Professional Documents

Culture Documents

Iveco Nef n45 n67 G Drive Eu 2002 88 Ce Service Manual Workshop Manual Free

Uploaded by

Anonymous V9fdC6Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iveco Nef n45 n67 G Drive Eu 2002 88 Ce Service Manual Workshop Manual Free

Uploaded by

Anonymous V9fdC6Copyright:

Available Formats

NEF SERIES

G-DRIVE application

N45 NEF45 AM1, NEF45 TM2

NEF45 SM1- NEF45 SM2 - NEF45 TM1

N67 NEF67 TE2 - NEF67 TM2 - NEF67 TM3

NEF67 SM1 (not emissioned)

G-Drive EU/2002/88/CE N SERIES SECTION 1 - GENERAL SPECIFICATIONS 3

CORRESPONDENCE BETWEEN TECHNICAL CODE AND COMMERCIAL CODE

Technical Code Commercial Code

F4GE0405A*F650 NEF45 AM1A

F4GE04055C*F650 NEF45 SM1A

F4GE04055A*F650 NEF45 SM2A

F4GE0485A*F650 NEF45 TM2A

F4GE0485C*F650 NEF45 TM1A

F4GE0685B*B600 NEF67 SM1

F4GE0685D*F650 NEF67 TM2A

F4GE0685B*F650 NEF67 TM3A

Print P4D32N002 E Base - November 2008

Revi - May 2011

G-Drive EU/2002/88/CE N SERIES SECTION 1 - GENERAL SPECIFICATIONS 3

CORRESPONDENCE BETWEEN TECHNICAL CODE AND COMMERCIAL CODE

Technical Code Commercial Code

F4HE0685A*F100 NEF67 TE2A

Print P4D32N002 E Base - November 2008

Revi - May 2011

N SERIES

EU/2002/88/CE

G-DRIVE application

N45

NEF45 AM1

NEF45 SM1- NEF45 SM2 - NEF45 TM1

NEF45 TM2

N67

NEF67 TE2 - NEF67 TM2 - NEF67 TM3

NEF67 SM1 (not emissioned)

Technical and Repair manual

G-Drive EU/2002/88/CE N SERIES 1

N SERIES G-Drive EU/2002/88/CE

F4GE N Series Part 1

F4HE N Series Part 2

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES 1

Part 1

F4GE N SERIES

Section

General specifications 1

Fuel 2

G-DRIVE applications 3

Overhaul and technical specifications 4

Tools 5

Safety prescriptions Appendix

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES SECTION 1 - GENERAL SPECIFICATIONS 1

SECTION 1

General Specifications

Page

CORRESPONDENCE BETWEEN TECHNICAL CODE

AND COMMERCIAL CODE . . . . . . . . . . . . . . . 3

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OIL VAPOUR RECIRCULATING SYSTEM . . . . . . . 7

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 8

- Version with turbocharger (4 cylinders) . . . . . . 8

- Version with turbocharger (6 cylinders) . . . . . . 9

- Version without turbocharger . . . . . . . . . . . . . 10

AIR INDUCTION BOOST DIAGRAM . . . . . . . . . . 11

- Boosting version engines . . . . . . . . . . . . . . . . . 11

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

- Inter-cooled engine version . . . . . . . . . . . . . . . 12

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES SECTION 2 - FUEL 1

SECTION 2

Fuel

Page

FUEL-INJECTION SYSTEM WITH STANADYNE

DB4 ROTARY PUMP . . . . . . . . . . . . . . . . . . . 3

- General information . . . . . . . . . . . . . . . . . . . . 3

- Description of working principles . . . . . . . . . . . 3

FEED PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

- Description of operation . . . . . . . . . . . . . . . . . 4

PRIMING PUMP . . . . . . . . . . . . . . . . . . . . . . . . . 5

FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES SECTION 3 - G-DRIVE APPLICATION 1

SECTION 3

G-DRIVE Application

Page

GENERAL INFORMATION . . . . . . . . . . . . . . . . 3

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . 4

- 4-cylinder engines . . . . . . . . . . . . . . . . . . . . . . 4

- 4-cylinder engines . . . . . . . . . . . . . . . . . . . . . . 6

PART ONE -

MECHANICAL COMPONENTS . . . . . . . . . 9

ENGINE OVERHAUL . . . . . . . . . . . . . . . . . . . . . 11

- Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

- Removing engine from radiator . . . . . . . . . . . . 11

- Engine setting operations for the assembly on

turning stand . . . . . . . . . . . . . . . . . . . . . . . . . . 16

- Disassembly of application components . . . . . 17

- STANADYNE D Series Pump . . . . . . . . . . 18

- Installation of rear components . . . . . . . . . . . . 26

- Flywheel installation . . . . . . . . . . . . . . . . . . . . . 29

- Installation of front components . . . . . . . . . . . 30

- Completion of engine re-assembly . . . . . . . . . 42

- Refitting engine to radiator . . . . . . . . . . . . . . . 43

- Rotary feed pump disassembly and assembly

procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

- Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

- Rotary feed pump setting check . . . . . . . . . . . 50

- Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ASSEMBLY PROCEDURE OF THE ADC100

ELECTRONIC ACTIVATOR ON STANADYNE

SERIES D INJECTION PUMPS . . . . . . . . . . 52

- Assembly of the actuator . . . . . . . . . . . . . . . . 53

PASSAGE FROM 50 HZ TO 60 HZ FOR NEF

MOTORS WITH STANADYNE PUMP . . . . . 54

- Passage from 50 Hz to 60 Hz . . . . . . . . . . . . . 54

Print P4D32N002 E Base - November 2008

2 SECTION 3 - G-DRIVE APPLICATION G-Drive EU/2002/88/CE N SERIES

Page Page

- Passage from 60 Hz to 50 Hz . . . . . . . . . . . . . 56 - Cooling liquid temperature sensor

(if present) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

- Stabilization of the rotation regime . . . . . . . . . 56

- Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

- Identification tag . . . . . . . . . . . . . . . . . . . . . . . . 56

- KSB Water temperature sensor . . . . . . . . . . . . 68

REPLACEMENT OF THE ELECTRO-VALVE AND - Oil pressure sensor . . . . . . . . . . . . . . . . . . . . . 69

THE SOLENOID VALVE THROTTLE ON

STANADYNE PUMPS . . . . . . . . . . . . . . . . . . 57

- Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

- Electro-valve replacement . . . . . . . . . . . . . . . . 58

- Pre-post heating resistor (if present) . . . . . . . . 69

- Replacement of the solenoid valve throttle . . . 60

PART THREE - TROUBLESHOOTING . . . . . . 71

- Feed system bleed procedure . . . . . . . . . . . . . 61 PART FOUR -

MAINTENANCE PLANINNG . . . . . . . . . . . 79

- Checks and controls . . . . . . . . . . . . . . . . . . . . 61

MAINTENANCE PLANNING . . . . . . . . . . . . . . 81

PART TWO -

ELECTRICAL EQUIPMENT . . . . . . . . . . . . . . 63 - Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

LOCATION OF ELECTRIC COMPONENTS - Planning of controls and periodical intervention 81

ON ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . 65

- Checks not included in maintenance planning-daily

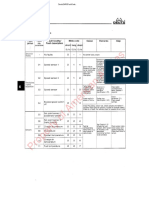

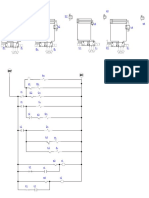

PRINCIPLE WIRING DIAGRAM . . . . . . . . . . . . . 66 checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

- KSB - Stanadyne pump connection cable . . . . 67 MAINTENANCE PROCEDURES . . . . . . . . . . . . 82

- Timer (if present) . . . . . . . . . . . . . . . . . . . . . . . 67 - Checks and controls . . . . . . . . . . . . . . . . . . . . 82

Base - November 2008 Print P4D32N002 E

G-Drive EU/2002/88/CE N SERIES TECHNICAL SPECIFICATIONS 1

SECTION 4

Overhaul and technical specifications

Page

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 3

- F4GE04 Engines . . . . . . . . . . . . . . . . . . . . . . . 3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 4

- F4GE04/F4GE06 Engines . . . . . . . . . . . . . . . . . 4

CLEARANCE DATA . . . . . . . . . . . . . . . . . . . . . 5

- F4GE04 Engines . . . . . . . . . . . . . . . . . . . . . . . 5

CLEARANCE DATA . . . . . . . . . . . . . . . . . . . . . 11

- F4GE04/F4GE06 Engines . . . . . . . . . . . . . . . . . 11

ENGINE OVERHAUL . . . . . . . . . . . . . . . . . . . . . 17

ENGINE REMOVAL AT THE BENCH . . . . . . . . 17

REPAIR OPERATIONS . . . . . . . . . . . . . . . . . . . . 18

CYLINDER UNIT . . . . . . . . . . . . . . . . . . . . . . . . 18

- Checks and measurements . . . . . . . . . . . . . . . 18

- Checking head supporting surface on cylinder

unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TIMING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 20

- Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

- Checking cam lift and pin alignment . . . . . . . . 21

BUSHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

- Bush replacement . . . . . . . . . . . . . . . . . . . . . . 23

- Tappets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

- Fitting tappets camshaft . . . . . . . . . . . . . . . . 23

OUTPUT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . 24

- Measuring journals and crankpins (4 cylinders) 24

- Measuring journals and crankpins (6 cylinders) 26

- Replacing oil pump control gear . . . . . . . . . . . 28

- Fitting main bearings . . . . . . . . . . . . . . . . . . . . 28

Print P4D32N002 E Base - November 2008

2 SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS G-Drive EU/2002/88/CE N SERIES

Page Page

- Finding journal clearance . . . . . . . . . . . . . . . . . 28 CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . 36

- Checking output shaft shoulder clearance . . . . 29 - Removing the valves . . . . . . . . . . . . . . . . . . . . 36

CONNECTING ROD PISTON ASSEMBLY . . 29 - Checking cylinder head wet seal . . . . . . . . . . . 37

- Piston pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 - Checking cylinder head supporting surface . . . 37

VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

- Conditions for proper pin-piston coupling . . . . 31

- Removing carbon deposits, checking and grinding

- Split rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

- Connecting rods . . . . . . . . . . . . . . . . . . . . . . . 32 - Checking clearance between valve stem and valve

guide and valve centering . . . . . . . . . . . . . . . . . 38

- Bushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

VALVE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . 39

- Fitting connecting rod-piston assembly . . . . . . 33

VALVE SEATS . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

- Connecting rod-piston coupling . . . . . . . . . . . . 33

- Regrinding replacing the valve seats . . . . . . . 39

- Fitting split rings . . . . . . . . . . . . . . . . . . . . . . . . 33

VALVE SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . 40

- Fitting connecting rod-piston assembly into cylinder

barrels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 FITTING CYLINDER HEAD . . . . . . . . . . . . . . . . 40

- Finding crankpin clearance . . . . . . . . . . . . . . . . 34 - Refitting the cylinder head . . . . . . . . . . . . . . . . 41

- Checking piston protrusion . . . . . . . . . . . . . . . 35 TIGHTENING TORQUE (FOR 4 AND 6 CYL.) 42

Base - Print P4D32N002 E

G-Drive EU/2002/88/CE N SERIES SECTION 5 - TOOLS 1

SECTION 5

Tools

Page

TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES APPENDIX 1

Appendix

Page

SAFETY PRESCRIPTIONS . . . . . . . . . . . . . . . . . 3

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES

Part 2

F4HE N SERIES

Section

General specifications 1

Fuel 2

G-DRIVE applications 3

Overhaul and technical specifications 4

Tools 5

Safety prescriptions Appendix

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES SECTION 1 - GENERAL SPECIFICATIONS 1

SECTION 1

General Specifications

Page

CORRESPONDENCE BETWEEN TECHNICAL CODE

AND COMMERCIAL CODE . . . . . . . . . . . . . 3

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OIL VAPOUR RECYCLING . . . . . . . . . . . . . . . . 5

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . 6

AIR INDUCTION - BOOST DIAGRAM . . . . . . . 7

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Print P4D32N002 E ase - November 2008

G-Drive EU/2002/88/CE N SERIES SECTION 2 - FUEL 1

SECTION 2

Fuel

Page

COMMON RAIL . . . . . . . . . . . . . . . . . . . . . . . . . 3

- General Specifications . . . . . . . . . . . . . . . . . . . 3

- System description . . . . . . . . . . . . . . . . . . . . . . 3

- Electric system . . . . . . . . . . . . . . . . . . . . . . . . . 3

WORKING PROCESS . . . . . . . . . . . . . . . . . . . . 5

FUEL SYSTEM LAYOUT . . . . . . . . . . . . . . . . . . . 6

MECHANICAL FEEDING PUMP . . . . . . . . . . . . 8

- Ordinary working condition . . . . . . . . . . . . . . . 8

- Overpressure condition in Exhaust unit . . . . . . 8

- Jettison condition . . . . . . . . . . . . . . . . . . . . . . . 8

CP3 HIGH PRESSURE PUMP . . . . . . . . . . . . . . . 9

- High pressure pump-inside structure . . . . . . . . 10

- Working principle . . . . . . . . . . . . . . . . . . . . . . 11

- Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

RAIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

RELIEF VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ELECTRO-INJECTOR . . . . . . . . . . . . . . . . . . . . . 14

- Injector in rest position . . . . . . . . . . . . . . . . . . 14

- Injection start . . . . . . . . . . . . . . . . . . . . . . . . . . 14

- Injection end . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES SECTION 3 - G-DRIVE APPLICATION 1

SECTION 3

G-DRIVE application

Page

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . 3

- Clearance data - 6 cyl. . . . . . . . . . . . . . . . . . . . 4

PART ONE -

MECHANICAL COMPONENTS . . . . . . . . . 5

ENGINE OVERHAUL . . . . . . . . . . . . . . . . . . . . . 7

- Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- Removing engine from radiator . . . . . . . . . . . . 7

- Engine setting operations for the assembly on

turning stand . . . . . . . . . . . . . . . . . . . . . . . . . . 10

- Disassembly of application components . . . . . 12

- Assembly of application components . . . . . . . 19

- Completion of the engine . . . . . . . . . . . . . . . . 31

- Refitting engine to radiator . . . . . . . . . . . . . . . 32

- Checks and inspections . . . . . . . . . . . . . . . . . . 35

PART TWO -

ELECTRICAL EQUIPMENT . . . . . . . . . . . . . 37

LOCATION OF MAIN ELECTRIC COMPONENTS

ON ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . 39

- EDC7 ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

- Cable on engine . . . . . . . . . . . . . . . . . . . . . . . 41

- Injectors connector (A) . . . . . . . . . . . . . . . . . . 42

- Sensors connector (C) . . . . . . . . . . . . . . . . . . 42

- Crankshaft sensor . . . . . . . . . . . . . . . . . . . . . . 43

- Timing sensor . . . . . . . . . . . . . . . . . . . . . . . . . 43

- Supercharging air pressure - temperature

sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

- Engine oil temperature-pressure sensor . . . . . 44

- Fuel temperature and pressure sensor . . . . . . 45

Print P4D32N002 E Base - November 2008

G-Drive EU/2002/88/CE N SERIES SEC

SECTION 4

Overhaul and technical specifications

Page

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . 3

- F4HE0685 Engine . . . . . . . . . . . . . . . . . . . . . . 3

- F4HE06 Engine . . . . . . . . . . . . . . . . . . . . . . . . 4

6 ENGINE OVERHAUL . . . . . . . . . . . . . . . . . . . 11

ENGINE REMOVAL AT THE BENCH . . . . . . . . 11

REPAIR OPERATIONS . . . . . . . . . . . . . . . . . . . . 12

CYLINDER UNIT . . . . . . . . . . . . . . . . . . . . . . . . 12

- Checks and measurements . . . . . . . . . . . . . . . 12

- Checking head supporting surface on cylinder

unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TIMING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 14

- Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

- Checking cam lift and pin alignment . . . . . . . . 14

BUSHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

- Bush replacement . . . . . . . . . . . . . . . . . . . . . . 15

- Tappets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- Fitting tappets camshaft . . . . . . . . . . . . . . . . 16

OUTPUT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . 17

- Measuring journals and crankpins . . . . . . . . . . 17

- Replacing oil pump control gear . . . . . . . . . . . 19

- Fitting main bearings . . . . . . . . . . . . . . . . . . . . 19

- Finding journal clearance . . . . . . . . . . . . . . . . . 19

- Checking crankshaft shoulder clearance . . . . . 20

CONNECTING ROD PISTON ASSEMBLY . . 20

- Piston pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

- Conditions for proper pin-piston coupling . . . 22

- Connecting rods . . . . . . . . . . . . . . . . . . . . . . . 23

Print P4D32N002 E Base - November 2008

2 SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS G-Drive EU/2002/88/CE N SERIES

Page Page

- Bushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 - Checking cylinder head supporting surface . . . 29

- Fitting connecting rod-piston VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

- Removing carbon deposits, checking and grinding

valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

- Connecting rod-piston coupling . . . . . . . . . . . . 24

- Checking clearance between valve stem and valve

- Fitting split rings . . . . . . . . . . . . . . . . . . . . . . . . 25 guide and valve centering . . . . . . . . . . . . . . . . . 30

- Fitting connecting rod-piston assembly into VALVE SEATS . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

cylinder barrels . . . . . . . . . . . . . . . . . . . . . . . . . 25

VALVE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . 31

- Finding crankpin clearance . . . . . . . . . . . . . . . . 26

- Regrinding replacing the valve seats . . . . . . . 31

- Checking piston protrusion . . . . . . . . . . . . . . . 27

VALVE SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . 33

CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . 28

FITTING CYLINDER HEAD . . . . . . . . . . . . . . . . 33

- Removing the valves . . . . . . . . . . . . . . . . . . . . 28 - Refitting the cylinder head . . . . . . . . . . . . . . . . 34

- Checking cylinder head wet seal . . . . . . . . . . . 29 TIGHTENING TORQUE . . . . . . . . . . . . . . . . . . 35

Base - November 2008 Print P4D32N002 E

G-Drive EU/2002/88/CE N SERIES SECTION 5 - TOOLS 1

SECTION 5

Tools

Page

TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Print P4D32N002 E Base - November 2008

G-Drive EU/20 APPENDIX 1

Appendix

Page

SAFETY PRESCRIPTIONS . . . . . . . . . . . . . . . . . 3

Print P4D32N002 E Base - November 2008

x

You might also like

- Iveco N Series Engine Workshop Service ManualDocument326 pagesIveco N Series Engine Workshop Service ManualFrydex Vgs83% (6)

- Technical Repair Manual N45 N67 ENU 426Document426 pagesTechnical Repair Manual N45 N67 ENU 426Вячелав Егоров100% (1)

- F32 Technical Repair ManualDocument131 pagesF32 Technical Repair ManualAndres Sorin100% (2)

- Iveco Nef45 67 SVC OpmDocument418 pagesIveco Nef45 67 SVC OpmMaqpower Engenharia100% (5)

- Nef N67 Ent M45 450Document212 pagesNef N67 Ent M45 450jvega_534120100% (7)

- Manual Motor 1103 y 1104Document120 pagesManual Motor 1103 y 1104Angel Dlsg100% (2)

- Engine Number Guide: Engines 2 Litre/cylinderDocument6 pagesEngine Number Guide: Engines 2 Litre/cylinderHeri PurnadiNo ratings yet

- NEF ENGINES E Ed 01 - 2005Document788 pagesNEF ENGINES E Ed 01 - 2005Teknik Makina100% (3)

- Iveco NEF TIER 3 SERIES Technical and Repair ManualDocument574 pagesIveco NEF TIER 3 SERIES Technical and Repair ManualAntnhe Bayu83% (6)

- F4ge9454h - AgriculturaDocument136 pagesF4ge9454h - Agriculturajvega_534120100% (2)

- F5ce9454 5454 9484 IndustrialDocument162 pagesF5ce9454 5454 9484 Industrialjvega_534120100% (1)

- NEF Tier 3 Electronic EngineDocument120 pagesNEF Tier 3 Electronic Enginevilla100% (4)

- XAS46 Part ListDocument82 pagesXAS46 Part ListAndi100% (3)

- InstallationDirective N45 MNA M10 N67 MNA M15 P3D64N003E May06Document74 pagesInstallationDirective N45 MNA M10 N67 MNA M15 P3D64N003E May06Avi GoldmanNo ratings yet

- FPT n67 Tm4 Briz Motors Technical Repair ManualDocument147 pagesFPT n67 Tm4 Briz Motors Technical Repair ManualAndres Sorin100% (3)

- 2506A E15TAG3 (TPD1581e2)Document14 pages2506A E15TAG3 (TPD1581e2)Rurouni Martínez100% (1)

- Engine F4CE9484 - F4HE9687 NEF Tier 3 AgricultureDocument6 pagesEngine F4CE9484 - F4HE9687 NEF Tier 3 AgricultureLuis Alberto Castillo Nieto33% (3)

- F4ce de Ge He9684 87 9454Document676 pagesF4ce de Ge He9684 87 9454jvega_534120100% (5)

- @perkins: 1100 Series 1104C-44TAG2Document2 pages@perkins: 1100 Series 1104C-44TAG2ghazipowerNo ratings yet

- 3054E and 3056E Industrial Engines-Engine SafetyDocument12 pages3054E and 3056E Industrial Engines-Engine SafetySantiago Capiato33% (3)

- IVECO 8031I06.05 y 8031I40.05 Especificaciones PDFDocument6 pagesIVECO 8031I06.05 y 8031I40.05 Especificaciones PDFJorge Luis BahamondeAzcarate50% (2)

- Om25413 6076 T, A PDFDocument124 pagesOm25413 6076 T, A PDFJaime F. Baquerizo100% (1)

- Iveco F4ge PDFDocument142 pagesIveco F4ge PDFHandy Lee67% (3)

- Manual de Partes Generador Dca-85usjDocument90 pagesManual de Partes Generador Dca-85usjgina paola de la vega0% (1)

- Fiat 8065 Iveco UseMaintanceManual 8060series Industrial L31022019E Jan05Document41 pagesFiat 8065 Iveco UseMaintanceManual 8060series Industrial L31022019E Jan05Dedy Cj100% (1)

- Manual de Partes Cummins C170Document64 pagesManual de Partes Cummins C170Carlos Alberto Ramirez Parra100% (1)

- Iveco Nef Engines F4ae Thru F4he Wshop ManualDocument788 pagesIveco Nef Engines F4ae Thru F4he Wshop ManualDarrell Nickels100% (19)

- Manual Tecnico Bomba StanadyneDocument3 pagesManual Tecnico Bomba StanadyneIvo Silva100% (4)

- F4HFE6131Document238 pagesF4HFE6131jvega_534120100% (8)

- Cummins China 4BTA3.9 G2Document5 pagesCummins China 4BTA3.9 G2joshua surbaktiNo ratings yet

- Dynapac Ca Rollers Workshop Manual Wheel Axle: Svedala Compaction and PavingDocument55 pagesDynapac Ca Rollers Workshop Manual Wheel Axle: Svedala Compaction and PavingMariê Ferreira Júnior100% (1)

- 87704086A NEF 6 Cyl MechanicalDocument545 pages87704086A NEF 6 Cyl Mechanicalиван Троянов100% (1)

- Motor IvecoDocument162 pagesMotor Ivecomax_cortes1987100% (8)

- Woodward DYNA 70025 Electronic Actuator Service BulletinDocument4 pagesWoodward DYNA 70025 Electronic Actuator Service BulletinSunthron SomchaiNo ratings yet

- D905 Kubota Diesel Engine ManualDocument6 pagesD905 Kubota Diesel Engine ManualJose MuñozNo ratings yet

- 95 kW NEF45 TM2X Diesel Engine SpecsDocument21 pages95 kW NEF45 TM2X Diesel Engine SpecsAdrian HernandezNo ratings yet

- Valtra N Series TractorDocument32 pagesValtra N Series Tractorciuca bogdanNo ratings yet

- PC2182Document478 pagesPC2182ErissonNo ratings yet

- IVECO NEF 4.5 Liter Diesel Engine Service Manual (Mechanical Rotary Injection)Document418 pagesIVECO NEF 4.5 Liter Diesel Engine Service Manual (Mechanical Rotary Injection)ناجى ابوعورة100% (6)

- Spec Sheet - 3306 250 KVA PrimeDocument4 pagesSpec Sheet - 3306 250 KVA PrimeAsantony Raj100% (1)

- Chapter 5 Deutz EMR 2 Fault Codes NewDocument8 pagesChapter 5 Deutz EMR 2 Fault Codes NewLhsan RajawiNo ratings yet

- Workshoo Stanadyne 05872Document4 pagesWorkshoo Stanadyne 05872Kevin TtitoNo ratings yet

- CATALOGO 1103 PerkinsDocument82 pagesCATALOGO 1103 PerkinsSamuel Solorzano0% (1)

- TP6710 - Operation Manual 7-28EFOZDDocument52 pagesTP6710 - Operation Manual 7-28EFOZDAnonymous M0OEZEKoGiNo ratings yet

- Cat 3056 Propulsion 138bkw Spec SheetsDocument12 pagesCat 3056 Propulsion 138bkw Spec Sheetsdleante0% (1)

- 1104D-44T Engine (PN1835 Jan08)Document2 pages1104D-44T Engine (PN1835 Jan08)Marinewants TwoBeinuNo ratings yet

- Nef 220 N67 MNS M22Document202 pagesNef 220 N67 MNS M22jvega_534120100% (3)

- 0961-0218 - I6 - 201603 - Manual de Partes GG - Ee. C30D6 India 2016Document81 pages0961-0218 - I6 - 201603 - Manual de Partes GG - Ee. C30D6 India 2016johan67% (3)

- 1103 1104 MechanicalDocument37 pages1103 1104 Mechanicaldouglas100% (1)

- 550kVA CaterpillarDocument16 pages550kVA CaterpillarfazalmusaferNo ratings yet

- Diagnostic Tool C4.4 - C2.2Document2 pagesDiagnostic Tool C4.4 - C2.2Alberto PANo ratings yet

- SECTION 1 - General SpecificationsDocument14 pagesSECTION 1 - General Specificationsيوسف وليد عبد الرحيمNo ratings yet

- 3BN0 Me5 PDFDocument21 pages3BN0 Me5 PDFJoao SilvaNo ratings yet

- Iveco Repair Manual C13turbocompoundtier3 P2d32c005eDocument10 pagesIveco Repair Manual C13turbocompoundtier3 P2d32c005ebrett100% (47)

- Xe Nâng BTDocument518 pagesXe Nâng BTlê hùng100% (1)

- Parts Catalog: 25 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25 HP (521cc) 2 Stroke ModelsRonei MartinsNo ratings yet

- Dehp 9400 MPDocument93 pagesDehp 9400 MPmarcelo francoNo ratings yet

- Service Manual: Land Cruiser PradoDocument52 pagesService Manual: Land Cruiser Pradocarlos Gutierrez De La HozNo ratings yet

- Iveco Nef45 tm1Document23 pagesIveco Nef45 tm1Antonio MartinNo ratings yet

- DT125 3BN0-ME5 Repair ManualDocument21 pagesDT125 3BN0-ME5 Repair Manualnb6hg867% (9)

- Fleetguard Es Liquid: Hazardous Substance. Non-Dangerous GoodsDocument10 pagesFleetguard Es Liquid: Hazardous Substance. Non-Dangerous GoodsAnonymous V9fdC6No ratings yet

- Corporate Brochure Part No. TitleDocument15 pagesCorporate Brochure Part No. TitleAnonymous V9fdC6No ratings yet

- Aventics V1.0: Catalogue Product ListDocument6 pagesAventics V1.0: Catalogue Product Listmuftah76No ratings yet

- EDC 7 Electronic Control UnitDocument5 pagesEDC 7 Electronic Control UnitAnonymous V9fdC6100% (3)

- GP-Pro EX Ladder Logic Quick Start GuideDocument21 pagesGP-Pro EX Ladder Logic Quick Start GuideAnonymous V9fdC6No ratings yet

- Aventics V1.0: Catalogue Product ListDocument6 pagesAventics V1.0: Catalogue Product Listmuftah76No ratings yet

- Feed-Through Terminal Block - PT 2,5-QUATTRO - 3209578: Key Commercial DataDocument30 pagesFeed-Through Terminal Block - PT 2,5-QUATTRO - 3209578: Key Commercial DataAnonymous V9fdC6100% (1)

- Mercedes Benz Fault Code ManualDocument107 pagesMercedes Benz Fault Code ManualAnthony75% (53)

- Sensor/actuator Terminal Block - STIO 2,5/3-2B/L - 3209015: Key Commercial DataDocument18 pagesSensor/actuator Terminal Block - STIO 2,5/3-2B/L - 3209015: Key Commercial DataAnonymous V9fdC6No ratings yet

- Pnuematic Control2 - 1Document1 pagePnuematic Control2 - 1Anonymous V9fdC6No ratings yet

- Component Name Quantity: Normally Open Push-Button 1Document1 pageComponent Name Quantity: Normally Open Push-Button 1Anonymous V9fdC6No ratings yet

- Lda 450Document48 pagesLda 450Mirza Smailbegovic67% (3)

- Catalog - GPST-3200 Series-GP4000 SeriesDocument38 pagesCatalog - GPST-3200 Series-GP4000 Seriesmuftah76No ratings yet

- Startup Guide: Pro-Des IgnerDocument69 pagesStartup Guide: Pro-Des Ignermuftah76No ratings yet

- PLC, Scada TrainingDocument47 pagesPLC, Scada TrainingSandeep Kumar100% (1)

- Series 58 Modular Version ISO 4401-03 (CETOP 03) P Max: Bar Max (See Table of Performances)Document4 pagesSeries 58 Modular Version ISO 4401-03 (CETOP 03) P Max: Bar Max (See Table of Performances)Anonymous V9fdC6No ratings yet

- PLC Chap05Document36 pagesPLC Chap05alinupNo ratings yet

- Compatibility of Bit SwitchDocument2 pagesCompatibility of Bit SwitchAnonymous V9fdC6No ratings yet

- Troubleshooting Guide: PreliminaryDocument152 pagesTroubleshooting Guide: PreliminaryFalgon IslamNo ratings yet

- Canopen Communication ModulesDocument2 pagesCanopen Communication Modulesmuftah76No ratings yet

- 3 Engine Speed ChangeDocument6 pages3 Engine Speed ChangeAnonymous V9fdC6No ratings yet

- Alarm Display - Tips & Tricks 1 PDFDocument15 pagesAlarm Display - Tips & Tricks 1 PDFalimoya13No ratings yet

- Starting Systems PDFDocument1 pageStarting Systems PDFAnonymous V9fdC6No ratings yet

- Auxiliaries PDFDocument14 pagesAuxiliaries PDFAnonymous V9fdC6No ratings yet

- 20 Pressure SpecificationsDocument7 pages20 Pressure SpecificationsAnonymous V9fdC6No ratings yet

- Caterpillar EMCPDocument40 pagesCaterpillar EMCPrealwild93% (59)

- Input and Output Ror Ecm PDFDocument1 pageInput and Output Ror Ecm PDFAnonymous V9fdC6No ratings yet

- EC350 Network Configuration and SecurityDocument1 pageEC350 Network Configuration and SecurityAnonymous V9fdC6No ratings yet

- Cat 3406c ManualDocument85 pagesCat 3406c ManualShaun Whittaker95% (39)

- Panel (EMCP) 4.2 Upgrade KitDocument2 pagesPanel (EMCP) 4.2 Upgrade KitAnonymous V9fdC6No ratings yet