Professional Documents

Culture Documents

Operation V N P T I 76

Uploaded by

Dhiraj SatyamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation V N P T I 76

Uploaded by

Dhiraj SatyamCopyright:

Available Formats

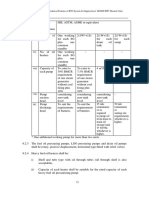

Lube oil pressure for motor iii) Take secondary air flow controll on manual

bearings low and/or and maintain correct air flow.

Corresponding Air heater tripped iv) Cut in oil burner adjacent to working mills.

(provided de-inter locking switch is

on "Interlock" position) and/or

Motor protection operated v) Check drum level is controlled on auto; if

necessary, take drum level control on

manual and maintain level.

vi) Check pulverizer in excess of 3 are tripped

starting from bottom.

vii) Check>that the load on the generator has

reduced to 100 - 120 MW (partial load relay

energised).

viii) Check that interconnecting dampers on air

and flue gas side open and tripped fans are

correctly isolated through interlocks.

ix) Check windbox pressure left and right is

maintained normal (about 75 mm WC).

x) Maintain steam temperature

xi) Check furnace flame condition

xii) Check that tripped pulverziers are correctly

isolated (hot air gates close, cold air dampers

come to minimum).

xiii) Investigate the cause of trip. Correct it and

restart the tripped fan.

2.11.7.One Feeder Trips

Support energy is removed i) Check that hot air gate closes & cold air

within 3 minutes of feeder damper opens full if pulveriser is running.

and/or

No coal flow alarm comes & ii) Clear the mill of the coal before stopping it.

low current relay picks up

simultaneously. (Feeder chear

pin given way and/or

Mill trips and/or iii) Stop the pulverizer if feeder cannot be

restarted immediately.

Feeder motor supply fails iv) Check that running mills share the load if

thermal load is on auto.

72

You might also like

- Boiler Mock Test 1 With AnswersDocument5 pagesBoiler Mock Test 1 With AnswersQuinton Tendai NyamhungaNo ratings yet

- Preventative Maintenance For Shut-Down and Start-Up of Dry Kilns That Will Not Be Used For 2 Months or LongerDocument3 pagesPreventative Maintenance For Shut-Down and Start-Up of Dry Kilns That Will Not Be Used For 2 Months or LongerSanjeet thakurNo ratings yet

- Boiler Do's & Don'tsDocument7 pagesBoiler Do's & Don'tsMithilesh YadavNo ratings yet

- Boiler operation-BHELDocument27 pagesBoiler operation-BHELDuggineni RamakrishnaNo ratings yet

- G7.1 Air Conditioning EquipmentDocument12 pagesG7.1 Air Conditioning EquipmentAlex ChoongNo ratings yet

- Dry out process types for transformer conditioningDocument4 pagesDry out process types for transformer conditioningAradhana Ray100% (1)

- Modified t2 MechanicalDocument5 pagesModified t2 MechanicalvictorsonNo ratings yet

- Cold Startup Boiler and TurbineDocument5 pagesCold Startup Boiler and TurbinejasvinderNo ratings yet

- Commissioning the S-Series TurbineDocument1 pageCommissioning the S-Series TurbineVilas m ChinkeNo ratings yet

- 2008-07-22 192646 InstallaDocument2 pages2008-07-22 192646 InstallasqubuNo ratings yet

- Inspection and Repair: Turbocharger 6G - 7Document1 pageInspection and Repair: Turbocharger 6G - 7James ChuNo ratings yet

- Maintaining Hot Water BoilersDocument10 pagesMaintaining Hot Water BoilersAnilNo ratings yet

- Manual Ato 7227 FX 2019 IngDocument10 pagesManual Ato 7227 FX 2019 IngAlvaro PadillaNo ratings yet

- 10 Common hydraulics guideDocument151 pages10 Common hydraulics guideValeriNo ratings yet

- FV1116TSDocument1 pageFV1116TSOscar VazquezNo ratings yet

- K3-VE COOLANT REPLACEMENT PROCEDUREDocument4 pagesK3-VE COOLANT REPLACEMENT PROCEDUREMhd AdityaNo ratings yet

- Quick Start ManualDocument8 pagesQuick Start ManualAmar AlarianyNo ratings yet

- E2152 7 05 01 - Stellantriebe PDFDocument17 pagesE2152 7 05 01 - Stellantriebe PDFJs WilyNo ratings yet

- c5 Presiones HidraulicasDocument16 pagesc5 Presiones HidraulicasMigue Angel Rodríguez CastroNo ratings yet

- Osha 29 CFR 1910.119 PDFDocument22 pagesOsha 29 CFR 1910.119 PDFSaúl Sánchez Mantilla100% (1)

- Troubleshooting Bagasse Boiler ProblemsDocument2 pagesTroubleshooting Bagasse Boiler Problemskumarmm1234No ratings yet

- SOP For FlushingDocument5 pagesSOP For Flushingmoms2No ratings yet

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- Ijmra 14668Document14 pagesIjmra 14668ffgffhggfNo ratings yet

- Reciprocating Maintenance ChecklistDocument1 pageReciprocating Maintenance ChecklistEllyson IlanoNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- Service Information M20Document72 pagesService Information M20Alexander100% (1)

- Check List Technam p2008jfDocument2 pagesCheck List Technam p2008jfGourav DasNo ratings yet

- Reciprocating Compressor Trouble Shooting GuidesDocument3 pagesReciprocating Compressor Trouble Shooting GuidesRahul ChandrawarNo ratings yet

- CSA C282 Maintenance ReqDocument2 pagesCSA C282 Maintenance Reqecto8totoNo ratings yet

- SOP-Pumping OperationDocument14 pagesSOP-Pumping OperationVoltonix InfratechNo ratings yet

- Hybrid Transaxle Coolant ReplacementDocument75 pagesHybrid Transaxle Coolant Replacementpejopo100% (1)

- Boiler InterlockDocument25 pagesBoiler InterlockapsNo ratings yet

- Cessna®: Service/Parts ManualDocument7 pagesCessna®: Service/Parts ManualFranco PugaNo ratings yet

- Fire Fighting Presentation Ali Hassan-Compressed-Pages-71-140Document70 pagesFire Fighting Presentation Ali Hassan-Compressed-Pages-71-140Crypto India100% (1)

- Turbine Troubleshooting: Top 15 Issues and SolutionsDocument6 pagesTurbine Troubleshooting: Top 15 Issues and Solutionskumarmm1234No ratings yet

- MAK Main Generator 8M25 Service InformationDocument35 pagesMAK Main Generator 8M25 Service InformationСергий Цеценов100% (1)

- Method Statement - Flushing and Pressure Test of Chilled Water PipeDocument5 pagesMethod Statement - Flushing and Pressure Test of Chilled Water PipelamNo ratings yet

- Operation & Maintenance: AnnuallyDocument1 pageOperation & Maintenance: AnnuallyADVIKA GOWTHAMNo ratings yet

- Overseas Locomotive Shipment Preparation GuideDocument6 pagesOverseas Locomotive Shipment Preparation Guideamir barekatiNo ratings yet

- Beni-Suef Transformer Erection Plan PDFDocument23 pagesBeni-Suef Transformer Erection Plan PDFMohamedNo ratings yet

- P2006T Tua Quick Checkli̇stDocument19 pagesP2006T Tua Quick Checkli̇staskinfirataskinNo ratings yet

- Air Box DrainsDocument12 pagesAir Box DrainsLuwīsi Karikamo RomaniNo ratings yet

- Well Activation: A) Compressor ApplicationDocument3 pagesWell Activation: A) Compressor ApplicationSAI KIRAN KOOCHIMANCHINo ratings yet

- Refrigerante Rav4 III 3Document2 pagesRefrigerante Rav4 III 3Osvaldo ChimbasNo ratings yet

- Agem 2nd UnitDocument18 pagesAgem 2nd UnitJanani .SNo ratings yet

- Operation Manual: Blower Heated Regeneration Adsorption Air DryerDocument16 pagesOperation Manual: Blower Heated Regeneration Adsorption Air DryerDavid AlencarNo ratings yet

- User Manual Beko BP209H (English - 312 Pages)Document2 pagesUser Manual Beko BP209H (English - 312 Pages)Nina KinaNo ratings yet

- Manual SG-15 PicnómetroDocument4 pagesManual SG-15 PicnómetroEduardoNo ratings yet

- Agem 2nd Unit NotesDocument18 pagesAgem 2nd Unit Notesmurjass85No ratings yet

- Adding The Control, Rigidity and Power of Hydraulics To A Pneumatic MachineDocument5 pagesAdding The Control, Rigidity and Power of Hydraulics To A Pneumatic MachineSoro FoxNo ratings yet

- Eberspacher Heater D1LC Install and Technical PDFDocument24 pagesEberspacher Heater D1LC Install and Technical PDFarminNo ratings yet

- gt110 PDFDocument43 pagesgt110 PDFEd DonnellonNo ratings yet

- Procedures Manual Volume Four: RevalidationDocument13 pagesProcedures Manual Volume Four: RevalidationTalha UsmaniNo ratings yet

- APDD 339A Sierra Long Term StorageDocument4 pagesAPDD 339A Sierra Long Term StorageCesar HernandezNo ratings yet

- Ascott Service Manual Iss - Part 2Document42 pagesAscott Service Manual Iss - Part 2Le BachNo ratings yet

- Rs Gas DieselDocument24 pagesRs Gas Dieselmikhail.glotovNo ratings yet

- CFD - ACUD CodeDocument6 pagesCFD - ACUD CodeDharmeswar SahNo ratings yet

- Transformer Alarm GuideDocument8 pagesTransformer Alarm GuideAhmed SallahNo ratings yet

- Super Critical Power - Part92Document1 pageSuper Critical Power - Part92Dhiraj SatyamNo ratings yet

- Super Critical Power - Part88Document1 pageSuper Critical Power - Part88Dhiraj SatyamNo ratings yet

- Super Critical Power - Part91Document1 pageSuper Critical Power - Part91Dhiraj SatyamNo ratings yet

- Standard Technical Features of BTG System for Supercritical Thermal UnitsDocument1 pageStandard Technical Features of BTG System for Supercritical Thermal UnitsDhiraj SatyamNo ratings yet

- Super Critical Power - Part86Document1 pageSuper Critical Power - Part86Dhiraj SatyamNo ratings yet

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part71Document1 pageSuper Critical Power - Part71Dhiraj SatyamNo ratings yet

- Super Critical Power - Part79Document1 pageSuper Critical Power - Part79Dhiraj SatyamNo ratings yet

- Super Critical Power - Part83Document1 pageSuper Critical Power - Part83Dhiraj SatyamNo ratings yet

- Suitable For Remote Manual OperationDocument1 pageSuitable For Remote Manual OperationDhiraj SatyamNo ratings yet

- Super Critical Power - Part78Document1 pageSuper Critical Power - Part78Dhiraj SatyamNo ratings yet

- Super Critical Power - Part80Document1 pageSuper Critical Power - Part80Dhiraj SatyamNo ratings yet

- Super Critical Power - Part77Document1 pageSuper Critical Power - Part77Dhiraj SatyamNo ratings yet

- Standard Technical Features of BTG System for Supercritical Thermal UnitsDocument1 pageStandard Technical Features of BTG System for Supercritical Thermal UnitsDhiraj SatyamNo ratings yet

- Super Critical Power - Part76Document1 pageSuper Critical Power - Part76Dhiraj SatyamNo ratings yet

- Super Critical Power - Part62Document1 pageSuper Critical Power - Part62Dhiraj SatyamNo ratings yet

- Super Critical Power - Part52Document1 pageSuper Critical Power - Part52Dhiraj SatyamNo ratings yet

- Super Critical Power - Part61Document1 pageSuper Critical Power - Part61Dhiraj SatyamNo ratings yet

- Technical Features BTG Thermal UnitsDocument1 pageTechnical Features BTG Thermal UnitsDhiraj SatyamNo ratings yet

- Super Critical Power - Part49Document1 pageSuper Critical Power - Part49Dhiraj SatyamNo ratings yet

- Super Critical Power - Part54Document1 pageSuper Critical Power - Part54Dhiraj SatyamNo ratings yet

- BTG System Technical Features for 660/800 MW Thermal UnitsDocument1 pageBTG System Technical Features for 660/800 MW Thermal UnitsDhiraj SatyamNo ratings yet

- Super Critical Power - Part57Document1 pageSuper Critical Power - Part57Dhiraj SatyamNo ratings yet

- Super Critical Power - Part56Document1 pageSuper Critical Power - Part56Dhiraj SatyamNo ratings yet

- Super Critical Power - Part53Document1 pageSuper Critical Power - Part53Dhiraj SatyamNo ratings yet

- Super Critical Power - Part48Document1 pageSuper Critical Power - Part48Dhiraj SatyamNo ratings yet

- Super Critical Power - Part50Document1 pageSuper Critical Power - Part50Dhiraj SatyamNo ratings yet

- Standard Technical Features of BTG System for Supercritical Thermal UnitsDocument1 pageStandard Technical Features of BTG System for Supercritical Thermal UnitsDhiraj SatyamNo ratings yet

- 7 Product Realization RequirementsDocument10 pages7 Product Realization RequirementsArman Ul Nasar0% (1)

- Syndicate 8 OPM HP CaseDocument3 pagesSyndicate 8 OPM HP CaseMiftah FirdausNo ratings yet

- LP1 TKZ 10XXX M M1a Man 8405 CDocument27 pagesLP1 TKZ 10XXX M M1a Man 8405 CPhong DoNo ratings yet

- Oil and Gas Production Handbook Ed3x0 - Web - Part11Document2 pagesOil and Gas Production Handbook Ed3x0 - Web - Part11joshua_tan_31No ratings yet

- Eee-Viii-Industrial Management - Electrical Estimation and e (06ee81) - NotesDocument123 pagesEee-Viii-Industrial Management - Electrical Estimation and e (06ee81) - NotesDilip TheLipNo ratings yet

- Investment Casting For Turbine BladesDocument4 pagesInvestment Casting For Turbine Bladeswiley_01No ratings yet

- 21 CFR 211.137 - Expiration Dating.Document3 pages21 CFR 211.137 - Expiration Dating.agarciah15891No ratings yet

- Uk Sic Code ListDocument7 pagesUk Sic Code ListvikasgodageNo ratings yet

- CHAPTER 7 Market StructureDocument87 pagesCHAPTER 7 Market StructureRia Athirah100% (1)

- WeldingDocument64 pagesWeldingLiyana100% (1)

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Profile of Dnanir Global Logistic Services in JeddahDocument17 pagesProfile of Dnanir Global Logistic Services in JeddahIlyas ShareefNo ratings yet

- Unit-3, Metal Froming ProcessDocument83 pagesUnit-3, Metal Froming ProcessMudit MaheshwariNo ratings yet

- Unifloor Specs HPLDocument1 pageUnifloor Specs HPLDeeksha Bahl DiwanNo ratings yet

- Taloja DatabaseDocument63 pagesTaloja DatabaseUday kumar100% (1)

- CIMDocument8 pagesCIMSree Ranjani GovardhanNo ratings yet

- Lithonia Fluorescent Contractor Price List 1984Document32 pagesLithonia Fluorescent Contractor Price List 1984Alan Masters100% (1)

- Broaching MachinesDocument21 pagesBroaching Machinesthong_bvtNo ratings yet

- MDI Production Concept: Turnkey Factories to Manufacture LocallyDocument21 pagesMDI Production Concept: Turnkey Factories to Manufacture Locallyraj_tgfNo ratings yet

- 3P SampleDocument7 pages3P SampleparagpunjabiNo ratings yet

- DS DMG DMU 60 MonoBLOCK Automotive Distributor enDocument1 pageDS DMG DMU 60 MonoBLOCK Automotive Distributor enPaul VeramendiNo ratings yet

- Easom Product CatalogDocument36 pagesEasom Product Catalogkaniappan sakthivel50% (2)

- Dmgt525 Materials ManagementDocument202 pagesDmgt525 Materials ManagementArasu RajaNo ratings yet

- DfmaDocument5 pagesDfmaIng Raul OrozcoNo ratings yet

- C&S Catlogue 90 W INDustrial 9200Document68 pagesC&S Catlogue 90 W INDustrial 9200Abhishek KumarNo ratings yet

- A 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFDocument8 pagesA 897 - A 897M - 03 Qtg5ny9bodk3tq - PDFMung Duong XuanNo ratings yet

- DOZC OL22420 en PDFDocument4 pagesDOZC OL22420 en PDFปรีชาลิ่มเศรษฐกานต์No ratings yet

- FAQ Latascreed 100Document2 pagesFAQ Latascreed 100Showri Raju AddagatlaNo ratings yet

- Monopolistic Competition: Test ADocument7 pagesMonopolistic Competition: Test Amas_999No ratings yet

- John Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialsDocument8 pagesJohn Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialssadhuNo ratings yet