Professional Documents

Culture Documents

HSE-P-06 Monitoring and Measurement Issue 2.1

Uploaded by

eng20072007Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE-P-06 Monitoring and Measurement Issue 2.1

Uploaded by

eng20072007Copyright:

Available Formats

HSE Procedures

SUEZ OIL COMPANY Cairo-HSE-P-06

Paper Copy Valid one month from Print Date

HSE Monitoring and Measurement Procedure

Cairo-HSE-P-06

1.0 Purpose

The purpose of this procedure is to describe how critical HSE parameters are identified,

monitored, measured and recorded.

2.0 Scope of application

This procedure covers procedures to be followed applicable to all SUCO operations at

Cairo and the fields. It includes activities generated and managed by Cairo Head Office and

implemented at the fields.

3.0 Responsibilities

The local HSE co-ordinator discusses with operations, maintenance and laboratory staff and

the HSE Assistant General Managers the optimum measurement regime for each critical

parameter.

The local HSE co-ordinator maintains a list of all critical parameters and relevant key

parameter measurement details.

Field and Division Managers are responsible for ensuring the required monitoring is done to

schedule.

When parameters fall outside the expected range then the Field or Division Manager is

responsible for ensuring that the corrective action system is used to record, investigate and

resolve the problem.

4.0 Procedure

4.1 Identifying Key Parameters

Any activity, product or service is identified as having the potential for significant Health

and Safety Risk or environmental impact or using the procedures, HSE Risk Assessment

Cairo HSE P-09 and Identification of Environmental Aspects, Cairo-HSE-P-05.

Once any activity, product or service has an identified significant risk or environmental

aspect then the essential elements for controlling that aspect need to be defined. This may

include provision of a written operating procedure or other control. In addition key

parameters for monitoring and measurement should be defined.

Whether a written operating procedure is provided or not, the need for recording

information to ensure the issue is under control is still required.

Issue 2.1 January 2005 Next Revision Date - 31/12/07 Page 1 of 4

HSE Procedures

SUEZ OIL COMPANY Cairo-HSE-P-06

Paper Copy Valid one month from Print Date

The local HSE co-ordinator maintains a list of all critical parameters and relevant key

parameter measurement details for these significant factors.

The co-ordinator updates the documentation with the new parameters when new parameters

to measure are identified.

4.2 Monitoring and Measurement Types

Key parameters fall into several categories. Those that can be:

Type 1 - Measured readily by an established measurement technique

e.g. internal site laboratory testing

Type 2 - Those that can be established periodically by surveys, observations or

counts

e.g. lighting, noise, radioactivity, stocks of sludge etc.

Type 3 - Those that require external assistance

e.g. specialized laboratory testing

Type 4 - Those that require measurement of progress or actions

e.g. corrective actions, project plans for environmental improvements etc.

Having identified the key parameters to be monitored and measured, the co-ordinator must

consider the above categories to determine the appropriate measurement category.

Note that key parameters may be measured by more than one of the above categories. For

example, routine water effluent emissions are monitored daily but also analysed annually by

external laboratory.

4.3 Measurement Information Required

The local environmental co-ordinator then discusses with operations, maintenance and

laboratory staff and the HSE Assistant General Managers to determine the optimum

measurement regime.

The criteria to be specified are

Hazard or risk/significant aspect

key characteristic

type of monitoring required

measurement units

desired value

acceptable range

measurement frequency and time/schedule

measurement method

calibration frequency and method

reporting of results

Issue 2.1 January 2005 Next Revision Date - 31/12/07 Page 2 of 4

HSE Procedures

SUEZ OIL COMPANY Cairo-HSE-P-06

Paper Copy Valid one month from Print Date

record retention and time

4.4 Non-conformance and Corrective Actions

Type 1 Measurements

When results fall outside the expected range of measurement corrective actions must be

taken to bring the parameter back into control. In addition these should be investigated

through the accident reporting and investigation system

Type 2 and 3 Measurements

These measurements are generally reviewed and evaluated by Field and Cairo HSE. In

these cases the corrective actions will be assigned based on the type of study or exercise

carried out. eg. re-testing, further study or other action.

Type 4 Measurements

Field Managers should review progress on these actions on a regular bi-monthly schedule.

Records of meeting minutes, action status or reviews should be kept.

Any actions that have slipped or are not effective should be discussed and further actions

proposed. This should also be minuted and followed up.

5.0 Applicable Forms

Monitoring and Measurement Sheet

6.0 Required Records

The HSE co-ordinator holds a summary sheet of key parameters being monitored.

Key parameters monitored are recorded on local results sheets.

Calibration status sheets are held by the relevant operations, maintenance, laboratory or

HSE staff who are responsible for arranging the calibration.

The HSE Assistant General Manager holds the schedule and records for testing done by

external laboratories.

Minutes of Field corrective action progress meetings are held by the Field HSE co-

ordinator.

Minutes of Project plan and progress review meetings are held by the relevant project

manager.

Issue 2.1 January 2005 Next Revision Date - 31/12/07 Page 3 of 4

HSE Procedures

SUEZ OIL COMPANY Cairo-HSE-P-06

Paper Copy Valid one month from Print Date

Critical HSE Parameters for Monitoring

ID HSE Risk Critical Measurement Desired Units Acceptable Frequency Test Method Calibration Results Record

orSignificant Aspect parameter Type Value Range or Schedule Method Reported Retention

(+frequency) to Time

Issue 2.1 January 2005 Next Revision Date - 31/12/07 Page 1of 4

You might also like

- HSE Performance Monitoring and MeasurementDocument6 pagesHSE Performance Monitoring and Measurementpawan pandey100% (4)

- 06 - Procedure For Performance Measurement MonitoringDocument5 pages06 - Procedure For Performance Measurement Monitoringbelhareth seifeddineNo ratings yet

- Environmental PlanDocument17 pagesEnvironmental PlanSakthi Kasi RajanNo ratings yet

- ISO 45001 HSE Manual and Forms ListDocument5 pagesISO 45001 HSE Manual and Forms ListWAN NORASHIKIN WAN MUSANo ratings yet

- Control of Substances Hazardous To Health (COSHH) Procedure Ref HS-0001-013-v2Document24 pagesControl of Substances Hazardous To Health (COSHH) Procedure Ref HS-0001-013-v2Tiago FerreiraNo ratings yet

- Environmental and Waste Management Plan (EMP) - 1Document31 pagesEnvironmental and Waste Management Plan (EMP) - 1Ekum EdunghuNo ratings yet

- WDC 2013-14 Health & Safety ReportDocument18 pagesWDC 2013-14 Health & Safety ReportSarah WalkerNo ratings yet

- Appendix 2 Hse Screening QuestionnaireDocument4 pagesAppendix 2 Hse Screening QuestionnaireSuad100% (1)

- HSE-P-07 Work Permit Procedure Issue 2.1Document30 pagesHSE-P-07 Work Permit Procedure Issue 2.1eng20072007100% (1)

- 2.2 Driving PolicyDocument2 pages2.2 Driving Policyoussama_88100% (1)

- FM - HSE COSHH Assessment-2Document3 pagesFM - HSE COSHH Assessment-2anisaanNo ratings yet

- Apendix 13-HSE Plan ManualDocument50 pagesApendix 13-HSE Plan ManualShahid IqbalNo ratings yet

- Health Safety and Environment Manual FSDocument101 pagesHealth Safety and Environment Manual FSZulhilmi Zalizan100% (1)

- Hsem-Sp-0014 Nidaa Journey ManagementDocument6 pagesHsem-Sp-0014 Nidaa Journey ManagementAhmed Imtiaz RaoNo ratings yet

- Planning and Procedures: Pdo Hse Management System Manual (CP-122)Document10 pagesPlanning and Procedures: Pdo Hse Management System Manual (CP-122)AHMEDNABTNo ratings yet

- CoP - 9.0 - Workplace WellnessDocument9 pagesCoP - 9.0 - Workplace WellnessAnonymous y1pIqcNo ratings yet

- 11-2.3.02 Coshh (Control of Substances Hazardous To Health)Document17 pages11-2.3.02 Coshh (Control of Substances Hazardous To Health)Francisco M. RamosNo ratings yet

- Incident Accident RegisterDocument2 pagesIncident Accident RegisterMuruganNo ratings yet

- HSE MGT - System PDFDocument70 pagesHSE MGT - System PDFNaveen Chaudhary100% (1)

- HSE Auditing ProcedureDocument15 pagesHSE Auditing Proceduresudeesh kumarNo ratings yet

- 10 Audit and Management Review Procedure FINALDocument3 pages10 Audit and Management Review Procedure FINALDayne Ocampo-SolimanNo ratings yet

- PTW AUDIT FORM SAFETYDocument1 pagePTW AUDIT FORM SAFETYdammyNo ratings yet

- 5 HseDocument48 pages5 HseKarthikNo ratings yet

- 95-0140 EP HSE Strategy and Policy Implementation GuideDocument90 pages95-0140 EP HSE Strategy and Policy Implementation GuideClive Nicli100% (1)

- Noise Monitoring Record FormDocument2 pagesNoise Monitoring Record FormMalefane Cortez TlatlaneNo ratings yet

- HSE - Operation Controls ABE-HSE-OP-01Document6 pagesHSE - Operation Controls ABE-HSE-OP-01Faisal RazaNo ratings yet

- Permit To Work ProcedureDocument42 pagesPermit To Work ProcedureKhuda Buksh100% (1)

- Site Safety Audit ReportDocument3 pagesSite Safety Audit Reportasem sawalmehNo ratings yet

- Minutes of Meeting-RC Safety Staff Meeting 6 23SEP15-Final DraftDocument5 pagesMinutes of Meeting-RC Safety Staff Meeting 6 23SEP15-Final DraftMohammed Jai Sujiya KhanNo ratings yet

- Marafiq OHSMS Pre-Qualification QuestionnaireDocument17 pagesMarafiq OHSMS Pre-Qualification QuestionnairemedobasNo ratings yet

- Powered Hand ToolsDocument4 pagesPowered Hand Toolssile15No ratings yet

- Machine excavation hazard analysisDocument7 pagesMachine excavation hazard analysisVenkadesh Periathambi100% (1)

- Toolbox Talk ChecklistDocument1 pageToolbox Talk ChecklistShafie ZubierNo ratings yet

- Sample HSE KPI Report - Doc2Document6 pagesSample HSE KPI Report - Doc2Edo-Abasi EkereNo ratings yet

- Project HSE Performance Monitoring ProcedureDocument12 pagesProject HSE Performance Monitoring ProcedureWinnie Eldama0% (1)

- HSE Auditing Procedure PDFDocument30 pagesHSE Auditing Procedure PDFHosam Mahmoud100% (2)

- HSE Formats (9508 - Part1)Document50 pagesHSE Formats (9508 - Part1)Paras Jani100% (1)

- Annexure - IV - Contractor HSE Capability Assessment Sheet - Rev 00 - VibrantDocument4 pagesAnnexure - IV - Contractor HSE Capability Assessment Sheet - Rev 00 - VibrantGovindKrishnanNo ratings yet

- HSE Management Plan RequirementsDocument5 pagesHSE Management Plan RequirementsMohamed Hadjkacem100% (1)

- Hse Plan EngDocument45 pagesHse Plan EngSayed DarwishNo ratings yet

- 3S HSE MS Docs ContentDocument85 pages3S HSE MS Docs Contentrashid zamanNo ratings yet

- Appendix A2.2 - Project Hse Plan PDFDocument20 pagesAppendix A2.2 - Project Hse Plan PDFEdo-Abasi Ekere100% (1)

- Safety Assessment Questionnaire AppendixDocument26 pagesSafety Assessment Questionnaire AppendixSignam Specialised CoatingsNo ratings yet

- Oil India Limited: Onshore Emergency Response PlanDocument23 pagesOil India Limited: Onshore Emergency Response Planaji sathyanandanNo ratings yet

- Monthly HSE Performance Report Form DTLP FEB-21Document2 pagesMonthly HSE Performance Report Form DTLP FEB-21Muhammad Khan100% (1)

- HSE Training Plan-2013Document1 pageHSE Training Plan-2013Abd ZouhierNo ratings yet

- Training Matrix ProcedureDocument5 pagesTraining Matrix ProcedureSérgio CoutoNo ratings yet

- Scaffold Safety AssessmentDocument2 pagesScaffold Safety Assessmentarnel sungkip100% (1)

- Safety Monitoring Plan (OGF-HSE-035)Document1 pageSafety Monitoring Plan (OGF-HSE-035)sarge18No ratings yet

- All Forms HSE Docs by Hseprof Com 1697423389Document76 pagesAll Forms HSE Docs by Hseprof Com 1697423389ahmedalderbi801No ratings yet

- ANTON - HSE Management Plan - 2022Document72 pagesANTON - HSE Management Plan - 2022Geyko RuslanNo ratings yet

- HSE Statistics PDFDocument5 pagesHSE Statistics PDFRashid100% (1)

- HSE Plan - IRQ-HPM-V1 - Mar 2021Document22 pagesHSE Plan - IRQ-HPM-V1 - Mar 2021amjed naama100% (2)

- Procedure For Objectives and TargetsDocument2 pagesProcedure For Objectives and TargetsSAKTHIVEL A100% (1)

- List of Record - HseDocument2 pagesList of Record - HseMohd FadlyNo ratings yet

- HSE Action PlanDocument3 pagesHSE Action PlanELANCHELIYANNo ratings yet

- HSE Monitoring and Measurement Procedure: Suez Oil CompanyDocument6 pagesHSE Monitoring and Measurement Procedure: Suez Oil Companyeng20072007No ratings yet

- HSE Monitoring and Measurement Procedure: Suez Oil CompanyDocument6 pagesHSE Monitoring and Measurement Procedure: Suez Oil CompanyzakalyNo ratings yet

- HSE-P-04 Periodic Evaluation of Legal Compliance Issue 2.1Document3 pagesHSE-P-04 Periodic Evaluation of Legal Compliance Issue 2.1eng20072007No ratings yet

- HSE-P-05 Identification of Environmental Aspects Issue 3.1Document14 pagesHSE-P-05 Identification of Environmental Aspects Issue 3.1eng20072007No ratings yet

- Water Treatment PidDocument1 pageWater Treatment Pideng20072007No ratings yet

- City Director of Public Works Organizational ChartDocument2 pagesCity Director of Public Works Organizational Charteng20072007No ratings yet

- Adding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017Document1 pageAdding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017eng20072007No ratings yet

- BlocksDrilling Line Rev-Peview PDFDocument11 pagesBlocksDrilling Line Rev-Peview PDFLa Ode Hadi AugustmanNo ratings yet

- Factory PidDocument1 pageFactory Pideng20072007No ratings yet

- City Director of Public Works Organizational ChartDocument2 pagesCity Director of Public Works Organizational Charteng20072007No ratings yet

- Factory PidDocument1 pageFactory Pideng20072007No ratings yet

- Oklahoma Corporation Commission: Packer Setting ReportDocument2 pagesOklahoma Corporation Commission: Packer Setting Reporteng20072007No ratings yet

- Warna Three: What Is Marketing?Document11 pagesWarna Three: What Is Marketing?eng20072007No ratings yet

- 1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3Document1 page1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3eng20072007No ratings yet

- Envelope Envelope-11Document1 pageEnvelope Envelope-11eng20072007No ratings yet

- DareDocument11 pagesDareeng20072007No ratings yet

- Reliability and Risk Assessment: Ace 4 ApDocument1 pageReliability and Risk Assessment: Ace 4 Apeng20072007No ratings yet

- El Sayed Amer Last UpdatedDocument3 pagesEl Sayed Amer Last Updatedeng20072007No ratings yet

- Ngdiploma EnglishDocument2 pagesNgdiploma Englisheng20072007No ratings yet

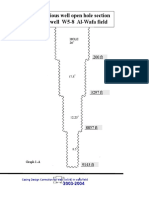

- Previous Well Open Hole Section For Well W5-8 Al-Wafa FieldDocument4 pagesPrevious Well Open Hole Section For Well W5-8 Al-Wafa Fieldeng20072007No ratings yet

- Block ProposalDocument11 pagesBlock Proposaleng20072007No ratings yet

- SuperbizDocument11 pagesSuperbizeng20072007No ratings yet

- 1007 DISQ 0 J SS 33030 Control Valve SpecificationDocument18 pages1007 DISQ 0 J SS 33030 Control Valve Specificationeng20072007No ratings yet

- Duplicate Cleaner LogDocument1 pageDuplicate Cleaner LogMuhammad Hafizuddin Bin JumadinNo ratings yet

- Gad SeparatorDocument3 pagesGad Separatoreng20072007No ratings yet

- 1007-Disq-0-L-ss-39151 Rev 2 Spec For Chemical Cleaning of PipingDocument10 pages1007-Disq-0-L-ss-39151 Rev 2 Spec For Chemical Cleaning of Pipingeng20072007No ratings yet

- 5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)Document6 pages5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)eng20072007No ratings yet

- 0 - Cources IntroductionDocument5 pages0 - Cources Introductioneng20072007No ratings yet

- احدث CVDocument4 pagesاحدث CVeng20072007No ratings yet

- 5-1 13 3/8" Surface Casing DesignDocument10 pages5-1 13 3/8" Surface Casing Designeng20072007No ratings yet

- 1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers SpecificationDocument18 pages1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers Specificationeng20072007No ratings yet

- 1007-DISQ-0-M-SS-42026-Rev.3 ValvesDocument13 pages1007-DISQ-0-M-SS-42026-Rev.3 Valveseng20072007No ratings yet

- 1007-Disq-0-L-ss-39154 Rev 2 Supplementary Purchasing Requirements For ValvesDocument14 pages1007-Disq-0-L-ss-39154 Rev 2 Supplementary Purchasing Requirements For Valveseng20072007No ratings yet

- 1007 Disq 0 G Ae 30033 Rev 5 Equipment ListDocument22 pages1007 Disq 0 G Ae 30033 Rev 5 Equipment Listeng20072007100% (1)

- Iso 27001 Auditor TrainingDocument19 pagesIso 27001 Auditor TrainingITOPS TeamNo ratings yet

- Eight Directions Feng ShuiDocument6 pagesEight Directions Feng Shuifree_scribdNo ratings yet

- ME 205 - Statics Course Syllabus: Fall 2015Document4 pagesME 205 - Statics Course Syllabus: Fall 2015Dhenil ManubatNo ratings yet

- On The Optimum Inter-Stage Parameters For Co Transcritical Systems Dr. Dan ManoleDocument8 pagesOn The Optimum Inter-Stage Parameters For Co Transcritical Systems Dr. Dan Manolemohammed gwailNo ratings yet

- TK17 V10 ReadmeDocument72 pagesTK17 V10 ReadmePaula PérezNo ratings yet

- Apostolic Faith: Beginn NG of World REV VALDocument4 pagesApostolic Faith: Beginn NG of World REV VALMichael HerringNo ratings yet

- ICT Backup Procedure PolicyDocument8 pagesICT Backup Procedure PolicySultan BatoorNo ratings yet

- Properties and Behavior of GasesDocument34 pagesProperties and Behavior of GasesPaul Jeremiah Serrano NarvaezNo ratings yet

- Bangladesh Red Crescent Society First Aid Kit SpecificationDocument1 pageBangladesh Red Crescent Society First Aid Kit SpecificationWORLDWIDE TRANSLATIONNo ratings yet

- AA Practice Problems on Amino Acids and Peptides (less than 40 charsDocument20 pagesAA Practice Problems on Amino Acids and Peptides (less than 40 charsNurlaeli NaelulmunaMajdiyahNo ratings yet

- Understanding the Difference Between Positive and Normative EconomicsDocument21 pagesUnderstanding the Difference Between Positive and Normative EconomicsKevin Fernandez MendioroNo ratings yet

- INDIAMART 25012022003631 Investor Presentation Q3FY2021-22Document84 pagesINDIAMART 25012022003631 Investor Presentation Q3FY2021-22geethvazNo ratings yet

- AMX-3 Prom AdaptorDocument18 pagesAMX-3 Prom AdaptorEmmanuel RamirezNo ratings yet

- Literature Review BUS 507 PDFDocument18 pagesLiterature Review BUS 507 PDFtanmoy8554No ratings yet

- Totally New Term Dates 2013.20Document9 pagesTotally New Term Dates 2013.20nabub8No ratings yet

- Vision CSP22 Abhyaas Test 3SDocument44 pagesVision CSP22 Abhyaas Test 3SManasa DevarakondaNo ratings yet

- Expository TextsDocument2 pagesExpository TextsJodi PeitaNo ratings yet

- Sujet Dissertation Sciences PolitiquesDocument7 pagesSujet Dissertation Sciences PolitiquesDoMyPaperSingapore100% (1)

- A Better Kiln CoatingDocument2 pagesA Better Kiln Coatingamir100% (4)

- Installation and Operating Instructions Gen-Key: Energy DivisionDocument22 pagesInstallation and Operating Instructions Gen-Key: Energy DivisionAnonymous RcxX0FcNo ratings yet

- Sample Problems Part FormDocument4 pagesSample Problems Part FormkenivanabejuelaNo ratings yet

- Red Lion MP Sensor Product Manual PDFDocument2 pagesRed Lion MP Sensor Product Manual PDFJigneshNo ratings yet

- Special Functions of Signal ProcessingDocument7 pagesSpecial Functions of Signal ProcessingSaddat ShamsuddinNo ratings yet

- CHAPTER 8 SULLIVAN MyReviewerDocument7 pagesCHAPTER 8 SULLIVAN MyReviewerFrances LouiseNo ratings yet

- Grade 9 SyllabusDocument23 pagesGrade 9 SyllabusClopzNo ratings yet

- Prophetic Dance - Mary JonesDocument7 pagesProphetic Dance - Mary Jonesm28181920No ratings yet

- Dslam Commissioning Steps Punjab For 960 PortDocument8 pagesDslam Commissioning Steps Punjab For 960 Portanl_bhn100% (1)

- Spiral Curve - Surveying and Transportation Engineering ReviewDocument3 pagesSpiral Curve - Surveying and Transportation Engineering ReviewGphone100% (2)

- What Is A Dry Well?Document4 pagesWhat Is A Dry Well?eullouNo ratings yet

- Lipofectamine3000 ProtocolDocument2 pagesLipofectamine3000 ProtocolSamer AshrafNo ratings yet