Professional Documents

Culture Documents

Field Moisture and Density Testing With Nuclear Gauge

Uploaded by

Anonymous 59kjvq4OLBCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Moisture and Density Testing With Nuclear Gauge

Uploaded by

Anonymous 59kjvq4OLBCopyright:

Available Formats

VDOTSoilsandAggregateCompaction

6 FIELDMOISTUREANDDENSITYTESTING

WITHTHENUCLEARGAUGE

LEARNINGOUTCOMES

Understandthecomponentsofthenucleargaugeandhowitisusedtomeasuremoistureanddensity

Understandtheproceduresforevaluatingmoistureanddensityusingthedirecttransmissionmethod

Understandthebasicregulationsthatgovernthestorage,transport,anduseofthenucleargauge

Understandbasicmaintenancetechniquesandproceduresforemergencyresponse

INTRODUCTION

Afterplacement andcompactionoftheembankmentmaterialbythecontractor,theinspectorthenconductsa

fielddensitytestandafieldmoisturecontenttestonthelift.Theresultsofthesefieldtestsarecomparedtothe

target values (see Chapter 5) to determine if the contractor has met specificationsfor density and moisture

contentofthatlift.

Section 303.04(h) and 305.03(a) of 2007 Road and Bridge Specifications stipulates that field density

determinationsaretobeperformedinaccordancewiththefollowingAASHTOtests:

T191DensityofSoilinPlacebytheSandConeMethod

T310DensityofSoilinPlacebytheNuclearGauge

SOILDENSITYTESTINGFLOWCHART

SettingTargetValues

LaboratoryProctor

OnePointProctor RunningFieldTests

SpeedyMoistureTest

DryingMoistureTest

SandConeDensityTest

NuclearGaugeDensityTest

IsSpecificationMet?

Moisture(Yes/No)

Density(Yes/No)

2016v1.0Chapter6|1

VDOTSoilsandAggregateCompaction

TROXLER3440NUCLEARGAUGE(FORSOILSANDAGGREGATEMATERIAL)

2016v1.0Chapter6|2

VDOTSoilsandAggregateCompaction

DETERMININGFIELDDENSITY&MOISTURECONTENTWITHTHENUCLEARGAUGE

The NuclearMoistureDensity device (or Nuclear Gauge)is specificallydesignedto measurethe moistureand

densityofsoils,aggregates,cement,andlimetreatedmaterials,andtomeasurethedensityofasphaltconcrete.It

offerstheInspectorandContractoramethodofobtainingfast,accurateandinplacemeasurementofdensities

andmoisture. With suitable calibrations, the devicegivesresultswhichare comparableto thosegiven by the

SandConeorVolumeMeterTest.

Thedeviceusesasmallradioactivesourcewhichsendsradiationthroughthematerialbeingtested,givingdata

whichcanbecorrelatedtodensityand/ormoisture.Whilenoradiationhazardisimposedontheoperatorwhen

followingthenormalproceduresofuse,apotentialhazarddoesexistif improperly used. Threewaysto limit

exposuretoradiationaretime,distance,andshielding.

Before operating a nuclear gauge a person must pass a Nuclear Safety course and be issued a

thermoluminescent dosimeter (TLD) badge. The badge measures exposure to radiation and is to be worn

whenever operating a nuclear gauge. The TLD is to be stored at least 10 feet from the gauge. Two gauges

shouldnotbeoperatedwithin33feetofoneanother. Incaseofanaccident,maintaina20footradiusaround

theaccidentsite.

COMPONENTSOFTHENUCLEARGAUGE

Asmallradioactivesourceislocatedinthetipofthestainlesssteelrodwhichisprimarilyusedfordensitytesting,

whereasanothersourceislocatedinsidethedevicewhichisusedspecificallyfortakingmoisture determinations

simultaneously. The probe rod is capable of being moved to the various desireddepths,as shownonthe

followingpages.Thepositionsarestampedontheguiderodforeasydeterminationoftheproperdepths.

The 3440 Nuclear Gauge providesthree different count times to be used for taking readings.The 15 second

setting is recommended to be used only in the roller pattern test method (Backscatter Method). The one

minute setting is used for all embankment and subgrade materials.The four minute setting isgenerallyused

forcalibration.

2016v1.0Chapter6|3

VDOTSoilsandAggregateCompaction

TROXLER3440NUCLEARGAUGE(HANDLEPOSITIONS)

TROXLER3440NUCLEARGAUGE(BASEANDDISPLAYSCREEN)

2016v1.0Chapter6|4

VDOTSoilsandAggregateCompaction

NUCLEARGAUGETHEORYOFOPERATIONS

The Nuclear Gauge is specificallydesignedto measurethe moisturecontent and density of soils, aggregates,

cementandlimetreatedmaterials,andtomeasurethedensityof BituminousConcrete.It offers the inspector

a methodof obtaining fast, accurate,inplacemeasurementofdensityandmoisture.Withsuitablelaboratory

calibrations, and proper field operation ofthe gauge, the devicegivesresultswhichare comparableto those

givenbythesandconeorvolumemetertests.

Thetipofthesourcerodcontainsasmallradioactivesource(Cesium137)whichemitsgammarays. Detectors

in the base ofthe gauge measurethis radiationandcalculatethe density ofthematerial. Thegaugehastwo

modestomeasuredensity:thedirecttransmissionmodeandbackscattermode.

IntheDirectTransmissionmode,thesourcerodisinsertedintothematerialtobetestedtothedesireddepth

of test. The 6 inch depth is the most recommended depth for testing densities and moisture content

simultaneously in soils used in backfills, embankments and subgrade.The4inchdepthisusedforbackfilling

aroundpipeandabutmentswherehandtampingandpneumatictampingisused. The8inchdepthisonlyused

whenspecifiedonthecontract.

Inthe backscatter mode,the gauge is placedonthe material to be tested andthe sourcerodislockedinthe

first position below the SAFE position. Since the rod is flush with the bottom of the gauge and no hole is

required for the rod, the backscatter mode is used only in conjunction with the roller pattern/control strip

methodfor testing densitieson asphalt concreteand allaggregatematerialsuchasbase,subbase,andselect

materials.

2016v1.0Chapter6|5

VDOTSoilsandAggregateCompaction

Thegaugehasaninternalradioactivesource (Americium241: Beryllium) thatemitsneutrons which measure

the hydrogen to determine moisture content.Any position below the SAFEpositioncanbeusedtodetermine

moisturecontent.

Problems may arise when testing materials containing mica, boron, cadmium and chlorine or when testing

heavyclaysandorganicmaterial.ItispermissibletousetheSpeedyMoistureTestertoverifynuclearresults.

Like the conventionaltest, the operator mustcomparethe resultsfromthe nucleargauge to theonepoint

proctororlaboratoryproctor. Thenucleardensityiscomparedtothemaximumdrydensitytocalculatethe

percentdensityandthemoisturecontentfromthenucleargaugeiscomparedtotheoptimummoisturelimits.

PRETESTWARMUPPROCEDURESFORTHE3440NUCLEARGAUGE

The standardcountshouldbe taken daily before any testing is doneto checkgauge operation and allow the

gauge to compensate for natural source decay. The 3440 gauge should be turned on and allowedto go

throughtheselftest(RAMTEST)beforebeginning. (NOTE:Itisveryimportantthatthe RAMTESTdisplayhas

endedbefore proceeding. During the test, the screenwill displaya countdown from 300 seconds and then

displayREADYonthescreen.)

Place the reference block on a flat surface with a minimum density of 100 lbs/ft3 at least 10 feet from any

structure and 33 feet from any otherradioactivesource,inthesamemanneraswhenusinganyothermodel

gauge. Placethegaugeonthereferenceblock,makingsurethatitisseatedflatandwithintheraisededges,with

therightsideofthegaugepushedfirmlyagainstthemetalplateontheblock. PressSTANDARDonthefinger

keypadforthedisplay:

StandardCount

DS= PressYES

IstheGaugeSTD.Block&

MS= SourceinSAFEPos?

Takenewcount?

PressYES

DS=.%P

TakingStandardCount MS=.%P

secondsremaining. Doyouwanttousethe

newSTD?

PressYEStoenterthenewcountsintomemory. NOTE:IfthescreendisplaysanFinsteadofa%P,first

look to see if you are too close to any structure or another gauge. Then press NO and take a new set of

counts.Ifthesecondsetfails,pressYESandtakethree(3)newstandardcounts.Refer tothegaugemanual

formoredetailedinstructions.

2016v1.0Chapter6|6

VDOTSoilsandAggregateCompaction

2016v1.0Chapter6|7

VDOTSoilsandAggregateCompaction

NUCLEARTESTINGPROCEDURESFOREMBANKMENTS

A constructionproject presentsvarious situationsinwhich compactiondataisrequired. Depending upon the

materialtobetested,therearedifferenttestingmethodsthatcanbeusedtoobtainthedata.Onemethodis

used fortestingembankmentand subgrades;whileanother methodis usedforaggregate base, subbase, and

selectmaterialandasphaltconcrete.

When performing a test, some preliminary test information must be obtained by conducting aOnePoint

Proctor.ThistestestablishesthemaximumobtainableDryDensityandOptimumMoistureContentforparticular

embankmentmaterial.Thistestshouldberunwhilethecontractoriscompactingthesoillayertobetested.

Ifanappreciableamountof+4Material(rockfragment,gravel,shale,etc.)isnoticedinthesoillayer,refer to

VTM1andVTM12,forpropertestinginstructions.Contact theQuarryor theDistrictMaterialsDivisionfor

thespecificgravityofthe+4materialwhenencountered.

Embankment/SubgradeTestingProcedures(DirectTransmissionMethod)

1) Thetestsitemustbeproperlyselectedandprepared. Chooseatestsiteonthecompactedlayerof soil

(orsoilmixture)representedbythe OnePointProctorTest. StandardCountsshouldhavebeentaken

inthemorningandaregoodforthatentiredaysuse.

2) Turnthegaugeontoallowthedevicetowarmupbeforetestingistobegin.Thisshouldbedonewhile

thetestsiteisbeingpreparedfortesting.

3) Toobtainaccurateresults,thenucleardevicemustbeseatedflushagainstthecompactedlayerofsoil.

Level an area to place the device, either with a shovel or the scraper plate. If significant voids

remainin the area where the deviceis to be placed,the voidsshouldbe filledwith smallamountsof

soil common to the site, and lightly tamped in place with the scraper plate and excess material

removed.

4) TotakeaDirectTransmissionDensityTestandaMoistureTestfollowtheprocedurelistedbelow.

a) Placethedrillrodguideonthetestsiteandinsertthedrillrodintotheguidesleeve.Placeone

footonthedrillrodguidetokeepitinposition.Drivetherod2inchesdeeperthanthedepthof

test.

2016v1.0Chapter6|8

VDOTSoilsandAggregateCompaction

b) Carefullyremovetherodanddrillrodguide.Placethegaugeovertheholeandextendthesource

rodintotheholetotherequiredtestdepth.Thisshouldbedoneinamannerwhichpreventsthe

sourcerodfromdisturbingthesidesofthehole.

c) Makesurethatthegaugeisrestingflushonthesurfaceandthatthesourcerodisinthelocked

position. Gentlypullon thegaugehousingsothat theextended sourcerodwillbetightagainst

thehole.

d) Confirmthat the gauge is onandthenpress TIME on the keypad and select one minute. The

displaypanelwillreadCOUNTTIME1min.andthen returntoREADY. PressingSHIFT8 on

thekeypadwillallowyoutoselecttheSoilsModeandthedisplaywillreadREADY.

e) To begin the test, press START/ENTER. After the gauge completes its count, the display will

show%PR(PercentCompaction),DD(Dry Density),WD(WetDensity),M(Moisture)and

%M (Moisture Content). Record these figures on the Fo r m TL124 (Report on Nuclear

EmbankmentDensities).

f) Now that the direct transmission and moisture tests are completed, gently retract handle to

2016v1.0Chapter6|9

VDOTSoilsandAggregateCompaction

the safe position, turn the power switch off, return the device to the field carrying case, and

finishcompletingtheFormTL124(ReportonNuclearEmbankmentDensities).

TakingtestsintheBackscatterPosition(AsphaltandAggregateOnly):

5) If for any reason a backscatterdensity and moisture test is required by the Materials Engineer or

representativeoftheMaterialsDivision,followtheprocedurelistedbelow:

a) Place the device on the prepared test site and lower the handle to the BackscatterPosition.

b) WiththeTIMEseton1minute,presstheSTART/ENTERbutton.

c) WhenthedisplayappearsrecordtheresultsontheFormTL124.

OnlyusethismethodoftestwheninstructedbyDistrictMaterialsTechnicians.

NOTE:When making density tests in close places, such as trenches and sidewalls,backgroundeffects

willbeencounteredthatwillgiveincorrectdensitymoisturereadings.Ifthisoccurs,seeinstructionsfor

backgroundcalculationsonPage618ofthischapter.

FillingouttheFormTL124:

1) Fill in LineE (MaximumDry Density) whichis transferredfromLineG of the OnePoint Proctor (Form

TL125).

2) FillinLineF(OptimumMoisture)whichistransferredfromLineHoftheOnePointProctor(FormTL125).

3) FillinLinesAthroughDandLineJusingtheinformationonthe3440NuclearGaugeDisplayScreen.

4) FillinLineK(PercentMinimumDensityRequired). DensityRequirementsarelocatedinAppendixC.

5) CalculatethePercentDensity(LineJ)bydividingtheDryDensity(LineC)bytheMaximumDryDensity

(LineE)andthenmultiplyingby100.

Lines G, H & I are only used when +4 Material has been encountered. When 10% or more +4 Materialis

encountered, the Dry Density (Line C) is divided by the Corrected Maximum Dry Density (Line H) and then

multipliedby100toobtainedthepercentcompaction. (SeeLineJ.)

Alsowhen10%ormore+4Materialisencountered,itisnecessarytodoamoisturecorrectionwhichwillbe

enteredonLineI. ThiswillbediscussedinChapter7.

2016v1.0Chapter6|10

VDOTSoilsandAggregateCompaction

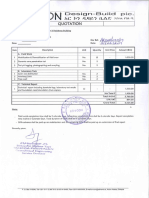

FormTL124(Rev.07/15)

VIRGINIADEPARTMENTOFTRANPORTATION

MATERIALSDIVISION

REPORTONNUCLEAREMBANKMENTDENSITIES(UNITMASSES)

ReportNo. 121A1 Date 06/22/2015 SheetNo. 1 of 1

RouteNo. 17 County Campbell

ProjectNo. 0017015104,C503

FHWANo. None

Testingfor Embankment

ModelNo. 3440 SerialNo. 23456 CalibrationDate 02/10/2015

STANDARDCOUNTDATA

Density 2830 Moisture 701

TestNo. 1 2 3 4

Location Stationft.(m) 585+00

of Ref.tocenterlineft.(m) at.C/L

Test Elevation +8/4

CompactionDepthofLiftin.(mm) 6

MethodofCompaction Sheepsfoot

A. WetDensity(lbs/ft3),WetUnitMass(kg/m3) =

3 3

B. MoistureUnitMass(lbs/ft orkg/m ) =

C. DryDensity(lbs/ft3),DryUnitMass(kg/m3)(AB) =

D. MoistureContent(BC)x100 =

3 3

OnePointProctorResults

E. MaximumDryDensity(lbs/ft ),DryUnitMass(kg/m )

= 124.2

Max.DryDensity(TL125LineG)

LabProctororOnePointProctor

10.7 OptimumMoisture(TL125LineH)

F. PercentOptimumMoisturefromLaborOnePointProctor =

8.612.8

G. PercentofPlus#4,(plus4.75mm) =

3 3

H. CorrectedMax.DryDensity(lbs/ft ),DryUnitMass(kg/m ) =

I. CorrectedOptimumMoisture =

3 3

J. PercentDryDensity(lbs/ft ),DryUnitMass(kg/m )

=

(CE)x100or(CH)x100

K. PercentMinimumDensityRequired =

Comments:

BY:

TITLE:

2016v1.0Chapter6|11

VDOTSoilsandAggregateCompaction

FormTL124(Rev.07/15)

VIRGINIADEPARTMENTOFTRANPORTATION

MATERIALSDIVISION

REPORTONNUCLEAREMBANKMENTDENSITIES(UNITMASSES)

ReportNo. 121A1 Date 06/22/2015 SheetNo. 1 of 1

RouteNo. 17 County Campbell

ProjectNo. 0017015104,C503

FHWANo. None

Testingfor Embankment

ModelNo. 3440 SerialNo. 23456 CalibrationDate 02/10/2015

STANDARDCOUNTDATA

Density 2830 Moisture 701

TestNo. 1 2 3 4

Location Stationft.(m) 585+00

of Ref.tocenterlineft.(m) at.C/L

Test Elevation +8/4

CompactionDepthofLiftin.(mm) 6

NuclearGaugeDisplayPanel

MethodofCompaction Sheepsfoot

%PR=97.0%

3 3

A. WetDensity(lbs/ft ),WetUnitMass(kg/m ) = 133.3 DD=120.5

3 3 WD=133.3

B. MoistureUnitMass(lbs/ft orkg/m ) = 12.8

M=12.8M%=10.6

3 3

C. DryDensity(lbs/ft ),DryUnitMass(kg/m )(AB) = 120.5

D. MoistureContent(BC)x100 = 10.6

3 3

E. MaximumDryDensity(lbs/ft ),DryUnitMass(kg/m )

= 124.2

LabProctororOnePointProctor

10.7

F. PercentOptimumMoisturefromLaborOnePointProctor =

8.612.8

PercentDensity

G. PercentofPlus#4,(plus4.75mm)

=

ProvidedbyGauge(%PR=97.0%)

3 3

H. CorrectedMax.DryDensity(lbs/ft

),DryUnitMass(kg/m ) =

Or

I. CorrectedOptimumMoisture

ManuallyCalculate =

3 3 DensityRequirement

J. PercentDryDensity(lbs/ft ),DryUnitMass(kg/m )

(LineC)(LineE)x100

= 97.0

(CE)x100or(CH)x100

(120.5124.2)x100=97.0% SeeAppendixC

K. PercentMinimumDensityRequired = 95.0

Comments:

BY:

TITLE:

2016v1.0Chapter6|12

VDOTSoilsandAggregateCompaction

DoestheMaterialmeetspecification?

Theactualdensityspecificationwillvarywiththeverticallocationofthematerialintheembankmentandwith

theamountof+4Materialwithinthefill(seebelow).

FinishedGrade

TopofEarthwork

PavementSection

(Subgrade)

(Asphalt&Aggregate)

SubgradeMaterial

6

(100%DensityRequired)

EmbankmentMaterial(OtherthanSubgrade)

(95%DensityRequired)

2016v1.0Chapter6|13

VDOTSoilsandAggregateCompaction

CORRECTINGFORHIGHMOISTUREREADINGS

As stated previously, theNuclearGaugeisspecificallydesignedtomeasurethemoisturecontent and

densityofsoils,aggregates,cementandlimetreatedmaterials.Thegaugehasaninternalradioactive

source(Americium241:Beryllium)anditusesthissourcetodeterminemoisturebyreleasingfastneutrons into

the compacted material. These fast neutrons are then slowed down, or thermalized, when they

interact with the nucleus of hydrogen, a key ingredient of the water molecule. However, some soils

(i.e. micaceous soils) contain highlevels of naturally bound hydrogen, which increases the

thermalization process. The gauge misinterprets this naturally bound hydrogen as excessive

moisturecontent.SucherrorsinmeasurementcanleadtoafalseDryDensityreading,whichinturn

may result in a false low or failing Percent Density value. When this situation arises, it is up to the

technician to correct the moisture and density reading using the following process and standard

calculations.

ExampleProblem:

Anucleartestconductedonahydrogenrichsoilhasproduced

false Moisture (M = 18.1, M% = 15.0) and Dry Density (DD = NuclearGaugeDisplayPanel

120.9) readings. These false readings in turn have prompted a %PR=93.5%

failingPercentDensityvalue(%PR=93.5%).

DD=120.9

3 WD=139.0

MaximumDryDensity=129.3lbs/ft

OptimumMoistureContent=9.2% M=18.1M%=15.0

OptimumMoistureRange(20%)=7.411.0%

MinimumDensityRequired=95.0%

SpeedyDialReading=8.9

ProceduralStepsforCorrectingtheMoistureandDryDensityReadings(FormTL124)

1) ConductaSpeedyMoistureTesttodeterminethecorrectMoistureContent(M%).

2) Adjust the Dry Density (Line C) by the dividing the original Wet Density (Line A) by the corrected

MoistureContent(M%)plus1.[DD=WD/(1+M%)]

3) AdjusttheMoistureUnitMass(LineB)bysubtractingthecorrectedDryDensityvaluefromtheoriginal

WetDensityvalue(LineA).[MM=WDDD]

4) Adjust the Percent Density (Line J) by dividing the corrected Dry Density value by the Maximum Dry

Densityvalue(LineE)andthenmultiplyingby100.[%PR=(DDMax.DD)x100]

2016v1.0Chapter6|14

VDOTSoilsandAggregateCompaction

FormTL124(Rev.07/15)

VIRGINIADEPARTMENTOFTRANPORTATION

CORRECTINGFORHIGHMOISTUREREADINGSUSINGTHESPEEDY

MATERIALSDIVISION

MOISTUREDEVICE

REPORTONNUCLEAREMBANKMENTDENSITIES(UNITMASSES)

ReportNo. 121A1 Date 06/22/2015 SheetNo. 1 of 1

RouteNo. 17 County Campbell

ProjectNo. 0017015104,C503

FHWANo. None

Testingfor Embankment

ModelNo. 3440 SerialNo. 23456 CalibrationDate 02/10/2015

STANDARDCOUNTDATA

Density 2830 Moisture 701

TestNo. 1 2 3 4

Location Stationft.(m) 585+00

of Ref.tocenterlineft.(m) at.C/L

Test Elevation +8/4

CompactionDepthofLiftin.(mm) 6

NuclearGaugeDisplayPanel

MethodofCompaction Sheepsfoot

%PR=93.5%

3 3

A. WetDensity(lbs/ft ),WetUnitMass(kg/m ) = 139.0 DD=120.9

MoistureContentissuspectedto

3beincorrectduetosoilproperties WD=139.0

B. MoistureUnitMass(lbs/ft orkg/m3) = 18.1

orconditions M=18.1M%=15.0

3 3

C. DryDensity(lbs/ft ),DryUnitMass(kg/m )(AB) = 120.9

D. MoistureContent(BC)x100 = 15.0

3 3

E. MaximumDryDensity(lbs/ft ),DryUnitMass(kg/m )

= 129.3

LabProctororOnePointProctor

9.2

F. PercentOptimumMoisturefromLaborOnePointProctor =

7.411.0

G. PercentofPlus#4,(plus4.75mm) =

H. CorrectedMax.DryDensity(lbs/ft3),DryUnitMass(kg/m3) =

FailingPercentDensityissuspected

I. CorrectedOptimumMoisture

tobeincorrectduetofalsehigh =

3 moisturereadings3

J. PercentDryDensity(lbs/ft ),DryUnitMass(kg/m )

= 93.5

(CE)x100or(CH)x100

K. PercentMinimumDensityRequired = 95.0

Comments:

BY:

TITLE:

2016v1.0Chapter6|15

VDOTSoilsandAggregateCompaction

FormTL124(Rev.07/15)

VIRGINIADEPARTMENTOFTRANPORTATION

CORRECTINGFORHIGHMOISTUREREADINGSUSINGTHESPEEDY

MATERIALSDIVISION

MOISTUREDEVICE

REPORTONNUCLEAREMBANKMENTDENSITIES(UNITMASSES)

ReportNo. 121A1 Date 06/22/2015 SheetNo. 1 of 1

RouteNo. 17 County Campbell

ProjectNo. 0017015104,C503

FHWANo. None

Testingfor Embankment

ModelNo. 3440 SerialNo. 23456 CalibrationDate 02/10/2015

STANDARDCOUNTDATA

Density 2830 Moisture 701

TestNo. 1 2 3 4

Step3AdjustMoistureMass

Location Stationft.(m) 585+00

of MM=WDDDRef.tocenterlineft.(m) at.C/L

Test MM=139.0126.6 Elevation +8/4

3

CompactionDepthofLiftin.(mm) MM=12.4lbs/ft 6

MethodofCompaction Sheepsfoot

3 3

A. WetDensity(lbs/ft ),WetUnitMass(kg/m ) = 139.0

Step2AdjustDryDensity

B. MoistureUnitMass(lbs/ft3orkg/m 3

) = 18.1 12.4

3 DD=WD(1+M%)3

C. DryDensity(lbs/ft ),DryUnitMass(kg/m

)(AB) = 120.9 126.6

DD=139.0(1+0.098)

D. MoistureContent(BC)x100

3 = 15.0 9.8

DD=126.6lbs/ft

3 3

E. MaximumDryDensity(lbs/ft ),DryUnitMass(kg/m )

= 129.3

LabProctororOnePointProctor

9.2

F. PercentOptimumMoisturefromLaborOnePointProcter =

Step1ConductaSpeedyMoistureTest 7.411.0

tocorrectMoistureContent

G. PercentofPlus#4,(plus4.75mm) =

H. CorrectedMax.DryDensity(lbs/ft3),DryUnitMass(kg/m3) =

I. CorrectedOptimumMoisture =

3 Step4CorrectPercentDensity

3

J. PercentDryDensity(lbs/ft ),DryUnitMass(kg/m

)

= 93.5 97.9

(CE)x100or(CH)x100 %PR=(DDMax.DD)x100

K. PercentMinimumDensityRequired

%PR=(126.6129.3)x100 = 95.0

%PR=97.9%

Comments:

BY:

TITLE:

2016v1.0Chapter6|16

VDOTSoilsandAggregateCompaction

BACKGROUNDCALCULATIONSFORTRENCHANDSIDEWALLMOISTURETESTING

When a 3440 Nuclear Gauge is operated within 24 inches of a vertical structure the density and moisture

counts will be affected due to gamma photons and neutrons echoing off the walls of the structure. Itis

necessary to perform a trench offset when testing backfill material around pipe culverts, abutments, near a

building,etc.Thiscorrectionshouldbeperformedeachdayandwhentrenchwallconditions(distancefromwall,

moisturecontent,materialcomposition,etc.)vary.

Theproceduretodeterminethebackgroundeffectandapplythenecessarycorrectionisasfollows:

1) TakethedailystandardcountwiththegaugeontheStandardBlockoutsidethetrenchandrecordthe

densityandmoisturevalues.

2) PlacethegaugeontheStandardBlockinsidethetrenchinthetestingareaandpressOFFSETonthe

displaypanel and select No. 3 TRENCHOFF.The gauge will show Trench Offset Disabledand ask if

you want to use Trench Offset. Press YES. The gauge will show trench offset for moisture and

density and ask if you want to change. Press YES to perform a new offset and NO to use the

existingoffsetconstants.Ifyouselectedyes,thegaugewillpromptyoutopressSTARTfor1minute

Standard Counts in the trench. Make sure to take counts the same distance from the wall as the

anticipated test readings. The density and moisture trench offset constants will be calculated and

stored. Whenthegaugeisnottobeusedfortrenchmeasurements,disabletheoffset.

2016v1.0Chapter6|17

VDOTSoilsandAggregateCompaction

SELFREGULATIONS&THEVDOTLICENSE

VDOT has a MaterialsLicenseissued by the Virginia Department of Health (VDH). The VDH is responsiblefor

ensuring the safety of people who work with radioactive byproduct materials and the security of such

materials. To control the risks associated with the use of nuclear byproduct materials, the VDH sets strict

health and safety standards for nuclear equipment, defines allowable limits for radiation exposure and

frequently conducts inspections of nuclear products and facilities. The VDH enforces the Code of Federal

Regulations ( C F R ) andallapplicablestaterequirementsgoverningtheuseofradioactivebyproductmaterials.

ThecodesareFederalandstatelawandtheyarebindinguponlicenseestouphold.

In addition to the CFR, licensees are governed by the provisions outlined in the license authorizing the

possessionofbyproductmaterial. ThepossessionofalicenseobligatestheDepartmenttoscrupulouslyperform

the actionsitstateditwouldperform to comply with the requirementsof it license. This commitmentis the

conditionunderwhichthe Department isable to receiveandthen retain the license. Failure to complycould

meana severefine,loss of license,or both, together with the potential consequences of bad publicity. The

provisionsofthelicensearejustascompellingastheCFRandgovernnuclearsafety.

Possession of a VDH license requires the licensee to adhere to safe practices and act asselfregulatorinthe

enforcement of regulations. This Agency is compelled to report its own infraction of rules to the VDH. To

enforce these safety regulations, periodic checks on theprogramtoseethatVDOTsemployeesarefollowing

the Departments instructions and radiation safety rules are an essential part of nuclear gauge safety and

effectiveprogrammanagement.VDOThasestablishedasystemofrecordscoveringthereceiptandtransferof

nuclear gauges. We must maintain records of radiation exposure of persons working in the program and

surveysareconductedtoevaluatetheeffectivenessofradiationsafetyprograms.

2016v1.0Chapter6|18

VDOTSoilsandAggregateCompaction

NUCLEARGAUGESTORAGEREQUIREMENTS

1) Radioactive Material signs shall be posted in the storage unit on the inside of the door in

accordancewithVirginiaDepartmentofHealthRadiationProtectionRegulations.

2) TheFormNoticetoEmployees,shallbepostedontheprojectbulletinboardwherethe nuclear gauge is

assigned, in accordance with Virginia Department of HealthRadiationProtectionRegulations.

3) The radioactive source when not in use and when left unattended shall be storedandsecured(locked,

bolted, etc.) at all timesagainst unauthorized removalfrom the storageplace,inaccordancewithVirginia

DepartmentofHealth Radiation Protection Regulations.ThemagentaandyellowFEDERALOFFENSEsign

shallbepostedonthelockedbluecarryingcasewhilethenucleargaugeisbeingstored.Theintentofthis

signistodiscouragethetheftofthegauge.

4) VDOT requires that an outside storage facility be used and that it be at least 10 feet from personnels

permanentworkstation(desk).SeeRoadandBridgeSpecifications,Section514.02(c).

5) ThenucleargaugeandTLDs(FilmBadge)storedshallbeatleast10feetapart.Badges shall be stored in

designatedareainsideprojecttrailer.

6) Therequiredrecordsoftransfershallbecompletedwhenthenucleargaugeisintransitontheprojectsite

by using log sheet locatedin the storage facility on the projectsite, or movedfromone assignedarea to

anotherorwhentransferredtoanotherlicense.

NUCLEARGAUGECALIBRATIONS

Thesourcedecaysatarateof2.2%peryearandtheelectronicshaveaminoramountofdriftfromagingparts.

Therefore,gauges are calibrated in the laboratory at least yearly under controlledconditionsusing the same

methodsoftestingasinthefield. Thegaugesarecalibratedonaseriesofblocksofknowndensityandmoisture

contents.

2016v1.0Chapter6|19

VDOTSoilsandAggregateCompaction

NUCLEARGAUGEMAINTENANCE

Thesourcerodinthe3400SeriesissupportedinlinearbearingspackedwithMagnalubeGgrease.Thegreaseis

retainedwithinthebearingsandthesoilkeptoutbyasystemofwipersandsealsatthetopandbottomofthe

centerpostofthegauge.Thesebearingswillrequirelittleornoservice,unlessthegaugeisoverhauled.Donot

lubricate.

Onthebottomsurfaceofthegaugeisaremovableplatewithabrassscraperringmountedinit.Thisringwill

remove most of the soil from the source rod. However, under some soil conditions, small amounts will be

carriedintotheslidingshieldassembly.Ifallowedtobuildup,thissoilcancausewearintheshieldcavityand

canultimatelybeforcedintothebearingsandruinthem.

Cleaning the cavity is relatively simple. Place the gauge on its side on a bench with the base away from the

operator.ThesourcerodshouldbelatchedintheSAFEposition.UsingaPhillipsscrewdriver,removethefour

screwsholdingthebottomplateassemblyinpositionandpryouttheassemblyusingaflatbladescrewdriver.

Usingthesametool,removetheslidingblockandspring.

Usingarag,stiffbrushandcompressedair,ifavailable,removeallsoilandwipecleanthecavity,slidingblock

andbottomplateassembly.Inspectallitemsforexcessivewearandreplaceifrequired.Checkthescraperring

toinsurethatitisfreetomoveinitsgroove.Iftheringisdamaged,itmaybereplacedorreplacetheassembly.

Thecleaningtimewilltakenolongerthanfive(5)minutes.

NuclearGaugeCleaningProcedures

1) Standingbehindthegaugewiththesourcerodpointingawayfromyou,placethegaugeonits

endandremovethescrewsfromthebottomplate.

2016v1.0Chapter6|20

VDOTSoilsandAggregateCompaction

2) Removethebottomplateandthetungstenslidingblockthatshieldsthesourcerod.

3) Cleantheareaaroundthetungstenslidingblock.Then,cleanandpolishthefaceoftheblocktoremove

allroughsurfaces.Donotgethandsnearthesourcerod.

2016v1.0Chapter6|21

VDOTSoilsandAggregateCompaction

4) Replacetheblockandplate.Cleanthegaugeanytimethatdifficultyisencounteredwhentryingtolower

and/orraisethesourcerod.

BatteryChargingforModel3440

A fully charged battery will last approximately 8 weeks under normal working conditions (8 hours/day). The

3440 display panel will give you the hours remaining on the current charge and, when it is running low, the

screenwilldisplayBATTERIESLOW!Youstillhaveafewhoursleftwhenthisdisplayoccursinordertofinishthe

currenttesting.Atthecompletionofthedaystestinghowever,thegaugeneedstobepluggedinovernightto

fullyrecharge.

IMPORTANT:Onlyrechargewhenthegaugeindicatesthatitislow.Needlessrechargingwillshortenthebattery

life.

AlkalineBatteryUse

Alkalinebatteriesmaybeusedwhenrechargingisnotanoption.Thegaugehasaseparatebatterycaseforthis

purpose.Refertomanualforfurtherinstructions.

CAUTION:Nevermixalkalineandrechargeablebatteriesinthegauge.Theymayexplodewhencharging!!!

2016v1.0Chapter6|22

VDOTSoilsandAggregateCompaction

INSTRUCTIONSTOFOLLOWINTHEEVENTOFANACCIDENT

DONOTDISCUSSINCIDENTWITHANYONEEXCEPTPOLICE,STATEMATERIALS

PERSONNEL,ANDYOURIMMEDIATESUPERVISOR.

(TheDistrictPublicRelationsSpecialistmustaddressallnewsmediaquestions)

1) Stopanddetainallequipmentorvehiclesinvolveduntiltheassessmentcanbemadetodetermineifthereis

anycontamination.Ifavehicleisinvolved,notifythelocalandstatepolice.Letthemknowthatradioactive

materialsareinvolved.Segregateanddetainallpersonsinvolved.

2) Assessandtreatlifethreateninginjuriesimmediately.Donotdelayadvancedlifesupportifvictimscannot

be moved. Move victims away from the radiation hazard area if possible, using proper patient transfer

techniquestopreventfurtherinjury.Staywithinthecontrolledareaifcontaminationissuspected.

3) Prohibiteating,drinking,orsmokingbypersonswhileattheaccidentscene.

4) Locatethegaugeandorsource,seeattachedchecklist.

5) Immediatelycordonoffatleasta20feetradiussurroundingthegaugeandparts,ifany.Keeponlookers

andallunnecessarypersonnelatasafedistance,whilecaringfororrescuinganypersonswhoareinjured.

6) Notify the nearest Radiation Safety Officer of the license holder to come and monitor the device to

determineifthereispossibleleakage.Givegooddirectionsastolocationofaccident.

7) Never let anyone remove the gauge, equipment or any articles that are involved in the accident until the

areahasbeenclearedbyamonitoringteam.

8) CompletetheNuclearAccidentChecklistlocatedintheBillofLadingaftertheRSOormonitoringteamhas

arrivedandassessedthesituation.TheEmergencyNotificationListisalsointheBillofLading.

2016v1.0Chapter6|23

VDOTSoilsandAggregateCompaction

NUCLEARGAUGETESTINGFLOWCHART

PretestandWarmUpProcedures

1) CleanGauge(IfNeeded)

2) WarmUpGauge(300seconds)

3) PerformStandardCount

(Mustbeperformeddaily)

4) ChargeBatteries(ifneeded)

(16hourminimumexceptinemergency,such

asRollerPattern)

SoilsTestingEquipment AggregateTestingEquipment

1) FilmBadge 1) FilmBadge

2) BillofLading 2) BillofLading

3) ScraperPlate 3) ScraperPlate

4) DrillRod 4) DrillRod

5) ExtractionTool 5) ExtractionTool

6) Hammer 6) Hammer

7) ProctorData 7) Proctor/TargetDensityData

8) ProperForm(i.e.TL124) 8) ProperForms(i.e.TL53,etc.)

SoilsTestingSitePreparation AggregatesTestingSitePreparation

1) ConstructionPlans(asanaidin 1) Chooserepresentativesite(notanarea

choosingtestsitesinproposedfills) withonlycoarseoronlyfinematerial)

2) Bladeoffarea(fillinvoidswith4 2) Donotfallintoasettestingroutine

material) (randomizetestingpatternsand

frequency)

AggregateTestingProcedures

SoilsTestingProcedures

1) Settimecontrol(1minuteforall

1) Settimecontrol(1minuteforall

testingexceptRollerPatterns)

testingexceptRollerPatterns)

2) PushStartbutton

2) Pullgaugeback

3) Stepbackfromgauge(atleasttwo

3) PushStartbutton

paces)

4) Stepbackfromgauge(atleasttwo

paces)

4) Backscattermethodforallaggregate

material

5) DirectTransmissionmethodforallsoil

5) DirectTransmissionmethodisonly

material

usedwhenvalidatingControlStrip

RecordDataandAcceptTestResults

Alltestresultsareacceptedbasedontheir

comparisontoknownTARGETdensitiesand

moistures

Soiltestsarecomparedtoproctorresults: AggregatematerialiscomparedtoControl

Moisturerangeforacceptanceis20%of Striptestresults:Moisturerangeis2

optimummoisture.Densityrangeis95%for percentagepointsofoptimummoisture.

embankmentmaterialandpipebackfilland Densityrangeisaminimumof95%foreach

100%forsubgradematerial individualreadingand98%foranaverageof

thesame5readings

2016v1.0Chapter6|24

VDOTSoilsandAggregateCompaction

TROUBLESHOOTINGGUIDEFORTHENUCLEARGAUGE

Problem ProbableCause Solution

Gaugeturnsoffafteritisturnedon 1. Gaugemaybewet.DONOTturn 1. Waituntilgaugedriesoff.

orwillnotturnonatall gaugeonuntilithasdried.

2. Batteriesarelow. 2. Rechargebatteriesminimumof16hours(short

andfrequentchargedrainsbatterylife).If

chargedoesntholdcallDistrictMaterials

Section.

ShortBatteryLife 1. Badoutlet. 1. Checkoutlet.

2. Batteriesarereachingendofcycleor 2. CalltheDistrictMaterialsSection.

chargeisntworking.

QuestionableStandardCounts 1. Gaugeneedsmorewarmuptimeor 1. Checktoseethatthegaugeisntonthe

isntproperlyseatedonthestandard standardblockbackwards. Cleanalldirt,gravel,

block. etc.fromthegaugestandardortestblock.

Makesurethesecountsaretakenexactlyasall

priortests.

2. Handleisntinthesafeposition. 2. Checkhandleposition.

3. Backgroundinterference. 3. Moveawayfromanylargestructures.

QuestionableMoistureCounts 1. Mica,asbestos,orotherhydrogenrich 1. RunaSpeedyMoisturetest.

materialisinthesoil.

2. Backgroundinterferencefromlarge 2. Movetestsiteawayfromstructuresorrun

structureortrenchwallifbelow backgroundcountiftestinginatrench.

groundlevel.

3. Internaltubefailure. 3. Runnewstandardcounttocheckgauge.

4. Handlenotlockedintestingposition 4. Checkhandleposition.

notch.

QuestionableDensityCounts 1. Presenceof+4Material. 1. Checkfor+4materialandtakecorrectiveaction

thatappliestoyourDistrict.

2. Testisnttakenonsoilrepresentedby 2. RunaProctortest.

Proctortestresult.

3. Internaltubefailure. 3. Runnewstandardcounts.

4. Handleisntlockedintotesting 4. Checkthehandleposition.

position.

2016v1.0Chapter6|25

VDOTSoilsandAggregateCompaction

CHAPTER6STUDYQUESTIONS

1) Batteriesshouldbecharged____________________________________________.

2) TrueorFalse.Thenucleargaugeshouldbewarmedupfirstthinginthemorningbeforeusingit.

3) TrueorFalse.Theonlymaintenanceperformedinthefieldiscleaningthenucleargaugeandchargingthe

batteries.

4) Whentakingastandardcount,thenucleargaugeshouldbeaminimumof__________ft.fromany

structureand__________ft.fromanyotherradioactivesource.

5) TrueorFalse. Cesium137islocatedinthetipofthestainlesssteelrodwhichisusedin taking moisture

determinationsandAmericium241:Berylliumis locatedinsidethenucleargaugeandisusedfordensity

testing.

6) W h e n t a k i n g StandardCountsthe ReferenceStandardshould be placed on whattypeofsurface?

7) Threewaystolimitexposuretoradiationare__________,____________,and____________.

8) Ifthe soilmaterial failsa nucleartest becauseofexcessivemoisture,the firststeptakenisto

_________________________.

9) Atestingmethodfortestingdensitieswherebythesourcerodisinsertedintothematerialtobetestedata

depthof4,6,or8inchesis_________________________.

10) If,duringconstruction,thedensityresultseitherchangesuddenly,orsimplydontmakesense,youshould

______________________________________________________________.

11) Ifthemoistureresultsfromthenucleartestappearhigh,the__________________________couldbeused

tocheckthemoisture.

12) Whenanucleargaugeisoperatedwithin24ofaverticalstructure,the_______________and

_______________areinfluencedbythestructure.

2016v1.0Chapter6|26

VDOTSoilsandAggregateCompaction

CHAPTER6PRACTICEPROBLEMS

NuclearGaugeTestingofSoilMaterial(DensityandMoisture)

TransfertheinformationfromeachPracticeProblembelowtotheFormTL124andthendetermine

whethereachtestpasses.

PracticeProblem1

NuclearGaugeDisplayPanel

ProctorData

MaximumDryDensity=114.6lbs/ft3 %PR=______%

OptimumMoisture=14.1% DD=114.2

WD=133.3

M=19.1M%=16.7

PracticeProblem2

NuclearGaugeDisplayPanel

ProctorData

MaximumDryDensity=106.9lbs/ft3 %PR=______%

OptimumMoisture=17.6% DD=105.7

WD=123.6

M=17.9M%=16.9

PracticeProblem3

NuclearGaugeDisplayPanel

ProctorData

MaximumDryDensity=112.1lbs/ft3 %PR=97.8%

OptimumMoisture=15.2% DD=109.6

WD=128.2

M=18.6M%=17.0

2016v1.0Chapter6|27

VDOTSoilsandAggregateCompaction

FormTL124(Rev.07/15)

VIRGINIADEPARTMENTOFTRANPORTATION

MATERIALSDIVISION

REPORTONNUCLEAREMBANKMENTDENSITIES(UNITMASSES)

ReportNo. 45 Date 06/22/2015 SheetNo. 1 of 1

RouteNo. 252 County Augusta

ProjectNo. 0252132101,C501

FHWANo. None

Testingfor Embankment

ModelNo. 3440 SerialNo. 23456 CalibrationDate 02/10/2015

STANDARDCOUNTDATA

Density 2844 Moisture 701

TestNo. 1 2 3 4

Location Stationft.(m) 305+00 305+60 306+20

of Ref.tocenterlineft.(m) at.C/L 10Lt. 7Lt.

Test Elevation +10/7 +3/10 +3/3

CompactionDepthofLiftin.(mm) 6 6 6

MethodofCompaction Sheepsfoot Sheepsfoot Sheepsfoot

A. WetDensity(lbs/ft3),WetUnitMass(kg/m3) =

3 3

B. MoistureUnitMass(lbs/ft orkg/m ) =

C. DryDensity(lbs/ft3),DryUnitMass(kg/m3)(AB) =

D. MoistureContent(BC)x100 =

3 3

E. MaximumDryDensity(lbs/ft ),DryUnitMass(kg/m )

=

LabProctororOnePointProctor

F. PercentOptimumMoisturefromLaborOnePointProctor =

G. PercentofPlus#4,(plus4.75mm) =

3 3

H. CorrectedMax.DryDensity(lbs/ft ),DryUnitMass(kg/m ) =

I. CorrectedOptimumMoisture =

3 3

J. PercentDryDensity(lbs/ft ),DryUnitMass(kg/m )

=

(CE)x100or(CH)x100

K. PercentMinimumDensityRequired =

Comments:

BY:

TITLE:

2016v1.0Chapter6|28

VDOTSoilsandAggregateCompaction

CHAPTER6PRACTICEPROBLEMS

NuclearGaugeTestingofSoilMaterial(CorrectingforHighMoisture)

PracticeProblem4

ThenucleardensitytestreportedontheFormTL124onthefollowingpageshowsafalsehighmoisture

content,assumedtobecausedbymicaceoussoil. CorrectthetestresultsusingaSpeedyMoistureMeter

andrecordtheresultsinthesecondcolumnoftheFormTL124.

SpeedyDialReading=9.6

2016v1.0Chapter6|29

VDOTSoilsandAggregateCompaction

FormTL124(Rev.07/15)

VIRGINIADEPARTMENTOFTRANPORTATION

MATERIALSDIVISION

REPORTONNUCLEAREMBANKMENTDENSITIES(UNITMASSES)

ReportNo. 1171 Date 06/22/2015 SheetNo. 1 of 1

RouteNo. 17 County Campbell

ProjectNo. 0017015104,C503

FHWANo. None

Testingfor Embankment

ModelNo. 3440 SerialNo. 23456 CalibrationDate 02/10/2015

STANDARDCOUNTDATA

Density 2830 Moisture 701

TestNo. 1 2 3 4

Location Stationft.(m) 85+00

of Ref.tocenterlineft.(m) at.C/L

Test Elevation +9/3

CompactionDepthofLiftin.(mm) 6

MethodofCompaction Sheepsfoot

3 3

A. WetDensity(lbs/ft ),WetUnitMass(kg/m ) = 141.0

3 3

B. MoistureUnitMass(lbs/ft orkg/m ) = 23.1

3 3

C. DryDensity(lbs/ft ),DryUnitMass(kg/m )(AB) = 117.9

D. MoistureContent(BC)x100 = 19.6

3 3

E. MaximumDryDensity(lbs/ft ),DryUnitMass(kg/m )

= 132.4

LabProctororOnePointProctor

9.2

F. PercentOptimumMoisturefromLaborOnePointProctor =

7.411.0

G. PercentofPlus#4,(plus4.75mm) =

3 3

H. CorrectedMax.DryDensity(lbs/ft ),DryUnitMass(kg/m ) =

I. CorrectedOptimumMoisture =

3 3

J. PercentDryDensity(lbs/ft ),DryUnitMass(kg/m )

= 89.0

(CE)x100or(CH)x100

K. PercentMinimumDensityRequired = 95.0

Comments:

BY:

TITLE:

2016v1.0Chapter6|30

You might also like

- Field Density Testing by Using A Nuclear Gauge PDFDocument21 pagesField Density Testing by Using A Nuclear Gauge PDFJaya SuriyaNo ratings yet

- Field Density Testing with Nuclear GaugeDocument32 pagesField Density Testing with Nuclear Gaugenikita6969No ratings yet

- 1) Nuclear Density Gauge TestDocument3 pages1) Nuclear Density Gauge TestPn EkanayakaNo ratings yet

- Field compaction testing using nuclear density gaugeDocument2 pagesField compaction testing using nuclear density gaugePraveen Kumar100% (1)

- CompactionDocument118 pagesCompactionSaleh HassanNo ratings yet

- Plate Load TestDocument3 pagesPlate Load TestniteshNo ratings yet

- Unconfined Compressive Strength of Cohesive Soil: Standard Test Method ForDocument7 pagesUnconfined Compressive Strength of Cohesive Soil: Standard Test Method ForJesus Luis Arce GuillermoNo ratings yet

- Aggregate Sub Base - Road Base Report SummaryDocument1 pageAggregate Sub Base - Road Base Report SummaryAbdul100% (1)

- Temperature problems in concretingDocument4 pagesTemperature problems in concretingMirosha NavaratnaNo ratings yet

- Microsoft Office Project - Snag List v1Document1 pageMicrosoft Office Project - Snag List v1Necdet KayıkcıNo ratings yet

- Curing Concrete 2013 0Document2 pagesCuring Concrete 2013 0ThobiasNo ratings yet

- Nuclear Density Test - Earthworks - Chapter - 12Document16 pagesNuclear Density Test - Earthworks - Chapter - 12Saud PathiranaNo ratings yet

- SDQCQAManualDocument344 pagesSDQCQAManualmoizm53No ratings yet

- Backfilling PDFDocument4 pagesBackfilling PDFAdjei BaldanNo ratings yet

- Concrete Repair SpecificationDocument14 pagesConcrete Repair Specificationwafikmh4No ratings yet

- Thermal Control in Mass ConcreteDocument2 pagesThermal Control in Mass ConcreteHandy Ham DannyNo ratings yet

- Method Statement For Load Test of Bored PileDocument11 pagesMethod Statement For Load Test of Bored Pilethanzawtun1981No ratings yet

- PJE CFA Piling PortfolioDocument46 pagesPJE CFA Piling Portfolioprasad perkaNo ratings yet

- Aggregate Elongation Index ValueDocument7 pagesAggregate Elongation Index ValuemlakkissNo ratings yet

- Temperature in Mass ConcreteDocument2 pagesTemperature in Mass ConcreteHandy Ham Danny100% (1)

- Bored pile construction procedureDocument57 pagesBored pile construction procedureOakar MinNo ratings yet

- Retaining Wall TerminologyDocument2 pagesRetaining Wall Terminologyhammads88No ratings yet

- 2005 Ground Vibration Due To Dynamic CompactionDocument10 pages2005 Ground Vibration Due To Dynamic CompactionTen FreireNo ratings yet

- Fences and Gates Construction Method StatementDocument44 pagesFences and Gates Construction Method StatementBadhur ZamanNo ratings yet

- Causes of Defects in Concrete StructuresDocument3 pagesCauses of Defects in Concrete StructuresSyed Mohd MehdiNo ratings yet

- BH Log ProcedureDocument9 pagesBH Log ProcedureMohammed Zuber InamdarNo ratings yet

- Post Cast Strip PDFDocument2 pagesPost Cast Strip PDFKwoshaba PidsonNo ratings yet

- Bond Strength of Mortar To Masonry Units: Standard Test Method ForDocument8 pagesBond Strength of Mortar To Masonry Units: Standard Test Method Foranon_694321072100% (1)

- Cold Weather Concreting TipsDocument2 pagesCold Weather Concreting TipsBoris DikovNo ratings yet

- Geotechnical Checklist-Geocon - Runwal PinncleDocument5 pagesGeotechnical Checklist-Geocon - Runwal PinncleKOMAL JOSHINo ratings yet

- Soil Compaction: Understanding the Key FactorsDocument19 pagesSoil Compaction: Understanding the Key FactorsArthNo ratings yet

- Brick Masonry DefinitionDocument9 pagesBrick Masonry Definitiondivi vasaNo ratings yet

- Compressive Strength Test of Concrete CubesDocument5 pagesCompressive Strength Test of Concrete CubesAyan RoyNo ratings yet

- 05-Density ReverseDocument7 pages05-Density ReverseSAFE SERVICES LHRNo ratings yet

- Objective: Civil Engineering Virtual LaboratoryDocument4 pagesObjective: Civil Engineering Virtual LaboratorySuraj MulikNo ratings yet

- STATIC AXIAL PILE LOAD TESTDocument15 pagesSTATIC AXIAL PILE LOAD TESTcecdesign09No ratings yet

- Roller Compacted Concrete For DamsDocument16 pagesRoller Compacted Concrete For Damsabhineet srivastavaNo ratings yet

- Is 4990-1993Document15 pagesIs 4990-1993PRASANT KUMAR BIPRANo ratings yet

- Managing Temporary Works: Andrea Robbins HM Inspector of Health and SafetyDocument47 pagesManaging Temporary Works: Andrea Robbins HM Inspector of Health and Safetyمحمد ابراهيم100% (1)

- Chapter 2 - Quantity Design FundamentalsDocument63 pagesChapter 2 - Quantity Design FundamentalsMursidi MalaiNo ratings yet

- BS 1377 Part 9: 1990 StandardDocument9 pagesBS 1377 Part 9: 1990 StandardDetoned StonedNo ratings yet

- Work Methodology For All Types Flooring Work R1Document19 pagesWork Methodology For All Types Flooring Work R1priyanka k lNo ratings yet

- A1-80-2 External Wall Tiling - 1 PDFDocument15 pagesA1-80-2 External Wall Tiling - 1 PDFZYWNo ratings yet

- How Are Cracked Sections Analyzed in SAFE. CSI SAFEDocument3 pagesHow Are Cracked Sections Analyzed in SAFE. CSI SAFEJaime Manalili LandinginNo ratings yet

- NPQS C2-10 Site Investigation ReportDocument26 pagesNPQS C2-10 Site Investigation ReportLukeNo ratings yet

- D4254 - Maximum Index Density and Unit Weight of Soils and Calculation of Relative DensityDocument8 pagesD4254 - Maximum Index Density and Unit Weight of Soils and Calculation of Relative DensityJhon Hilario AquinoNo ratings yet

- Method Statement Geo Technical Investigation: 1. PurposeDocument7 pagesMethod Statement Geo Technical Investigation: 1. PurposeJ. Kumar Infraprojects LtdNo ratings yet

- Silver Schmidt ManualDocument47 pagesSilver Schmidt ManualEl LlacunaNo ratings yet

- Compressive Strength of Concrete CubesDocument3 pagesCompressive Strength of Concrete CubesoneakshayNo ratings yet

- D5080.Rapid Determination of Percent CompactionDocument9 pagesD5080.Rapid Determination of Percent CompactionleocivilNo ratings yet

- CU Triaxial Test ResultsDocument39 pagesCU Triaxial Test ResultsCatriona Cassandra SantosNo ratings yet

- Remedial Measures To A Building Settlement ProblemDocument5 pagesRemedial Measures To A Building Settlement ProblemEswara PrasadNo ratings yet

- Placing ConcreteDocument62 pagesPlacing ConcreteSyahierah RedzuanNo ratings yet

- Soil Exploration, Sampling, and In Situ TestsDocument50 pagesSoil Exploration, Sampling, and In Situ TestsHaider Yousef100% (1)

- Triaxial Testing of Granular Soil (Colliat-Dangus, 1988)Document21 pagesTriaxial Testing of Granular Soil (Colliat-Dangus, 1988)Abraham FIgueroa ARevaloNo ratings yet

- 1 MS - Pouring of ConcreteDocument8 pages1 MS - Pouring of ConcreteFauzi MastamNo ratings yet

- Asset Upload File587 118183Document42 pagesAsset Upload File587 118183Yzhel LopezNo ratings yet

- RDSO Test Procedures of SoilDocument20 pagesRDSO Test Procedures of SoilAshok ChaudharyNo ratings yet

- Soil TestDocument31 pagesSoil Testnatarajannalanth67% (3)

- Validation of Nuclear Gauge Density-Meter Readings Against Sand Replacement MethodDocument6 pagesValidation of Nuclear Gauge Density-Meter Readings Against Sand Replacement MethodGerald MaregesiNo ratings yet

- Designing for Construction SafetyDocument52 pagesDesigning for Construction SafetyAnonymous 59kjvq4OLBNo ratings yet

- Simple Delivery Order Template DownloadDocument1 pageSimple Delivery Order Template DownloadAnonymous 59kjvq4OLBNo ratings yet

- UnconfinedDocument4 pagesUnconfinedRen SalazarNo ratings yet

- Bullet LicenseDocument1 pageBullet LicensekaliamahsksiNo ratings yet

- A Review of Geotechnical Behavior of Stabilized SoilsDocument62 pagesA Review of Geotechnical Behavior of Stabilized SoilsAnonymous 59kjvq4OLBNo ratings yet

- Contoh Delivery OrderDocument2 pagesContoh Delivery OrderAnonymous 59kjvq4OLB100% (3)

- Lab Experiment #5: Standard Proctor Compaction TestDocument4 pagesLab Experiment #5: Standard Proctor Compaction TestfadyNo ratings yet

- InfoDocument1 pageInfoAnonymous 59kjvq4OLBNo ratings yet

- Water Quality Index BrochureDocument2 pagesWater Quality Index BrochureHolo ZoroNo ratings yet

- ReadmeDocument1 pageReadmeAnonymous 59kjvq4OLBNo ratings yet

- STAAD Report" STAAD.Pro structural analysis reportDocument7 pagesSTAAD Report" STAAD.Pro structural analysis reportAnonymous 59kjvq4OLBNo ratings yet

- Assignment 2Document2 pagesAssignment 2Anonymous 59kjvq4OLBNo ratings yet

- Designing for Construction SafetyDocument52 pagesDesigning for Construction SafetyAnonymous 59kjvq4OLBNo ratings yet

- Soil Stabilization Methods and MaterialsDocument38 pagesSoil Stabilization Methods and Materialstyas_pramesthi100% (5)

- Impact of Wastewater To EnvironmentDocument1 pageImpact of Wastewater To EnvironmentAnonymous 59kjvq4OLBNo ratings yet

- Experiment 3 - Total SolidDocument13 pagesExperiment 3 - Total SolidAnonymous 59kjvq4OLBNo ratings yet

- Report Buckling of StructsDocument7 pagesReport Buckling of StructsAnonymous 59kjvq4OLBNo ratings yet

- Soil Types and Properties GuideDocument13 pagesSoil Types and Properties GuideAnonymous 59kjvq4OLB100% (1)

- Experiment 3 - Total SolidDocument13 pagesExperiment 3 - Total SolidAnonymous 59kjvq4OLBNo ratings yet

- Chapter 2 Aggregate PDFDocument17 pagesChapter 2 Aggregate PDFmoshilizaNo ratings yet

- MSI06 Span DeflectionDocument5 pagesMSI06 Span DeflectionSyamsul IzuanNo ratings yet

- MSI07 Force in A Statically Determinate Cantilever TrussDocument6 pagesMSI07 Force in A Statically Determinate Cantilever TrussAnonymous 59kjvq4OLBNo ratings yet

- Hydraulic Apr 09 PDFDocument15 pagesHydraulic Apr 09 PDFAnonymous 59kjvq4OLBNo ratings yet

- Chapter 1 Cement Civil Engineering MaterialDocument12 pagesChapter 1 Cement Civil Engineering MaterialAnonymous 59kjvq4OLB100% (1)

- SyaitanDocument2 pagesSyaitanAnonymous 59kjvq4OLBNo ratings yet

- SMM2Document139 pagesSMM2Shazwan Taib0% (1)

- Climate Change AyeipDocument16 pagesClimate Change AyeipAnonymous 59kjvq4OLBNo ratings yet

- Final Report Format for STAAD.Pro Roof Truss AnalysisDocument1 pageFinal Report Format for STAAD.Pro Roof Truss AnalysisAnonymous 59kjvq4OLBNo ratings yet

- Tips For The Muet Reading ExaminationDocument3 pagesTips For The Muet Reading ExaminationAnonymous 59kjvq4OLB100% (1)

- The Third Plate by Dan BarberDocument10 pagesThe Third Plate by Dan BarbersimasNo ratings yet

- Technical Manual - Soil and Water ConservationDocument16 pagesTechnical Manual - Soil and Water ConservationRafliNo ratings yet

- PT - Science 4 - Q4 V2Document5 pagesPT - Science 4 - Q4 V2Blizelle Jane OquiasNo ratings yet

- Method Statement Retaining WallDocument3 pagesMethod Statement Retaining WallPravin Pelanisamy100% (1)

- Astm d1194Document3 pagesAstm d1194Pablo MenendezNo ratings yet

- Nursery SetupDocument82 pagesNursery Setupsautulhakim100% (2)

- Nitrophoska Special BrochureDocument8 pagesNitrophoska Special Brochuresree778899No ratings yet

- De Kiem Tra 1 Tiet Lan 3 Tieng Anh 8 Thi Diem HotDocument5 pagesDe Kiem Tra 1 Tiet Lan 3 Tieng Anh 8 Thi Diem HotDiệu NguyễnNo ratings yet

- A Brief Review of Compressed Stabilized Earth Brick CSEBDocument7 pagesA Brief Review of Compressed Stabilized Earth Brick CSEBMauricio SilesNo ratings yet

- in Situ StressesDocument4 pagesin Situ StressesJoanna GuidoNo ratings yet

- Chapter OneDocument8 pagesChapter OneGreg EnyinnaNo ratings yet

- Almond 1Document20 pagesAlmond 1Mahantesh PanchalNo ratings yet

- A Prototype Model For Continuous Agriculture FieldDocument5 pagesA Prototype Model For Continuous Agriculture Fieldnikelton12No ratings yet

- CIEN 3134 Soil Mechanics Course OverviewDocument49 pagesCIEN 3134 Soil Mechanics Course OverviewAndrick AlvarezNo ratings yet

- Proforma For Geotechnical Inv. Using Test Pit & DCP Tets - G+3 BuildingDocument1 pageProforma For Geotechnical Inv. Using Test Pit & DCP Tets - G+3 BuildingsintayhuNo ratings yet

- Petroleum Microbiology Lecture 5 Oil SpillDocument49 pagesPetroleum Microbiology Lecture 5 Oil SpillBarnabasNo ratings yet

- Annex H. MVNP Management Plan (CY 2018-2022) PDFDocument122 pagesAnnex H. MVNP Management Plan (CY 2018-2022) PDFAlen Clyde67% (3)

- Organic Agriculture Gr12 Module8.Final For TeacherDocument24 pagesOrganic Agriculture Gr12 Module8.Final For TeacherArlene Caceres GacheNo ratings yet

- 8em Bio PDFDocument202 pages8em Bio PDFJ SoujanyaNo ratings yet

- 7 Ways To Plant PotatoesDocument6 pages7 Ways To Plant Potatoesmolnar755100% (1)

- Free NABARD Horticulture e-bookDocument10 pagesFree NABARD Horticulture e-bookPrasun KumarNo ratings yet

- Outline Thesis FinalDocument36 pagesOutline Thesis FinalFemie Jhay MaatubangNo ratings yet

- MoRTH 300 Earthwork, Erosion Control and DrainageDocument64 pagesMoRTH 300 Earthwork, Erosion Control and DrainageApurv PatelNo ratings yet

- Grade 5 Agric, Science and Tech, Ict Paper 1Document6 pagesGrade 5 Agric, Science and Tech, Ict Paper 1mtetwabNo ratings yet

- Fertilizer Catalogue (UreaN46 & DAP 18:46:0)Document7 pagesFertilizer Catalogue (UreaN46 & DAP 18:46:0)Ajay PandeyNo ratings yet

- Time Learning Competencies/Objectives Topic/S DLL/ (Class A) Weekly Home Learning Plan (Class B)Document3 pagesTime Learning Competencies/Objectives Topic/S DLL/ (Class A) Weekly Home Learning Plan (Class B)Michelle Ann Soledad100% (1)

- The Role of Microorganisms in Bioremediation-A ReviewDocument9 pagesThe Role of Microorganisms in Bioremediation-A ReviewKashmeera Geethanjali AnirudhanNo ratings yet

- Abattoir Layout and Construction PDFDocument24 pagesAbattoir Layout and Construction PDFKarthikeyan Balakrishnan78% (18)

- Line Spring Calculation by SPT-15.03.18Document6 pagesLine Spring Calculation by SPT-15.03.18Nazmul HassanNo ratings yet