Professional Documents

Culture Documents

Abetong Tank c14 Tryck

Uploaded by

ingemekanicalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abetong Tank c14 Tryck

Uploaded by

ingemekanicalCopyright:

Available Formats

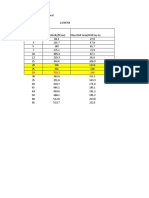

Technical Data

Dimension table, features and quality

The exibility of the system is illustrated below. Due to two panel thicknesses,

240 and 300 mm, referring to the thickness of the rib at the joint, optimal tank

characteristics is achieved. All tank sizes in between the values in the table are

available with consideration to heights and number of panels.

Number

of panels

Internal diameter

240 300 3,0 4,0

Volume for different heights (m3)

6,0 8,0 10,0 12,0 14,0

Abetong Tank C14

11 7,77 7,66 146 195 293 390 488 569 664

15 10,89 10,77 283 378 567 756 945 1110 1295

20 14,76 14,64 518 690 1035 1380 1725 2038 2377

25 18,62 18,50 821 1095 1643 2190 2738 3244 3784

30 22,47 22,36 1194 1593 2389 3185 3981 4727 5515

35 26,32 26,20 1637 2183 3274 4365 5457 6489 7571

40 30,17 30,05 2149 2866 4298 5731 7164 8529 9950

45 34,02 33,90 2731 3641 5461 7282 9102 10846 12654

50 37,86 37,74 3382 4509 6763 9018 11272 13441 15682

55 41,70 41,58 4102 5470 8204 10939 13674 16315 19034

60 45,55 45,43 4892 6523 9784 13045 16221 19465 22710 Abetong tank features:

65 49,39 49,27 5751 7669 11503 15337 19078 22894

- Unique utilizations diversity.

70 53,23 53,11 6680 8907 13360 17814 22167 26601

75 57,07 56,95 7678 10238 15357 20476 25487 30585 - Leads the way with cutting edge

80 60,91 60,79 8746 11661 17492 23323 29039 34847 technology.

85 64,75 64,63 9883 13178 19766 26355 32822

- For heights up to 14 m and volumes

90 68,59 68,47 11090 14786 22180 29573 36837

up to around 35,000 m3.

All volumes refer to full tank height. - Ultimate and resource efcient tank

Normal gures refer to diameter and volume for 240 mm thick panels. system.

Bold gures refer to diameter and volume for 300 mm thick panels.

The internal diameter referred to is the minimum diameter (to the centre of the panel). - Industrial controlled production facilities.

The exact limits for 240 and 300 panels respectively are depending on load conditions

and on local building regulations and can vary from case to case. SWEDISH PRECAST TECHNOLOGY - Durable solutions for coming

generations.

Abetong is a member of HeidelbergCement Group,

- The reliable tank system.

General Codes for design guidance and production which is the global market leader in aggregates and

European Standard for design of concrete structures, EN 1992-1-1, Eurocode 2: Design of concrete structures Part 1-1: General rules and rules a prominent player in the elds of cement, concrete - For better building.

for buildings. There is also a number of other approved EN standards applicable for tank design e.g. EN 1992-3: Eurocode 2 Design of concrete and other downstream activities, making it one of the

structures Part 3: Liquid retaining and containment structures, and EN 1991-4: Eurocode 1 Actions on structures Part 4: Silos and tanks. worlds largest manufacturers of building materials. - Abetong precast partner to trust.

SS EN 206-1. Our design calculation software is independent of standards, and can therefore be used for various national codes. The company employs some 70,000 people at 2,800

locations in more than 50 countries.

Concrete exposure factors Quality assurance, QHSE

Abetong tanks are produced to endure most harsh conditions. - ISO 9001

Inside tank factors up to XD2+XA2 - ISO 14001

Outside tank factors up to XC4+XF3 - Afliated to BBC

Concrete strength

From C40/50 up to C55/67 and with water cement ratio down to 0,4.

Safety and guarantees

- Waterproof guarantee in accordance to EN 1992, Eurocode 2: Abetong AB

- Design of concrete structures-3 Liquid Retaining Structures table 7.105 Tightness class 1-3. Box 24

- Material and goods 2 years guarantee. SE-351 03 VXJ

- 5 years guarantee period for Abetongs workmanship. Phone +46 470 965 00

- 10 years liability period for Abetongs total works. Fax +46 470 160 81

info@abetong.com

www.abetong.com

Long lifetime, maintenance free and functionality are the key

words of Abetongs concept. Abetong leads the way with C14 Characteristics Optional Products

precast tank technology and expertise of more than Functionality Durable and optimized solutions

50 000 tanks worldwide. Abetong tanks have unique The Abetong concept consists of manufacturing and erection of precast

utilization diversity; we can cover your requirements and and prestressed concrete tank panels on a cast in situ bottom slab. The

meet your demands. tanks are prestressed vertically to resist and overcome calculated loads

without cracks.

Abetong Tanks

Proven technology

Abetong tanks have the most reliable technology for resource efcient tanks are

The tan

prestressed

prestre

precast tanks, corresponding to meet the challenge of mankind to build vertically

vertica

a sustainable society. Prestressing post

and po Abetong tank roof Manhole

principle. tensioned

tension

horizontally

horizon Complete systems for precast roofs The tanks are normally designed

Precast tank technology from Abetong has been delivered and devel- giving an are available, perfect for potable with additional holes, pipes, steel

almost

oped for over three decades. We can deliver complete concepts for crackfree

crack water tanks. plates etc. or with different types of

tanks to comply with most types of applications. From procurement data The bottom slab is cast on site while the tank panels are structure.

structu manholes.

we offer design, production and installation of your tank. produced in a controlled and supervised environment. nt.

The industrial production facilities help to reduce work

ork at

Due to our patented details, innovative design and high concrete quality, height to a minimum This also leads to less waste, clean

the tank installation is rapid, health and safety controlled, and practical site conditions and fast erection. The structure will has

in most weather conditions. The structure is homogeneous and enables superior characteristics to a traditional poured in situ tank.

an almost crackfree structure due to built-in compressive forces. Concrete

is grouted

The vertical joints between the precast panels and the between the

By working in close cooperation with clients and using our exible horizontal joint between the bottom slab and the panels panels and

the bottom

system to meet the clients requirements, we can give the best technical are grouted with concrete.

slab, water

and economical solutions. proong

Circumferential mono strands are then post tensioned in materials

and methods

Abetong tanks can be placed above ground, partly in ground or below order to keep the joints compressed. are used.

Abetong tank free span roof Lining system

ground. They can be found on all continents based on license produc- For fermenter tanks our semi- The tanks can fully or partly be t-

tion partnerships. Abetong deliver the safest post tensioning on the market. insulated prestressed roof slabs ted with cast in linings for various

All the strands are secured in ducts which are pumped full work as an optimal and durable applications, for example gas reten-

Grease

The unique

with grout from below. and safe tri- design. tion and acid resistance.

Environmental Control Furthermore the strands are PE-sheathed and greased.

PE-sheathed

ple corrosion

protection of

Possible/optional placements

For a better environment the tendons

Basically a triple corrosion protection system ensures that gives long Optional heating ducts

term benets

Concrete is the natural choice when structure features are of great the tendons serve the tank structure without mainte- Duct as well as

importance. Abetong tanks have a long lifetime that gives durable solu- nance. Injected a homo-

grout geneous

tions for generations to come. Unbonded strand structure.

Our mission is to provide tank infrastructure for clean tech facilities,

recycling solutions and renewable energy plants.

Important clients Storage tanks Treatment tanks

Abetong tanks are waterproof and can be used for various applications, Municipal authorities Fire water Aeration

Agricultural industry Potable Balancing

for example water supply, waste and water treatment, industrial liquid Dairy plants and food industry Sludge Digestion Precast wheeltrack & Precast wheeltrack &

storage and bioenergy use. Power plants Bund Biogas internal channel external channel

Pharmaceutical industry Safety Clarication

Chemical industry Digestion Settling For settling tanks, Abetong chan- Abetong can optimize precast

With a long term perspective, we develop and offer resource efcient Paper mill industry Process water Filtration nels and wheeltracks are performed solutions in accordance to the

Mining industry Irrigation

tank systems to serve for a better environment. Steel industry Biofuel silos chip bins

in high strength concrete for long customers requirements of the

lifetime and practical service. facility.

You might also like

- Demag CC 2600 500 Te: Member of Al Jaber GroupDocument18 pagesDemag CC 2600 500 Te: Member of Al Jaber GroupSantosh PatilNo ratings yet

- Collection conveyance Excess Saving statementDocument2 pagesCollection conveyance Excess Saving statementBipin PatilNo ratings yet

- Model BVBS Vertical In-Line Strainers: DescriptionDocument4 pagesModel BVBS Vertical In-Line Strainers: Descriptionwalter ruizNo ratings yet

- INSTR Panel Guard 701 770 140425Document2 pagesINSTR Panel Guard 701 770 140425ernst22No ratings yet

- Tricone Bit BrochureDocument8 pagesTricone Bit BrochureDony ArifNo ratings yet

- AUMUND Apron FeedersDocument12 pagesAUMUND Apron Feederschannakeshava pandurangaNo ratings yet

- Dripnet PC 17640-007252Document2 pagesDripnet PC 17640-007252Hernan RiosNo ratings yet

- Hi - Span DeckDocument2 pagesHi - Span DeckJubin MathewNo ratings yet

- DDDDDDDDDDDDDDDDocument2 pagesDDDDDDDDDDDDDDDfredjbps@gmail.comNo ratings yet

- Structures Plan, L (M) WT of Raft Slab Super STR WT (KN) Total Self WT (KN)Document4 pagesStructures Plan, L (M) WT of Raft Slab Super STR WT (KN) Total Self WT (KN)Roshan KejariwalNo ratings yet

- Grade 4.6 and 8.8 Bolt Capacities and Bearing ValuesDocument1 pageGrade 4.6 and 8.8 Bolt Capacities and Bearing ValuesHussein NasserNo ratings yet

- Datasheet PTC 200 DsDocument9 pagesDatasheet PTC 200 Dsdheeraj SureshNo ratings yet

- Conduit & Trunking Capacity ChartDocument20 pagesConduit & Trunking Capacity ChartvelisbarNo ratings yet

- Final Year Design Lectures - Mar 2018: List of AttachmentsDocument9 pagesFinal Year Design Lectures - Mar 2018: List of AttachmentsjayaprinaNo ratings yet

- Expt 7 - Tesion TestDocument9 pagesExpt 7 - Tesion Testjyoti swaroop repaka100% (1)

- Steel Wire Rope: Factors Affecting Rope Life Tensile GradeDocument1 pageSteel Wire Rope: Factors Affecting Rope Life Tensile GradeHUNG NIKKONo ratings yet

- FlowCon Fabric Air Diffuser Design ManualDocument12 pagesFlowCon Fabric Air Diffuser Design Manuallheo cayabasNo ratings yet

- Flexible Road Overlay Design by FWDDocument9 pagesFlexible Road Overlay Design by FWDafifa kausar100% (1)

- Cross Sectional Area of Reinforcement at Given Bar SpacingDocument1 pageCross Sectional Area of Reinforcement at Given Bar SpacingAndrian TanjayaNo ratings yet

- Cross sectional area of reinforcement at given bar spacing and diametersDocument1 pageCross sectional area of reinforcement at given bar spacing and diametersLynx101No ratings yet

- Cross Sectional Area of Reinforcement at Given Bar SpacingDocument1 pageCross Sectional Area of Reinforcement at Given Bar Spacingrodain najjarNo ratings yet

- Code Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Document4 pagesCode Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Edwardhutauruk100% (1)

- Generation Oct 2023Document10 pagesGeneration Oct 2023rudra.mc5No ratings yet

- Horizontal Tank VolumeDocument6 pagesHorizontal Tank VolumeNitin KurupNo ratings yet

- Ms Plate Weight Chart in KGDocument6 pagesMs Plate Weight Chart in KGMF IQBALNo ratings yet

- NG DS Series I Thermistor 10K3A1 A-779628Document6 pagesNG DS Series I Thermistor 10K3A1 A-779628BaltazarNo ratings yet

- ARTIFEX INFRA - 44mm Decksheet ProfileDocument1 pageARTIFEX INFRA - 44mm Decksheet ProfileAmit SharmaNo ratings yet

- PVC Pipes: Complete PVC Piping SystemDocument2 pagesPVC Pipes: Complete PVC Piping SystemSyed Shariq HassanNo ratings yet

- PVC Pipes Fittings BrochureDocument2 pagesPVC Pipes Fittings BrochureSarmad ShahNo ratings yet

- Fulcrum Winch Series: Standard FeaturesDocument4 pagesFulcrum Winch Series: Standard FeaturesBang OchimNo ratings yet

- Rivulis Katif English Metric 20190509 WebDocument4 pagesRivulis Katif English Metric 20190509 Webkvsj2001No ratings yet

- Milroyal C Pumps DatasheetDocument12 pagesMilroyal C Pumps Datasheetdevil3300No ratings yet

- Dimensions and Dimensional Tolerances of Long Radius Elbows 45 and 90 Degrees and 3D Elbows, NPS 1 - 2 To NPS 48, ASME B16.9Document3 pagesDimensions and Dimensional Tolerances of Long Radius Elbows 45 and 90 Degrees and 3D Elbows, NPS 1 - 2 To NPS 48, ASME B16.9sennimalaiNo ratings yet

- Tank Calibration Report: Tag No. 1DT-702Document5 pagesTank Calibration Report: Tag No. 1DT-702Sachin DapseNo ratings yet

- Radiator ELEKS EcopanDocument1 pageRadiator ELEKS EcopanStelian BerceaNo ratings yet

- Process and Equipment Experiment: Fluid CircuitDocument9 pagesProcess and Equipment Experiment: Fluid CircuitNguyễn ThuNo ratings yet

- Cost EstimationDocument4 pagesCost EstimationAmit Kumar MishraNo ratings yet

- Protan Mining Brochure - Ventilation DuctingDocument12 pagesProtan Mining Brochure - Ventilation DuctingTom HightNo ratings yet

- Figure 4 MaterialsDocument4 pagesFigure 4 MaterialsMEHMET MERTNo ratings yet

- Wire Ropes: Construction, Specification & SelectionDocument22 pagesWire Ropes: Construction, Specification & SelectionDhruv Bhalala100% (1)

- 1 KSB ULTRA CatalogueDocument2 pages1 KSB ULTRA CatalogueHarshad AthawaleNo ratings yet

- Prebending Chart MCB R-40 in Mat. With Max YP 360 Mpa 2,5THDocument1 pagePrebending Chart MCB R-40 in Mat. With Max YP 360 Mpa 2,5THMarcelo DinizNo ratings yet

- Rain Water Pipe Sizing calculation sheetDocument1 pageRain Water Pipe Sizing calculation sheetAnonymous VEqJ96RNo ratings yet

- Maximum Recommended Flow Through Compressed Air PipeDocument3 pagesMaximum Recommended Flow Through Compressed Air PipehanshanantaNo ratings yet

- Certex Product Catalogue Chapter 001 PDFDocument69 pagesCertex Product Catalogue Chapter 001 PDFAther AliNo ratings yet

- SKF Flex CouplingsDocument9 pagesSKF Flex CouplingsWaskitoNo ratings yet

- Potency & Rate SettingsDocument41 pagesPotency & Rate SettingseuroconsultbgNo ratings yet

- Kirti Steel Industries: Price ListDocument8 pagesKirti Steel Industries: Price ListSANGHVI OVERSEASNo ratings yet

- Polycab Wires Latest Price ListDocument1 pagePolycab Wires Latest Price Listandcha.exe100% (1)

- Centricast CL 1520 Data SheetDocument6 pagesCentricast CL 1520 Data SheetOlmer Romero MendezNo ratings yet

- High Capacity TablesDocument46 pagesHigh Capacity Tablesjunhe898No ratings yet

- Design Aids PDFDocument9 pagesDesign Aids PDFBilal Al-MuhtasebNo ratings yet

- Pt. Magdatama - Brosur Wabo Elastomeric Bearing PadDocument2 pagesPt. Magdatama - Brosur Wabo Elastomeric Bearing PadFitbar Oats0% (1)

- Max Flow Through PipeDocument9 pagesMax Flow Through PipeAmey RaneNo ratings yet

- Terex-Demag AC500-2 Dimensions and SpecsDocument11 pagesTerex-Demag AC500-2 Dimensions and SpecsYay B. GicoNo ratings yet

- Shearbox Group 1 - 3 (20.26.28-04-2023)Document3 pagesShearbox Group 1 - 3 (20.26.28-04-2023)KaraboNo ratings yet

- Category 6 Cable: DescriptionDocument2 pagesCategory 6 Cable: DescriptionkapilNo ratings yet

- Wattage ChartDocument1 pageWattage Chartff_jeffNo ratings yet

- LT Power Cables - Aluminium Conductor: Havells BrandDocument20 pagesLT Power Cables - Aluminium Conductor: Havells BrandVimal SinghNo ratings yet

- General Purpose Outdoor Led Guide PDFDocument8 pagesGeneral Purpose Outdoor Led Guide PDFingemekanicalNo ratings yet

- Residential: Solutions Application GuideDocument28 pagesResidential: Solutions Application GuideingemekanicalNo ratings yet

- IoT CharmDocument2 pagesIoT CharmingemekanicalNo ratings yet

- Bibm Factbook 2015 (Final)Document11 pagesBibm Factbook 2015 (Final)ingemekanicalNo ratings yet

- General Purpose Outdoor Led Guide PDFDocument8 pagesGeneral Purpose Outdoor Led Guide PDFingemekanicalNo ratings yet

- SDPV31306Document65 pagesSDPV31306bdsisira100% (1)

- Correctional Facilities: Infrastructure Lighting & Controls SolutionsDocument16 pagesCorrectional Facilities: Infrastructure Lighting & Controls SolutionsingemekanicalNo ratings yet

- Correctional Facility Outdoor LED LightingDocument8 pagesCorrectional Facility Outdoor LED LightingingemekanicalNo ratings yet

- 3D Printing Buyers Guide-FinalDocument7 pages3D Printing Buyers Guide-FinalingemekanicalNo ratings yet

- Spectroscopic Signatures of IsomerizationDocument192 pagesSpectroscopic Signatures of IsomerizationingemekanicalNo ratings yet

- Climate Change Science ProjectDocument14 pagesClimate Change Science ProjectingemekanicalNo ratings yet

- AN4481Document3 pagesAN4481ingemekanicalNo ratings yet

- Second LifeDocument9 pagesSecond LifeingemekanicalNo ratings yet

- ThermocoupleDocument8 pagesThermocoupleDilip AryaNo ratings yet

- 3DVIAComposer V6R2013 Fact SheetDocument9 pages3DVIAComposer V6R2013 Fact SheetingemekanicalNo ratings yet

- 04 - Miniature Piston PumpsDocument6 pages04 - Miniature Piston PumpsingemekanicalNo ratings yet

- AC Induction MotorsDocument3 pagesAC Induction MotorsingemekanicalNo ratings yet

- 1112.6127v1 Truth and The Liar ParadoxDocument10 pages1112.6127v1 Truth and The Liar ParadoxingemekanicalNo ratings yet

- IEQ CompleteDocument19 pagesIEQ Completeharshal patilNo ratings yet

- SECTION 303-06 Starting SystemDocument8 pagesSECTION 303-06 Starting SystemTuan TranNo ratings yet

- 2 Scour VentDocument8 pages2 Scour VentPrachi TaoriNo ratings yet

- KoyoDocument4 pagesKoyovichitNo ratings yet

- Sibuyan Island ResiliencyDocument12 pagesSibuyan Island ResiliencyEndangeredSpeciesNo ratings yet

- Ro-Buh-Qpl: Express WorldwideDocument3 pagesRo-Buh-Qpl: Express WorldwideverschelderNo ratings yet

- Internal Audit ChecklistDocument18 pagesInternal Audit ChecklistAkhilesh Kumar75% (4)

- Plate-Load TestDocument20 pagesPlate-Load TestSalman LakhoNo ratings yet

- Chemistry of FormazanDocument36 pagesChemistry of FormazanEsteban ArayaNo ratings yet

- Tds G. Beslux Komplex Alfa II (25.10.19)Document3 pagesTds G. Beslux Komplex Alfa II (25.10.19)Iulian BarbuNo ratings yet

- Sayre Materia Medica-3Document87 pagesSayre Materia Medica-3ven_bams5840No ratings yet

- A Study On Customer Satisfaction Towards Honda Bikes in CoimbatoreDocument43 pagesA Study On Customer Satisfaction Towards Honda Bikes in Coimbatorenkputhoor62% (13)

- BCP-8000 User's ManualDocument36 pagesBCP-8000 User's ManualAsad PatelNo ratings yet

- NDE Procedure - Radiographic TestingDocument43 pagesNDE Procedure - Radiographic TestingJeganeswaranNo ratings yet

- SRS Design Guidelines PDFDocument46 pagesSRS Design Guidelines PDFLia FernandaNo ratings yet

- FST Handbook 2014-Final Copy 1 PDFDocument382 pagesFST Handbook 2014-Final Copy 1 PDFDelvon DownerNo ratings yet

- 1"a Study On Employee Retention in Amara Raja Power Systems LTDDocument81 pages1"a Study On Employee Retention in Amara Raja Power Systems LTDJerome Samuel100% (1)

- 2019 Course CatalogDocument31 pages2019 Course CatalogDeepen SharmaNo ratings yet

- Innovative Food Science and Emerging TechnologiesDocument6 pagesInnovative Food Science and Emerging TechnologiesAnyelo MurilloNo ratings yet

- IEEE T&D Insulators 101 Design CriteriaDocument84 pagesIEEE T&D Insulators 101 Design Criteriasachin HUNo ratings yet

- Fundermax Exterior Technic 2011gb WebDocument88 pagesFundermax Exterior Technic 2011gb WebarchpavlovicNo ratings yet

- Religion in Space Science FictionDocument23 pagesReligion in Space Science FictionjasonbattNo ratings yet

- Space DynamicsDocument37 pagesSpace Dynamicspurushottam KashyapNo ratings yet

- Letter of MotivationDocument4 pagesLetter of Motivationjawad khalidNo ratings yet

- Traffic Violation Monitoring with RFIDDocument59 pagesTraffic Violation Monitoring with RFIDShrëyãs NàtrájNo ratings yet

- Cost Analysis and Financial Projections for Gerbera Cultivation ProjectDocument26 pagesCost Analysis and Financial Projections for Gerbera Cultivation ProjectshroffhardikNo ratings yet

- Chapter 16 - Energy Transfers: I) Answer The FollowingDocument3 pagesChapter 16 - Energy Transfers: I) Answer The FollowingPauline Kezia P Gr 6 B1No ratings yet

- Cyclograph User ManualDocument15 pagesCyclograph User ManualPeter BateNo ratings yet

- Antonovsky (1979)Document280 pagesAntonovsky (1979)M.Fakhrul Kurnia100% (1)

- ProtectionDocument160 pagesProtectionSuthep NgamlertleeNo ratings yet