Professional Documents

Culture Documents

Sae J755 PDF

Uploaded by

JuniorJavier Olivo FarreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sae J755 PDF

Uploaded by

JuniorJavier Olivo FarreraCopyright:

Available Formats

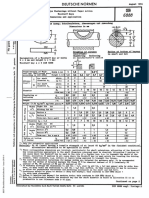

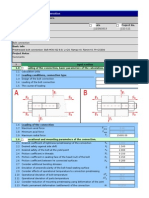

APPROVED S.A.E.

STANDARD DIMENSIONS FOR SHAFTS 3/4 TO 3 INCHES IN DIAMETER

Nom Keyway Keyway Keyway End of Ext.

Diameter Taper Thread c Dia. of Lgth. of Keyway

Shaft Width Side Depth Taper to Beyond Undercut Cotter-Pin Hole Cotter-Pin, Q Nuts

Small End Length

a Fillet F Pin end Pin end

d

Length

End

Dia. B D E Radius b Taper

of Thd

R (drill) Nom Plain Jamb

A Min. Max C Nom Min Max Nom Min Max Dia. Tpi G H J K L M N P dia. Length Size thick, T thick,W X

MARINE PROPELLER SHAFT END DIMENSIONS

0.624 0.626 2 0.1865 0.1875 0.095 0.097 13 1 1 1 -13 1

0.726 0.728 2 0.249 0.250 0.125 0.127 11 1 1 1 -11 1

1 0.827 0.829 2 0.249 0.250 0.125 0.127 10 1 1 1 1 -10 2

1 0.929 0.931 3 0.249 0.250 0.125 0.127 10 1 1 1 1 -10 2

1 1.030 1.032 3 0.3115 0.3125 0.157 0.160 9 1 2 1 1 -9 2

1 1.132 1.134 3 0.3115 0.3125 0.157 0.160 1 8 1 2 1 1 1-8 1 3

1 1.233 1.235 4 0.374 0.375 0.189 0.192 1 7 2 2 2 1 1-7 1 3

1 1.437 1.439 5 0.4365 0.4375 0.219 0.222 1 7 2 2 1 1 2 1 1-7 1 4

2 1.640 1.642 5 0.499 0.500 0.251 0.254 1 6 2 3 1 1 2 2 1-6 1 4

2 1.843 1.845 6 0.5610 0.5625 0.281 0.284 1 5 3 3 1 1 3 2 1-5 1 1 5

2 2.046 2.048 7 0.6235 0.625 0.312 0.315 1 5 3 3 1 1 3 2 1-5 1 1 6

2 2.257 2.259 7 0.6235 0.625 0.313 0.316 2 4 3 4 1 1 3 2 2-4 2 1 6

3 2.460 2.462 8 0.7485 0.750 0.311 0.314 2 4 3 4 1 1 4 3 2-4 2 1 7

DIMENSIONS OF SHAFTS FROM 3-1/4 TO 8 INCHES IN DIAMETER

Nom Keyway Keyway End of Ext.

Diameter Taper Keyway Thread c Dia. of Lgth. of Sleeve Dia. e Clear- Keyway

Width Side Depth Taper to Beyond Undercut Cotter-Pin Hole Cotter-Pin, Q Nuts

Shaft Small End a Fillet d

U

Length F End Pin end Pin end ance Length

Dia. B D E Radius Taper

of Thd

R (drill) Nom Plain Jamb

A Min. Max C Nom Min Max Nom Min Max Dia. Tpi G H J K L M N P dia. Length Size thick, T thick,W Min Max Z X

3 2.663 2.665 9 0.7485 0.750 0.311 0.314 2 4 4 5 2 2 4 3 2-4 2 1 3.870 3.872 8

3 2.866 2.868 10 0.8735 0.875 0.310 0.313 2 4 4 5 2 2 4 3 2-4 2 1 4.120 4.122 9

3 3.069 3.071 10 0.8735 0.875 0.310 0.313 2 4 4 5 2 2 4 3 2-4 2 1 4.369 4.371 10

4 3.272 3.274 11 1 0.9985 1.000 0.309 0.312 3 4 5 5 2 2 5 3 3-4 3 1 4.619 4.621 10

4 3.827 3.829 10 1 1.123 1.125 0.373 0.376 3 4 5 6 2 2 3-4 3 1 5.243 5.245 9

5 4.249 4.251 12 1 1.248 1.250 0.434 0.437 3 4 6 7 3 3 3-4 3 2 5.993 5.995 10

5 4.671 4.673 13 1 1.248 1.250 0.435 0.438 4 4 6 7 3 3 1 4-4 4 2 6.492 6.494 12

*6 4.791 4.793 14 1 1.373 1.375 0.493 0.496 4 4 7 8 3 3 1 4-4 4 2 6.992 6.994 13

*6 5.187 5.189 15 1 1.373 1.375 0.494 0.497 4 4 8 9 4 4 1 4-4 9 2 7.492 7.494 14

*7 5.582 5.584 17 1 1.498 1.500 0.555 0.558 5 4 9 10 4 4 1 5-4 5 2 8.117 8.120 15

*7 5.978 5.980 18 1 1.498 1.500 0.556 0.559 5 4 9 10 5 5 1 5-4 5 3 8.616 8.619 16

*8 6.374 6.376 19 1 1.748 1.750 0.553 0.556 5 4 9 10 5 5 1 5-4 5 3 9.240 9.243 18

* 6" through 8" shaft has 1 inch per foot taper, " per inch taper. Angle with centerline is 2 23' 9". MARINE PROPELLERS HUB BORE DIMENSIONS

a Keyway shall be cut parallel to taper. Taper: Per Foot = "

b Fillets are recommended for keyways in shafts through 2" in diameter. fillets are mandatory for shafts Per Inch - " Angle with centerline = 1 47' 24"

above 2" in diameter.

c Threads are Unified and American Standard, Class 3A..

Dia. Small End Keyway Width Keyway Side Depth

d Nuts are to be semi-finished stock, American Standard B18.2. A C D

e The shaft sleeve shown is recommended practice, but the use of a sleeve is optional. Std.

Taper Min. Max. Nom. Min. Max. Nom. Min. Max.

0.608 0.610 0.1865 0.1875 0.098 0.100

0.710 0.712 0.249 0.250 0.129 0.131

1 0.812 0.814 0.249 0.250 0.129 0.131

1 0.913 0.915 0.249 0.250 0.129 0.131

1 1.015 1.017 0.3115 0.3125 0.162 0.165

1 1.116 1.118 0.3115 0.3125 0.161 0.164

1 1.218 1.220 0.374 0.375 0.195 0.198

HUB

1 1.421 1.423 0.4365 0.4375 0.226 0.229

2 1.624 1.626 0.499 0.500 0.259 0.262

2

2

1.827

2.030

1.829

2.032

0.561

0.6235

0.5625

0.625

0.291

0.322

0.294

0.325

P R O P E L L E R B O R I N G

2 2.233 2.235 0.6235 0.625 0.322 0.325 To insure retention of inherent factory accuracy,

3 2.437 2.439 0.7485 0.750 0.323 0.326

3 2.640 2.642 0.7485 0.750 0.323 0.326 order your propeller factory-bored whenever

3 2.843 2.845 0.8735 0.875 0.324 0.327

3 3.046 3.048 0.8735 0.875 0.324 0.327 possible. When bored in the field, propellers

4 3.249 3.251 1 0.9985 1.000 0.326 0.329 should be bored to the pilot hole, NOT to the

4 3.796 3.798 1 1.123 1.125 0.388 0.391

5 4.218 4.220 1 1.248 1.250 0.450 0.453 hub or blade edges.

5 4.640 4.642 1 1.248 1.250 0.450 0.453

*6 4.749 4.751 1 1.373 1.375 0.517 0.520

*6 5.145 5.147 1 1.373 1.375 0.516 0.519

*7 5.541 5.543 1 1.498 1.500 0.579 0.582

*7 5.937 5.939 1 1.498 1.500 0.579 0.582 * 6" through 8" shaft has 1 inch per foot taper, " per inch taper.

*8 6.332 6.334 1 1.748 1.750 0.582 0.585 Angle with centerline is 2 23' 9".

Overseas specifications on request.

You might also like

- Propeller Shaft Tolerance Tables - Straightness, Diameter, LengthDocument3 pagesPropeller Shaft Tolerance Tables - Straightness, Diameter, LengthnyaungzinNo ratings yet

- ANSI-ASME B17.1-1967 (R 2003) Keys and KeyseatsDocument19 pagesANSI-ASME B17.1-1967 (R 2003) Keys and KeyseatsChristian Pazmiño86% (7)

- DIN 5462 - RanhuraDocument2 pagesDIN 5462 - RanhuraPedro Trindade0% (1)

- Austenitic Cast IronDocument2 pagesAustenitic Cast Ironkatchani123No ratings yet

- Miller 09Document149 pagesMiller 09Emílio BeckerNo ratings yet

- ISO4156 Spline Design CalcsDocument10 pagesISO4156 Spline Design CalcsmaheshmbelgaviNo ratings yet

- Optical sighting method for aligning ship propulsion shaftsDocument2 pagesOptical sighting method for aligning ship propulsion shaftsAlfredo Ortiz BocanegraNo ratings yet

- ASME B16.5 - List of Material SpecificationDocument3 pagesASME B16.5 - List of Material Specificationjr_satish6965No ratings yet

- HOW FLANGE FINISH AFFECTS GASKET PERFORMANCEDocument8 pagesHOW FLANGE FINISH AFFECTS GASKET PERFORMANCEVenkateswaran venkateswaranNo ratings yet

- Basic Engine Model Curve Number: Marine Cummins EngineDocument2 pagesBasic Engine Model Curve Number: Marine Cummins EngineVincen Lim100% (2)

- Cat c280-8 MarinoDocument4 pagesCat c280-8 MarinoHugo GodoyNo ratings yet

- RP H102 PDFDocument1 pageRP H102 PDFsahandstmNo ratings yet

- Product Catalogue For David BrownDocument12 pagesProduct Catalogue For David BrownIzdiharBinRosland0% (1)

- Saej 10 V 003Document4 pagesSaej 10 V 003neojfbNo ratings yet

- Aise - No 11 Standards - Pr-tr011-007Document11 pagesAise - No 11 Standards - Pr-tr011-007Tango Beltza100% (3)

- Asme Y14.35m-97Document23 pagesAsme Y14.35m-97Emmanuel Luna100% (2)

- 3512C 2365 BHP - SpecDocument4 pages3512C 2365 BHP - SpecJoseramirezjlrt100% (1)

- Kirloskar Pneumatic Co. Ltd. - Compressed Air, Air-ConditDocument2 pagesKirloskar Pneumatic Co. Ltd. - Compressed Air, Air-ConditTara MurrayNo ratings yet

- Standard: Hydraulic CylindersDocument27 pagesStandard: Hydraulic CylindersAlexsandro Cavalcanti de Souza100% (2)

- Iso 10100Document16 pagesIso 10100jaime jeanpierre bernal olarte100% (1)

- ASME BTH-1 Lifting Lug DesignDocument4 pagesASME BTH-1 Lifting Lug DesignTim McCorkle50% (2)

- Catalog Fukui SL SeriesDocument59 pagesCatalog Fukui SL SeriesFilipe Simoes Oliveira100% (1)

- DNV-ST-0194 - Oct 2021Document27 pagesDNV-ST-0194 - Oct 2021BillNo ratings yet

- Asme Sec Viii D2 Art D-2 PDFDocument10 pagesAsme Sec Viii D2 Art D-2 PDFDieguitoOmarMoralesNo ratings yet

- Kumera Helical and Bevel Gear UnitsDocument138 pagesKumera Helical and Bevel Gear UnitsPIRATASANTANA100% (1)

- Astm A283Document2 pagesAstm A283Ahmad Udin100% (1)

- Cross Reference Ro SteelsDocument17 pagesCross Reference Ro SteelsJosé SilvérioNo ratings yet

- NES 304 Part 2-Shafting Auxiliaries PDFDocument36 pagesNES 304 Part 2-Shafting Auxiliaries PDFSameer Salvi100% (1)

- Shaft Design PDFDocument27 pagesShaft Design PDFRaverl XNo ratings yet

- DIN 28091-2 GasketDocument20 pagesDIN 28091-2 Gasketengfaridmalk100% (1)

- Loading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesDocument12 pagesLoading Factors Within The Strength Calculation Procedure For Involute Marine Gears With Parallel AxesNenad VulićNo ratings yet

- Marine Engine: SpecificationsDocument4 pagesMarine Engine: SpecificationsSiding BarroNo ratings yet

- ABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14Document14 pagesABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14cupidkhhNo ratings yet

- 3512B B 861bkW 1155bhp 1200rpmDocument6 pages3512B B 861bkW 1155bhp 1200rpmFernandez Gonzalo100% (1)

- Fem 1001 B1Document25 pagesFem 1001 B1Maey AkimNo ratings yet

- AGMA 2015 915-1-A02Document108 pagesAGMA 2015 915-1-A02danielk32100% (1)

- V250MDC Project Guide GEK-115179b PDFDocument174 pagesV250MDC Project Guide GEK-115179b PDFElias Abu FakherNo ratings yet

- Hydraulic Turbines Their Design and Equipment NechlebaDocument321 pagesHydraulic Turbines Their Design and Equipment NechlebaSasank100% (4)

- Crawler Cranes American 9310A - 225 TonDocument4 pagesCrawler Cranes American 9310A - 225 TondzeballoNo ratings yet

- Sheave DesignDocument6 pagesSheave DesignZach DockterNo ratings yet

- Aws 14.1Document141 pagesAws 14.1MaelstormcrowNo ratings yet

- Tenmat Feroform T14 DatasheetDocument1 pageTenmat Feroform T14 DatasheetmusebladeNo ratings yet

- Valvulas Hidraulicas Parker PDFDocument464 pagesValvulas Hidraulicas Parker PDFRyA94No ratings yet

- Tolerances For The Manufacture of PropellersDocument3 pagesTolerances For The Manufacture of PropellersDhmazz ILhamNo ratings yet

- Keel Cooling SizingDocument4 pagesKeel Cooling Sizinganhha1670% (1)

- Ansi B4.2 Limits and Fits Standard (General)Document76 pagesAnsi B4.2 Limits and Fits Standard (General)Swapnil RajeshNo ratings yet

- DIN-6888-Wood Ruff Key Dim and ApplicatioinDocument2 pagesDIN-6888-Wood Ruff Key Dim and ApplicatioinManikandan Veerasekaran100% (3)

- Agma 2101-D04 PDFDocument66 pagesAgma 2101-D04 PDFrafael moran100% (1)

- Formula For Area and Volumes PDFDocument2 pagesFormula For Area and Volumes PDFSumit KumarNo ratings yet

- DNV Cert of WinchDocument6 pagesDNV Cert of WinchSRARNo ratings yet

- Crane Wheel Heat Treating MethodsDocument20 pagesCrane Wheel Heat Treating Methodsgmurdzhev67% (3)

- SAE 64 Bronze Material PropertiesDocument1 pageSAE 64 Bronze Material PropertiesIbsonhNo ratings yet

- Lifting lug design data and calculationsDocument8 pagesLifting lug design data and calculationsluis nunezNo ratings yet

- ArquitectónicaDocument5 pagesArquitectónicaGStefy CedBattNo ratings yet

- Socket Head Cap ScrewsDocument1 pageSocket Head Cap Screwsapi-3848892100% (5)

- LC-326 SM Cylinder CAN Production HALT No. (T1) Process Q-Inspection Check SheetDocument36 pagesLC-326 SM Cylinder CAN Production HALT No. (T1) Process Q-Inspection Check Sheetsegar PalanisamyNo ratings yet

- Trider Scheda Tecnica ENDocument2 pagesTrider Scheda Tecnica ENHFNo ratings yet

- Suction Head Calculation: Local Factors of FittingsDocument1 pageSuction Head Calculation: Local Factors of Fittingsmohamad azipNo ratings yet

- Center of Gravity CalculatorDocument2 pagesCenter of Gravity CalculatorAalekh PrajapatiNo ratings yet

- Marine Bearing Installation Manual PDFDocument64 pagesMarine Bearing Installation Manual PDFJuniorJavier Olivo Farrera100% (1)

- Engineering ManualDocument57 pagesEngineering ManualCes Rico-CepriaNo ratings yet

- Stepped Hulls - Feb07Document13 pagesStepped Hulls - Feb07JuniorJavier Olivo FarreraNo ratings yet

- How To Evaluate BoatsDocument4 pagesHow To Evaluate BoatsMetin MehelNo ratings yet

- Fatigue and Fracture Mechanics Analysis of Threaded ConnectionsDocument402 pagesFatigue and Fracture Mechanics Analysis of Threaded ConnectionsAmir Hooshang Ghadymi MahaniNo ratings yet

- Detecting Bearing Defects Under High Noise LEVELS - A CLASSIFIER FUSION APPROACH PDFDocument7 pagesDetecting Bearing Defects Under High Noise LEVELS - A CLASSIFIER FUSION APPROACH PDFJuniorJavier Olivo FarreraNo ratings yet

- Performance Prediction of Hulls With Transverse Steps - v4Document40 pagesPerformance Prediction of Hulls With Transverse Steps - v4Maximilien Abrell50% (2)

- How To Evaluate BoatsDocument14 pagesHow To Evaluate BoatsJuniorJavier Olivo FarreraNo ratings yet

- Bearingfailure PDFDocument22 pagesBearingfailure PDFMohamed Altaf Jaffer100% (1)

- Barden Bearing Failures Us enDocument15 pagesBarden Bearing Failures Us enIbrahimElKelany100% (1)

- Ghassemi+i+in PMR 2015 2Document9 pagesGhassemi+i+in PMR 2015 2JuniorJavier Olivo FarreraNo ratings yet

- Basic Principles of Propulsion 14 26Document13 pagesBasic Principles of Propulsion 14 26JuniorJavier Olivo Farrera100% (1)

- Marine Transmission SystemsDocument6 pagesMarine Transmission SystemsJuniorJavier Olivo FarreraNo ratings yet

- Stepped Hulls - Feb07 PDFDocument3 pagesStepped Hulls - Feb07 PDFletuvioNo ratings yet

- Marine Diesel Engine Service Manual 6LY2-STE 6LY2A-STP 6LYA-STPDocument234 pagesMarine Diesel Engine Service Manual 6LY2-STE 6LY2A-STP 6LYA-STPJuniorJavier Olivo Farrera100% (1)

- Marine Propulsion Systems: DescriptionDocument6 pagesMarine Propulsion Systems: DescriptionJuniorJavier Olivo FarreraNo ratings yet

- Product Selection Guide 2018Document148 pagesProduct Selection Guide 2018JuniorJavier Olivo FarreraNo ratings yet

- Upfront CAE For Simulation-Driven Shape Optimization: SoftwareDocument4 pagesUpfront CAE For Simulation-Driven Shape Optimization: SoftwareJuniorJavier Olivo FarreraNo ratings yet

- Drop - AngleDocument10 pagesDrop - AngleJuniorJavier Olivo FarreraNo ratings yet

- HVDSafety Guide V3Document2 pagesHVDSafety Guide V3eng_ahmed_1500No ratings yet

- P 06Document23 pagesP 06Priyesh SaxenaNo ratings yet

- Hydraulic Schematic SymbolsDocument12 pagesHydraulic Schematic SymbolsswainpiyushNo ratings yet

- HSC Guide To ColorsDocument1 pageHSC Guide To ColorscupidkhhNo ratings yet

- Principios Básicos para El Diseño de Instalaciones de Bombas CentrífugasDocument392 pagesPrincipios Básicos para El Diseño de Instalaciones de Bombas CentrífugasChristian Vargas94% (16)

- HSC Part 4 E-July16Document390 pagesHSC Part 4 E-July16JuniorJavier Olivo FarreraNo ratings yet

- Part 7 Corrigenda-July16Document2 pagesPart 7 Corrigenda-July16JuniorJavier Olivo FarreraNo ratings yet

- HSC Nandgi E-CopyrightDocument8 pagesHSC Nandgi E-CopyrightJuniorJavier Olivo FarreraNo ratings yet

- Alloy-Steel and Stainless Steel Bolting For Low-Temperature ServiceDocument8 pagesAlloy-Steel and Stainless Steel Bolting For Low-Temperature ServiceGian SennaNo ratings yet

- Aimpoint CompM4 QRP2 Spacer User Manual ENGDocument8 pagesAimpoint CompM4 QRP2 Spacer User Manual ENGROBERT ERICK KAHN LEON0% (1)

- HINO E13C DIESEL ENGINE WORKSHOP MANUALDocument413 pagesHINO E13C DIESEL ENGINE WORKSHOP MANUALmahadeo ramphal100% (15)

- Screw Cutting by Hand Methods: 1. Purpose of Thread CuttingDocument21 pagesScrew Cutting by Hand Methods: 1. Purpose of Thread CuttingTajmar JamesNo ratings yet

- 3 Fasteners HandBook PDFDocument13 pages3 Fasteners HandBook PDFFelipe FernandezNo ratings yet

- Fasteners Product BackgroundDocument11 pagesFasteners Product BackgroundAriff AziziNo ratings yet

- Van Keuren Catalog 2012Document60 pagesVan Keuren Catalog 2012Juan Posada GNo ratings yet

- Miscellaneous Miscellaneous: MitutoyoDocument40 pagesMiscellaneous Miscellaneous: MitutoyoIsmael 8877No ratings yet

- Maryland Metrics KeensertsDocument60 pagesMaryland Metrics KeensertsThor InternationalNo ratings yet

- RE - Atlas Copco - Upbox W2465 - 2 - en PDFDocument99 pagesRE - Atlas Copco - Upbox W2465 - 2 - en PDFFreddy GuevaraNo ratings yet

- Automotive Gaskets and FastenersDocument42 pagesAutomotive Gaskets and FastenersRhenzCarloLeonatoNo ratings yet

- CTN10 Compressor AssemblyDocument17 pagesCTN10 Compressor AssemblyKakashi KamotoNo ratings yet

- Scotch-W Scotch-Weld ProductDocument24 pagesScotch-W Scotch-Weld ProductAnca AnghelNo ratings yet

- Hexagon, Socket Head Shoulder Screws (Metric Series) : An American National StandardDocument22 pagesHexagon, Socket Head Shoulder Screws (Metric Series) : An American National StandardJoel CieltoNo ratings yet

- Doosan-DL550-Manual de Taller Del Motor Scania DC13Document321 pagesDoosan-DL550-Manual de Taller Del Motor Scania DC13Martin100% (3)

- Continuous Polymer Reactor Design PDFDocument139 pagesContinuous Polymer Reactor Design PDFJulio UribeNo ratings yet

- Carbon and Alloy Nuts (Metric) : Standard ForDocument8 pagesCarbon and Alloy Nuts (Metric) : Standard Forpramod wattamwarNo ratings yet

- Single Motor Opens Two Doors MechanismDocument34 pagesSingle Motor Opens Two Doors MechanismKanagarajan100% (1)

- Operations and Service Manual BF Micro Adhesive Applicator With Micro Optima Module Hot Melt Adhesive ApplicatorDocument34 pagesOperations and Service Manual BF Micro Adhesive Applicator With Micro Optima Module Hot Melt Adhesive ApplicatorEribert De OliveiraNo ratings yet

- BoltCon - 02Document105 pagesBoltCon - 02Marinel1955100% (1)

- b18 2 2Document42 pagesb18 2 2Gustavo Fama100% (2)

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 030235-0Document19 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 030235-0Chris HendonNo ratings yet

- Engineering Drawing Upload PDFDocument86 pagesEngineering Drawing Upload PDFShowkat BhatNo ratings yet

- Catalogo Machuelos OSG PDFDocument1,484 pagesCatalogo Machuelos OSG PDFELISANo ratings yet

- LPCB Sprinkler Pipe Hanger Testing & Requirments PDFDocument12 pagesLPCB Sprinkler Pipe Hanger Testing & Requirments PDFAkmal Hazuan SulaimanNo ratings yet

- Fundamental Principles of Mechanical EngineeringDocument249 pagesFundamental Principles of Mechanical Engineeringkalede2No ratings yet

- 1990 PONTIAC FIREBIRD Service Repair Manual PDFDocument40 pages1990 PONTIAC FIREBIRD Service Repair Manual PDFuksjefmmdNo ratings yet

- MK Factory EquipmentDocument152 pagesMK Factory EquipmentironalejanNo ratings yet

- 五十铃isuzu Hatichi 4hk1 6hk1 ManualDocument351 pages五十铃isuzu Hatichi 4hk1 6hk1 Manual蔡苏100% (2)

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document23 pagesOperating Manual: Eagleburgmann Mechanical Seal (M.S.)kiranNo ratings yet