Professional Documents

Culture Documents

A216

Uploaded by

Fariz Andriawan0 ratings0% found this document useful (0 votes)

19 views3 pagesa216

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenta216

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views3 pagesA216

Uploaded by

Fariz Andriawana216

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

STD-ASTM ABLB/A2DOM-ENGL 2993 MM 0759510 Ob20534 S00 mm

afl) Designation:

216/A216M — 93 (Reapproved 1998)

ro Henares Sadatoatin Soy

“ae ie ge Say

nae yen Famers Say,

Standard Specification for

Stee! Castings, Carbon, Suitable for Fusion Welding, for

High-Temperature Service’

Thc stnde se unr he aed ion A21A2I6M, he bes ime lowing te epaton ites yar

"rig ato nthe ce frei. th er flat rvs A momber in prs ines the year st ea

‘Nsarerstinteplon

cars a eal chute ss te las revo eyo

is onde Bw pe for by genie of he Daren of fen

1. Scope

LLL This specification? covers carbon steel castings for

valves, flanges, fitings, or other pressure-containing parts for

high-temperature service and of quality suitable for assembly

with other castings or wrought-steel parts by fusion welding,

1.2 Three grades, WCA, WCB, and WCC, are covered in

this specification. Selection will’ depend upon design and

service conditions, mechanical properties, and the high tem-

perature characteristics

113 The values stated in cither inch-pound units oF ST nits

tre to be regarded separately as standand. Within the text, the

SH units are shown in brackets. The values stated in each

system are not exact equivalents; therefore, each system must

be used independently of the other. Combining values from the

Loww systems iiay result i) nonconformance with the specif

cation,

2, Keferenced Documents

2.1 ASTM Standards:

AABWAABEM Practice for Steel Castings, Welding, Quali-

fications of Pracedures and Personnel?

ATOMAT0IM Specification for Steel Cestings, General

Requirements, for Pressure-Containing Pans

E 165 Test Method for Liquid Penetrant Examination*

1.709 Guide for Magnetic Particle Examination

22 Manufacturers’ Standardizaion Society of the Valve

and Fangs Industry Standard:

'SP 55 Sieel Castings for Valve, Flanges, and Fittings, and

Other Components (Visual Method)*

"This pct i uo he jarisition of ASTM Commies Ao te,

‘Gare eon aggoved De. 15, 195. Plas Apo 16 Onin

"rar ASME Boe noe Yee Coe op

can SAcHGSA-2160 9 Seen If tht oak

Shaman of ASTM Stan, Yo I

* aalabe from Manat Seodadition Sosey of he Valve and

Copyright by the American Sociely For Testing & Materials

‘ue Now 02 09°3721 1998

‘3. General Conditions for Delivery

3.1, Material furnished to this specification shall conform to

‘the requirements of Specification A'703/A 703M, including

ny supplementary requirements that ate indicated in the

purchase order. Failure to comply with the general equice-

‘ments of Specification A 703/A 703M constitutes nonconfor-

rane with this specification, In case of confict between the

requirements of this specification and Specification A 703/

A 703M, this specification shall prevail

4. Ordering Information

4.1 The inguiry and order should include or indicate the

following

41.1 A. description of the casting by pattem number or

raving, (dimensional tolerances shall be included on the

casting drawing),

4.1.2 Grade of steel,

4.13 Options in the specification, and

4.1.4 The supplementary requirements desired including the

standards of acceptance

5, Heat Treatment

5.1 Allcastings shall receive a eat treatment proper to their

design end chemical composition

$5.2 Castinge shall be furnished in the annealed, or normal-

ied, oF normalized and tempered condition unless Supplemen-

tary Requirement $15 is specified

3.3 Heat trement shall be performed after castings have

been allowed to cool below the transformation rang.

6, Temperature Controt

6.1 Furnace temperatures for heat treating shall be effec:

tively controlled by pyrometer

7. Chemical Composition

7.1 The steel shall conform to the requirements as to

chemical composition prescribed in Table I

STD-ASTM AZDE/AZLEM-ENGL 1993 MMH 0759530 0620535 747 mm

4) A 216/a216m

TABLE 1 Chomioal Requirements

TABLE 2 Tensile Requirements

erent conposton.

Gam uw Gace

wea woe Woo

Gare, max oa" 000" 025°

ancuneo, may fie No 0°

Prosser! max oo = bet

Shicor. max 080, 80 000

Stone nial elorent

‘Corps es om am om

Net max osm = ass

‘oma as bs astm

Neyesoran mex x aaa

‘nuiom, ma nr eT)

‘eres o 00% 7 raares above th pete mairun Wa be emi

‘rorcach oaution f 201% bw be apsiiad maximum aon contr |

ireos e 008% Un above the specie’ man il bo pemied

rea oun 201% bow he spsied astrum earn content 0

rere of D8 rraganessceeve ta spected maxi lb permed ©

Siranmom of 1.0

8, Tensile Requirements

8.1 Stee! used for the castings shall conform tothe require

‘ments as to tensile properties prescribed in Table 2

9. Quality

9.1 The surfare of the casting shall he examined vieually

and shall be free of adhering sand, scale, cracks, and hot tars.

Other surface discontinuities shall meet the visual acceptance

standards specified in the order. Visual Method SP-93 of other

visual standards may be used to define acceptable surface

discontent and finish Unacceptable visual surface discon-

tinuities shall be removes! and their removal verified by visual

‘examination of the resultant cavities,

9.2 When additional inspection 1 desired, Supplementary

Requirements $4, $5, and S10 may be ordered

9.3 The castings shall nat be peened. plugged, o¢ imperg-

nated t0 stop leaks

Gee rade

Dea tosas) jas ess)

‘elt stanh mn, wien) 38 BO)

‘engon 2 a 2 2

[EO min?

“Durine by whe 02% ofon atod or GSW etansor aerial

hon Cl at bar ar edn onze tag a proved fn Spier

ATOR TOR, he gag lng 1 voducedcoan dare 0 dst 804107

10, Repair by Welding

10.1 Repairs shall be made using procedures and welders

qualified under Practice 4 488/A 488M.

10.2 Weld repairs shall be inspected to the same quality

standards that are used to inspect the castings. When castings

ate produced sith Supplementary Requirement $$ speciied,

weld repairs shall be inspected by magnetic particle examina-

tion tothe same standards that are used to inspect the casings.

‘When castings are produced with Supplementary Requirement

'S5 specified, weld repairs on castings that have leaked on

hydrostatic tes, or on castings in which the depth of any cavity

prepared for repair welding exceeds 20 % ofthe wall thickness

or Lin, [25 mm, whichever is smaller, oF on castings in which

any cavity prepared for welding is greater than approximately

10 in7165 cm’), shall be radiographed to the same standards

hat ate used wo aspoet the castings

103 Castings containing any repair weld that exceeds 20 %

of the wall thickness or I in, [25 mm], whichever is smaller. or

that exceeds approximately 10 in [65 em] i area, or that was

made to correct hydrostatic test defects, shall be stress relieved

or heat-treated after welding, This mandatory sess rellet of

heat-treatment shall be in accordance with the procedure

‘qualification used

LL, Keywords

111 carbon steel; high temperature; pressure containing.

pat; steel castings

SUPPLEMENTARY REQUIREMENTS.

The following supplementary requirements shall not apply unless specified in the purchase order. A

list of standardized supplementary requirements for use atthe option of the purchaser is included in

Specification A703/A 703M. Those which are ordinarily considered suitable for use with this

specification are given below. Others enumerated in A703/A 703M may be used with this

specification upon sgreement berween the manufecturer and purchaser.

Copyright by the American Sociely For Testing & Materials

‘ue Now 02 09.3741 1989

STD-ASTM AZLb/AZUEM-ENGL 1993 MMM 0759520 Ob2053b ba3 mm

ha rtevaaten

SL. Unspecified Flements,

$2 pestrction Tests tn Cadi m

wes

on

$3. Bend Test so Cuton equiva (CR) shall beeen se

SA. Magnet Parte Inspection tla

5. Radiographic Inspection cen coMe Set MOsY,, MAY

10, Examination of Weld Preparation

10.1 The mod of performing the mignedic particle or oe 7

Jiquid penetrant test shall be in accordance with Practice E 709 S18, Quench and Temper Beat

co Practice E165

SUL. Carbon Equivalent

Sit When specified on the onder, the maximum carbon

suivant shall be

‘The Ameran Seif Teng and Matis aks ro poston respecting te val of any pats ht assed commen

sn any ham mondo fs std Users i sand re exprsay ied Patera Oe aN of ay

(eth dte vek st eigen ccnp, ae ena ee oh rape

‘Te sandr sic evan at any tine By he reaponsie echnical camenienad rune eed wey re yar and

totes star tnporoved owen, Your Gone riage ron ots ina ro aoa Seas

fr shaul be aatesod fo ASTM Meadqurios.Yur caramnts il receiv carat coneteran at meng of he reeponstie

‘Eira stn, who nay san ya el te create Rca iy os a et

Copyright by the American Sociely For Testing & Materials

‘ue Now (2 09-3742 1999

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Pppurg 1987Document39 pagesPppurg 1987Andreas Galih Pamungkas100% (5)

- NF en Iso 6506-1Document24 pagesNF en Iso 6506-1cris5001100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Kekuatan ScafDocument9 pagesKekuatan ScafFariz AndriawanNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- ASTM A194 - CS Bolting PDFDocument11 pagesASTM A194 - CS Bolting PDFFariz Andriawan100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 02 IntroDocument11 pages02 IntroTitis W. PratiwiNo ratings yet

- 03 Peta Hazard Surabaya PDFDocument18 pages03 Peta Hazard Surabaya PDFFariz AndriawanNo ratings yet

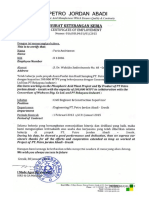

- SKKDocument1 pageSKKFariz AndriawanNo ratings yet

- Scaffolding Training PresentationDocument49 pagesScaffolding Training PresentationFariz Andriawan0% (1)

- Sni 03-1755-1990Document3 pagesSni 03-1755-1990Fariz AndriawanNo ratings yet

- Kekuatan Scaf PDFDocument9 pagesKekuatan Scaf PDFFariz AndriawanNo ratings yet

- Info THR 2017 PDFDocument1 pageInfo THR 2017 PDFFariz AndriawanNo ratings yet

- SNI 03-xxxx-2000 (Kayu) PDFDocument117 pagesSNI 03-xxxx-2000 (Kayu) PDFVergiane RailashaNo ratings yet

- BULANDocument1 pageBULANFariz AndriawanNo ratings yet

- Perpres Nomor 172 Tahun 2014Document12 pagesPerpres Nomor 172 Tahun 2014ayahbaiNo ratings yet

- KPP Peserta Tes Its 15 Maret 2012 Sesi2Document2 pagesKPP Peserta Tes Its 15 Maret 2012 Sesi2Fariz AndriawanNo ratings yet

- Book 1Document1 pageBook 1Fariz AndriawanNo ratings yet

- Surabaya engineer applies for marketing roleDocument3 pagesSurabaya engineer applies for marketing roleFariz AndriawanNo ratings yet