Professional Documents

Culture Documents

Square Blind Flange With Stiffener UL

Uploaded by

joerijiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Square Blind Flange With Stiffener UL

Uploaded by

joerijiCopyright:

Available Formats

PT PROFAB INDONESIA Page 3

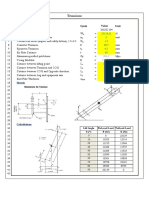

JN919 Blind Flange Thickness Calculation

For Hydrotest Condition

Based on Roark's & Young Formula of Stress and Strain

Design Pressure P 13.00 MPa

Design Temperature T 80.00 C

Test Pressure TP 19.50 MPa

Pipe Diameter OD 900.00 mm

Pipe Thickness ts 44.45 mm

Pipe Inside Diameter d 860.00 mm

Pipe radius a 430.00 mm

Blind Diameter Bd 930.00 mm

Blind section angle for calculation 90.00 deg

Material of blind EH - 36 or DH - 36 or equivalent

Material Yield strength Sy 355.00

Allowable Stress of blind = 0.67 * Sy Sab 237.85 N/mm2

Blind thickness choosen t 70.00 mm

Blind Adequacy per Roark & Young Plate Thickness

Total Load for one sector q = TP = 19.50 N/mm2

Modulus of Elastisity E = 200000.00 N/mm2

poisson's ratio used = 0.30

Maximum stress in the plate,

(Ref. Formulas for stress and strain by Roark & Young )

Table 24, Case No. 28

max = qa2

t2

As, = 90.00 deg

= 0.293

Hence max = 215.45 N/mm2

Result max < Sab SAFE

Maximum deflection of the plate,

(Ref. Formulas for stress and strain by Roark & Young )

Table 24, Case No. 28

Ymax = (*q*a^4)/E*t^3

As, = 90.00 deg

= 0.0144

Hence Ymax (uncorroded) = 0.1399416 mm

Result Ymax < t/2 SAFE

Blind Flange Welding Check

For Hydrotest Condition

Design Pressure P 13.00 MPa

Design Temperature T 80.00 C

Test Pressure TP 19.50 MPa

Pipe Diameter OD 900.00 mm

Pipe Thickness ts 44.45 mm

Pipe Inside Diameter d 811.10 mm

Pipe radius a 405.55 mm

Tension force due to internal pressure at blind flange : Pt 10075655.16 N 2265097 lbf

Fillet weld length around on Pipe & blind, Lf = *OD = 2827 mm = 111.32 in

Groove weld length around on Pipe & blind, Lg = *OD = 2827 mm = 111.32 in

Fillet weld leg dimension, wf = 20 mm = 0.79 in

Groove weld depth dimension, wg = 40 mm = 1.57 in

Welding area of fillet weld, Af = wf * Lf = 56549 mm2

Welding area of groove weld, Ag = wg * Lg = 113097 mm2

Allowable weld stress, Sw = 66.19 MPa = 9600 psi

Load on weld per linear length of weld:

Tension stress of weld, St = Pt / (Af + Ag) = 59.39 MPa = 8614 psi

Weld Status St < Sa PASS

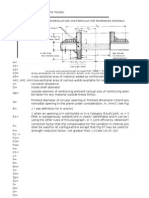

Blind Flange Thickness Calculation

For Hydrotest Condition

Based on Roark's & Young Formula of Stress and Strain

Design Pressure P 1.03 Mpa = 150 Psi

Design Temperature T 90.00 C = 194 F

Test Pressure TP 1.34 Mpa = 194 Psi

Pipe Diameter OD 508.00 mm

Pipe Thickness ts 15.00 mm

Pipe Inside Diameter d 478.00 mm

Pipe inside radius r 239.00 mm

Blind Diameter Bd 508.00 mm

Material of blind SA-516 Gr.70

Material Yield strength Sy 260.00 MPa

Allowable Stress of blind = 0.67 * Sy Sab 174.20 MPa (For safety factor)

Blind thickness choosen t 12.00 mm

Blind Adequacy per Roark & Young Plate Thickness

Total Load for one sector q = TP = 1.34 N/mm2

Modulus of Elastisity E = 200000.00 N/mm2

poisson's ratio used = 0.30

Rectangular plate dimension a= 250.00 mm

b= 250.00 mm

Maximum stress in the plate,

(Ref. Formulas for stress and strain by Roark & Young, 7th Edition )

Table 11.4, Case No. 1a

max = qb2

t2

As, a/b = 1.00

= 0.287

Hence max = 167.15 N/mm2

Result max < Sab SAFE

Maximum deflection of the plate,

(Ref. Formulas for stress and strain by Roark & Young, 7th Edition )

Table 11.4, Case No. 1a

Ymax = (*q*b^4)/E*t^3

As, a/b = 1.00

= 0.0444

Hence Ymax (uncorroded) = 0.6724718 mm

Result Ymax < t/2 SAFE

Stiffener of Blind Flange

For Hydrotest Condition

1. Vertical stiffener Calculation

Stiffener to be used :

Stiffener size 12mm THK x 150 width

Stiffener thick, ta = 12.0 mm 0.5 in

Elastic modulus, E = 200000 MPa

Minimum yield strength, Sy = 260.0 MPa 37709.8 psi

Allowable stress, Sa = 0.67*Sy = 174.2 MPa 25265.6 psi

Allow. moment of inertia for horizontal stiffener (I a) = 0.6912 cm4 0.02 in4

Allow. section modulus of vertical stiffener (Za) = 0.58 cm3 0.0 in3

Distance between vertical stiffener, L = 250 mm 9.8 in

Height of vertical stiffener, H = 75 mm 3.0 in

Load per unit length w = TP x d = 640.52 N/mm

Required section modulus of vertical stiffener

Z = 0.0642*0.036*w*L*H2 = 0.16 cm3 0.01 in3

Sa

Check Stiffener Z < Za = PASS

Required moment of inertia

Imin = 0.7*w*L4 = 0.38 cm4 0.01 in4

192*E*ta

Check Stiffener Imin < Ia = PASS

2. Horizontal stiffener Calculation

Stiffener to be used :

Stiffener size 12mm THK x 150 width

Stiffener thick, ta = 12.0 mm 0.5 in

Elastic modulus, E = 200000 MPa

Minimum yield strength, Sy = 335.0 MPa 48587.6 psi

Allowable stress, Sa = 0.67*Sy = 224.45 MPa 32553.7 psi

Allow. moment of inertia for horizontal stiffener (I a) = 0.6912 cm4 0.02 in4

0.58 cm

3

Allow. section modulus of vertical stiffener (Za) = 0.0 in3

Distance between horizontal stiffener, L = 250 mm 9.8 in

Length of horizontal stiffener, H = 75 mm 3.0 in

Load per unit length w = TP x d = 640.52 N/mm

Required section modulus of horizontal stiffener

Z = 0.0642*0.036*w*H*L2 = 0.12 cm3 0.01 in3

Sa

Check Stiffener Z < Za = PASS

Required moment of inertia

Imin = 0.7*w*H4 = 0.38 cm4 0.01 in4

192*E*ta

Check Stiffener Imin < Ia = PASS

Blind Flange Thickness Calculation

For Hydrotest Condition

Based on Roark's & Young Formula of Stress and Strain

Design Pressure P 1.03 Mpa = 150 Psi

Design Temperature T 90.00 C = 194 F

Test Pressure TP 1.34 Mpa = 194 Psi

Pipe Diameter OD 508.00 mm

Pipe Thickness ts 15.00 mm

Pipe Inside Diameter d 478.00 mm

Pipe inside radius r 239.00 mm

Blind Diameter Bd 508.00 mm

Material of blind SA-516 Gr.70

Material Yield strength Sy 260.00 MPa

Allowable Stress of blind = 0.67 * Sy Sab 174.20 MPa (For safety factor)

Blind thickness choosen t 25.00 mm

Blind Adequacy per Roark & Young Plate Thickness

Total Load for one sector q = TP = 1.34 N/mm2

Modulus of Elastisity E = 200000.00 N/mm2

poisson's ratio used = 0.30

Rectangular plate dimension a= 508.00 mm

b= 508.00 mm

Maximum stress in the plate,

(Ref. Formulas for stress and strain by Roark & Young, 7th Edition )

Table 11.4, Case No. 1a

max = qb2

t2

As, a/b = 1.00

= 0.287

Hence max = 159.02 N/mm2

Result max < Sab SAFE

Maximum deflection of the plate,

(Ref. Formulas for stress and strain by Roark & Young, 7th Edition )

Table 11.4, Case No. 1a

Ymax = (*q*b^4)/E*t^3

As, a/b = 1.00

= 0.0444

Hence Ymax (uncorroded) = 1.2679222 mm

Result Ymax < t/2 SAFE

You might also like

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Longitudinal Bending Stress: M1 Allowable Limit RemarkDocument16 pagesLongitudinal Bending Stress: M1 Allowable Limit RemarkSandal JepitNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Wind Calculation SheetDocument32 pagesWind Calculation SheetaauppalNo ratings yet

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- PV Elite Vessel Analysis Program HorizontalDocument55 pagesPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNo ratings yet

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiNo ratings yet

- Design of Flanges - Optional Type 2010Document59 pagesDesign of Flanges - Optional Type 2010bakellyNo ratings yet

- Weld stress check for FAVID clips and demister clipsDocument3 pagesWeld stress check for FAVID clips and demister clipsrsubramaniNo ratings yet

- Gasket Dimension (ASME B16.5 & B16.47)Document4 pagesGasket Dimension (ASME B16.5 & B16.47)amaNo ratings yet

- #754 v-3103 Spreader & Lifting 60 DegreeDocument12 pages#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- Tutorial of WRC 107 For Lifting LugsDocument20 pagesTutorial of WRC 107 For Lifting LugsPeterWayNo ratings yet

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Pipe Cap Thickness Calculation for ASME Section VIIIDocument9 pagesPipe Cap Thickness Calculation for ASME Section VIIILcm TnlNo ratings yet

- Saddle Calc PD5500Document4 pagesSaddle Calc PD5500rsubramaniNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Clip PlatformDocument24 pagesClip Platformwisnu_bayusaktiNo ratings yet

- Design of base plate for columnDocument6 pagesDesign of base plate for columnsoumyaNo ratings yet

- Analysis of a rectangular pressure vesselDocument7 pagesAnalysis of a rectangular pressure vesselPressure VesselNo ratings yet

- Saddle CalcDocument26 pagesSaddle CalcVamsi S100% (2)

- Platform Cleat Calculations for No. 1 at El. 47700Document4 pagesPlatform Cleat Calculations for No. 1 at El. 47700shaishavNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Internal Pipe Distributor Design ProcedureDocument5 pagesInternal Pipe Distributor Design Proceduresenthil kumarNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Design of Flanges - Weld Neck Type 2010Document58 pagesDesign of Flanges - Weld Neck Type 2010bakellyNo ratings yet

- Collar bolt sizing calculationDocument2 pagesCollar bolt sizing calculationMohammad Zahid50% (2)

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- Calculation of Trunnions Rev3Document3 pagesCalculation of Trunnions Rev3Bilel MahjoubNo ratings yet

- Nozzle ReinforcementDocument8 pagesNozzle ReinforcementHafizi HZnumismatic0% (1)

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- Tema Nozzle LoadDocument4 pagesTema Nozzle LoadkanhuNo ratings yet

- Horizontal Vessel Stress AnalysisDocument12 pagesHorizontal Vessel Stress AnalysissridharNo ratings yet

- Stiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselDocument4 pagesStiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselEstuardo Javier Gan RodríguezNo ratings yet

- Saddle Calc PD5500Document6 pagesSaddle Calc PD5500Vamsi SNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Lifting Lug Design CalculationsDocument17 pagesLifting Lug Design CalculationsSiva baalan100% (1)

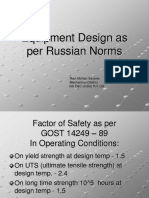

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikasNo ratings yet

- Spherical Shells en 13445-3 - 7.4.3Document3 pagesSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- Ccsviiid1 2260Document2 pagesCcsviiid1 2260DieguitoOmarMoralesNo ratings yet

- Slot Expansion CalculationDocument1 pageSlot Expansion CalculationSarfaraz KhanNo ratings yet

- Calc. Fillet Weld Transverse Load-Jacket ClosureDocument6 pagesCalc. Fillet Weld Transverse Load-Jacket ClosureAsep MulyadiNo ratings yet

- Blind Calculation - RoarkDocument10 pagesBlind Calculation - Roarkrustamriyadi100% (2)

- Wall Thickness Calculation Verification under StressDocument1 pageWall Thickness Calculation Verification under StresshhgjdfNo ratings yet

- ISO 13623 pipe wall thickness calculation for Mahani-2 projectDocument6 pagesISO 13623 pipe wall thickness calculation for Mahani-2 projectRanjan KumarNo ratings yet

- HDD Installation CalculationsDocument4 pagesHDD Installation Calculationslive4sankar100% (1)

- Rectangular Tank Satu LagiDocument1 pageRectangular Tank Satu LagiSteve MoonNo ratings yet

- Hays Pressure Drop Calculator ChartsDocument7 pagesHays Pressure Drop Calculator Chartsjoeriji0% (1)

- BC Lifting Arrangement ULDocument3 pagesBC Lifting Arrangement ULjoerijiNo ratings yet

- IFC FabStrainers - CatDocument40 pagesIFC FabStrainers - CatSpoonful BurnsideNo ratings yet

- Packed Bed Pressure Drop vs. Char SizeDocument11 pagesPacked Bed Pressure Drop vs. Char SizejoerijiNo ratings yet

- Concrete Rail Block CalcDocument2 pagesConcrete Rail Block CalcjoerijiNo ratings yet

- Barge Stability GuidelinesDocument10 pagesBarge Stability Guidelinesnautilus73100% (2)

- Packed Bed Pressure Drop vs. Char Size v3Document12 pagesPacked Bed Pressure Drop vs. Char Size v3joerijiNo ratings yet

- Hays Pressure Drop Calculator ChartsDocument7 pagesHays Pressure Drop Calculator Chartsjoeriji0% (1)

- Pressure DropDocument19 pagesPressure DropGigis Kintan MyarthalunaNo ratings yet

- P4 Design SummaryDocument1 pageP4 Design SummaryjoerijiNo ratings yet

- Caison Buckling CheckDocument3 pagesCaison Buckling CheckjoerijiNo ratings yet

- Buckling CheckDocument1 pageBuckling CheckjoerijiNo ratings yet

- Davit Arm CalculationDocument4 pagesDavit Arm Calculationjoeriji0% (1)

- Base Plate CheckDocument6 pagesBase Plate CheckjoerijiNo ratings yet

- BC Lifting Arrangement ULDocument3 pagesBC Lifting Arrangement ULjoerijiNo ratings yet

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiNo ratings yet

- Sample - Weight & COG Estimation FormatDocument4 pagesSample - Weight & COG Estimation FormatjoerijiNo ratings yet

- Hall Design For SpeechDocument1 pageHall Design For SpeechSarovar SaroNo ratings yet

- Thick Seam Mining Methods and Problems Associated With It: Submitted By: SAURABH SINGHDocument13 pagesThick Seam Mining Methods and Problems Associated With It: Submitted By: SAURABH SINGHPrabhu PrasadNo ratings yet

- CANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenDocument6 pagesCANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenIsmenia HelenaNo ratings yet

- Iwwusa Final Report IdsDocument216 pagesIwwusa Final Report IdsRituNo ratings yet

- Catalogue PDFDocument4 pagesCatalogue PDFShivam GuptaNo ratings yet

- Release emotions with simple questionsDocument10 pagesRelease emotions with simple questionsDubravko ThorNo ratings yet

- Pyrolysis ProjectDocument122 pagesPyrolysis ProjectSohel Bangi100% (1)

- Sri Lanka, CBSLDocument24 pagesSri Lanka, CBSLVyasIRMANo ratings yet

- The Issue of Body ShamingDocument4 pagesThe Issue of Body ShamingErleenNo ratings yet

- Assurance Audit of Prepaid ExpendituresDocument7 pagesAssurance Audit of Prepaid ExpendituresRatna Dwi YulintinaNo ratings yet

- CMC4 Controller Technical Support DocumentDocument148 pagesCMC4 Controller Technical Support DocumentZurab ChanturiaNo ratings yet

- CVR College of Engineering: UGC Autonomous InstitutionDocument2 pagesCVR College of Engineering: UGC Autonomous Institutionshankar1577No ratings yet

- UNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Document6 pagesUNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Bergonsolutions AingelNo ratings yet

- Facelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger FaceDocument136 pagesFacelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger Faceugur gebologluNo ratings yet

- Lecturer No 1 - Transformer BasicDocument1 pageLecturer No 1 - Transformer Basiclvb123No ratings yet

- Fci FC CotsDocument25 pagesFci FC CotsMatthew DuNo ratings yet

- Latihan Soal Recount Text HotsDocument3 pagesLatihan Soal Recount Text HotsDevinta ArdyNo ratings yet

- Etoposide JurnalDocument6 pagesEtoposide JurnalShalie VhiantyNo ratings yet

- Working Capital Management at Padmavathi Co-operative BankDocument53 pagesWorking Capital Management at Padmavathi Co-operative BankMamidishetty Manasa67% (3)

- College Physics Reasoning and Relationships 2nd Edition Nicholas Giordano Solutions ManualDocument36 pagesCollege Physics Reasoning and Relationships 2nd Edition Nicholas Giordano Solutions Manualshippo.mackerels072100% (22)

- Eca Important QuestionsDocument3 pagesEca Important QuestionsSri KrishnaNo ratings yet

- Packetfence Network Devices Configuration Guide: For Version 3.5.0Document76 pagesPacketfence Network Devices Configuration Guide: For Version 3.5.0René FabricioNo ratings yet

- Rules & Guidelines of Elliott WaveDocument12 pagesRules & Guidelines of Elliott WaveNd Reyes100% (2)

- Psyclone: Rigging & Tuning GuideDocument2 pagesPsyclone: Rigging & Tuning GuidelmagasNo ratings yet

- The Seven Seals of Revelation and The SevenDocument14 pagesThe Seven Seals of Revelation and The Sevenyulamula100% (2)

- The Ultimate Manifesting Money Blueprint by Sonia RicottiDocument34 pagesThe Ultimate Manifesting Money Blueprint by Sonia RicottiViolet VioletNo ratings yet

- German BasicDocument60 pagesGerman BasicchahirNo ratings yet

- Avanto Magnet System Error MessagesDocument21 pagesAvanto Magnet System Error MessagesMuhammad Ahmad75% (4)

- Linked ListDocument83 pagesLinked Listshahida18No ratings yet

- The Teacher and The LearnerDocument23 pagesThe Teacher and The LearnerUnique Alegarbes Labra-SajolNo ratings yet