Professional Documents

Culture Documents

2 - TM 1703 ACP InstallManual - en

Uploaded by

Constantin NinovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 - TM 1703 ACP InstallManual - en

Uploaded by

Constantin NinovCopyright:

Available Formats

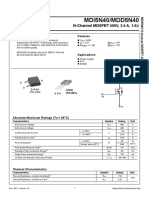

TM 1703 ACP

Installation

2005 by VA TECH SAT GmbH & Co

All rights reserved

Any type of disclosure and reproduction of this

document or of parts thereof is permitted only with

VA TECH SAT's prior written consent.

Technical specifications serve the purpose of

describing the products only and do not represent

any warranted characteristics in legal terms.

Subject to change - also as regards technological

aspects.

Identification TM_ACP_Install.103

Version.Revision 1.03

Issuing date 18.11.05

This document is applicable to the following product(s):

TM 1703 ACP

Note

In this document, for easy readability, is named as follows:

CP-6003 [GC6-003--] as CP-6003

CP-6003 [GC6-003-A] as CP-6003-A

ii DC6-015-1.03 Installation TM 1703 ACP

Table of Contents

Table of Contents

1. Introduction ........................................................................................................1-1

1.1. Purpose ....................................................................................................................................1-1

1.2. Conventions used.....................................................................................................................1-1

1.3. Target Group ............................................................................................................................1-1

1.4. Safety Information ....................................................................................................................1-2

1.5. Further Documents...................................................................................................................1-2

2. Architecture ........................................................................................................2-1

2.1. Mechanical Design ...................................................................................................................2-1

2.2. Configurations (Examples) .......................................................................................................2-2

2.2.1. 2 Peripheral Elements TM 1703 ACP, electrically connected .........................................2-2

2.2.2. 16 Peripheral Elements TM 1703 ACP, electrically connected .......................................2-3

2.2.3. 16 Peripheral Elements TM 1703 ACP, optically connected ...........................................2-4

2.2.4. 16 Peripheral Elements TM 1703 ACP, optically connected ...........................................2-5

3. Components .......................................................................................................3-1

3.1. Master Control Modules ...........................................................................................................3-1

3.2. Serial Interface Modules...........................................................................................................3-2

3.2.1. Serial Interface Processor (SIP) .......................................................................................3-2

3.2.2. Network Interface Processor (NIP) ...................................................................................3-3

3.2.3. Field Bus Interface Processor (FIP)..................................................................................3-3

3.3. Bus Interface Module................................................................................................................3-4

3.4. Peripheral Modules...................................................................................................................3-5

4. Assembly ............................................................................................................4-1

4.1. Necessary Material...................................................................................................................4-1

4.2. How and where can Installation take place? ............................................................................4-2

4.2.1. Installation Location ..........................................................................................................4-2

4.2.2. Installation Position ...........................................................................................................4-2

4.2.3. Space Requirement ..........................................................................................................4-3

4.2.4. Environmental Conditions.................................................................................................4-4

4.3. Installation of TS35 Rail (DIN Rail)...........................................................................................4-5

4.4. Installation of Cable Duct..........................................................................................................4-6

4.5. Installation of Master Control Element .....................................................................................4-7

4.5.1. Removal/Shifting of the Master Control Element..............................................................4-8

4.5.2. Securing Master Control Element against Slipping ..........................................................4-9

4.6. Installation of Bus Interface Modules .....................................................................................4-10

4.6.1. Optical Ax Bus ................................................................................................................4-10

4.6.1.1. Removing/Shifting the Optical Bus Interface Module .............................................4-11

4.6.2. Electrical Ax Bus .............................................................................................................4-11

4.7. Installing TM Modules.............................................................................................................4-12

4.7.1. Design and Elements of a Module..................................................................................4-12

4.7.2. Handling..........................................................................................................................4-13

4.7.3. Connection......................................................................................................................4-14

4.7.4. Order...............................................................................................................................4-15

5. Wiring Communication ......................................................................................5-1

5.1. Configuring Master Control Element with Serial Interface Modules (SIM)...............................5-2

5.1.1. Opening the Housing ........................................................................................................5-3

5.1.2. Removing/Fitting the SIM Retainer Clip CP-6003-A.........................................................5-4

5.1.3. Installing Patch Plugs and SIMs .......................................................................................5-4

5.1.4. Fixing the SIMs .................................................................................................................5-6

5.1.5. Configuration Notes ..........................................................................................................5-8

Installation TM 1703 ACP DC6-015-1.03 iii

Table of Contents

5.2. Wiring Communication............................................................................................................. 5-9

5.2.1. Serial Communication .................................................................................................... 5-10

5.2.1.1. Point-to-Point Traffic / Multi-Point Traffic via Dedicated Line Modem and WT

Channel Modem ..................................................................................................... 5-10

5.2.1.2. Multi-Point Traffic via Glass Fibre Optic and Star Connection............................... 5-11

5.2.1.3. Analog Dial-up Traffic............................................................................................. 5-12

5.2.1.3.1. Westermo TD35 Modem with external Power Supply .................................... 5-13

5.2.1.4. ISDN Dial-up Traffic ............................................................................................... 5-15

5.2.1.5. Dial-up traffic analog/GSM/ISDN............................................................................ 5-17

5.2.1.6. GSM Dial-up Traffic................................................................................................ 5-19

5.2.2. LAN Communication (Ethernet TCP/IP) ........................................................................ 5-21

5.2.3. Field Bus/Profi Bus Communication .............................................................................. 5-22

6. Wiring for the Reception of Time Signals........................................................ 6-1

6.1. DCF77 Receiver ...................................................................................................................... 6-1

6.2. GPS Satellite Receiver ............................................................................................................ 6-2

6.2.1. Wiring for the receipt of the minute pulse ........................................................................ 6-2

6.2.2. Wiring for the receipt of the serial time signal .................................................................. 6-3

6.3. LAN Time Server ..................................................................................................................... 6-5

7. Wiring Watchdog and Error .............................................................................. 7-1

8. Power Supply..................................................................................................... 8-1

8.1. Power Supply Master Control Element.................................................................................... 8-2

8.2. Power Supply Peripheral Element (Power Supply Module PS-6620) ..................................... 8-2

8.3. Power Supply Bus Interface Module (CM-0842) ..................................................................... 8-3

8.4. Fuse Protection........................................................................................................................ 8-3

8.5. Primary Mains Unit / Standard Type........................................................................................ 8-4

9. Wiring Peripheral Elements .............................................................................. 9-1

9.1. Master Control Element CP-6003-A Peripheral Control Module PE-6400 ......................... 9-2

9.2. Master Control Element CP-6003 Bus Interface Module CM-084x .................................... 9-3

9.3. Master Control Element CP-6003-A Bus Interface Module CM-084x ................................ 9-4

9.4. Bus Interface Module CM-0843 Peripheral Control Module PE-6400 ................................ 9-5

9.5. Bus Interface Module CM-0842 Peripheral Control Module PE-6401(2) ........................... 9-6

9.6. Bus Interface Module CM-0842 Bus Interface Module CM-0843 ....................................... 9-7

10. Wiring Process Peripherals ............................................................................ 10-1

10.1. Peripheral Connector............................................................................................................. 10-2

10.2. TE-6450 Wiring the Data Transmission.............................................................................. 10-3

10.3. Wiring of analog measured values ........................................................................................ 10-5

11. Shielding .......................................................................................................... 11-1

12. Protective Earthing / Grounding .................................................................... 12-1

13. Labelling........................................................................................................... 13-1

13.1. Labeling Master Control Element .......................................................................................... 13-2

13.1.1. CP-6003 ......................................................................................................................... 13-2

13.1.1.1. Equipment Identification, Region Number, Component Number ........................... 13-2

13.1.1.2. Plant- and Location Designation ............................................................................ 13-3

13.1.2. CP-6003-A...................................................................................................................... 13-3

13.1.2.1. Equipment Identification, Region Number, Component Number ........................... 13-3

13.1.2.2. Plant- and Location Designation ............................................................................ 13-4

13.2. Labeling Peripheral Element.................................................................................................. 13-5

13.2.1. Region Number, Component Number, PBA Number .................................................... 13-5

13.2.2. Plant- and Location Designation .................................................................................... 13-6

iv DC6-015-1.03 Installation TM 1703 ACP

Table of Contents

13.2.3. Equipment Identification (EI)...........................................................................................13-7

13.3. Terminal Labeling ...................................................................................................................13-8

13.4. Individual Terminal Point Labeling .........................................................................................13-9

13.5. Terminal Coding ...................................................................................................................13-10

14. Parameter Setting Preparation........................................................................14-1

14.1. Physical connection between Toolbox PC and TM 1703 ACP ..............................................14-1

14.1.1. Direct connection via toolbox cable ................................................................................14-2

14.1.2. Serial via modem ............................................................................................................14-3

14.1.3. Via Ethernet (TCP/IP, TELNET) .....................................................................................14-4

14.1.4. Via Ethernet (TCP/IP, TELNET) and Terminal Server (serial) .......................................14-5

14.2. Logical Connection between Toolbox PC und AK 1703 ACP ................................................14-6

14.3. Flash Card ..............................................................................................................................14-7

14.3.1. Inserting Flash Card........................................................................................................14-8

14.3.2. Withdrawing Flash Card..................................................................................................14-9

A. Readers Reactions........................................................................................... A-1

Installation TM 1703 ACP DC6-015-1.03 v

Table of Contents

Pictures

Pic. 2-1 TM 1703 ACP System Architecture ...................................................................................... 2-1

Pic. 2-2 TM 1703 ACP System Electrical Connection..................................................................... 2-2

Pic. 2-3 TM 1703 ACP System Electrical and Optical Connection ................................................. 2-3

Pic. 2-4 TM 1703 ACP System Electrical and Optical Connection ................................................. 2-4

Pic. 2-5 TM 1703 ACP System Electrical and Optical Connection ................................................. 2-5

Pic. 4-1 Possible installation positions ............................................................................................... 4-2

Pic. 4-2 Space requirement ................................................................................................................ 4-3

Pic. 4-3 TS35 rail screwed.................................................................................................................. 4-5

Pic. 4-4 Installing master control element .......................................................................................... 4-7

Pic. 4-5 Removing master control element ........................................................................................ 4-8

Pic. 4-6 Fixing master control element ............................................................................................... 4-8

Pic. 4-7 Securing master control element against slipping ................................................................ 4-9

Pic. 4-8 Installing Optical Ax Bus Interface Module ......................................................................... 4-10

Pic. 4-9 Removing Optical Ax Bus Interface Module ....................................................................... 4-11

Pic. 4-10 Elements of an I/O module.................................................................................................. 4-12

Pic. 4-11 Module installation............................................................................................................... 4-13

Pic. 4-12 Detailed picture of the guide ............................................................................................... 4-14

Pic. 4-13 Last module with protective cap and end bracket............................................................... 4-15

Pic. 5-1 Communication interfaces CP-6003 ..................................................................................... 5-1

Pic. 5-2 Opening the housing ............................................................................................................. 5-3

Pic. 5-3 Removing retainer clip for SIMs ............................................................................................ 5-4

Pic. 5-4 Identification of the slots........................................................................................................ 5-4

Pic. 5-5 Correct position of a patch plug in CP-6003 ......................................................................... 5-5

Pic. 5-6 Correct installation of a SIM in CP-6003 ............................................................................... 5-6

Pic. 5-7 Installing retainer clip for SIMs .............................................................................................. 5-6

Pic. 5-8 Correct installation of a SIM in CP-6003-A ........................................................................... 5-7

Pic. 6-3 Mount SM-0551 on SM-2556 ................................................................................................ 5-7

Pic. 5-9 Connection Dedicated Line Modem/Channel Modem - Master Control Element ............... 5-10

Pic. 5-10 Connection CP-6003 CM-0827 ........................................................................................ 5-11

Pic. 5-11 Connection Eurocom 24 Modem - Master Control Element ............................................... 5-12

Pic. 5-12 Cable Circuitry Master Control Element Eurocom 24 Modem ......................................... 5-12

Pic. 5-13 Connection TM 1703 ACP - Westermo TD35..................................................................... 5-13

Pic. 5-14 Cable Circuitry Master Control Element Westermo TD-35 ............................................. 5-14

Pic. 5-15 Connection ISDN Modem - Master Control Element .......................................................... 5-15

Pic. 5-16 Cable Circuitry Master Control Unit ISDN Modem........................................................... 5-16

Pic. 5-17 Connection TM 1703 ACP - Westermo ID-90 LV ............................................................... 5-17

Pic. 5-18 Cable Circuitry Master Control Unit Westermo ID-90 LV................................................. 5-18

Pic. 5-19 Connection GSM Modem - Master Control Element........................................................... 5-19

Pic. 5-20 Cable Circuitry Master Control Unit GSM Modem ........................................................... 5-20

Pic. 5-21 Connection Ethernet - Master Control Element .................................................................. 5-21

Pic. 5-22 Connection Field Bus/Profi Bus - Master Control Element ................................................. 5-22

Pic. 6-1 Wiring DCF77 Receiver ........................................................................................................ 6-1

Pic. 6-2 Minute pulse via GPS163 receiver........................................................................................ 6-2

Pic. 6-3 Serial time signal via GPS receiver....................................................................................... 6-3

Pic. 6-4 Cable wiring for serial time signal ......................................................................................... 6-3

Pic. 6-5 Wiring LAN Time Server ....................................................................................................... 6-5

Pic. 7-1 Wiring Watchdog and Error................................................................................................... 7-1

Pic. 7-2 Wiring Watchdog and Error (Example) ................................................................................. 7-1

Pic. 8-1 Supply master control element.............................................................................................. 8-2

Pic. 8-2 Supply Peripheral Element (Power Supply Module PS-6620).............................................. 8-2

Pic. 8-3 Supply Bus Interface Module ................................................................................................ 8-3

Pic. 9-1 Cabling CP-6003-A with peripheral control module PE-6400 ............................................... 9-2

Pic. 9-2 Cabling CP-6003 with Bus Interface Module CM-084x......................................................... 9-3

Pic. 9-3 Cabling CP-6003-A with Bus Interface Module..................................................................... 9-4

Pic. 9-4 Cabling Bus Interface Module CM-0843 with Peripheral Control Module PE-6400 ............. 9-5

vi DC6-015-1.03 Installation TM 1703 ACP

Table of Contents

Pic. 9-5 Cabling Bus Interface Module CM-0842 with Peripheral Control Module PE-6401 ..............9-6

Pic. 9-6 Cabling Bus Interface Module CM-0842 with Bus Interface Module CM-0843 .....................9-7

Pic. 10-1 Wired I/O modules ...............................................................................................................10-1

Pic. 10-2 External wiring in 3-wire technique ......................................................................................10-2

Pic. 10-3 Cable Clamping....................................................................................................................10-3

Pic. 10-4 TE-6450 External Circuitry...................................................................................................10-4

Pic. 10-5 Wiring of analog measured values.......................................................................................10-5

Pic. 11-1 Strain-relieved and grounded cable. ....................................................................................11-1

Pic. 12-1 Masseverbindung TM 1703 ACP - Montageblech ...............................................................12-1

Pic. 12-2 Masseverbindung TM 1703 ACP - TS35 Schiene ...............................................................12-1

Pic. 13-1 Labeling TM 1703 ACP........................................................................................................13-1

Pic. 13-2 CP-6003 with plate for Equipment Identification, Region- and Component Number ..........13-2

Pic. 13-3 CP-6003 with optional plate for Plant and Location.............................................................13-3

Pic. 13-4 CP-6003-A with plate for Equipment Identification, Region- and Component Number.......13-3

Pic. 13-5 CP-6003-A with optional plate for Plant and Location .........................................................13-4

Pic. 13-6 Peripheral element with plate for region-, component- and PBA number ...........................13-5

Pic. 13-7 Peripheral element with optional plate for Plant and Location.............................................13-6

Pic. 13-8 Equipment Identification.......................................................................................................13-7

Pic. 13-9 Module with terminal labeling...............................................................................................13-8

Pic. 13-10 Module with individual terminal point labeling......................................................................13-9

Pic. 13-11 Coded terminal...................................................................................................................13-10

Pic. 14-1 Direct connection via toolbox cable .....................................................................................14-2

Pic. 14-2 Connection via serial modems.............................................................................................14-3

Pic. 14-3 Connection via ethernet .......................................................................................................14-4

Pic. 14-4 Connection via ethernet and terminal server .......................................................................14-5

Pic. 14-5 Toolbox Engineering ............................................................................................................14-6

Pic. 14-6 Inserting Flash Card.............................................................................................................14-7

Pic. 14-7 Inserting Flash Card.............................................................................................................14-8

Pic. 14-8 Withdrawing Flash Card.......................................................................................................14-9

Installation TM 1703 ACP DC6-015-1.03 vii

Table of Contents

viii DC6-015-1.03 Installation TM 1703 ACP

Introduction

1. Introduction

1.1. Purpose

This handbook describes how the hardware of a TM 1703 ACP system is to be installed and which

preparations are to be made for the subsequent parameter settings.

Thereby the following points are described step-by-step:

N Conception of the architecture

N Installation of the hardware

N Label

N Wiring

N Parameter Setting Preparation

1.2. Conventions used

Hint

is important information about the product, the handling of the product or the respective part of the

documentation, to which special attention is to be given.

N Outputs visible on the screen are described in this font.

N Inputs via keyboard or mouse keys and visible on the screen are also described in this

font.

1.3. Target Group

This handbook is intended for persons who are entrusted with the design and installation of

TM 1703 ACP systems.

Installation TM 1703 ACP DC6-015-1.03 1-1

Introduction

1.4. Safety Information

This handbook contains information that you must observe for your own personal safety as well for the

prevention of property damage. The information is emphasized by a warning triangle and depending on

the degree of danger is represented as follows:

Danger

means that death, serious bodily injury or considerable property damage will occur, if

the appropriate precautionary measures are not carried out.

Warning

means that death, serious bodily injury or considerable property damage can occur, if

the appropriate precautionary measures are not carried out.

Caution

means that minor bodily injury or property damage could occur, if the appropriate

precautionary measures are not carried out.

Attention

means that property damage could occur, if the appropriate precautionary measures are not carried

out.

1.5. Further Documents

System Data Sheet TM 1703 ACP MC6-007-1

System Data Sheet CP-6003/CPC65 MC6-010-1

System Element Manual PE-640x/TCIO65 DC6-005-1

System Element Manual PE-640x/USIO65 DC6-010-1

TM 1703 ACP Operation and Service DC6-017-1

1-2 DC6-015-1.03 Installation TM 1703 ACP

Architecture

2. Architecture

2.1. Mechanical Design

A TM 1703 ACP system consists of one master control element, up to a maximum of 4 bus interface

modules (electrical and/or optical) and up to 16 peripheral elements.

A peripheral element consists of a power supply module, a peripheral control module and up to a

maximum of 8 I/O-modules. The modules are fitted on a TS35 rail (DIN rail).

Optionally the master control element can be configured with up to 2 serial interface modules (SIM) for

the communication with other automation units or control systems.

Master conrtol element Bus interface module (electrical) Bus interface modul (optical)

Max. 8 I/O-modules

TS35 rail

Peripheral control module (elektrical or optical)

Power supply module

Pic. 2-1 TM 1703 ACP System Architecture

Installation TM 1703 ACP DC6-015-1.03 2-1

Architecture

2.2. Configurations (Examples)

2.2.1. 2 Peripheral Elements TM 1703 ACP, electrically connected

CP-6003

.. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

..

Communication with .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

..

other automation units 2

.. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

..

.. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

..

.. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

..

.. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

..

1

.. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

..

.. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

.. .. .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. . .

.. .

..

I/O modules

Ax 1703 peripheral bus (electrical)

PE-6400

16 Mbps

PS-6620

USB cable, length up to 3 m

Pic. 2-2 TM 1703 ACP System Electrical Connection

2-2 DC6-015-1.03 Installation TM 1703 ACP

Architecture

2.2.2. 16 Peripheral Elements TM 1703 ACP, electrically connected

CP-6003

Note:

all in all up to 16 peripheral elements

1 ... 4

Communication with

other automation units

CM-0843

Ax 1703 peripheral bus (electrical) CM-0843

16 Mbps

patch cable, length up to 3 m

.. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

.

.. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

.

16

.. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

.

.. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. .

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

Ax 1703 peripheral bus (electrical)

15

16 Mbps

.. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. .

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

.

USB cable, length up to 3 m .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

.

.. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

.

1

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .. .

.. ..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

.

I/O modules

PE-6400

PS-6620

Pic. 2-3 TM 1703 ACP System Electrical and Optical Connection

Installation TM 1703 ACP DC6-015-1.03 2-3

Architecture

2.2.3. 16 Peripheral Elements TM 1703 ACP, optically connected

CP-6003

Note:

all in all up to 16 peripheral elements

1 ... 4

1 ..... 4

Communication with

other automation units

CM-0842 CM-0842

Ax 1703 peripheral bus (electrical)

16 Mbps

patch cable, length up to 3 m

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

.

16

.. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. . .

.. ..

. .. .

.. . .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. ..

..

.. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. . .

.. ..

. .. .

.. . .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. ..

..

Ax 1703 peripheral bus (optical)

15

16 Mbps, optical fibre,

.. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. . .

.. ..

. .. .

.. . .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. ..

..

length up to 200 m .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .. .

.. . .

.. ..

. .. .

.. . .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. ..

..

.. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. .

..

.. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. .

..

1

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. .

..

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. . .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. ..

.. .. .

.. ..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .. .

.. .

..

I/O modules

PE-6401

PS-6620

Pic. 2-4 TM 1703 ACP System Electrical and Optical Connection

2-4 DC6-015-1.03 Installation TM 1703 ACP

Architecture

2.2.4. 16 Peripheral Elements TM 1703 ACP, optically connected

CP-6003

Note:

all in all up to 16 peripheral elements

Ax 1703 peripheral bus (electrical)

Communication with 16 Mbps

other automation units patch cable, length up to 3 m

1 ... 4 1 ... 4

1 ..... 4

CM-0843

CM-0842 CM-0842 CM-0843

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

Ax 1703 peripheral bus (electrical) 16

16 Mbps .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

USB cable, length up to 3 m

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

15

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

1

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

I/O modules

PE-6400

PS-6620

Ax 1703 peripheral bus (optical)

16 Mbps, optical fibre,

length up to 200 m

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

16

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

15

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

1

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

.. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .. .

.. ..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

. .

..

.

PE-6401

PS-6620

Pic. 2-5 TM 1703 ACP System Electrical and Optical Connection

Installation TM 1703 ACP DC6-015-1.03 2-5

Architecture

2-6 DC6-015-1.03 Installation TM 1703 ACP

Components

3. Components

3.1. Master Control Modules

Designation Item Number

CP-6003-A Master Control Module GC6-003-A

CP-6003 Master Control Module GC6-003--

Installation TM 1703 ACP DC6-015-1.03 3-1

Components

3.2. Serial Interface Modules

3.2.1. Serial Interface Processor (SIP)

Designation Item Number

SM-2541 Serial interf.processor (MP) BA2-541

SM-2551 Serial Interface Processor 2 SS BC2-551

SM-0551 Ser. Interface Processor 2 SS BC0-551

3-2 DC6-015-1.03 Installation TM 1703 ACP

Components

3.2.2. Network Interface Processor (NIP)

Designation Item Number

SM-2554 Network Interface Ethernet 10/100TX (electrical) BC2-554

SM-2556 Ser.Interface+Ethernet 10/100FX BC2-556

3.2.3. Field Bus Interface Processor (FIP)

Designation Item Number

SM-2545 Profibus Interface (Master) BA2-545

Installation TM 1703 ACP DC6-015-1.03 3-3

Components

3.3. Bus Interface Module

Designation Item Number

CM-0843 Ax 1703 bus interface electrical GA0-843

Ax 1703-Bus-Interface 4x fiber optical GA0-842

3-4 DC6-015-1.03 Installation TM 1703 ACP

Components

3.4. Peripheral Modules

Designation Item Number

PS-6620 Power Supply Module 24-60 VDC GC6-620