Professional Documents

Culture Documents

Crosby Eye Bolt G 291

Uploaded by

pandiangvOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crosby Eye Bolt G 291

Uploaded by

pandiangvCopyright:

Available Formats

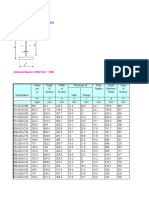

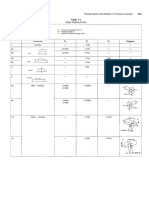

Forged Eye Bolts

SEE APPLICATION AND

WARNING INFORMATION

Para Espaol: www.thecrosbygroup.com On Page 180-181

G-291

Forged Steel - Quenched and Tempered.

Fatigue rated at 1-1/2 times the Working Load Limit at 20,000 cycles.

All Bolts Hot Dip galvanized after threading (UNC).

Furnished with standard Hot Dip galvanized hex nuts.

Recommended for in-line pull.

Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design

factor, proof load and temperature requirements. Importantly, these bolts meet other critical

performance requirements including fatigue life, impact properties and material traceability, not

addressed by ASME B30.26.

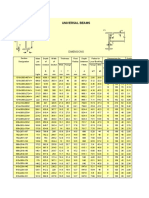

G-291

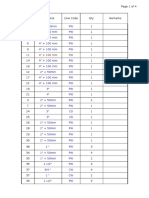

Regular Nut Eye Bolts

Shank Working Dimensions

Dia. & Load Weight (mm)

Length G-291 Limit Per 100

(mm) Stock No. (t)* (kg) A B C D E F G H

6.35 x 51.0 1043230 .29 3.72 6.35 12.7 25.4 6.35 38.1 51.0 77.5 14.2

6.35 x 102 1043258 .29 5.31 6.35 12.7 25.4 6.35 63.5 102 129 14.2

7.94 x 57.0 1043276 .54 6.03 7.85 15.7 31.8 7.85 38.1 57.0 90.5 17.5

7.94 x 108 1043294 .54 11.3 7.85 15.7 31.8 7.85 63.5 108 141 17.5

9.53 x 63.5 1043310 .70 10.6 9.65 19.1 38.1 9.65 38.1 63.5 105 22.4

9.53 x 114 1043338 .70 13.4 9.65 19.1 38.1 9.65 63.5 114 155 22.4

9.53 x 152 1043356 .70 16.0 9.65 19.1 38.1 9.65 63.5 152 194 22.4

12.7 x 82.5 1043374 1.18 22.8 12.7 25.4 51.0 12.7 38.1 82.5 137 28.4

12.7 x 152 1043392 1.18 30.0 12.7 25.4 51.0 12.7 76.0 152 206 28.4

12.7 x 203 1043418 1.18 37 12.7 25.4 51.0 12.7 76.0 203 257 28.4

12.7 x 254 1043436 1.18 40 12.7 25.4 51.0 12.7 76.0 254 308 28.4

12.7 x 305 1043454 1.18 52 12.7 25.4 51.0 12.7 76.0 305 359 28.4

15.9 x 102 1043472 2.35 47 15.7 31.8 63.5 15.7 51.0 102 170 36.6

15.9 x 152 1043490 2.35 54 15.7 31.8 63.5 15.7 76.0 152 221 36.6

15.9 x 203 1043515 2.35 61 15.7 31.8 63.5 15.7 76.0 203 272 36.6

15.9 x 254 1043533 2.35 70 15.7 31.8 63.5 15.7 76.0 254 322 36.6

15.9 x 305 1043551 2.35 76 15.7 31.8 63.5 15.7 102 305 373 36.6

19.1 x 114 1043579 3.26 76 19.1 38.1 76.0 19.1 51.0 114 195 42.9

19.1 x 152 1043597 3.26 84 19.1 38.1 76.0 19.1 76.0 152 233 42.9

19.1 x 203 1043613 3.26 94 19.1 38.1 76.0 19.1 76.0 203 284 42.9

19.1 x 254 1043631 3.26 107 19.1 38.1 76.0 19.1 76.0 254 335 42.9

19.1 x 305 1043659 3.26 117 19.1 38.1 76.0 19.1 102 305 386 42.9

19.1 x 381 1043677 3.26 135 19.1 38.1 76.0 19.1 127 381 462 42.9

22.2 x 127 1043695 4.80 122 22.4 44.5 89.0 22.4 63.5 127 222 51.0

22.2 x 203 1043711 4.80 140 22.4 44.5 89.0 22.4 102 203 298 51.0

22.2 x 305 1043739 4.80 181 22.4 44.5 89.0 22.4 102 305 400 51.0

25.4 x 152 1043757 6.03 191 25.4 51.0 102 25.4 76.0 152 262 58.5

25.4 x 229 1043775 6.03 213 25.4 51.0 102 25.4 102 229 338 58.5

25.4 x 305 1043793 6.03 245 25.4 51.0 102 25.4 102 305 414 58.5

25.4 x 457 1043819 6.03 295 25.4 51.0 102 25.4 178 457 567 58.5

31.8 x 203 1043837 9.52 340 31.8 63.5 127 31.8 102 203 340 73.0

31.8 x 305 1043855 9.52 408 31.8 63.5 127 31.8 102 305 441 73.0

31.8 x 508 1043873 9.52 549 31.8 63.5 127 31.8 152 508 645 73.0

*Ultimate Load is 5 times the Working Load Limit. Working Load Limit shown is for in-line pull.

Maximum Proof Load is 2 times the Working Load Limit.

150 Copyright 2011 The Crosby Group LLC

All Rights Reserved

You might also like

- Eye Bolt DetailDocument1 pageEye Bolt Detailshalinimanjunath2020No ratings yet

- Jaw & Jaw TurnbucklesDocument1 pageJaw & Jaw TurnbucklesSavin TimofteNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyGustavo ArancibiaNo ratings yet

- UK Tee SectionDocument3 pagesUK Tee SectionViskar SupportNo ratings yet

- Weights NewDocument16 pagesWeights NewQuintusNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- UNIVERSAL BEAM DIMENSIONSDocument241 pagesUNIVERSAL BEAM DIMENSIONSeng_muhammad88No ratings yet

- BS 6 For Reference PDFDocument32 pagesBS 6 For Reference PDFSoe SoeNo ratings yet

- Universal Beam Section PropertiesDocument4 pagesUniversal Beam Section Propertiesloft diamondNo ratings yet

- Universal Columns (UC), Section Properties Dimensions & PropertiesDocument8 pagesUniversal Columns (UC), Section Properties Dimensions & PropertiesSuresh Babu100% (1)

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)rezetane mohamed amineNo ratings yet

- Hot Roled SectionsDocument58 pagesHot Roled Sectionsmohamed AlasadyNo ratings yet

- UKC PropertiesDocument2 pagesUKC PropertiesytbanNo ratings yet

- Lamp Flag Fence Post DesignDocument16 pagesLamp Flag Fence Post DesignJupiter AbianNo ratings yet

- Uk Sections Datasheets 100723Document20 pagesUk Sections Datasheets 100723pkdscdubaiNo ratings yet

- Sectional Properties of SteelDocument72 pagesSectional Properties of Steeladera1No ratings yet

- British and European SectionsDocument89 pagesBritish and European SectionsgenergiaNo ratings yet

- Tooth Gear SEW Linha KDocument7 pagesTooth Gear SEW Linha KSolver Manutenção IndustrialNo ratings yet

- Steel Section Table ConciseDocument36 pagesSteel Section Table ConciseVance KangNo ratings yet

- Universal Beams Advance UKB: DimensionsDocument10 pagesUniversal Beams Advance UKB: DimensionszulaikhaNo ratings yet

- Z-Section Dimensions & Properties - MetsecDocument3 pagesZ-Section Dimensions & Properties - Metsecadil_khan648No ratings yet

- Tees (T) Split From UC, Section Properties Dimensions & PropertiesDocument14 pagesTees (T) Split From UC, Section Properties Dimensions & PropertiesSuresh BabuNo ratings yet

- P201: Handbook of Structural Steelwork 3rd Edition: Universal BeamsDocument44 pagesP201: Handbook of Structural Steelwork 3rd Edition: Universal Beamsmbhanusagar.keynesNo ratings yet

- Tata Steel Section Ciold and Hot Section PDFDocument96 pagesTata Steel Section Ciold and Hot Section PDFSyedNo ratings yet

- Jaw & Eye Turnbuckles: All Rights Reserved 188Document1 pageJaw & Eye Turnbuckles: All Rights Reserved 188agustinNo ratings yet

- Equal Leg Angles EN 10056-1 - 1998Document1 pageEqual Leg Angles EN 10056-1 - 1998Axiv The GreatNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsHusam AhmedNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFAnonymous omQzt3KgzwNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFNicolae FloreaNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFneutron_87No ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSteven KuaNo ratings yet

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)D.M.Ravindra DhanapalaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsvysakh51No ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsMuhammad Wazim AkramNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsKingston RivingtonNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSérgio BernardesNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFLavanyan SatchithananthanNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetPratyadip DuttaNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFFrederick BruceNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsAdnan NajemNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsInfinity GHNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsYaziq NabilNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFSyed Shoaib RazaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsSyamil DzulfidaNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetMarzuqi A. HalimNo ratings yet

- Steel Universal Beams Ub Datasheet PDFDocument6 pagesSteel Universal Beams Ub Datasheet PDFSend MailNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFcruz enrique rodrguez lunaNo ratings yet

- British Steel Sections Datasheets PDFDocument18 pagesBritish Steel Sections Datasheets PDFSherin ShajiNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub Datasheetzulkhairi lopNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetsarathNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsRahesh MNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub Datasheetsiva kumar rambalaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionFrom EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- As Me Certificate Holder ReportDocument5 pagesAs Me Certificate Holder ReportpandiangvNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 06 Eurocodes Steel Workshop WALDDocument6 pages06 Eurocodes Steel Workshop WALDpandiangvNo ratings yet

- CharttorqueswgDocument2 pagesCharttorqueswgYutana RuxnakNo ratings yet

- Peppers Catalogue Approved AccessoriesDocument16 pagesPeppers Catalogue Approved AccessoriespandiangvNo ratings yet

- Force and Moment Sketches ModelDocument1 pageForce and Moment Sketches ModelpandiangvNo ratings yet

- Washer ThicknessDocument2 pagesWasher ThicknesspandiangvNo ratings yet

- Ship Motion LoadDocument4 pagesShip Motion LoadpandiangvNo ratings yet

- Xylan Offshore FlierDocument2 pagesXylan Offshore FlierpandiangvNo ratings yet

- 999 Industrial Guide 2010Document42 pages999 Industrial Guide 2010kasosei100% (1)

- Peppers Catalogue Approved AccessoriesDocument16 pagesPeppers Catalogue Approved AccessoriespandiangvNo ratings yet

- Studding Outlets Dimensions & SpecificationsDocument2 pagesStudding Outlets Dimensions & SpecificationspandiangvNo ratings yet

- S2 - Jaw and Jaw-136Document1 pageS2 - Jaw and Jaw-136pandiangvNo ratings yet

- UBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffDocument4 pagesUBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffpandiangvNo ratings yet

- Nut DetailsDocument1 pageNut DetailspandiangvNo ratings yet

- Project Execution PlanDocument1 pageProject Execution PlanpandiangvNo ratings yet

- Wind Load Calculation ReportDocument2 pagesWind Load Calculation ReportpandiangvNo ratings yet

- Design Base Plate ThicknessDocument6 pagesDesign Base Plate ThicknesspandiangvNo ratings yet

- Load-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigDocument12 pagesLoad-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigpandiangvNo ratings yet

- Buoyancy: M. Bahrami Fluid Mechanics (S 09) Fluid Statics 9Document5 pagesBuoyancy: M. Bahrami Fluid Mechanics (S 09) Fluid Statics 9RonoNo ratings yet

- F1554 Grade 105 - F1554 Anchor BoltsDocument2 pagesF1554 Grade 105 - F1554 Anchor BoltspandiangvNo ratings yet

- A Lok Tube FittingsDocument88 pagesA Lok Tube FittingsCesarNo ratings yet

- Design and Development PlanningDocument6 pagesDesign and Development PlanningpandiangvNo ratings yet

- TMCP Steels For Offshore StructuresDocument3 pagesTMCP Steels For Offshore StructurespandiangvNo ratings yet

- Guidance Notes RevisionDocument8 pagesGuidance Notes RevisionpandiangvNo ratings yet

- FAC1 Z 833001 - Rev 5Document1 pageFAC1 Z 833001 - Rev 5pandiangv100% (1)

- Pub57 - CDS - Guide (2006 W-2010 Update)Document78 pagesPub57 - CDS - Guide (2006 W-2010 Update)Russ FordNo ratings yet

- WRC Input InstructionDocument2 pagesWRC Input InstructionpandiangvNo ratings yet

- N1192-ST - Colour CoadingDocument4 pagesN1192-ST - Colour CoadingpandiangvNo ratings yet

- Data Sheet ExxonMobil HDPE HD 9856BDocument2 pagesData Sheet ExxonMobil HDPE HD 9856BMayrarelCadpeNo ratings yet

- SHAW 101.2 EPD EcoWorxCommercialCarpetTile 29november2012Document14 pagesSHAW 101.2 EPD EcoWorxCommercialCarpetTile 29november2012ignaciovillanuevaNo ratings yet

- EOQ Inventory Model ExplainedDocument44 pagesEOQ Inventory Model ExplainedDileep SinghNo ratings yet

- Romac 611 Pipe Restraining System GuideDocument2 pagesRomac 611 Pipe Restraining System GuideQubit SizedNo ratings yet

- Operations Management Chapter 1 MCQsDocument53 pagesOperations Management Chapter 1 MCQsshoebIAS33% (3)

- F79 Environmental Quality (Scheduled Wastes)Document6 pagesF79 Environmental Quality (Scheduled Wastes)Bala Equal BalanceNo ratings yet

- Cost Control & Cost ReductionDocument12 pagesCost Control & Cost ReductionTasmeer Un Nazir100% (1)

- Asphalt SegregationDocument4 pagesAsphalt SegregationHaris MahinicNo ratings yet

- Pickling and Passivating of Stainless SteelDocument4 pagesPickling and Passivating of Stainless SteelSds Mani SNo ratings yet

- Water Cement RatioDocument6 pagesWater Cement RatioPrashant PradhanNo ratings yet

- Walworth Safety Steel Catalog2012 1Document76 pagesWalworth Safety Steel Catalog2012 1rasko65No ratings yet

- 4-Case Study-Procter - and - Gamble and WallmartDocument7 pages4-Case Study-Procter - and - Gamble and WallmartHimanshu Dhawan0% (1)

- Poster Corrosion Well Logging 9Document1 pagePoster Corrosion Well Logging 9Moh Abd Ben100% (1)

- Reguler - Kelompok 1 SoalDocument4 pagesReguler - Kelompok 1 SoalKezia BatubaraNo ratings yet

- 2008 Municipal Ordinance 07Document50 pages2008 Municipal Ordinance 07Ernan Baldomero100% (1)

- Config Docs BPDDocument21 pagesConfig Docs BPDJitendra D DhandeNo ratings yet

- Guide To General Tolerance - ISO 2768 1&2 StandardDocument6 pagesGuide To General Tolerance - ISO 2768 1&2 StandardQuality controller100% (1)

- 1.airhose g261 Green LineDocument22 pages1.airhose g261 Green LineMichael ThomasNo ratings yet

- Introduction To Plant LayoutDocument31 pagesIntroduction To Plant LayoutSavantNo ratings yet

- Use of Plastic Waste in Road ConstructionDocument29 pagesUse of Plastic Waste in Road ConstructionJayan Vijayan100% (1)

- 01-50-911 en Soldadura MIG y TIGDocument24 pages01-50-911 en Soldadura MIG y TIGjuliae194No ratings yet

- Cost of QualityDocument128 pagesCost of QualityNdomaduNo ratings yet

- Masterfill™ 300: Semi - Flexible Epoxy Joint SealantDocument2 pagesMasterfill™ 300: Semi - Flexible Epoxy Joint SealantDoby YuniardiNo ratings yet

- Nature and Scope of Operations ManagementDocument2 pagesNature and Scope of Operations ManagementSathya GaneshNo ratings yet

- OPM National Bicycle Company D1 Section 1Document19 pagesOPM National Bicycle Company D1 Section 1Tony JosephNo ratings yet

- The 16 Losses PDFDocument3 pagesThe 16 Losses PDFsenzo scholarNo ratings yet

- TruDocument3 pagesTruLeiNo ratings yet

- Nandan Petrochem LTD - Company ProfileDocument12 pagesNandan Petrochem LTD - Company ProfileNandan Petrochem LtdNo ratings yet

- CleanersDocument8 pagesCleanersblackhawkNo ratings yet

- Expansion of Water Treatment PlantDocument20 pagesExpansion of Water Treatment PlantRohail AfzalNo ratings yet