Professional Documents

Culture Documents

Section of Hook

Uploaded by

GogyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section of Hook

Uploaded by

GogyCopyright:

Available Formats

International Journal of Innovations in Engineering and Technology (IJIET)

Design and Stress Analysis 0f Various Cross

Section of Hook

G.E.V.Ratnakumar

PG Student Dept. of Mechanical Engineering

NOVA college of Engineering and Technology,India

B. Jitendra Kumar

Asst. Professor, Dept. of Mechanical Engineering

Nova College of Engineering and Technology, India

Kalapala Prasad

Asst. Professor, Dept. of Mechanical Engineering

JNTU Kakinada, India

Abstract: Crane hook is a curved beam. Hooks are employed in heavy industries to carry tones of loads safely. These

hooks have a big role to play as far as the safety of crane loaded is concerned. With more and more industrialization the

rate at which these hooks are forged are increasing. This project is carried out to study the stress variation in crane hooks

for different cross sections such as circular and square and for different radii of curvature as well, experimentally and

theoretically. Experimentally, the loads are obtained for different crane hooks for 5mm elongation on UTM (Universal

Testing Machine). And then the stresses induced in the crane hooks against the loads obtained from experimentation are

also calculated theoretically using curved beam theory. Then the different crane hooks are modeled in Pro-E 2.0 and then

analysis is done for modeled hooks using ANSYS 12.1 to find the stresses induced in the hooks. Then the stresses

evaluated from curved beam theory and ANSYS12.1 are compared and conclusions are made

Keywords: crane hook, Pro-e, ANSYS12.1, curved beam theory, Universal Testing Machine.

I. INTRODUCTION

A hook block is an assembly to which the hook of a hoist or crane is attached, it typically consists of a steel

enclosure housing a number of sheaves or pulleys that carry the ropes or chains that facilitate the lifting of a load.

Although this sounds unnecessarily complex, it would be impossible for a crane or hoist to operate efficiently and

safely if the crane hook was simply attached directly to a rope and then raised or lowered by the cranes boom

and winch system. A hook block allows for a considerable amount of flexibility and safety in lifting operations as

opposed to a direct connection. One of the most important functions of any hook block is facilitating of a free

turning or rotating hook arrangement. When loads are lifted, it is often necessary to turn the load to position it in a

new location or to avoid striking obstructions. A crane hook attached directly to the hoist ropes would cause the

ropes to twist if the load was turned from its original orientation. This would have a number of undesirable effects

such as over-stressing the ropes and boom pulleys, creating an unbalanced load, and causing the load to swing back

in an uncontrolled fashion when released. A hook block allows loads to be freely rotated without changing the

orientation of the hoist ropes. To minimize the failure of crane hook, the stress induced in it must be studied. A

crane is subjected to continuous loading and unloading. This may causes fatigue failure[6,7,8] of the crane hook but

the load cycle frequency is very low. If a crack is developed in the crane hook, mainly at stress concentration areas,

it can cause fracture of the hook and lead to serious accidents. In ductile fracture, the crack propagates continuously

and is more easily detectable and hence preferred over brittle fracture. In brittle fracture, there is sudden propagation

of the crack and the hook fails suddenly [9,10]. This type of fracture is very dangerous as it is difficult to detect.

Strain aging embrittlement due to continuous loading and unloading changes the microstructure. Bending stresses

combined with tensile stresses, weakening of hook due to wear, plastic deformation due to overloading, and

Volume 4 Issue 4 December 2014 90 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

excessive

Thermal stresses are some of the other reasons for failure. Hence continuous use of crane hooks may increase the

magnitude of these stresses and ultimately result in failure of the hook.

II. CURVED BEAM THEORY

The flexural formula is accurate for symmetrically loaded straight beams subjected to pure bending. It is also

generally used to obtain approximate results for the design of straight beams subjected to shear loads, when the

plane of loads, when the plane of loads contains the shear centre and is parallel to a principal axis of the beam; the

resulting errors in the computed stresses are small enough to be negligible as long as the beam length is at least five

times the maximum cross-sectional dimension. In addition, the flexure formula is reasonably accurate I the analysis

of curved beams for which the radius of curvature is more than five times the beam depth. However, for curved

beams the error in the computed stress predicted by the flexure formula increases as the ratio of the radius of

curvature of the beam to the depth of the beam decreases in magnitude. Hence, as this ratio decreases, one needs a

more accurate solution for curved beams. Timoshenko and Goodier (1970) have presented a solution based on the

theory of elasticity for the linear elastic behavior of curved beams of rectangular cross sections for the loading. They

used polar coordinates and obtained relations for the radial stress , the circumferential stress ), and the shear

stress .However, most curved beams do not have rectangular cross sections. Therefore, in the following we

present an approximate curved beam solution that is generally applicable to all symmetrical cross sections.

Fig1: Circumferential stress distribution in a rectangular section curved Beam

2.1. CIRCUMFERENTIAL STRESSES IN A CURVED BEAM

The circumferential stress[11] distribution for the curved beam(fig:1) is obtained by substituting to obtain the curved

beam formula.

2.2 RADIAL STRESSES IN CURVED BEAMS

The radial stresses [11] stress distribution for the curved beam is obtained by substituting to obtain

the curved beam formula.

Volume 4 Issue 4 December 2014 91 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

III. METHODOLOGY

Three mild steel Circular rods of 12mm diameter and 20cm, 22cm and 25cm lengths are heated up to red

hot condition (re-crystallization temp) and these rods are bent into shape of hook with 3cm, 4cm and 5cm radii of

curvature respectively(fig:2). Similarly, Three mild steel square rods of 12mm side and 20cm, 22cm and 25cm

lengths are heated up to red hot condition (re-crystallization temp) and these rods are also bent into shape of hook

with 3cm, 4cm and 5cm radii of curvature respectively shown below(fig:3)

Fig 2: Hooks of circular c/s of 5cm, 4cm and 3cm radii Fig 3: Hooks of square c/s of 5cm, 4cm and 3cm radii

of curvature. of curvature.

3.1.PREPARATION OF EYE BOLT

An Eye-Bolt of 16mm diameter with 15mm eye diameter is prepared for loading the crane hooks on UTM.

It is made by hot forging method as that of hooks. Initially the rod is heated up to re-crystallization temperature i.e,

red hot condition then the rod is shaped like Eye-Bolt by using anvil and forging tools and the diameter of the rod is

16mm (fig:4) and this rod is used for support the hook in the UTM machine.

Fig 4: Eye-Bolt

3.2 EXPERIMENTAL STRESSES USING CURVED BEAM THEORY

By applying the load gradually on hooks on UTM up to 5mm displacement, the following graphs (fig: 5 to 10) are

obtained from the computer which is interfaced with the UTM

Volume 4 Issue 4 December 2014 92 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

Crane hooks of circular cross section:

Load vs Elongation

Fig 5: Circular hook of 30mm Radius of Curvature Fig 6: Circular hook of 40mm Radius of Curvature

Fig 7: Circular hook of 50mm Radius of Curvature

Crane hooks of square cross section

Fig 8: Square hook of 30mm Radius of Curvature Fig 9: Square hook of 40mm Radius of Curvature

Volume 4 Issue 4 December 2014 93 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

Fig 10: Square hook of 40mm Radius of Curvature

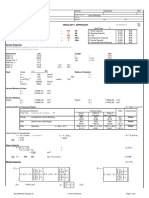

The loads to which crane hooks withstand for 5mm elongation[4]

Sl.no Cross-section of Radius of Load

hook curvature (kN)

30 6.96

1 Circular of 12 dia 40 4.26

50 3.42

30 5.6

2 Square of 12 side 40 2.8

50 2.16

Table 1: Comparisons of Round and Square Rods in UTM Machine

3.4 STRESS CALCULATIONS USING CURVED BEAM THEORY

The crane hooks are tested on UTM for 5mm deformation. But actually the crane hooks are designed for 0.5mm

deflection[1,2,3,5] against the load applied. Otherwise the load carrying capacity of a crane hook is the load at

which it undergoes 0.5 to 1mm.The load carrying capacity of crane hooks for 0.5mm deformation is given below

Cross-section of Radius of Load

S no curvature

hook (kN)

(mm)

30 1.15

1 Circular of 12 dia 40 0.95

50 0.9

30 1.1

2 Square of 12 side 40 0.9

50 0.8

Table 2: Theoretical values Of Circular and Square Rods

Crane Hook of Circular Cross Section:

Area of the round rod (A) = b

Am== 2 (R ) for circle

Volume 4 Issue 4 December 2014 94 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

Mx=P.R

Crane Hook of Square Cross Section:

Area of square rod (A) = b(c-a)

Am = b ln

Radius (R) = , Mx=P.R

3.5 THEORETICAL STRESSES USING FINITE ELEMENT ANALYSIS (ANSYS 12.1)

MODELING IN PRO-E:

The Hooks of Circular and Square cross sections of radius of curvature 30,40,50 mm are designed in the software of

Pro-E 2.0 (fig:11 to 15)

FIG 11: PRO-E Model of Crane hook of circular Fig 12: PRO-E Model of Crane hook of circular

cross section30mm Radius of Curvature cross section 40mm Radius of Curvature

Volume 4 Issue 4 December 2014 95 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

Fig 13: PRO-E Model of Crane hook of Square 30 mm Fig 14: PRO-E Model of Crane hook of Square 40 mm cross section

cross section

Fig 15: PRO-E Model of Crane hook of Square 50 mm cross section

Volume 4 Issue 4 December 2014 96 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

ANALYSIS IN ANSYS 12.1:

The crane hooks are loaded as per the loads mentioned in the table 1 for square cross section and table 2 for circular

cross section hooks

Fig 16: Crane hook after Meshing and Loading Fig 17: Stress distribution in 30mm radius of curvature

Fig 18: Stress distribution in 40mm radius of curvature Fig 19: Stress distribution in 50mm radius of curvature

Volume 4 Issue 4 December 2014 97 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

For crane hook of Square cross section

Fig 20: Stress distribution in 30mm Fig 21: Stress distribution in 40mm Fig 22: Stress distribution in 50mm

radius of curvature radius of curvature radius of curvature

IV. RESULTS

The comparison of the theoretical stress and the experimental stress values for different radius of curvature

of 30mm 40mm and 50mm rods. The stress values are tabulated below in table -3 for circular and in table-4 for

square cross sections.

For circular cross section: For Square cross section:

Table 3: Comparison of Theoretical and Practical Table 4: Comparisons of Theoretical and Practical stresses for stresses

circular rod for square rod

Radius of Experimental Theoretical Radius of Experimental Theoretical

Curvature stresses (N/m) stresses S.No Curvature stress stresses

S.No (mm) (N/m) (mm) (N/m) (N/m)

1 30 290 221.346

1 30 165.16 126.139

2 40 300.63 222.733

2 40 167.08 123.734

3 50 360 246.625 3 50 179.10 127.596

400 crane hook of 200

cranehookofsquarec/s

300

circular c/s

150

200 sse

expt rt 100

s exptstress

100 stress

50 theostress

theo

0 stress 0

0 20 40 60

0 10 20 30 40 50 60

radius of curvature

radiusofcurvature

Fig 23: Stress distribution comparison for circular c/s Fig 24: Stress distribution comparison for Square c/s hook

hook between experiments and theoretical results between experiments and theoretical results

Volume 4 Issue 4 December 2014 98 ISSN: 2319 1058

International Journal of Innovations in Engineering and Technology (IJIET)

V. CONCUSIONS

It is observed from above tables and graphs that the Experimental stress values are greater than Theoretical stress

values for all the hooks. The reason may be in ANSYS the crane hook is assumed as linear, isotropic and prismatic,

but actually, the hooks prepared may not be linear, Isotropic and prismatic therefore the stress values induced in

Experiments all are greater

REFERENCES

[1] Proceedings of the 14th international conference;2010 oct 21-22;Kaunas university of Technology,Lithunaina.Kanuas:Technological.161-

164.

[2] Cook, R. 1992. Circumferential stresses in curved beams,Journal of Applied Mechanics-Transactions of the ASME 59: 224-225.

[3] Yu Huali, H.L. and Huang Xieqing, Structure-strength of Hook with Ultimate Load by Finite Element Method, Proceedings of the

International Multi Conference of Engineers and Computer Scientists, 2009 Vol II IMECS 2009,March 18 - 20, 2009, Hong Kong.

[4] S. Vinodh, R. Ravikumar, (2012),"Application of probabilistic finite element analysis for crane hook design", Journal of Engineering,

Design and Technology, Vol. 10 Iss: 2 pp. 255 275.

[5] Narvydas, E. 2010. Modeling of a crane hook wearand stress analysis. Transport Means 2010: Proceedings of the 14th international

conference; 2010 Oct 21-22; Kaunas University of Technology, Lithuania. Kaunas: Technologija. 161-164.

[6] Sloboda, A.; Honarmandi, P. 2007. Generalized elasticity method for curved beam stress analysis: Analytical and numerical comparisons

for a lifting hook, Mechanics Based Design of Structures and Machines 35: 319-332.

[7] Peterson, R.E. 1974. Stress Concentration Factors. New York: John Wiley & Sons, Inc. 336 p.

[8] 8: Pilkey, W.D. 1997. Petersons Stress Concentration Factors, 2nd ed. New York: John Wiley & Sons, Inc. 544 p.

[9] http://dx.doi.org/10.1002/9780470172674.

[10] Paloto, J.C.; Santos, R.D.; Dominguez, P. 2003. Stress concentration factors for a circular hole in curved beams under bending loads. Strain

39: 27-30.

[11] http://dx.doi.org/10.1046/j.1475-1305.2003.00042.x.

[12] Narvydas, E. 2010. Modeling of a crane hook wear and stress analysis. Transport Means 2010: Proceedings of the 14th international

conference; 2010 Oct 21-22; Kaunas University of Technology, Lithuania. Kaunas: Technologija. 161-164.

[13] BORESI AND SIDEBOTTOM/ Advanced strength of materials.

Volume 4 Issue 4 December 2014 99 ISSN: 2319 1058

You might also like

- Exploring Buckling and Post-Buckling Behavior of Incompressible Hyperelastic Beams Through Innovative Experimental and Computational ApproachesDocument21 pagesExploring Buckling and Post-Buckling Behavior of Incompressible Hyperelastic Beams Through Innovative Experimental and Computational ApproachesGogyNo ratings yet

- 52 Structure New PDFDocument7 pages52 Structure New PDFVino EngineeringNo ratings yet

- Investigation On The Design of Double-Stage Scissor Lifts Based On Parametric Dimension TechniqueDocument19 pagesInvestigation On The Design of Double-Stage Scissor Lifts Based On Parametric Dimension TechniqueGogyNo ratings yet

- Global Sensitivity Analysis For Bridge Crane System by Surrogate ModelingDocument17 pagesGlobal Sensitivity Analysis For Bridge Crane System by Surrogate ModelingGogyNo ratings yet

- Experimental and Numerical Analyses On Axial Cyclic Behavior of H-Section Aluminium Alloy MembersDocument19 pagesExperimental and Numerical Analyses On Axial Cyclic Behavior of H-Section Aluminium Alloy MembersGogyNo ratings yet

- Global Sensitivity Analysis For Bridge Crane System by Surrogate ModelingDocument8 pagesGlobal Sensitivity Analysis For Bridge Crane System by Surrogate ModelingGogyNo ratings yet

- Optimization of The Multi Level Spring Restrainer For Bridges by Hybrid Particle Swarm and Gravitational Search AlgorithmDocument13 pagesOptimization of The Multi Level Spring Restrainer For Bridges by Hybrid Particle Swarm and Gravitational Search AlgorithmGogyNo ratings yet

- Cat Hunting Optimization Algorithm: A Novel Optimization AlgorithmDocument23 pagesCat Hunting Optimization Algorithm: A Novel Optimization AlgorithmGogyNo ratings yet

- Shapes of Energy - Active Segments of Steel BuildingDocument14 pagesShapes of Energy - Active Segments of Steel BuildingGogyNo ratings yet

- Productivity Analysis and Associated Risks in Steel StructuresDocument18 pagesProductivity Analysis and Associated Risks in Steel StructuresGogyNo ratings yet

- Intelligent Skin and Occupancy in The Context of Increasing Energy Efficiency in BuildingsDocument8 pagesIntelligent Skin and Occupancy in The Context of Increasing Energy Efficiency in BuildingsGogyNo ratings yet

- Comparative Analysis of Hatch Cover Stocking Gantry Crane Hooks Manufactured From St37 and Weldox700 Steels Under Static Loading ConditionsDocument9 pagesComparative Analysis of Hatch Cover Stocking Gantry Crane Hooks Manufactured From St37 and Weldox700 Steels Under Static Loading ConditionsGogyNo ratings yet

- Lifting BEAMSDocument90 pagesLifting BEAMSGogyNo ratings yet

- Considering The Moment Effect On The Bolts' Circular Distribution in The End-Plate ConnectionDocument9 pagesConsidering The Moment Effect On The Bolts' Circular Distribution in The End-Plate ConnectionGogyNo ratings yet

- Mechanical Analysis of Forged Steel Ramshorn Hook-An Experimental StudyDocument6 pagesMechanical Analysis of Forged Steel Ramshorn Hook-An Experimental StudyGogyNo ratings yet

- Assessment of Virtual Reality Based Safety Training Simulator For Electric Overhead Crane OperationsDocument13 pagesAssessment of Virtual Reality Based Safety Training Simulator For Electric Overhead Crane OperationsGogyNo ratings yet

- Design Optimization of Bullock Cart YokeDocument9 pagesDesign Optimization of Bullock Cart YokeGogyNo ratings yet

- Female Musicians and DancersDocument60 pagesFemale Musicians and DancersGogyNo ratings yet

- Training Simulator For Acquiring Operational Skill To Operate Overhead Traveling Crane While Suppressing Load SwayDocument13 pagesTraining Simulator For Acquiring Operational Skill To Operate Overhead Traveling Crane While Suppressing Load SwayGogyNo ratings yet

- Curvilinear Mesh AdaptationDocument15 pagesCurvilinear Mesh AdaptationGogyNo ratings yet

- Products CatalogDocument72 pagesProducts CatalogΑΝΑΣΤΑΣΙΟΣ ΣΑΦΡΙΔΗΣNo ratings yet

- Failure Modes of Pumps' Mechanical Parts and Coating Solutions For Wear ProblemsDocument101 pagesFailure Modes of Pumps' Mechanical Parts and Coating Solutions For Wear ProblemsGogyNo ratings yet

- Kaiyuan CatalogDocument6 pagesKaiyuan CatalogGogyNo ratings yet

- A Virtual Reality System For Training OperatorsDocument3 pagesA Virtual Reality System For Training OperatorsGogyNo ratings yet

- Contemporary Meets Old in Rehabilitating Historic BuildingsDocument13 pagesContemporary Meets Old in Rehabilitating Historic BuildingsGogyNo ratings yet

- Automatic Design Algorithms For Securing The Ground Contact Stability of Mobile CranesDocument13 pagesAutomatic Design Algorithms For Securing The Ground Contact Stability of Mobile CranesGogyNo ratings yet

- Experimental and Numerical Analyses On Axial Cyclic Behavior of H-Section Aluminium Alloy MembersDocument19 pagesExperimental and Numerical Analyses On Axial Cyclic Behavior of H-Section Aluminium Alloy MembersGogyNo ratings yet

- Gantry Girder DesignDocument45 pagesGantry Girder DesignmonaliNo ratings yet

- Study On Overturn Proof Monitoring System of Mobile CraneDocument10 pagesStudy On Overturn Proof Monitoring System of Mobile CraneGogyNo ratings yet

- Heavy Lift Installation Study of Offshore Structure 2004Document203 pagesHeavy Lift Installation Study of Offshore Structure 2004Quang-derer75% (4)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Crustal Deformation FinalDocument56 pagesCrustal Deformation FinalSha ShaNo ratings yet

- 0 STAR-CCM+ - Reference Guide2012Document8 pages0 STAR-CCM+ - Reference Guide2012triya_vadgamaNo ratings yet

- Thermodynamics - Fundamentals and Its Application in ScienceDocument554 pagesThermodynamics - Fundamentals and Its Application in ScienceSchreiber_Dieses50% (2)

- Shailesh Final ThesisDocument70 pagesShailesh Final Thesisabdulazeez88No ratings yet

- Ministry of Road Transport & Highways S&R (P&B) SectionDocument2 pagesMinistry of Road Transport & Highways S&R (P&B) SectionAnish PanchalNo ratings yet

- Thin vs. Thick ShellsDocument1 pageThin vs. Thick ShellsMauricio_Vera_5259100% (1)

- AB1019 Supercapacitors in Smart MetersDocument2 pagesAB1019 Supercapacitors in Smart MeterseyadNo ratings yet

- Pavement Design Spreadsheet - CCAA MethodDocument37 pagesPavement Design Spreadsheet - CCAA MethodShoyeeb Ahmed0% (1)

- Thapar University, PatialaDocument1 pageThapar University, PatialasahibjotNo ratings yet

- TDS BS Epoxy 614Document2 pagesTDS BS Epoxy 614Rock RulzNo ratings yet

- Gen Chem 2 - Lesson 3. Uniques Properties of Water and The Structure of SolidsDocument17 pagesGen Chem 2 - Lesson 3. Uniques Properties of Water and The Structure of Solids.....No ratings yet

- Modeling of Welded Connections in Solidworks Simulation: Conference PaperDocument6 pagesModeling of Welded Connections in Solidworks Simulation: Conference PaperpatrickNX9420No ratings yet

- Experiment # 4 Heat of Solution: Van't Hoff Isochore Method: DLNK DT H RTDocument5 pagesExperiment # 4 Heat of Solution: Van't Hoff Isochore Method: DLNK DT H RTIzzyNo ratings yet

- Dynamic Mechanical Analysis (DMA)Document17 pagesDynamic Mechanical Analysis (DMA)nervthcNo ratings yet

- Solar Water Heater Using Nano FluidsDocument5 pagesSolar Water Heater Using Nano Fluidssarfraz hussainNo ratings yet

- Desmopan KU 2-8080Document1 pageDesmopan KU 2-8080Shailendra KumarNo ratings yet

- Modeling of Metamaterial Absorber Structures in Ansys HFSSDocument38 pagesModeling of Metamaterial Absorber Structures in Ansys HFSSyogesh pal singh50% (2)

- HydraulicsDocument190 pagesHydraulicsMathurathipan Rajendraseelan89% (9)

- Burn-In, Reliability Testing, and Manufacturing ofDocument19 pagesBurn-In, Reliability Testing, and Manufacturing ofAbhinav SrivastavNo ratings yet

- Quantum Mechanical Model Explains Electron Behavior in AtomsDocument79 pagesQuantum Mechanical Model Explains Electron Behavior in AtomsLuis NunesNo ratings yet

- PhD in Physics focuses on Condensed MatterDocument13 pagesPhD in Physics focuses on Condensed Matterdreampedlar_45876997No ratings yet

- D Block Elements Imp QuestionsDocument34 pagesD Block Elements Imp Questionsangadkardam9No ratings yet

- 06 08 Jet Kulkarni PDFDocument13 pages06 08 Jet Kulkarni PDFRicardo Horacio LoreficeNo ratings yet

- Strut and WalingDocument2 pagesStrut and WalingChan Kin CheungNo ratings yet

- Lectut-CEN-307-PDF-Stresses in Track Relief of StressesDocument37 pagesLectut-CEN-307-PDF-Stresses in Track Relief of StressesAyush P GuptaNo ratings yet

- RO4000 Laminates Data SheetDocument4 pagesRO4000 Laminates Data SheetJavier De La VegaNo ratings yet

- Form 5 Chemistry - Chapter 4: Polymer (Part 1)Document4 pagesForm 5 Chemistry - Chapter 4: Polymer (Part 1)KuhanrajaNo ratings yet

- BT Mix DesignDocument5 pagesBT Mix DesignGhaffar LaghariNo ratings yet

- Review On LBMDocument9 pagesReview On LBMSomdeb BandopadhyayNo ratings yet