Professional Documents

Culture Documents

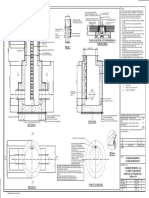

General: Schedule of CHB & Ceramic Block Reinforcement

Uploaded by

bobmarley20161934Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General: Schedule of CHB & Ceramic Block Reinforcement

Uploaded by

bobmarley20161934Copyright:

Available Formats

GENERAL

THE GENERAL NOTES AND SPECIAL REQUIREMENTS ARE SUPPLEMENTAL TO AND FORM PARTOF THE

PLANS, DRAWINGS AND SPECIFICATIONS, WHERE DETAILS OR REQUIREMENTS ARE NOT

COVERED BY THE PLANS OR SPECIFICATIONS. THESE GENERAL CONSTRUCTION NOTES SHALL BE

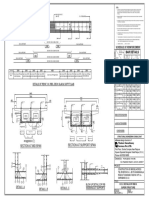

E. UNLESS OTHERWISE NOTED IN THE PLANS, ALL BEDDED SLABS SHALL BE E. UNLESS OTHERWISE NOTED IN THE PLAN, PROVIDED FRAMING STIFFENER COLUMNS AND F. WHEN A BEAM CROSSES A GIRDER, REST BEAM BARS ON TOP OF GIRDER BARS, BEAM

USED INSOFAR AS THEY ARE APPLICABLE TO SATISFY REQUIREMENTS OF GOOD CONSTRUCTION

REINFORCED WITH 10mm DIAMETER REBAR AT 0.25m O.C. EACH WAY AT CENTER STIFFENER BEAMS NOT MORE THAN 3.0M APART. STIFFENER COLUMNS SHALL HAVE REINFORCING BARS SHALL BE SYMMETRICAL ABOUT THE CENTERLINE WHENEVER

PRACTICE. IN CASE OF QUESTIONS ARISING FROM THE INTERPRETATION OF OR CONFLICT WITH

OF SLAB, AND CONSTRUCTION JOINTS FOR SAME SHALL NOT BE MORE THAN 18m A WIDTH EQUAL TO THE WALL THICKNESS BUT NOT LESS THAN 115mm. POSSIBLE. A. MATERIALS

OTHER DOCUMENTS, THE ATTENTION OF THE OWNER/ENGINEERS MUST BE CALLED IN WRITING.

APART. A1. STRUCTURAL STEEL - STEEL TO BE USED FOR FABRICATION AND ERECTION OF

G. GENERALLY NO SPLICE SHALL BE PERMITTED AT POINTS WHERE CRITICAL BENDING THIS STRUCTURE SHALL COMPLY WITH ALL THE PERTINENT PROVISIONS OF AISC

GENERAL NOTES F. PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLAB (TWO ADJACENT STRESSES OCCUR, SPLICES WHERE SO PERMITTED SHALL BE AS INDICATED IN TABLE SPECIFICATION FOR THE DESIGN, FABRICATION AND ERECTION OF STRUCTURAL

DISCON-TINUOUS EDGES AS SHOWN BELOW.) "A" AND "B" WELDED SPLICES SHALL DEVELOP IN TENSION AT LEAST 125% OF THE STEEL FOR BUILDINGS 2005-13th EDITION.

SPECIFIED YIELD STRENGTH OF THE BAR. NO MORE THAN 50% OF THE BARS ANY ONE

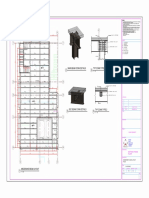

A. ALL REINFORCING BARS SHALL BE HIGH GRADE FOR DIA 16mm AND LARGER

SECTION SHALL BE ALLOWED TO BE SPLICED THEREIN. a. STEEL SHAPES

FOR DIA 12mm AND 10mm YIELD STRENGTH OF 275 MPa (40,000 PSi)

MAINTAIN TS/YS RATIO > 1.25. 5-D10 BOTTOM BARS 4-D12mm WITH WIDE FLANGE ASTM A992, ANGLES, CHANNELS, PLATES SHALL BE ASTM A36.

BEAM @ 0.20m. O.C. H. LEAST 900mm

D10 TIES @ 200mm O.C. SPACED AT 250mm O.C. b. BOLTS

B. ALL REINFORCING BARS SHALL BE DEFORMED IN ACCORDANCE WITH ASTM-A615.

ALL BOLTS, NUTS AND WASHERS SHALL CONFORM TO A325

UNLESS OTHERWISE INDICATED. ANCHOR BOLTS SHALL ASTM F1554 UNLESS

C. BARS OF REINFORCED CONCRETE EXPOSED TO THE WEATHER SHALL PREFERABLY BE SB-1 / SC-1 NOTED OTHERWISE

PROTECTED AT LEAST 38mm.THIS PROVISION MAY BE WAIVED WHEN ADEQUATE

WATERPROOFING IS PROVIDED BUT SHALL IN NO CASE BE LESS THAN 20mm. 5-D10 TOP BARS WALL BASE c. WELDS

@ 0.20m. O.C.

ALL WELDS SHALL BE IN ACCORDANCE WITH AWS STRUCTURAL WELD

D. IN THE INTERPRETATION OF DRAWINGS, INDICATED DIMENSIONS SHALL GOVERN AND CODE D1-1 LATEST REVISION FOR SHIELDED METAL ARC WELDING

DISTANCES OR SIZES SHALL NOT BE SCALED FOR CONSTRUCTION PURPOSES. PROCESS, ELECTRODES E-70 SHALL CONFORM TO AWS AS-1 OR LATEST

EDITION. SUBMERGED ARC WELDING PROCESS MAY BE USED AT THE

E. IN REFERENCE TO OTHER DRAWINGS, SEE ARCHITECTURAL DRAWINGS FOR DEPRESSIONS LINTEL IN BLOCK WALLS (PER 100mm THICKNESS) OPTION OF FABRICATOR UPON THE APPROVAL OF ENGINEER UNLESS NOTED

IN FLOOR SLABS, OPENING IN WALLS AND SLABS, INTERIOR PARTITIONS, LOCATION OTHERWISE

CLEAR SPAN L TOT. LENGTH MIN. fc' HEIGHT OF REINFORCEMENT

OF DRAINS, ETC.

m L+0.40 MPa LINTEL (cm) BOTTOM TOP B. QUALITY CONTROL

F. IN CASE OF DISCREPANCIES AS TO THE LAYOUT DIMENSIONS AND ELEVATIONS BETWEEN THE A. CONTRACTOR SHALL REPORT TO THE ENGINEER ACTUAL UNUSUAL SOIL CONDITIONS

STRUCTURAL PLANS AND OTHER DRAWINGS, THE CONTRACTOR SHALL NOTIFY BOTH THE A. FOR ALL TIED COLUMNS AND PEDESTALS PROVIDE EXTRA 4 SETS OF TIES AT 100mm 1.20 1.60 1-D12 1-D12

UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY OF SOIL IN WRITING B1. REFER TO SPECIFICATIONS FOR QUALITY CONTROL TESTING REQUIREMENTS.

O.C. FOR COLUMN REINFORCEMENTS JUST ABOVE THE FLOOR, JUST BELOW THE 1.50 1.90 1-D12 1-D12

STRUCTURAL ENGINEERS AND THE OWNER'S REPRESENTATIVE OR SITE ENGINEER IN WRITING BEFORE DEPOSITING CONCRETE. B2. STEEL SHAPES

GIRDER AND AT CONSTRUCTION JOINTS. 1.80 2.20 1-D12 1-D12

BEFORE PROCEEDING WITH THE AFFECTED WORK. EVERY BATCH OF STRUCTURAL STEEL SHAPE FOR FABRICATION SHALL

B. FOOTING SHALL REST AT LEAST 2.00m BELOW FINISHED GRADE LINE UNLESS 2.10 2.50 27.6 20.0 1-D16 1-D16 HAVE THE MANUFACTURER'S MILL CERTIFICATE SHOWING THEIR

B. COLUMN AND PEDESTAL TIES SHALL BE PROTECTED EVERYWHERE BY A COVERING OF 2.40 2.80 1-D16 1-D16 CHEMICAL AND PHYSICAL PROPERTIES. OWNER EXERCISES THE RIGHT

OTHERWISE INDICATED.

CONCRETE CAST MONOLITHICALLY WITH THE CORE WITH MINIMUM THICKNESS OF 2.70 3.10 1-D16 1-D16 TO UNDERTAKE DESTRUCTIVE OR NON-DESTRUCTIVE TESTING OF SAMPLES

NOTE ON CONCRETE MIXES AND PLACING 40mm.

C. UNLESS OTHERWISE SPECIFIED, ALL FOOTINGS SHALL REST ON DENSE SAND OR VERY FROM MATERIALS USED FOR THE PROJECT.

3.00 3.40 1-D16 1-D16

HARD CLAY. THIS MAY SOMETIMES REQUIRE OVEREXCAVATION OF ABOUT 1000mm 3.30 3.70 1-D16 1-D16

G. THE CONTRACTOR SHALL SUBMIT THE SCHEDULE OF POURING AND LOCATIONS AT FROM PRESCRIBED BOUNDARY LEVEL. SUCH OVEREXCAVATION SHALL BE REPLACED B3. WELD FINISH

3.60 4.00 1-D16 1-D16

CONSTRUCTION JOINTS TO THE FIELD ENGINEER AT LEAST FOUR (4) DAYS PRIOR WITH WELL COMPACTED GRANULAR FILL. COMPACTION SHALL BE TO 95% OF MDD BASED ON ASTM D698. ALL WELDS SHALL BE FREE FROM UNDERCUTS, PINHOLES AND CRACKS,

TO THE POURING FOR APPROVAL. NON-DESTRUCTIVE TESTING MAY BE CONDUCTED AT WELDS DEEMED NOT

C. UNLESS OTHERWISE NOTED IN PLANS, CAMBER ALL BEAMS AND GIRDERS AT LEAST

D. PROVIDE 100mm PLAN OFFSET FOR LEAN CONCRETE POURS. 6.35mm FOR EVERY 457 CENTIMETERS OF SPAN, EXCEPT CANTILEVERS FOR WHICH IN CONFORMITY WITH THE SPECIFICATION AND SHALL BE TO

H. WET CURING OF CONCRETE SHALL BE CONTINUOUS FOR MINIMUM PERIOD OF TEN (10) NOTE: ALL CHB SHALL BE LOAD BEARING AND ALL HOLLOWS SHALL BE COMPLETELY CONTRACTOR'S ACCOUNT.

THE CAMBER SHALL BE AS NOTED IN PLANS OR AS ORDERED BY THE ENGINEER BUT

DAYS IMMEDIATELY AFTER POURING. E. CONTINUE COLUMN STIRRUPS SPACING AND CONFIGURATION TOWARDS THE FOUNDING LEVEL. IN NO CASE LESS THAN 19.05mm FOR EVERY 3m OF FREE SPAN. FILLED WITH HIGHLY FLOWABLE MORTAR

C. FABRICATION

I. THE CONTRACTOR SHALL FURNISH AND MAINTAIN ADEQUATE FORMS FOR SHORINGS F. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENT SHALL BE 75mm CLEAR FOR D. TYPICAL BAR BENDING AND CUTTING DETAILS FOR BEAMS AND GIRDERS SHALL BE ALL LINTEL BEAMS SHALL BE PROVIDE WITH 10MM DIAMETER 2 LEGGED STIRRUPS 1 @ 50MM @ C1. WELDS

UNTIL THE CONCRETE MEMBERS HAVE ATTAINED THEIR SUFFICIENT STRENGTH FOR CONCRETE DEPOSITED AGAINST THE GROUND AND 50mm FOR CONCRETE DEPOSITED AS SHOWN IN FIG. 6 FOR FLAT SLABS OR SLAB BENDS REFER TO PLAN. REST @ 100MM FROM BOTH ENDS ALL WELDED CONNECTIONS SHALL DEVELOP THE FULL STRENGTH OF THE

THE WORKING CONDITION ANTICIPATED. AGAINST A FORMWORK. MEMBER CONNECTED.

J. ALL CONCRETE WORKS SHALL BE DONE IN ACCORDANCE WITH THE ACI 318-08 G. VERIFY WITH ALL CONCERNED DISCIPLINES, ALL EMBEDDED MECHANICAL & ELECTRICAL ITEMS, BEFORE d. LENGTH OF WELDS:

TOP REINFORCEMENT

BUILDING CODE REQUIREMENTS FOR REINFORCED CONCRETE AND ALL STRUCTURAL CONCRETE POURING. THE MINIMUM LENGTH OF FILLET SHALL NOT BE LESS

STEEL WORK IN ACCORDANCE WITH A.I.S.C. SPECIFICATIONS 360-05 IN SO FAR AS THEY DO NOT THAN 4 TIMES THE NOMINAL SIZE WHERE INTERMITTENT WELDS

CONFLICT WITH THE REQUIREMENTS OF THE NATIONAL STRUCTURAL CODE FOR BUILDING AND MAY BE USED THE LENGTH OF SEGMENT SHALL NOT BE LESS

LOCAL CODES. THAN 4 TIMES THE WELD SIZE WITH A MIN. OF 40mm.

HEIGHT

LINTEL

e. END RETURN OF FILLET WELDS

SIDE OR END FILLET WELDS TERMINATING AT END OR SIDES

OF

K. A.C.I. REFERS TO AMERICAN CONCRETE INSTITUTE A.I.S.C. TO AMERICAN

TOP REINFORCEMENT SHALL BE RETURNED CONTINUOUSLY FOR A DISTANCE NOT LESS

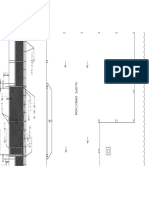

INSTITUTE OF STEEL CONSTRUCTION AND A.S.T.M. TO AMERICAN SOCIETY FOR SCHEDULE OF CHB & CERAMIC BLOCK REINFORCEMENT THAN TWICE THE NOMINAL SIZE OF THE WELD.

TESTING MATERIALS.

BLOCK REINFORCEMENT TABLE "A"

NOTES: 10mm f. USE E70 ELECTRODES FOR ALL WELDS IN STRUCTURAL STEEL

L. UNLESS OTHERWISE INDICATED IN PLANS OR NOTED IN THE SPECIFICATION, THE THICKNESS

TENSION BARS

MINIMUM 28TH DAY CYLINDER COMPRESSIVE STRENGTH OF CONCRETE SHALL BE (NOMINAL) HORIZONTAL VERTICAL

A. MINIMUM LAPS AT SPLICE=0.25m EMBEDMENT LENGTH & LAP SPLICES g. SEE SPECIFICATIONS FOR NDT TEST REQUIREMENTS.

AS FOLLOWS:

B. PROVIDE RIGHT ANGLED REINFORCE- IN CENTIMETERS

MENT @ CORNERS 1.00m LONG. h. ALL WELDERS SHALL BE CERTIFIED WITH CURRENT CERTIFICATION

1. FOOTINGS, FOOTING TIE BEAMS: 100mm D10 @ 400mm D10 @ 300mm O.C.

C. WHERE CHB OR CERAMIC BLOCK WALLS BAR SIZE fc'=27.6 MPa CARRIED IN PERSON.

fc' = 21 MPa (3,000 psi) 150mm D10 @ 400mm D10 @ 300mm O.C.

2. COLUMNS: ADJOIN COL, RC BEAMS & WALLS. DOWELS W/ DEFORMED EMBEDMENT LAPPED

SAME AS VERT. OR HOR. C2. BOLTS

fc' = 21 MPa (3,000 psi) 200mm D10 @ 400mm D10 @ 300mm O.C.

3. BEAMS AND GIRDERS: REINF. SHALL BE PROVIDED. 10 30 30

i. MINIMUM EDGE DISTANCE:

fc' = 21 MPa (3,000 psi) 12 30 36 A. ALL VERTICALLY EMBEDDED PIPES FOR UTILITIES, ETC. SHALL BE MAXIMUM 100mm DIAMETER

THE MINIMUM EDGE DISTANCE OF BOLTS SHALL CONFORM TO

4. CHB LOAD BEARING WALL 16 36 45 SINGLE RIGID GALVANIZED IRON PIPE UNLESS OTHERWISE SPECIFIED OR APPROVED THE REQUIREMENTS OF AISC STEEL MANUAL 13th EDITION.

fc' = 21 MPa (3,000 psi) 20 36 55 IN WRITING BY THE STRUCTURAL ENGINEER.

PROVIDE HORIZONTAL & VERTICAL STIFFENER BEAMS AND COLUMNS AT 3000mm TYPICAL

5. WAREHOUSE SLAB ON GRADE (BURNISHED FLOOR SLAB) 22 52.5 62.5 THE MAXIMUM EDGE DISTANCE FROM BOLT CENTER SHALL BE

fc' = 21 MPa (3,000 psi) B. SUCH PIPES WHEN SO EMBEDDED SHALL NOT TAKE UP MORE THAN FOUR (4) PERCENT

25 56 95 12 TIMES THICKNESS OF THE PLATE BUT NOT TO EXCEED

ALL MASONRY WALLS SUPPORTED ON SOIL SHALL BE PROVIDED WITH A 600mm WIDE, 300mm THICK WALL FOUNDATION OF THE GROSS AREA OF THE CONCRETE MEMBER.

28 71 121 150mm.

EMBEDED 900mm DEEP FROM FINISHED GRADE LINE REINFORCED WITH 16mm DIAMETER TRANSVERSE BOTTOM BARS

M. 1. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT j. MINIMUM PITCH:

SPACED @ 200mm O.C. & LONGITUDINAL TEMPERATURE BARS ON TOP OF THE TRANSVERSE BARS. MASONRY WALL 32 93 156 C. ALL HORIZONTALLY EMBEDDED PIPES SHALL NOT BE ALLOWED UNLESS SPECIFICALLY INDICATED PLANS OR WITH

SEGREGATION, RE-HANDLING OR FLOWING. PLACING SHALL BE DONE PREFERABLY WITH SHALL BE CENTERED ON THE FOUNDATION. ON CENTER SPACING OF BOLTS SHALL NOT BE LESS THAN

BUGGIES, BUCKETS OR WHEELBARROWS, NO CHUTE WILL BE ALLOWED EXCEPT TO

36 151 179 PRIOR APPROVAL OF THE ENGINEER IN WRITTING. 3 TIMES THE NOMINAL DIAMETER OR 75mm WHICHEVER IS LARGER.

TRANSFER

CONCRETE FROM HOPPERS TO BUGGIES, WHEELBARROWS OR BUCKETS IN WHICH CASE C3. TOLERANCES

THEY SOME VARIATIONS EXPECTED IN THE FINISH OVERALL DIMENSIONS OF

SHALL NOT EXCEED SIX (6) METERS IN AGGREGATE LENGTH. TABLE "B" FRAMES SHALL NOT EXCEED THE ROLLING TOLERANCES FOR CROSS-

COMPRESSION BARS A. FILL AND SUBGRADES UNDER SLABS AND FOOTINGS SHALL BE COMPACTED TO A SECTIONAL DIMENSIONS, CAMBER AND SWEEP PERMITTED UNDER ASTM

2. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE USE OF VIBRATORS UNLESS EMBEDMENT LENGTH & LAP SPLICES MINIMUM 95% OF MAXIMUM DRY DENSITY BASED ON ASTM D-698 SPECIFICATION.

AUTHORIZED IN WRITING BY THE DESIGNER AND ONLY FOR UNUSUAL CONDITIONS WHERE A. ALL WALLS SHALL BE REINFORCED ACCORDING TO THE FOLLOWING SCHEDULE OF IN CENTIMETERS D. ERECTION

B. MAXIMUM LIFT THICKNESS FOR COMPACTION SHALL BE 250mm.

VIBRATION IS EXTREMELY DIFFICULT TO ACCOMPLISH. WALL REINFORCEMENT UNLESS OTHERWISE INDICATED IN THE PLANS.

BAR SIZE fc'=27.6 MPa C. MONITOR QUALITY OF COMPACTION USING AN INDEPENDENT TESTING LABORATORY. D1.

BRACING:

B. SEE ARCH. PLANS FOR SEISMIC GAP USING PROPRIETARY ITEMS. REFER TO STRUCTURAL PLANS FOR CUSTOM USE ASTM D-1558 PROCEDURE OR NUCLEAR GAGE ASTM D- THE FRAME OF STEEL STRUCTURE SKELETON SHALL BE CARRIED UP TRUE

3. SAMPLING FOR COMPRESSIVE STRENGTH TESTS SHALL BE MADE IN ACCORDANCE DEFORMED

MADE GAPS FOR LATERAL MOVEMENT EMBEDMENT LAPPED AND PLUMB, WITHIN THE LIMITS DEFINED IN THE AISC CODE OF STANDARD

WITH SPECIFICATIONS BUT SHALL NOT LESS THAN 1 SET FOR EACH DAY OF POUR.

PRACTICE. TEMPORARY BRACING SHALL BE PROVIDED TO RESIST ALL LOADS

10 20 30

INCLUDING ERECTION EQUIPMENT.

4. ALL FORMED CONCRETE INCLUDING EXTERIOR & INTERIOR WALLS SHALL BE POURED 12 20 30

STRAIGHT TO FINISH. WALL REINFORCEMENT VERTICAL

REMARKS 16 23 32.5 D2. ALIGNMENT:

THICKNESS HORIZONTAL VERTICAL SECTION

20 28 37.5 1.) CONTRACTOR SHALL ENSURE THAT ALL EXISTING STRUCTURES ARE PROPERLY AND NO RIVETTING, PERMANENT BOLTING OR WELDING SHALL BE DONE UNTIL

100mm D12 @ 250mm O.C. D12 @ 300mm O.C. HOR. BARS @

VERT. STAG. BARS

22 25 45 ADEQUATELY SUPPORTED AGAINST SETTLEMENT OR MOVEMENT DURING EXCAVATION. STRUCTURE HAS BEEN PROPERLY ALIGNED.

NOTES ON CONCRETE SLABS 125mm D12 @ 200 O.C. D12 @ 250 O.C. CENTER, VERT. 25 37 51

150mm D12 @ 250 O.C. D12 @ 300 O.C. BARS STAG. OUTSIDE HOR. BARS 28 42 57.5 D3. SAGRODS AND CROSS BRACINGS SHALL BE INSTALLED AND TIGHTENED BEFORE

N. ALL SLAB REINFORCEMENT SHALL BE 20.0mm CLEAR MINIMUM FROM BOTTOM AND FROM 175mm D12 @ 220 O.C. D12 @ 250 O.C. INSTALLATION OF ROOFING OR WALL CLADDING.

32 46 64

THE TOP OF SLAB. 200mm D12 @ 250 O.C.E.F. D12 @ 300 O.C.E.F. BOTH FACES

VERT. BARS 36 51 72 E. PAINTING AND SURFACE PREPARATION

225mm D12 @ 200 O.C.E.F. D12 @ 250 O.C.E.F. HOR. BARS SHALL 1. ALL SLABS ON GRADE SHALL BE DESIGNED WITH A MAXIMUM WATER CEMENT RATIO

250mm D12 @ 300 O.C.E.F. D12 @ 350 O.C.E.F. BE OUTSIDE E1. STEEL TO BE USED FOR ERECTION OF THIS STRUCTURE SHALL BE PAINTED AND

O. UNLESS OTHERWISE DETAILED, IN CONTINUOUS SLAB HAVING SAME REINFORCEMENT HOR. BARS OF 0.42 ANY DECREASE IN WORKABILITY SHALL BE COMPENSATED USING PLASTICIZER.

ITS SURFACE PREPARED IN COMPLIANCE WITH THE SPECIFICATIONS.

RUNNING IN ONE DIRECTION, REINFORCING BARS SHALL BE BENT UP, EXTENDED,

OR CUT AS FOLLOWS : 2. ALL SLOPES SHALL BE POURED INTEGRAL WITH SLAB. OVERLAYS OR TOPPING SHALL

E2. CONTRACTOR TO VERIFY WITH REPRESENTATIVES - PAINTING AND SURFACE

NOT BE ALLOWED.

REINFORCING BARS SHALL HAVE 25mm MINIMUM CLEAR CONCRETE COVER FROM FACE OF WALL EXCEPT PREPARATION SPECIFICATION BEFORE PROCEEDING WITH WORK.

FOR WALLS IN CONTACT WITH THE GROUND WHERE A MINIMUM OF 75mm SHALL BE PROVIDED, AND FOR 3. ADDITION OF 15% FLYASH TYPE "F" BY WEIGHT OF CEMENT SHALL BE MADE ON THE

EXPOSED FACES OF FORMED WALLS WHERE THE MINIMUM SHALL BE 50mm CLEAR. SLAB CONCRETE

1] CONTRACTOR TO SUBMIT MILL CERTIFICATE FOR GRADE 60 REBARS WITH

(VERIFY)

2 EDGE 4. CONTINUOUS WET CURING OF CONCRETE BY PONDING SHALL BE DONE FOR AT LEAST CATEGORICAL STATEMENT THAT NO QT/TMT BARS WILL BE IN BATCH TO BE

BARS C. CARRY VERTICAL BARS AT LEAST 600mm ABOVE FLOOR LEVEL TO PROVIDE FOR SPLICES, WHEN NECESSARY C. IF BEAM REINFORCING BARS END IN A WALL THE CLEAR DISTANCE FROM THE BAR 14 DAYS.

STOP AT 50mm BELOW TOP SLAB OR SOLID BAND WHERE THE WALL ENDS.VERTICAL AND HORIZONTAL BARS DELIVERED AT SITE. ANY QT/TMT REBARS TESTED AT SITE MAY CAUSE

200 MIN. TO THE FARTHER FACE OF THE WALL SHALL NOT BE LESS THAN 25mm. EMBEDMENT REJECTION OF WHOLE BATCH

SHALL BE SPLICED BY LAPPING A DISTANCE EQUAL TO 40 BAR DIAMETERS AND WIRED SECURELY WITH NO. LENGTH SHALL BE AS SHOWN IN TABLE "A" FOR TENSION BARS AND TABLE "B" FOR 5. SEE ARCHITECTURAL PLANS FOR WAREHOUSE FLOOR FINISH.

16 G.I. WIRE PROVIDED THAT SPLICES IN ADJACENT BARS ARE STAGERED AT LEAST 1.60m O.C.(SEE FIG. 4) COMPRESSION BARS.

D. IF THERE ARE TWO OR MORE LAYERS OF REINFORCING BARS USE 25mm DIAMETER BAR

SEPARATORS SPACED ABOUT 90 CENTIMETERS ON CENTER. IN NO CASE SHALL THERE

BE LESS THAN TWO (2) SEPARATORS BETWEEN LAYERS OF BARS. A MAP LAYOUT OF THE BURIED CREEK AFFECTING VARIOUS STRUCTURES IS

INCLUDED. CONTRACTOR TO DEMARCATE LOCATION DURING SITE EXCAVATION.

E. MINIMUM CONCRETE PROTECTION FOR REINFORCING BARS SHALL BE AS SHOWN IN FIG. 7. TREATMENT OF THE BURIED CREEK SHALL BE AS PER PLANS.

REFER TO GEOTECHNICAL REPORT.

SEE NOTE

C. IF SLABS ARE REINFORCED BOTHWAYS, BARS ALONG THE SHORTER SPAN SHALL BE NOTE:

PLACED BELOW THOSE ALONG THE LONG SPAN AT THE CENTER AND OVER AT THE 20mm CLEAR FOR JOIST

SUPPORTS. FOR THE REINFORCING BARS NEAR THE SUPPORTS, THE SPACING OF 40mm CLEAR FOR BEAMS

SPLICE

THE BARS AT THE COLUMN STRIPS SHALL BE APPROXIMATELY ONE AND WEBB BARS

400

& GIRDERS.

h

FLOOR LEVEL SEE NOTE

ONE HALF (1-1/2) THAT IN THE MIDDLE STRIPS BUT IN NO CASE GREATER THAN

TWO AND ONE HALF (2-1/2) TIMES THE SLAB THICKNESS NOR 45 CENTIMETERS.

D. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY DISTRIBUTED AROUND THE SECTION PLANE AND SHALL SEE NOTE D25

NOT BE LESS THAN 0.0018xBT AND THE SPACING NOT GREATER THAN 250mm. b SEPARATOR

D. UNLESS OTHERWISE NOTED IN THE PLAN, ALL OPENINGS IN WALLS 250mm OR LARGER SHALL BE REINFORCED

AROUND WITH 2-D20 BARS FOR 225mm, 175mm 150mm WALLS, USE 2-D16 BARS FOR 125mm AND 100mm WALLS,

USE 2-12mm BARS (SEE FIG. 5). ALL WALLS SPANNING OPENINGS SHALL HAVE VERTICAL REINFORCEMENT BENT

TO U-FORM LIKE STIRRUPS AND SPACED ACCORDING TO THE SCHEDULE UNLESS OTHERWISE NOTED (SEE

SECTION A OF FIG. 5)

2-BARS

U-FORM

OPEN

2-BARS

U-FORM

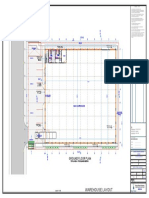

CONTRACTOR: CLIENT/OWNER : PROJECT TITLE: REGISTERED ENGINEER: PROJECT MANAGER: REFERENCES DRAWING: REVISION: SHEET CONTENT: DRAWN BY: DATE: 1/9/17

TRADE: ARCHITECTURAL STRUCTURAL ELECTRICAL MECHANICAL MARK REV. NO. DATE DESCRIPTION GENERAL NOTES CHECKED BY: NMD SCALE: AS SHOWN

2ND ST. FPIP

Agacons Construction Inc. Philippines Inc. BARANGAY ULANGO TANAUAN TOWER 2 NOEL M. DONATO ** DWG. NO. APPROVED BY: SAVE DATE:

CIVIL * MECHANICAL * ELECTRICAL CONTRACTOR TANAUAN CITY, BATANGAS FIRST PHILIPPINES INDUSTRIAL PARK

Tanauan Factory CIVIL/STRUCTURAL ENGINEER A.C.I PROJECT IN CHARGE REV. DRAWING NO : REV:

PHILIPPINES

APPROVED: DATE: LOCATION:

2ND ST. FPIP, BARANGAY ULANGO,

TANAUAN CITY, BATANGAS PHILIPPINES

REG. NO: 79498

ISSUED ON:*

PTR NO: *

ISSUED AT: QUEZON CITY DATE: CAD FILE NAME : S1 00

You might also like

- PlanDocument8 pagesPlanMark Christian EsguerraNo ratings yet

- Structual Plan 2-Storey ResidentialDocument9 pagesStructual Plan 2-Storey ResidentialMark Christian EsguerraNo ratings yet

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Document1 pageConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASNo ratings yet

- Structural Notes & Specifications: 3 FormworksDocument1 pageStructural Notes & Specifications: 3 FormworksRonnie Buico Conejos CENo ratings yet

- General Slab On Ground Concrete Concrete Continued Chemical AnchorsDocument12 pagesGeneral Slab On Ground Concrete Concrete Continued Chemical AnchorsJelenaNo ratings yet

- Design: Construction NotesDocument1 pageDesign: Construction NotesLhea May Paz SarguetNo ratings yet

- General Construction Notes:: Notes On Beams and GirdersDocument1 pageGeneral Construction Notes:: Notes On Beams and GirdersJaycee RollanNo ratings yet

- StrucDocument3 pagesStrucAlvin DeliroNo ratings yet

- E:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntDocument2 pagesE:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntHoang Nguyen HuyNo ratings yet

- Structural Specifications and Standard DetailsDocument1 pageStructural Specifications and Standard Detailsdomin domNo ratings yet

- Ipil - Main Building Structural Plan - 10.10.23Document9 pagesIpil - Main Building Structural Plan - 10.10.23Mark Andykenn Liaga MaglinteNo ratings yet

- s3-11 - Tower 1 Shear Wall ElevationDocument1 pages3-11 - Tower 1 Shear Wall ElevationJason toraldeNo ratings yet

- C-1 Mark C-2: Stair Detail 2 Stair Detail 3Document1 pageC-1 Mark C-2: Stair Detail 2 Stair Detail 3Ysabelle TagarumaNo ratings yet

- Key Plan: Boiler Unit #1Document2 pagesKey Plan: Boiler Unit #1Jitendra DubeyNo ratings yet

- Neral NotesDocument6 pagesNeral NotesNam Trần Nguyễn NhậtNo ratings yet

- Water TankDocument1 pageWater TankProject ManagerStructuresNo ratings yet

- Annex 02Document12 pagesAnnex 02rukshan jayasingheNo ratings yet

- 400kV ICT1 RegisterDocument27 pages400kV ICT1 RegisterMidhun VargheseNo ratings yet

- Zoleta Residence - Structural PlansDocument5 pagesZoleta Residence - Structural PlansJc SulitNo ratings yet

- Residential bldg-CS0Document1 pageResidential bldg-CS0ar.arvinarceNo ratings yet

- Floor Plan: DRY BalconyDocument1 pageFloor Plan: DRY Balconysaurabh kotechaNo ratings yet

- Confidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116Document1 pageConfidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116mirza.adeelNo ratings yet

- Beam SideDocument1 pageBeam SideKwaku frimpongNo ratings yet

- Setting Out: NotesDocument1 pageSetting Out: NotesKwaku frimpongNo ratings yet

- KwakuDocument1 pageKwakuKwaku frimpongNo ratings yet

- Fa 3RDDocument1 pageFa 3RDAhmed KhalilNo ratings yet

- 4124 Ai Du 21130i046s01 Is01 - Checkprint - DineshDocument1 page4124 Ai Du 21130i046s01 Is01 - Checkprint - Dineshamit bagchiNo ratings yet

- Details - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End DetailsDocument1 pageDetails - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End Detailsacurvz2005No ratings yet

- Stairs and Platform PDFDocument1 pageStairs and Platform PDFBenderlip CortezNo ratings yet

- Orion: New Pta Complex ProjectDocument1 pageOrion: New Pta Complex ProjectAli KayaNo ratings yet

- See Detail 1: NotesDocument1 pageSee Detail 1: NotesYazan MohammadNo ratings yet

- General notes and steelwork specificationsDocument1 pageGeneral notes and steelwork specificationsKeise AliNo ratings yet

- Notes:: Hinge DetailsDocument1 pageNotes:: Hinge DetailsYazan MohammadNo ratings yet

- NDRS FOB Part-1 Superstructure NOC DrawingsDocument3 pagesNDRS FOB Part-1 Superstructure NOC Drawingsrakesh bhartiNo ratings yet

- Annex 10 - KnowledgeDocument1 pageAnnex 10 - KnowledgeHaryono MrNo ratings yet

- 1.air Blower-Tesr - Sludge Sump STR DetailDocument1 page1.air Blower-Tesr - Sludge Sump STR DetailRohit JangidNo ratings yet

- Structural PlanDocument1 pageStructural PlanGenevieve GayosoNo ratings yet

- v9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFDocument1 pagev9r49g3zk0pg - 12. KPLC Warehouse Revised May 2014 GFEllyella ElormNo ratings yet

- 04-R.C.C DETAIL IN R.I.B-ModelDocument1 page04-R.C.C DETAIL IN R.I.B-ModelManvendra Singh RaghuwanshiNo ratings yet

- Sa-0224302 0004 0001Document1 pageSa-0224302 0004 0001Bilal ChohanNo ratings yet

- Pedestal Details: General NotesDocument1 pagePedestal Details: General Notesmhazarath murariNo ratings yet

- Section Aa' Section BB' Section CC': DRG NoDocument1 pageSection Aa' Section BB' Section CC': DRG NoSamta YadavNo ratings yet

- Sample Structural DrawingDocument1 pageSample Structural DrawingCherish Taguinod Aliguyon100% (1)

- Ysc Ms 769 DW 0001sht2of2 Rev BDocument1 pageYsc Ms 769 DW 0001sht2of2 Rev BbalamuralinakshatraNo ratings yet

- Plumbing Permit Drawings PDFDocument3 pagesPlumbing Permit Drawings PDFJeremy BoyceNo ratings yet

- Structural Notes for I-Joist and Steel FramingDocument12 pagesStructural Notes for I-Joist and Steel FramingShekh Muhsen Uddin AhmedNo ratings yet

- 400kV ICT2 RegisterDocument27 pages400kV ICT2 RegisterMidhun VargheseNo ratings yet

- Terrace Floor General NotesDocument1 pageTerrace Floor General NotesradhapunnaNo ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 3TOM YEENo ratings yet

- s101 - Mezzenine Floor Layout PlanDocument1 pages101 - Mezzenine Floor Layout PlanOsama FouadNo ratings yet

- Ttag NTC Sds Mep DP MB 01Document1 pageTtag NTC Sds Mep DP MB 01Đỗ Thanh HùngNo ratings yet

- Detailed column and footing reinforcement notesDocument1 pageDetailed column and footing reinforcement notesom RakseNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- AB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCODocument1 pageAB-036400 - Ceramic Board and Blanket Installation - SAUDI ARAMCOAkhil GeorgeNo ratings yet

- ADC Part 2Document1 pageADC Part 2Maung PDDNo ratings yet

- First Floor Level Beam Details Part-2 (Sheet-1 of 2)Document1 pageFirst Floor Level Beam Details Part-2 (Sheet-1 of 2)Sumit LathwalNo ratings yet

- Typical Structural Abbreviations Typical Symbols Legend Typical Plan NotesDocument33 pagesTypical Structural Abbreviations Typical Symbols Legend Typical Plan NotesINNOBUNo7No ratings yet

- Akhilesh Tiwari Prda-ModelDocument1 pageAkhilesh Tiwari Prda-ModelSHUBHAM KUMARNo ratings yet

- Pulse Velocity Using Concrete PropertiesDocument1 pagePulse Velocity Using Concrete Propertiesbobmarley20161934No ratings yet

- Slip Form Front Page OnlyDocument1 pageSlip Form Front Page Onlybobmarley20161934No ratings yet

- Reference For Acicode PDFDocument1 pageReference For Acicode PDFbobmarley20161934No ratings yet

- Reference For Acicode PDFDocument1 pageReference For Acicode PDFbobmarley20161934No ratings yet

- ACI Manual of Concrete Inspection PDFDocument1 pageACI Manual of Concrete Inspection PDFSushil Dhungana33% (3)

- Map 1m Below Metro ManilaDocument1 pageMap 1m Below Metro Manilabobmarley20161934No ratings yet

- Front Page Design and Control of MixDocument1 pageFront Page Design and Control of Mixbobmarley20161934No ratings yet

- Reinforcement Front PageDocument1 pageReinforcement Front Pagebobmarley20161934No ratings yet

- Reference For Acicode PDFDocument1 pageReference For Acicode PDFbobmarley20161934No ratings yet

- Water Cement RatioDocument1 pageWater Cement Ratiobobmarley20161934No ratings yet

- Guide To Hot Weather Front Page OnlyDocument1 pageGuide To Hot Weather Front Page Onlybobmarley20161934No ratings yet

- Sample CheckDocument1 pageSample Checkbobmarley20161934No ratings yet

- Crude OilDocument1 pageCrude Oilbobmarley20161934No ratings yet

- Random CheckDocument1 pageRandom Checkbobmarley20161934No ratings yet

- Bar Lap Gap SpacingDocument1 pageBar Lap Gap Spacingbobmarley20161934No ratings yet

- Mechanical LoadingDocument1 pageMechanical Loadingbobmarley20161934No ratings yet

- Concrete Duct BankDocument1 pageConcrete Duct Bankbobmarley20161934No ratings yet

- BlurDocument1 pageBlurbobmarley20161934No ratings yet

- Front FenceDocument1 pageFront Fencebobmarley20161934No ratings yet

- DL RatioDocument1 pageDL Ratiobobmarley20161934No ratings yet

- Corrosion-Understanding The Basics Front PageDocument1 pageCorrosion-Understanding The Basics Front Pagebobmarley20161934No ratings yet

- STAAD Design ParametersDocument8 pagesSTAAD Design Parametersbobmarley20161934No ratings yet

- Commentary Chapter 10Document1 pageCommentary Chapter 10bobmarley20161934No ratings yet

- A To B 8.250 Meters: Sap2000 Computer ModelDocument4 pagesA To B 8.250 Meters: Sap2000 Computer Modelbobmarley20161934No ratings yet

- Sample Hydro PowerDocument2 pagesSample Hydro Powerbobmarley20161934No ratings yet

- Analysis and Design of A Simple Surge TankDocument7 pagesAnalysis and Design of A Simple Surge Tankbobmarley20161934No ratings yet

- Construction JointDocument1 pageConstruction Jointbobmarley20161934No ratings yet

- ASCE Steel Penstock Front Page OnlyDocument1 pageASCE Steel Penstock Front Page Onlybobmarley20161934No ratings yet

- Hydraulic Structures Front PageDocument1 pageHydraulic Structures Front Pagebobmarley20161934No ratings yet

- CaptureDocument1 pageCapturebobmarley20161934No ratings yet

- Fracture Mechanics HandbookDocument27 pagesFracture Mechanics Handbooksathya86online0% (1)

- Study Guide For Kawabata's "Of Birds and Beasts"Document3 pagesStudy Guide For Kawabata's "Of Birds and Beasts"BeholdmyswarthyfaceNo ratings yet

- Eye Floaters Cure - Natural Treatment For Eye FloatersDocument34 pagesEye Floaters Cure - Natural Treatment For Eye FloatersVilluri Venkata Kannaapparao50% (2)

- The New York Times OppenheimerDocument3 pagesThe New York Times Oppenheimer徐大头No ratings yet

- Parallel Merge Sort With MPIDocument12 pagesParallel Merge Sort With MPIIrsa kanwallNo ratings yet

- Write EssayDocument141 pagesWrite Essayamsyous100% (1)

- ISO 18794. Café. Análisis Sensorial. Vocabulario. Ingles PDFDocument16 pagesISO 18794. Café. Análisis Sensorial. Vocabulario. Ingles PDFluigi sanchezNo ratings yet

- Rio 20 Conference SummaryDocument3 pagesRio 20 Conference SummaryAyush BishtNo ratings yet

- Writing Patterns NotesDocument2 pagesWriting Patterns NoteslwitsfadontNo ratings yet

- Ear Discharge (Otorrhoea) FinalDocument24 pagesEar Discharge (Otorrhoea) Finaljaya ruban100% (1)

- Committees of UWSLDocument10 pagesCommittees of UWSLVanshika ChoudharyNo ratings yet

- Development of Overall Audit StrategyDocument4 pagesDevelopment of Overall Audit StrategyPhrexilyn PajarilloNo ratings yet

- Agriculture DisciplineDocument3 pagesAgriculture DisciplineUmair FaheemNo ratings yet

- Data & InformationDocument48 pagesData & InformationDave DearingNo ratings yet

- List of Licensed Insurance Intermediaries Kenya - 2019Document2 pagesList of Licensed Insurance Intermediaries Kenya - 2019Tony MutNo ratings yet

- PistonDocument247 pagesPistonmeyyiti01No ratings yet

- Addams Family Character BreakdownDocument2 pagesAddams Family Character BreakdowngabreNo ratings yet

- Listening & Speaking Test_Unit 6 ReviewDocument4 pagesListening & Speaking Test_Unit 6 ReviewMaii PhươngNo ratings yet

- 20 ASL Circular-1 PDFDocument3 pages20 ASL Circular-1 PDFAlagu MurugesanNo ratings yet

- Business Ethics and Social ResponsibilityDocument16 pagesBusiness Ethics and Social Responsibilitytitan abcdNo ratings yet

- Quarter 4 English 3 DLL Week 1Document8 pagesQuarter 4 English 3 DLL Week 1Mary Rose P. RiveraNo ratings yet

- Nucor at A CrossroadsDocument10 pagesNucor at A CrossroadsAlok C100% (2)

- E Book On ADC ProductsDocument29 pagesE Book On ADC ProductsSudharani YellapragadaNo ratings yet

- Political Education and Voting Behaviour in Nigeria: A Case Study of Ogbadibo Local Government Area of Benue StateDocument24 pagesPolitical Education and Voting Behaviour in Nigeria: A Case Study of Ogbadibo Local Government Area of Benue StateMohd Noor FakhrullahNo ratings yet

- EHV AC Transmission System Design and AnalysisDocument104 pagesEHV AC Transmission System Design and Analysispraveenmande100% (1)

- REINFORCED CONCRETE DESIGNDocument22 pagesREINFORCED CONCRETE DESIGNEMIL JOHN P. ANTONIONo ratings yet

- MEM - Project Pump and TurbineDocument22 pagesMEM - Project Pump and TurbineAbhi ChavanNo ratings yet

- Worldcom, Inc.: Corporate Bond Issuance: CompanyDocument14 pagesWorldcom, Inc.: Corporate Bond Issuance: CompanyLe Nguyen Thu UyenNo ratings yet

- Assess White PaperDocument6 pagesAssess White PaperCristian ColicoNo ratings yet

- Simulation of The Pyrolysis Process From Plastic WasteDocument5 pagesSimulation of The Pyrolysis Process From Plastic WasteManicks VelanNo ratings yet