Professional Documents

Culture Documents

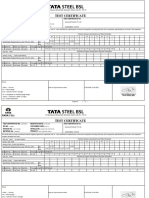

Test Certificate b8m

Uploaded by

singaravelan narayanasamyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Certificate b8m

Uploaded by

singaravelan narayanasamyCopyright:

Available Formats

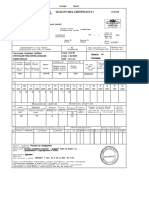

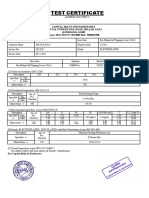

TEST CERTIFICATE AS PER EN10204-3.

1

ZEMKAD TOOLS & FASTENERS CERTIFICATE NO: 12039

CHALLAN NO: -- INVOICE NO: 12039 DATE: 06.03.17

CUSTOMER : P.O.No:

Certified that goods mentioned below meets the requirement of SA193Gr.B8M CL 1

CHEMICAL ANALYSIS FOR BOLT

SIZE C% SI% Mn% S% P% Cr% Ni% Mo%

Min - - - - - 16.00 10.00 2.00

Max 0.080 1.00 2.00 0.030 0.045 18.00 14.00 3.00

Size Heat No Qty Actual Observation Figures

M12 X100 23145 20 0.022 0.125 1.139 0.020 0.023 16.115 10.125 2.125

M14 X 100 23146 150 0.024 0.152 1.125 0.022 0.026 16.128 10.119 2.136

M18 X 100 23147 174 0.026 0.136 1.141 0.026 0.024 16.147 10.136 2.114

M20 X 100 23148 366 0.021 0.145 1.152 0.021 0.022 16.152 10.117 2.118

M24 X 120 23149 340 0.027 0.139 1.144 0.027 0.020 16.118 10.148 2.115

PHYSICAL TEST RESULTS OF BOLT TAKEN AT RANDOM FROM FINISHED PRODUCTS

Size Yield Stress UTS Mpa Elongation Reduction Hardness

Area

Min 205 515 30% 50% ---

Max -- -- -- -- 18 HRC

Actual Obsevation Figures

M12 X100 224 520 33.29% 54.14% 14- 15 HRC

M14 X 100 215 524 38.26% 57.28% 10- 11 HRC

M18 X 100 219 536 39.15% 59.23% 12 -13 HRC

M20 X 100 214 538 40.33% 60.11% 15-16HRC

M24 X 120 210 550 31.18% 65.22% 13-14 HRC

MACRO ETCH TEST (AS PER ASTM E 381 PLATED I) CARRIED OUT & FOUND

SATISFACTORY

CARBIDE SOLUTION TREATED AT 1080 C

QUENCHING MEDIA - WATER

FOR ZEMKAD TOOLS AND FASTENERS

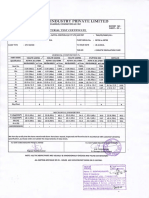

TEST CERTIFICATE AS PER EN10204-3.1

ZEMKAD TOOLS & FASTENERS CERTIFICATE NO: 12039

CHALLAN NO: -- INVOICE NO: 12039 DATE: 06.03.17

CUSTOMER : M/s P.O.No:

Certified that goods mentioned below meets the requirement of SA 194 Gr8M CL1

CHEMICAL ANALYSIS FOR HEX NUT

SIZE C% SI% Mn% S% P% Cr% Ni% Mo%

Min - - - - - 16.00 10.00 2.00

Max 0.080 1.00 2.00 0.030 0.045 18.50 14.00 3.00

Size Heat No Qty Actual Observation Figures

M12 14826 20 0.020 0.130 1.140 0.021 0.025 16.165 10.152 2.140

M14 14827 150 0.022 0.152 1.151 0.025 0.028 16.171 10.166 2.146

M18 14828 174 0.024 0.123 1.136 0.020 0.026 16.115 10.128 2.123

M20 14829 366 0.023 0.147 1.125 0.024 0.020 16.123 10.144 2.114

M24 14830 340 0.028 0.155 1.114 0.022 0.019 16.148 10.136 2.157

MECHANICAL TEST RESULTS OF HEXAGONAL NUTS TAKEN AT RANDOM FROM

FINISHED PRODUCTS

Size Hardness HRB Proof Load KN

M12 72.6 58.1

M14 73.2 79.7

M18 74.5 138.5

M20 76.2 168.9

M24 77.8 218.6

MACRO ETCH TEST (AS PER ASTM E 381 PLATED I) CARRIED OUT & FOUND

SATISFACTORY

CARBIDE SOLUTION TREATED AT 1080 C

QUENCHING MEDIA - WATER

FOR ZEMKAD TOOLS AND

You might also like

- Reinforced ConcreteDocument13 pagesReinforced ConcreteRenukadevi Rpt17% (18)

- MTC For BoltDocument2 pagesMTC For Boltrizwan40% (5)

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- Al Jazeera Steel Mill Test ReportDocument1 pageAl Jazeera Steel Mill Test Reportsnehalmdeshmukh100% (1)

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Document1 pageMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (2)

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- IS 1852 - 1985 - Reff2022Document28 pagesIS 1852 - 1985 - Reff2022singaravelan narayanasamy100% (1)

- MILL TEST CERTIFICATE FOR 304 STAINLESS STEELDocument1 pageMILL TEST CERTIFICATE FOR 304 STAINLESS STEELMANIMARAN QC100% (1)

- Test Certificate: CM/L-NO:5530357Document10 pagesTest Certificate: CM/L-NO:5530357TARUNKUMARNo ratings yet

- Sample MTC For Anchor BoltDocument1 pageSample MTC For Anchor BoltSALMAN PARVEZ ROKADIANo ratings yet

- IS 10748_2004 Compliant HR Steel Coils CertificateDocument1 pageIS 10748_2004 Compliant HR Steel Coils CertificateravigurajapuNo ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- Ball Valve MTCDocument1 pageBall Valve MTCAdnanAtifNo ratings yet

- 23-Grade 8.8 Bolt & Nut (Iso)Document1 page23-Grade 8.8 Bolt & Nut (Iso)anoordheen100% (2)

- Astm A193-2020Document14 pagesAstm A193-2020singaravelan narayanasamyNo ratings yet

- 622888Document1 page622888DeepakNo ratings yet

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- QUALITY MILL CERTIFICATE FOR HOT ROLLED STEEL ROUND, ANNEALED GRADE AISI4140Document1 pageQUALITY MILL CERTIFICATE FOR HOT ROLLED STEEL ROUND, ANNEALED GRADE AISI4140Mohamed NabeilNo ratings yet

- Test CertificateDocument7 pagesTest CertificateVinay YadavNo ratings yet

- 4140 Material For TubeDocument2 pages4140 Material For Tubesharafudheen_sNo ratings yet

- Jindal Steel & Power Limited: Page 1 of 6Document1 pageJindal Steel & Power Limited: Page 1 of 6pranesh kadam100% (2)

- SS304-1 2THK PDFDocument1 pageSS304-1 2THK PDFrajNo ratings yet

- Test CertificateDocument2 pagesTest CertificatePRITESHNo ratings yet

- Test Certificate For Galvanized Steel CoilsDocument1 pageTest Certificate For Galvanized Steel CoilsS.SHANMUGA SABAREESANNo ratings yet

- JSW Steel TMT Test CertificateDocument2 pagesJSW Steel TMT Test Certificatevenkata krishna reddy MorthlaNo ratings yet

- Is 513 2016Document16 pagesIs 513 2016santosh kumar50% (14)

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocument1 pageTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaNo ratings yet

- Astm A262-2015 (R2021)Document20 pagesAstm A262-2015 (R2021)singaravelan narayanasamyNo ratings yet

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Document3 pagesMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasNo ratings yet

- Design of A Fluidized Drum GranulatorDocument6 pagesDesign of A Fluidized Drum GranulatorditchcheNo ratings yet

- ASTM A194-A194M-20aDocument12 pagesASTM A194-A194M-20aViviana Leon100% (8)

- Quality Assurance Plan For Is 2062 E250 GR BRDocument2 pagesQuality Assurance Plan For Is 2062 E250 GR BRSUBHOMOYNo ratings yet

- Tata Steel Hot Rolled Coils Test CertificateDocument1 pageTata Steel Hot Rolled Coils Test CertificateMohd YaskeenNo ratings yet

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmNo ratings yet

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Test Certificate: (AS PER EN 10204 TYPE 3.1)Document2 pagesTest Certificate: (AS PER EN 10204 TYPE 3.1)qualityNo ratings yet

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- Sample Is 4923Document1 pageSample Is 4923VSSR CONSULTANTS100% (1)

- 694Document1 page694Mauricio Ramirez100% (1)

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- ESAB Welding HandbookDocument31 pagesESAB Welding Handbookhooky1100% (4)

- Astm F606.F606M-2021Document19 pagesAstm F606.F606M-2021singaravelan narayanasamyNo ratings yet

- Cold Rolled Steel Sheets SpecificationDocument10 pagesCold Rolled Steel Sheets Specificationsingaravelan narayanasamyNo ratings yet

- RINL Vizag Steel Plant issues quality test certificateDocument1 pageRINL Vizag Steel Plant issues quality test certificateRINL GZB0% (1)

- Din en Iso 7090 PDFDocument8 pagesDin en Iso 7090 PDFsingaravelan narayanasamyNo ratings yet

- Astm E1077-2021Document10 pagesAstm E1077-2021Anonymous tIwg2AyNo ratings yet

- DR System ConciseDocument37 pagesDR System ConciseJiten KarmakarNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- 10MM - 60.960 TonDocument4 pages10MM - 60.960 TonRAJKUMAR CHATTERJEE. (RAJA.)100% (1)

- ASTM E1251 2017 Ver A PDFDocument10 pagesASTM E1251 2017 Ver A PDFaizaz65No ratings yet

- Filter DesignDocument4 pagesFilter Designhassan11783No ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- MTC - Al JazeeraDocument1 pageMTC - Al JazeeraArmağan DemirelNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- MTC FITTINGSDocument5 pagesMTC FITTINGSAzee TitouNo ratings yet

- Test Certificate Hot Rolled, Medium High Tensile Steel: SailDocument3 pagesTest Certificate Hot Rolled, Medium High Tensile Steel: SailJignesh Jagjivanbhai PatelNo ratings yet

- M12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Document1 pageM12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Athul T.NNo ratings yet

- Test CertificateDocument1 pageTest CertificatequalityNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Tube S2 HFS MTCDocument1 pageTube S2 HFS MTCunnamed90No ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- Test CertificateDocument2 pagesTest CertificateTARUNKUMARNo ratings yet

- Somasila Grey Granite Test ReportDocument2 pagesSomasila Grey Granite Test ReportRakesh ReddyNo ratings yet

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- 6063 Aluminum Alloy PropertiesDocument1 page6063 Aluminum Alloy Propertiestrieu vy phamNo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Heat No S13Document1 pageHeat No S13Siddharth ParmarNo ratings yet

- Final Inspection ReportDocument1 pageFinal Inspection ReportC. M. JebinNo ratings yet

- IS-1730 1989 Reff2019Document11 pagesIS-1730 1989 Reff2019singaravelan narayanasamyNo ratings yet

- Chemical and Mechanical Test Results for Cast Iron ComponentsDocument4 pagesChemical and Mechanical Test Results for Cast Iron Componentssingaravelan narayanasamyNo ratings yet

- Is 9879-1998 (Ra-2021)Document8 pagesIs 9879-1998 (Ra-2021)singaravelan narayanasamyNo ratings yet

- IS 1173 - 1978 - Reff2019Document9 pagesIS 1173 - 1978 - Reff2019singaravelan narayanasamyNo ratings yet

- WCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSDocument9 pagesWCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSsingaravelan narayanasamyNo ratings yet

- Is 8811-1998 (Ra-2018)Document8 pagesIs 8811-1998 (Ra-2018)singaravelan narayanasamy100% (1)

- Q/Lam&Ijfiij E@ Rmf5 ?M - : Fa-DwDocument5 pagesQ/Lam&Ijfiij E@ Rmf5 ?M - : Fa-Dwsingaravelan narayanasamyNo ratings yet

- Methods For'Measuring Case Depth of Steel: Indian StandardDocument7 pagesMethods For'Measuring Case Depth of Steel: Indian Standardsingaravelan narayanasamyNo ratings yet

- Methods of Samrling and Test For Paints, VarnishesDocument9 pagesMethods of Samrling and Test For Paints, Varnishessingaravelan narayanasamyNo ratings yet

- Pulley PartsDocument3 pagesPulley Partssingaravelan narayanasamyNo ratings yet

- LSS - 04 - 19 - 20 - 060419 PDFDocument1 pageLSS - 04 - 19 - 20 - 060419 PDFsingaravelan narayanasamyNo ratings yet

- Aluminium Alloy Ingots PDFDocument1 pageAluminium Alloy Ingots PDFsingaravelan narayanasamyNo ratings yet

- A 498 - 98 Qtq5oc1sruqDocument4 pagesA 498 - 98 Qtq5oc1sruqsingaravelan narayanasamyNo ratings yet

- A940Document4 pagesA940singaravelan narayanasamyNo ratings yet

- Hardox 400 UkDocument2 pagesHardox 400 Uksingaravelan narayanasamyNo ratings yet

- E 123 - 02 - RteymwDocument5 pagesE 123 - 02 - Rteymwsingaravelan narayanasamyNo ratings yet

- 080m40 En8 BlackDocument3 pages080m40 En8 BlackAbhishek SharmaNo ratings yet

- Hardox 400 UkDocument2 pagesHardox 400 Uksingaravelan narayanasamyNo ratings yet

- Dimensions of Physical Quantities DensityDocument100 pagesDimensions of Physical Quantities DensityGerman Rincon UrregoNo ratings yet

- ESD Protection in CMOS: Characterization and Failure AnalysisDocument113 pagesESD Protection in CMOS: Characterization and Failure AnalysisElisavNirolfNo ratings yet

- Specifications: 3516C - SS Marine PropulsionDocument5 pagesSpecifications: 3516C - SS Marine PropulsionAidel MustafaNo ratings yet

- Experion Scada PinDocument7 pagesExperion Scada PinKhalid AliNo ratings yet

- WPD Flotationdrying PDFDocument19 pagesWPD Flotationdrying PDFVvbjNo ratings yet

- The Z-Transform: Introduction and DerivationDocument16 pagesThe Z-Transform: Introduction and DerivationAnanth SettyNo ratings yet

- How to Operate AAS with SignPal & PhotoPRINTDocument25 pagesHow to Operate AAS with SignPal & PhotoPRINTLucian DogariuNo ratings yet

- TV Compatibility with Verbatim HDDsDocument2 pagesTV Compatibility with Verbatim HDDsmirciulicacatyNo ratings yet

- Sap MM LSMWDocument18 pagesSap MM LSMWMani balan100% (1)

- Velp ZX3 Vortex PDFDocument5 pagesVelp ZX3 Vortex PDFarodassanchez0% (1)

- Carimin Acacia Stability-Onhire Loading JerunDocument6 pagesCarimin Acacia Stability-Onhire Loading Jerunh2sbnj86b4No ratings yet

- Fajs FSXDocument8 pagesFajs FSXJunhy Bandeira CassandraNo ratings yet

- FG - BDER-78 Technical Catalogue - Technical - UNDocument8 pagesFG - BDER-78 Technical Catalogue - Technical - UNAnh Le NgocNo ratings yet

- Composite Repair PDFDocument13 pagesComposite Repair PDFNarendra PalandeNo ratings yet

- LV12 - Drive Shafts - Issue 1Document19 pagesLV12 - Drive Shafts - Issue 1Đức HòangNo ratings yet

- Assessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Document12 pagesAssessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Ma Liu Hun VuiNo ratings yet

- Alketerge EDocument4 pagesAlketerge EYohanes OktavianusNo ratings yet

- Developing Recycled PET Fiber for Concrete ReinforcementDocument8 pagesDeveloping Recycled PET Fiber for Concrete ReinforcementJunaid Ahmad100% (1)

- Micron Ezeprox Access Control KeypadDocument4 pagesMicron Ezeprox Access Control KeypadThuy VuNo ratings yet

- Amphenol Musician Range PDFDocument8 pagesAmphenol Musician Range PDFtrc_wmNo ratings yet

- Mixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Document84 pagesMixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Masayu MYusoffNo ratings yet

- 2014 Solder Joint ReliabilityDocument18 pages2014 Solder Joint ReliabilitychoprahariNo ratings yet

- Motion ReportDocument2 pagesMotion Reportmikeb-erau100% (2)

- Fire Risk AssessmentDocument13 pagesFire Risk Assessmentteuku zulfikarNo ratings yet