo ratings yet

- BromoDragonfly SynthDocument70 pagesBromoDragonfly SynthMartin Cortex Luley100% (1)