Professional Documents

Culture Documents

Windows: Sub-Headings

Uploaded by

nicommercialsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Windows: Sub-Headings

Uploaded by

nicommercialsCopyright:

Available Formats

Directory Previous

Previous Next Search Exit

Windows

Table of Contents

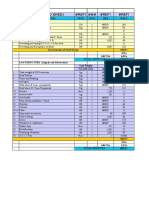

Sub-Headings Figure 5Latch Notch 5

Safety 2 Figure 6Entrance Door Glass

Warnings 2 Replacement 6

Cautions 2 Figure 7Filler Strip Tool 6

Notes 2 Figure 8Horizontal Section 7

Description of Operation 2 Figure 9Vertical Section 8

Rear Emergency Exit Window Figure 10Horizontal Section

Removal 2 Through Transit Sliding Window 8

Split Sash Emergency Exit Window Figure 11Vertical Section Through

Removal 3 Transit Window 9

Transit Sliding Emergency Exit

Push Out 3

Window Removal and Replacement 3

Windows and Windshields 3

Split Sash Window and Glass

Replacement 3

Window Latch Replacement 5

Entrance Door Glass Replacement 6

Rear Vision Glass Replacement 6

Transit Sliding Window Maintenance 6

Glass Replacement Procedure 7

List of Figures

Emergency Exit Figures

Figure 1Rear Emergency Exit

Window 2

Figure 2Split Sash Emergency

Exit Window 2

Figure 3Transit Sliding Emergency

Exit Push Out Window

22

Windshield Glass Replacement

Figure 1Glass Installation 3

Figure 2Installing Glazing Rubber 3

Figure 3Reassemble Window 5

Figure 4Window Latch

Replacement 5

All American Windows 1

Directory Previous

Previous Next Search Exit

Windows

Safety

The purpose of this safety summary is

twofold. First, it is to help ensure the safety

and health of individuals performing service Figure 1Rear Emergency Exit

on, or operation of, this Blue Bird product. Window

Second, it is to help protect equipment.

Before performing any service or operating

procedure on this Blue Bird product,

individuals should read and adhere to the

applicable warnings, cautions and notes

located throughout this Blue Bird Service

Manual.

Warnings

Warnings apply to a procedure or practice

that, if not correctly adhered to, could result

in injury or death. Particular attention

should be paid to sections of this manual Figure 2Split Sash Emergency Exit

where warnings appear. Window

Cautions

Cautions apply to a procedure or practice

that, if not correctly adhered to, could result

in damage to or destruction of equipment.

Notes

Notes are used to explain, clarify or

otherwise give additional insight for a given Figure 3Transit Sliding Emergency

subject, product or procedure. Please note Exit Push-Out Window

that on occasion, notes too may advise of

potential safety issues.

Description of Operation Rear Emergency Exit

The following information has two parts:

Window Removal and

1. Emergency Exit Windows

2. Window Replacement

Replacement

For information on glass removal and

replacement procedures for the Rear

Note Emergency Exit Window, please refer to

Glass replacement should meet standards in Windows and Windshields (specifically,

specification FMVSS 205 and 217. Rear Vision Glass).

2 All American Windows

Directory Previous

Previous Next Search Exit

Split Sash Emergency

Exit Window Removal

and Replacement

For information on glass removal and

replacement procedures for the Rear

Emergency Exit Window, please refer to

Windows and Windshields (specifically,

Split Sash Windows).

Figure 1Glass Installation

Transit Sliding 4. Seal glass to glazing rubber from

Emergency Exit Push- outside of the bus with an adhesive

sealant, such as Silastic 732 RTV

Out Window Removal Adhesive/Sealant.

5. Apply soapy solution to filler strip

and Replacement channel on glazing rubber to act as a

For information on glass removal and lubricant for easier installation of filler

replacement procedures for a Transit Sliding strip.

Emergency Exit Push-Out Window, please 6. Using filler strip tool, insert fillet strip

refer to Windows and Windshield into channel on glazing rubber. Figure

(specifically, Transit Sliding Windows). 2.

Windows & Windshields

Windshield Glass

Replacement

Note

The windshield is four-piece flat.

Figure 2Installing Glazing Rubber

Remove vertical filler strip in glazing rubber

on each side of broken glass. Remove

horizontal filler strip in glazing rubber on Split Sash Window and

top and bottom of broken glass. It will be Glass Replacement

necessary to cut the horizontal filler strip

after it is pulled past the glass. Note

The glass used in the Blue Bird bus meets

1. Starting at a corner, push glass free of FMVSS 205 and 217. When a glass is

glazing rubber from inside of bus broken, it should be replaced with identical

outward and remove. glass.

2. Position new glass in glazing rubber.

3. Using installation tool, work glass into 1. Remove four screws securing window

glazing rubber. Figure 1. frame to bow. Figure 3.

All American Windows 3

Directory Previous

Previous Next Search Exit

2. Pull window to inside of body and 4. On bottom glass, simply pull aluminum

remove. channel off top and bottom of glass.

3. Remove six screws (three on each side 5. To remove glass from top part of

of window) holding assembly together. window, remove 6 screws holding frame

around glass.

4 All American Windows

Directory Previous

Previous Next Search Exit

Figure 3Reassemble Window

6. Reassemble window by reversing above

procedure.

7. Apply weather seal caulking around

window frame to prevent leaking.

Warning

When replacing broken or damaged glass,

use extreme care at all times to prevent

personal injury. Use proper replacement

parts, tools and personal protective

equipment, such as gloves and safety

goggles.

Figure 4Window Latch

Replacement

Window Latch Replacement

1. Remove screw and block located in side

channel directly above stationary glass.

Figure 4.

2. Lower sliding sash so that latch enters

notch covered by block removed in Step

1.

3. With latch in large notch, push finger

holes outward until inside edge is

exposed. Pull latch out of finger hole

opening. Figure 5. Figure 5Latch Notch

4. Finger latch is pried off attached metal

latch with any tool that provides

leverage. Latch may now be removed

and replaced. Note

5. Reassemble by reversing procedure. Lubricate latches and sliding seal of top

window with silicon spray every 30 days.

See decal on driver's window.

All American Windows 5

Directory Previous

Previous Next Search Exit

6. Wrap a cord around the glazing rubber

Entrance Door Glass and rest glass on bottom window flange

Replacement from the inside of the bus body. Figure

1. Apply pressure against glass from the 6.

outside of the bus, starting at a corner, 7. Apply pressure from the inside of the

push glass and glazing rubber off metal bus body to ensure glass is seated

flange. Figure 6. properly. Pull cored slowly and work

glazing rubber onto the window flange.

8. Using filler strip tool, insert filler strip

into channel on glazing rubber. Filler

strip tool is available from your

distributor. Figure 7.

Figure 6Entrance Door Glass

Replacement

2. Remove glazing rubber from around

glass.

3. Put glazing rubber on new glass.

Figure 7Filler Strip Tool

4. Wrap a cord around the glazing rubber

and rest the glass on the bottom flange 9. Apply clear caulking around glass and

of the opening from outside the bus. window flange on the outside of bus

5. Pull cord slowly and work glazing body to insure that no leaks occur.

rubber onto metal flange.

6. Apply pressure to glass from inside of

bus to assure proper seal. Transit Sliding Window

Maintenance

See Figures 8 through 11.

Rear Vision Glass

Replacement

1. Remove filler strip from channel in Caution

glazing rubber. Do not pry window frame from body without

2. Apply pressure against glass from the loosening sealer. Unless sealer is loosened,

outside of the bus starting at a corner, window frame will be bent.

push glass and glazing rubber off metal

flange.

3. Remove glazing rubber from glass. Note

4. Put glazing rubber from glass.

On push out windows, when hinge screws

5. Apply a soapy solution to the flange on

are removed and interior latch released,

the bus body and to the filler strip

window sash may be removed from frame.

channel on glazing rubber. This acts as

a lubricant for easier installation.

6 All American Windows

Directory Previous

Previous Next Search Exit

1. Remove screws in outside aluminum 5. Lift and pull window out of section.

extrusion. 6. Remove four screws and take out

2. Loosen sealer between window frame vertical brace (6) located in the center of

with putty knife. the window. Figure 8 and Figure 10.

3. Pry out using screwdriver. 7. Remove two window stops (one on each

4. Reverse procedure for installation. side of the top of window).

8. Slide glass to the center of the window.

9. Spread apart the inner frame (4) just

Glass Replacement enough to lift glass frame (7) out.

10. To remove glass from frame, slide

Procedure rubber seal (8) out of vertical rail (9)

1. To remove push-out transit sliding exposing two screws.

window, release window lever (1) 11. Window glass is removable after screws

located inside the bus at the bottom of are removed. Remove glass.

each push-out window. Figure 8 and 12. To replace glass, slip glazing vinyl seal

Figure 9. around glass and slide into frame.

2. See Remove hinge screws (2) on outside 13. Reassemble by reversing procedure.

of body. Figure 9.

3. Lift and pull window out of section.

4. To remove stationary transit sliding

window. Remove all screws between

inner frame (4) and outer frame (5).

Figure 8Horizontal Section

All American Windows 7

Directory Previous

Previous Next Search Exit

Figure 9Vertical Section

Figure 10Horizontal Section Through Transit Sliding Window

8 All American Windows

Directory Previous

Previous Next Search Exit

Figure 11Vertical Section Through

Transit Window

Back to Top

All American Windows 9

You might also like

- 501-05 Interior Trimming Panel and Trimming PICKUP JMCDocument14 pages501-05 Interior Trimming Panel and Trimming PICKUP JMCRusonegroNo ratings yet

- Remove Panel For Roof Pillar at Rear (C-Pillar) - Remove Panel For Roof Pillar at Rear (D - Pillar)Document1 pageRemove Panel For Roof Pillar at Rear (C-Pillar) - Remove Panel For Roof Pillar at Rear (D - Pillar)api-3744308No ratings yet

- VFD Valve Cleaning ProcedureDocument4 pagesVFD Valve Cleaning ProcedureJimy Alex Vargas RimacNo ratings yet

- Door Glass (Window) : GM Cavalier/Sunfire 1995-2000 Repair GuideDocument2 pagesDoor Glass (Window) : GM Cavalier/Sunfire 1995-2000 Repair GuidedarherreraNo ratings yet

- Listwa Zewnętrzna - Insignia 13-17Document18 pagesListwa Zewnętrzna - Insignia 13-17Poczciwy CypekNo ratings yet

- Ultimaker 2+ - Repair Manual - Glass PlateDocument3 pagesUltimaker 2+ - Repair Manual - Glass Platemiruna apostolNo ratings yet

- Workshop Manual: TF SeriesDocument94 pagesWorkshop Manual: TF Seriesjrrodrigueza2No ratings yet

- H300L SvcManualDocument44 pagesH300L SvcManualcontato.olokoclipsNo ratings yet

- Body Structure and Body Electrical-2.7CTI M209Document192 pagesBody Structure and Body Electrical-2.7CTI M209Luis Le'sp PurizacaNo ratings yet

- Mirror Power Repair GuideDocument5 pagesMirror Power Repair GuidepitoNo ratings yet

- Sunroof Air Deflector Replacement: Removal ProcedureDocument20 pagesSunroof Air Deflector Replacement: Removal ProcedureYuliantara RahmatNo ratings yet

- Workshop Manual: TF SeriesDocument94 pagesWorkshop Manual: TF SeriesmailforspamNo ratings yet

- GLASSES, WINDOW SYSTEM & MIRRORS GUIDEDocument24 pagesGLASSES, WINDOW SYSTEM & MIRRORS GUIDECarlos Eduardo ZelidonNo ratings yet

- Fastener Tightening Specifications: Document ID: 1749122Document26 pagesFastener Tightening Specifications: Document ID: 1749122mebarki aberraoufNo ratings yet

- 2008 Jeep Wrangler 4 Door, Leak Corrections.: Corrective Action: Service Bulletin 23-020-08 Dated June 20Document6 pages2008 Jeep Wrangler 4 Door, Leak Corrections.: Corrective Action: Service Bulletin 23-020-08 Dated June 20noeleberryNo ratings yet

- Glass and Mirrors On: Section 9LDocument13 pagesGlass and Mirrors On: Section 9LmacarsalNo ratings yet

- LT36720 Drain Valve Service InstructionsDocument3 pagesLT36720 Drain Valve Service InstructionsKe HalimunNo ratings yet

- Window GlassDocument6 pagesWindow Glasspavel35No ratings yet

- Workshop Manual: TF SeriesDocument55 pagesWorkshop Manual: TF SeriesDblogic GatesNo ratings yet

- Glasses, Window System & Mirrors: SectionDocument24 pagesGlasses, Window System & Mirrors: SectionOmar RodriguezNo ratings yet

- Body Repair Manualcaptiva Roof, Back Panel Andrear Floor PanelDocument15 pagesBody Repair Manualcaptiva Roof, Back Panel Andrear Floor PanelMassahiro FilhoNo ratings yet

- Caution: Skytrak Second Exit Installation InstructionsDocument4 pagesCaution: Skytrak Second Exit Installation Instructionsorange rangerNo ratings yet

- Customer Satisfaction Notification L15 Right Side Door LatchesDocument20 pagesCustomer Satisfaction Notification L15 Right Side Door LatchesRms AutomotrizNo ratings yet

- RF PDFDocument10 pagesRF PDFJessica EdwardsonsNo ratings yet

- 04 - Operating Manual Vibrating ScreenDocument3 pages04 - Operating Manual Vibrating ScreenAbeer HarisNo ratings yet

- 2004jeep Grand Cherokee WJ - 1886Document1 page2004jeep Grand Cherokee WJ - 1886friase911No ratings yet

- Rear Window Glass 8212 Regulator Removal and Installation PDFDocument3 pagesRear Window Glass 8212 Regulator Removal and Installation PDFMichael HernandezNo ratings yet

- Руководство По Эксплуатации Набора Для Ремонта Ветрового Стекла.engDocument21 pagesРуководство По Эксплуатации Набора Для Ремонта Ветрового Стекла.engskulikov191974No ratings yet

- 93ZJ Secc 8T Power MirrorsDocument6 pages93ZJ Secc 8T Power Mirrorshelgith74No ratings yet

- Manually Closing The Vario RoofDocument7 pagesManually Closing The Vario RoofdavgrovesNo ratings yet

- JEEP WJ 2000 Service ManualDocument117 pagesJEEP WJ 2000 Service Manualdoniluz0% (4)

- Door Mirrors, Removing and InstallingDocument4 pagesDoor Mirrors, Removing and Installingmefisto06cNo ratings yet

- Renault Laguna Window RegulatorDocument4 pagesRenault Laguna Window RegulatorkladOConnorNo ratings yet

- 29.exterior Trim, BumpersDocument16 pages29.exterior Trim, BumpersKuba SwkNo ratings yet

- Removing and installing a VW windscreenDocument9 pagesRemoving and installing a VW windscreencristianNo ratings yet

- FV10i-DOC Manual 001 V1 EN 20101201 PDFDocument16 pagesFV10i-DOC Manual 001 V1 EN 20101201 PDFManos RantidisNo ratings yet

- Install roof bars on Saab 900, 9000 and 9-3Document6 pagesInstall roof bars on Saab 900, 9000 and 9-3kindergarten111No ratings yet

- Audi 80/avant (B4) Doors SetingDocument5 pagesAudi 80/avant (B4) Doors SetingAdrian HofnărNo ratings yet

- Front Side Door Window Replacement PDFDocument1 pageFront Side Door Window Replacement PDFY. VásquezNo ratings yet

- Oprava Stahovačky OknaDocument27 pagesOprava Stahovačky OknaSedli02No ratings yet

- Bumpers - Front Bumper CoverDocument3 pagesBumpers - Front Bumper CoverDumitru SergiuNo ratings yet

- 1 Bolt 4 Bottom Door Panel 7 Window Side Panel 2 Door Handle 5 Pin For Central Locking 8 Bolt 3 Cover 6 Upper Door Paneling, Center SectionDocument2 pages1 Bolt 4 Bottom Door Panel 7 Window Side Panel 2 Door Handle 5 Pin For Central Locking 8 Bolt 3 Cover 6 Upper Door Paneling, Center SectionFlorin CiudinNo ratings yet

- Outside Door HandlesDocument7 pagesOutside Door HandlescoopthinkNo ratings yet

- Rear Quarter WindowDocument2 pagesRear Quarter WindowHidayat KassimNo ratings yet

- 143 - WaterleaksDocument11 pages143 - WaterleaksGedas GvildysNo ratings yet

- Step 1 - Reset The SunroofDocument5 pagesStep 1 - Reset The SunroofElisha RuwanikaNo ratings yet

- Body Deassembly 5 6 Bumper Door GlassDocument9 pagesBody Deassembly 5 6 Bumper Door GlassCarlos TecnicNo ratings yet

- Service Manual 2006 Matiz INTERIOR TRIMDocument14 pagesService Manual 2006 Matiz INTERIOR TRIMEnrico Wolf100% (1)

- H300M InstallDocument16 pagesH300M InstallAleksandarNo ratings yet

- Flush Bonded Windows: ToolsDocument42 pagesFlush Bonded Windows: ToolsMoto UputstvaNo ratings yet

- How to Remove Car Windows Safely in an EmergencyDocument1 pageHow to Remove Car Windows Safely in an EmergencyyamegNo ratings yet

- Volvo Trucks North America Recalls VN Models for Sleeper Bunk Window DefectDocument13 pagesVolvo Trucks North America Recalls VN Models for Sleeper Bunk Window DefectJonah RagleNo ratings yet

- Mz562863ex Lancer PG1Document7 pagesMz562863ex Lancer PG1fonid53894No ratings yet

- 2002 Altima rear door rattle fixDocument2 pages2002 Altima rear door rattle fixPMNo ratings yet

- User Manual Trinocular Compound LED Microscope: Model M8311Z SeriesDocument22 pagesUser Manual Trinocular Compound LED Microscope: Model M8311Z SeriesMarcelo WillyNo ratings yet

- Eiki 392 Overhead Projector Users Manual ENDocument8 pagesEiki 392 Overhead Projector Users Manual ENTerrence JonesNo ratings yet

- Window Finger Trap Check and RepairDocument4 pagesWindow Finger Trap Check and Repairpedro ruizNo ratings yet

- SSP - 002 - ru - Ремонт и замена стеколDocument36 pagesSSP - 002 - ru - Ремонт и замена стеколmamukoNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- D DO OO OR R & & W Wiin ND DO OW W F Fiitt Ttiin NG GS SDocument2 pagesD DO OO OR R & & W Wiin ND DO OW W F Fiitt Ttiin NG GS SnicommercialsNo ratings yet

- D DO OO OR R & & W Wiin ND DO OW W F Fiitt Ttiin NG GS SDocument2 pagesD DO OO OR R & & W Wiin ND DO OW W F Fiitt Ttiin NG GS SnicommercialsNo ratings yet

- Glazing Accessories GuideDocument2 pagesGlazing Accessories GuidenicommercialsNo ratings yet

- SHADES TECHNICS HYDROFLUSH BOWL KIT MANUALDocument11 pagesSHADES TECHNICS HYDROFLUSH BOWL KIT MANUALnicommercialsNo ratings yet

- Hull Coach Parking LeafletDocument2 pagesHull Coach Parking LeafletnicommercialsNo ratings yet

- 010 h2 AdhesivetapesDocument1 page010 h2 AdhesivetapesnicommercialsNo ratings yet

- Burngreave - Fir Vale Masterplan Outlines Regeneration StrategyDocument96 pagesBurngreave - Fir Vale Masterplan Outlines Regeneration StrategynicommercialsNo ratings yet

- A60 Mansfield A614 (A1 North) : T S R eDocument1 pageA60 Mansfield A614 (A1 North) : T S R enicommercialsNo ratings yet

- 4-2043 LED Instruction SheetDocument2 pages4-2043 LED Instruction SheetnicommercialsNo ratings yet

- TELMA Frictionless Braking System Maintenance ManualDocument20 pagesTELMA Frictionless Braking System Maintenance ManualRafa Diaz100% (2)

- Telma ManualDocument10 pagesTelma ManualnicommercialsNo ratings yet

- Biomorphic Architecture Approach in Building FormDocument6 pagesBiomorphic Architecture Approach in Building Formzack levanNo ratings yet

- Tender Boq - xls139170140Document12 pagesTender Boq - xls139170140Sheikh Nouman Mohsin RamziNo ratings yet

- Kerala PWD Quality Control Manual for BuildingsDocument508 pagesKerala PWD Quality Control Manual for BuildingsvivekNo ratings yet

- Vista Blinds & Curtains Brochure September 2013Document8 pagesVista Blinds & Curtains Brochure September 2013vistablindsNo ratings yet

- 990 - Slider A PDFDocument6 pages990 - Slider A PDFDengSyahNo ratings yet

- Lighting DesignDocument43 pagesLighting DesignNikhil Thakur100% (1)

- Detail of Measurement Name of Work:-Construction of Proposed Commercial Building of Smt. Rajni Rawat D/O Shri Shyam Singh RawatDocument27 pagesDetail of Measurement Name of Work:-Construction of Proposed Commercial Building of Smt. Rajni Rawat D/O Shri Shyam Singh RawatAtul UniyalNo ratings yet

- Sealants Adhesives PDFDocument4 pagesSealants Adhesives PDFvtbkNo ratings yet

- 2022-April Imagine Kit CatalogDocument96 pages2022-April Imagine Kit CatalogEmanuel PapasNo ratings yet

- E4-E5 Architecture Chapter-1 Importance of Orientation in Building PlanningDocument11 pagesE4-E5 Architecture Chapter-1 Importance of Orientation in Building PlanningRoshan RoyNo ratings yet

- Spa and Salon AreasDocument11 pagesSpa and Salon AreasPratyusha HalderNo ratings yet

- Initial Test Paper 6th GradeDocument2 pagesInitial Test Paper 6th GradeLiliana BajdechiNo ratings yet

- Is 1200 (Part 15) 1987 Method of Measurement of Building and Civil Engineering Works, Part 15 - Painting, Polishing, Varnishing EtcDocument14 pagesIs 1200 (Part 15) 1987 Method of Measurement of Building and Civil Engineering Works, Part 15 - Painting, Polishing, Varnishing EtcSanjeev JainNo ratings yet

- All Ultrex Casement AwningDocument10 pagesAll Ultrex Casement AwningBeamer GuyNo ratings yet

- OTTV - Building Design (Malaysia)Document64 pagesOTTV - Building Design (Malaysia)Julie Tan100% (1)

- PASSIVE STACK VENTILATION GUIDEDocument12 pagesPASSIVE STACK VENTILATION GUIDEHimanshu Ruhilla50% (4)

- AW139 00 Chapter 56Document19 pagesAW139 00 Chapter 56JamesNo ratings yet

- Differentiations Between Gold Plus Glass and AIS in The Area of Product and Product Based CategoriesDocument6 pagesDifferentiations Between Gold Plus Glass and AIS in The Area of Product and Product Based CategoriesAman SahniNo ratings yet

- Mercedes c124 Regulacja SzybyDocument4 pagesMercedes c124 Regulacja SzybyPiotr SokołowskiNo ratings yet

- Proposed construction of two-storey three-bedroom residenceDocument3 pagesProposed construction of two-storey three-bedroom residenceAr John Bernard AbadNo ratings yet

- Civil4M Aluminium Sliding Works ChecklistDocument1 pageCivil4M Aluminium Sliding Works ChecklistKishoreNo ratings yet

- The Illustrated Guide To The Houses of America (Architecture Art Ebook) PDFDocument280 pagesThe Illustrated Guide To The Houses of America (Architecture Art Ebook) PDFalbin8No ratings yet

- Good Building Practices Guideline PDFDocument262 pagesGood Building Practices Guideline PDFPatrice Audet100% (1)

- The Yukaghir and The Yukaghirized Tungus. Memoirs of The AMNH - Vol.13Document154 pagesThe Yukaghir and The Yukaghirized Tungus. Memoirs of The AMNH - Vol.13bushcraftruNo ratings yet

- Proposed Two Storey Building Project EstimateDocument8 pagesProposed Two Storey Building Project EstimateOrnelAsperasNo ratings yet

- Skilled Manpower Training Manual Draft PDFDocument48 pagesSkilled Manpower Training Manual Draft PDFtroyel99No ratings yet

- BOQDocument47 pagesBOQAbdullah.N FAAliNo ratings yet

- Macroflo User Guide: Ies Virtual Environment 6.5Document17 pagesMacroflo User Guide: Ies Virtual Environment 6.5leungNo ratings yet

- International Concern: Industrial Sectional DoorsDocument44 pagesInternational Concern: Industrial Sectional DoorsNgô Sỹ HộiNo ratings yet

- Superb Examples of Container Architecture 3rd EdDocument283 pagesSuperb Examples of Container Architecture 3rd Edcsolergibert100% (1)