Professional Documents

Culture Documents

25.03 MRL For Abrasive Service

Uploaded by

Anonymous LeC3YexoBoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25.03 MRL For Abrasive Service

Uploaded by

Anonymous LeC3YexoBoCopyright:

Available Formats

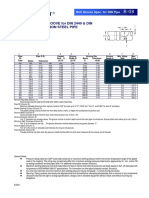

SPECIAL IPS GROOVE SPECIFICATIONS 25.

03

Groove Dimensions for Rubber Lining

for abrasive services

RUBBER OR URETHANE LINED PIPE

Rubber or urethane lined pipe, connected with Victaulic couplings, has proven to be a most

practical and economical method of conveying abrasive fluids and slurries, showing savings in

maintenance cost over unlined metal pipe in such services. The use of rubber-lined metal pipe

combines abrasive-resistant properties of rubber or urethane with the rigidity and strength of

metal.

Urethane or rubber-lined pipe is available with Victaulic grooved ends from leading companies

in different types of linings, for handling abrasive solids in water. The type of lining selected

for a particular operation is determined by the conditions under which the system will operate.

Request publication 25.10 for information on lined fittings for corrosive services.

A 1 2 3 4 5 6 7

B Dimensions Inches/millimeters

H Pipe

Outside Diameter Gasket Seat Gasket Width Groove Dia.

+0 Inches/mm A B C

-0.030" Min.

Nominal Allow.

Size Tol. Tol. Tol. H Wall

Inches +.000 +.000 +.000 +0.000 Thick.

mm Basic Tolerance Basic (+0.00) Basic (+0.00) Basic (+0.00) 0.030 T

1 1.315 +0.013 0.013 0.562 0.030 0.312 0.030 1.190 0.015 0.437 0.133

C 0.030" R 25 33.4 +0.33 0.33 14.27 0.76 7.92 0.76 30.23 0.38 11.10 3.38

1 1.660 +0.016 0.013 0.562 0.030 0.312 0.030 1.535 0.015 0.437 0.140

FOR ABRASION RESISTANCE ONLY 32 42.2 +0.41 0.33 14.27 0.76 7.92 0.76 38.99 0.38 11.10 3.56

NOTE: Dimensions apply to steel pipe and 1 1.900 +0.019 0.019 0.562 0.030 0.312 0.030 1.775 0.015 0.437 0.145

Victaulic fittings. *Based on nominal dimensions 40 48.3 +0.48 0.48 14.27 0.76 7.92 0.76 45.09 0.38 11.10 3.68

(without tolerances). 2 2.375 +0.024 0.024 0.562 0.030 0.312 0.030 2.250 0.015 0.437 0.154

50 60.3 +0.61 0.61 14.27 0.76 7.92 0.76 57.15 0.38 11.10 3.91

Column 1 Nominal IPS Pipe Size. Nominal

Metric (ISO) Pipe Size. 2 2.875 +0.029 0.029 0.562 0.030 0.312 0.030 2.720 0.018 0.437 0.188

65 73.0 +0.74 0.74 14.27 0.76 7.92 0.76 69.09 0,46 11.10 4.78

Column 2 IPS Outside Diameter. Metric (ISO) 3.000 +0.030 0.030 0.562 0.030 0.312 0.030 2.845 0.018 0.437 0.188

Outside Diameter. The outside diameter of cut 3 O.D. 76.1 +0.76 0.76 14.27 0.76 7.92 0.76 72.26 0.46 11.10 4.78

grooved pipe shall not vary more than the toler- 3 3.500 +0.035 0.031 0.562 0.030 0.312 0.030 3.344 0.018 0.437 0.188

ance listed. For IPS pipe, the maximum allowable 80 88.9 +0.89 0.79 14.27 0.76 7.92 0.76 84.94 0.46 11.10 4.78

tolerance from square cut ends is 0.030" for 2 - 3 "; 3 4.000 +0.040 0.031 0.562 0.030 0.312 0.030 3.834 0.020 0.437 0.188

0.045" for 4 - 6"; and 0.060" for sizes 8" O.D. and 90 101.6 +1.02 0.79 14.27 0.76 7.92 0.76 97.38 0.51 11.10 4.78

above measured from true square line. For (ISO) 4 4.500 +0.045 0.031 0.562 0.030 0.344 0.030 4.334 0.020 0.437 0.203

metric pipe, the maximum allowable tolerance 100 114.3 +1.14 0.79 14.27 0.76 8.73 0.76 110.08 0.51 11.10 5.16

from square cut ends is 0,76 mm for sizes 20 - 80 5 5.563 +0.056 0.031 0.562 0.030 0.344 0.030 5.395 0.022 0.437 0.203

mm; 1,14 mm for sizes 100 - 150 mm; and 1,52 125 141.3 +1.42 0.79 14.27 0.76 8.73 0.76 137.03 0.56 11.10 5.16

mm for sizes 200 mm and above, measured 6.500 +0.063 0.031 0.562 0.030 0.344 0.030 6.330 0.022 0.437 0.219

from the true square line. 6. O.D. 165.1 +1.60 0.79 14.27 0.76 8.73 0.76 160.78 0.56 11.10 5.56

Column 3 Gasket Seat. The pipe surface 6 6.625 +0.063 0.031 0.562 0.030 0.344 0.030 6.455 0.022 0.437 0.219

shall be free from indentations and projections 150 168.3 +1.60 0.79 14.27 0.76 8.73 0.76 163.96 0.56 11.10 5.56

from the end of the pipe to the groove, to 8 8.625 +0.063 0.031 0.625 0.030 0.469 0.030 8.441 0.025 0.500 0.238

provide a leak-tight seat for the gasket. All loose 200 219.1 +1.60 0.79 15.88 0.76 11.91 0.76 214.40 0.64 12.70 6.05

paint, scale, dirt, chips, grease, and rust must be 10 10.750 +0.063 0.031 0.625 0.030 0.469 0.030 10.562 0.027 0.500 0.250

removed. Rubber lining must be ground flush 250 273.0 +1.60 0.79 15.88 0.76 11.91 0.76 268.28 0.69 12.70 6.35

with pipe O.D. to a smooth finish for proper 12 12.750 +0.063 0.031 0.625 0.030 0.469 0.030 12.531 0.030 0.500 0.279

gasket seating. 300 323.9 +1.60 0.79 15.88 0.76 11.91 0.76 318.29 0.76 12.70 7.09

It continues to be Victaulics recommendation 14 14.000 +0.063 0.031 0.938 0.030 0.500 0.030 13.781 0.030 0.813 0.281

that pipe be square cut. Beveled pipe may not 350 355.6 +1.60 0.79 23.83 0.76 12.70 0.76 350.04 0.76 20.65 7.14

be used. Gasket seat A is measured from the 16 16.000 +0.063 0.031 0.938 0.030 0.500 0.030 15.781 0.030 0.813 0.312

end of the rubber lining. 400 406.4 +1.60 0.79 23.83 0.76 12.70 0.76 400.84 0.76 20.65 7.92

Column 4 Groove Width. Bottom of groove 18 18.000 +0.063 0.031 1.000 0.030 0.500 0.030 17.781 0.030 0.875 0.312

450 457.2 +1.60 0.79 25.40 0.76 12.70 0.76 451.64 0.76 22.23 7.92

to be free of loose dirt, chips, rust and scale that

may interfere with proper coupling assembly. 20 20.000 +0.063 0.031 1.000 0.030 0.500 0.030 19.781 0.030 0.875 0.312

500 508.0 +1.60 0.79 25.40 0.76 12.70 0.76 502.44 0.76 22.23 7.92

Maximum permissible radius at bottom of

groove is 0.025" (0,64 mm). 22 22.000 +0.063 0.031 1.000 0.060 0.500 0.030 21.656 0.030 0.875 0.375

550 559.0 +1.60 0.79 25.40 1.52 12.70 0.76 550.06 0.76 22.23 9.53

Column 5 Groove Diameter. The groove must

24 24.000 +0.063 0.031 1.000 0.060 0.500 0.030 23.656 0.030 0.875 0.375

be of uniform depth for the entire pipe circum- 600 610.0 +1.60 0.79 25.40 1.52 12.70 0.76 600.86 0.76 22.23 9.53

ference. Groove must be maintained within the

30 30.000 +0.063 0.031 1.750 0.060 0.625 0.030 29.500 0.063 1.625 0.625

C diameter tolerance listed. 750 762.0 +1.60 0.79 44.45 1.52 15.88 0.76 749.30 1.60 41.28 15.88

Column 6 Lead edge of groove to end of pipe 36 36.000 +0.093 0.031 1.750 0.060 0.625 0.030 35.500 0.063 1.625 0.625

after machining to allow rubber lining. 900 914.4 +2.36 0.79 44.45 1.52 15.88 0.76 901.7 1.60 41.28 15.88

For complete contact information, visit www.victaulic.com

25.03 1585 REV B UPDATED 09/2010

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

25.03

You might also like

- Manual de Servicio Motor Dodge Jeep Chrysler Pentastar 3.6lDocument62 pagesManual de Servicio Motor Dodge Jeep Chrysler Pentastar 3.6lTomas75% (4)

- HR Policy For Hotel IndustriesDocument5 pagesHR Policy For Hotel IndustriesHR Forum India78% (9)

- Fugro - Method Statement - For Geotechnical InvestigationDocument4 pagesFugro - Method Statement - For Geotechnical Investigationsindalisindi100% (1)

- Din 11850 PDFDocument2 pagesDin 11850 PDFLeonardoNo ratings yet

- PIC001 P&ID Documentation CriteriaDocument79 pagesPIC001 P&ID Documentation Criteriazabiruddin786No ratings yet

- Zick AnalysisDocument12 pagesZick AnalysisrksahayNo ratings yet

- Ignition System Spark Test DiagnosisDocument24 pagesIgnition System Spark Test DiagnosisMohamed l'Amine75% (4)

- 7 Surprising Cyberbullying StatisticsDocument4 pages7 Surprising Cyberbullying StatisticsJuby Ann Enconado100% (1)

- Past The Shallows EssayDocument2 pagesPast The Shallows EssaycaitlinNo ratings yet

- 25.03 - Vitaulic RanuradoDocument3 pages25.03 - Vitaulic RanuradoABAD ALEXANDER MORENO ZÁRATENo ratings yet

- Vitaulic Style 77 para Recubrimiento en GomaDocument1 pageVitaulic Style 77 para Recubrimiento en GomaALESSANDRO DEL PIERONo ratings yet

- Es Cut Groove Specifications 25.02Document3 pagesEs Cut Groove Specifications 25.02Mathew WolfNo ratings yet

- ASC Groove Specifications v01Document6 pagesASC Groove Specifications v01Pape DiopNo ratings yet

- B-05 Standard Roll Groove-RevFDocument2 pagesB-05 Standard Roll Groove-RevFAgreen AnggadaNo ratings yet

- Copper Pipes To BS EN 1057Document12 pagesCopper Pipes To BS EN 1057wkcNo ratings yet

- Design: Technical DetailsDocument4 pagesDesign: Technical DetailsDanialNo ratings yet

- B-05 Standard Roll Groove-RevGDocument2 pagesB-05 Standard Roll Groove-RevGDeniNo ratings yet

- DIN Pipe Roll Groove SpecificationDocument1 pageDIN Pipe Roll Groove SpecificationIsaacNo ratings yet

- Desin BasisDocument13 pagesDesin BasisArifin ZakyNo ratings yet

- Well Tube 1050514Document12 pagesWell Tube 1050514Mustafa AlhoubaniNo ratings yet

- STD Groove SpecDocument4 pagesSTD Groove SpeccatullusNo ratings yet

- Material Specification HS-90: Coiled TubesDocument12 pagesMaterial Specification HS-90: Coiled TubesalejandrosamuelNo ratings yet

- Technical Details: WipersDocument4 pagesTechnical Details: WipersRPINILLA (EICO S.A.)No ratings yet

- Analysis of groundwater flow using Thiem, Cooper and Theis methodsDocument87 pagesAnalysis of groundwater flow using Thiem, Cooper and Theis methodsHarbleidy Ibarra IbarraNo ratings yet

- Original Groove System (OGS) Groove Specifications: DimensionsDocument7 pagesOriginal Groove System (OGS) Groove Specifications: DimensionsDalberto RamirezNo ratings yet

- D 1587 - 94 Rde1odctukve PDFDocument6 pagesD 1587 - 94 Rde1odctukve PDFLupita CarelyNo ratings yet

- Area of Steel Calculation: (Limit State)Document16 pagesArea of Steel Calculation: (Limit State)RAVI PRAKASH SAININo ratings yet

- 38 Design of SlabiDocument11 pages38 Design of Slabiabdullah rahmanNo ratings yet

- Travel Time Di LahanDocument7 pagesTravel Time Di Lahanedoardushipyan edoedueNo ratings yet

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Document5 pagesDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaNo ratings yet

- Appendix B: Pipe Size DataDocument7 pagesAppendix B: Pipe Size DataSatyshikh SrivNo ratings yet

- Tablas de CañeriasDocument11 pagesTablas de CañeriascesarNo ratings yet

- T 310 PG 103-104 PDFDocument2 pagesT 310 PG 103-104 PDFJossimar PerezNo ratings yet

- Stas 438-2-91 RDocument4 pagesStas 438-2-91 RSzabolcs KovacsNo ratings yet

- NyaDocument1 pageNyaahmat kharisNo ratings yet

- SDOF Damped Forced Vibration - NewmarkDocument5 pagesSDOF Damped Forced Vibration - NewmarkAbu Hadiyd Al-IkhwanNo ratings yet

- EN 755 - Part 3Document2 pagesEN 755 - Part 3myusernameatscribdNo ratings yet

- Standard Specifications Roll and Cut Groove For Steel Pipe and Other IPS Pipe Technical Data General DescriptionDocument6 pagesStandard Specifications Roll and Cut Groove For Steel Pipe and Other IPS Pipe Technical Data General DescriptionShaik's PeerNo ratings yet

- Cold Rolled Sheets HINDALCODocument3 pagesCold Rolled Sheets HINDALCOADIPESHNo ratings yet

- Technical Details: Piston SealsDocument4 pagesTechnical Details: Piston SealsvicoraulNo ratings yet

- D265T063Document6 pagesD265T063adhyharmonypngNo ratings yet

- Piston Seals: Technical DetailsDocument4 pagesPiston Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Penthor 964: External StandardDocument2 pagesPenthor 964: External StandardAnjani kumarNo ratings yet

- Mecanismo de manivelas, especificaçãoDocument4 pagesMecanismo de manivelas, especificaçãoAparecidaMarquesNo ratings yet

- Weight CalculationDocument14 pagesWeight CalculationAkshay KadiaNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Endseal Pipe Groove SpecificationsDocument4 pagesEndseal Pipe Groove SpecificationsJason MillerNo ratings yet

- Brochure Tooth Lock WashersDocument6 pagesBrochure Tooth Lock WashersHala Ibrahim El-BassyouniNo ratings yet

- Particle Size ConversionDocument1 pageParticle Size ConversionManchoNo ratings yet

- L-Type STEEL (GB 9946-1988)Document3 pagesL-Type STEEL (GB 9946-1988)Luong Bui DangNo ratings yet

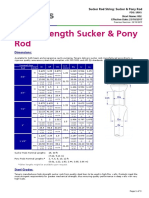

- High Strength Sucker & Pony Rod: DimensionsDocument3 pagesHigh Strength Sucker & Pony Rod: DimensionsDavid LluguinNo ratings yet

- PE Pipe - Earthwork and Road Reinstatment CalculationDocument15 pagesPE Pipe - Earthwork and Road Reinstatment Calculationrim deNo ratings yet

- Critical Seal Design Tolerance Charts: Recommended Shaft and Bore TolerancesDocument3 pagesCritical Seal Design Tolerance Charts: Recommended Shaft and Bore TolerancesRameshNo ratings yet

- High Carbon Wire RodDocument9 pagesHigh Carbon Wire Rodninganray6316100% (1)

- Aries™ MWD: ApplicationsDocument3 pagesAries™ MWD: ApplicationsRicardo Miguel Carranza ChuhuiNo ratings yet

- Conduit and Wire Installation Manhours per Linear Meter GuideDocument4 pagesConduit and Wire Installation Manhours per Linear Meter GuideAbdullahHusainNo ratings yet

- DynaDrill (SLB) 5 IN 7-8 Lobe 8.4 STGDocument1 pageDynaDrill (SLB) 5 IN 7-8 Lobe 8.4 STGLeonardo BarriosNo ratings yet

- THREAD DATA CHART: Metric Thread - Coarse PitchDocument2 pagesTHREAD DATA CHART: Metric Thread - Coarse PitchJosh SaundersNo ratings yet

- Ba Threads SpecDocument1 pageBa Threads Specprasadjoshi781429No ratings yet

- NAYADocument1 pageNAYAhenry_gtNo ratings yet

- ASTM Sieve Chart and TYLER Mesh SizesDocument1 pageASTM Sieve Chart and TYLER Mesh SizesWilder CubaNo ratings yet

- Hs 80 Coil Tubing TSHDocument13 pagesHs 80 Coil Tubing TSHAymeeenNo ratings yet

- Wave Washer For BearingsDocument2 pagesWave Washer For Bearingspradipbhosale81No ratings yet

- Socket Weld 6Document2 pagesSocket Weld 6chetanNo ratings yet

- Explicit Solutions For Critical and Normal Depths in Channels With Different ShapesDocument8 pagesExplicit Solutions For Critical and Normal Depths in Channels With Different ShapesAnonymous LeC3YexoBoNo ratings yet

- Buckling of Steel Shells European Recommendations PDFDocument136 pagesBuckling of Steel Shells European Recommendations PDFAnonymous LeC3YexoBoNo ratings yet

- Nordbak Wearing Compd MsdsDocument5 pagesNordbak Wearing Compd MsdsAnonymous LeC3YexoBoNo ratings yet

- General Reference RISA-Tekla LinkDocument116 pagesGeneral Reference RISA-Tekla LinkAnonymous LeC3YexoBoNo ratings yet

- Silo BucklingDocument14 pagesSilo BucklingrahilmlNo ratings yet

- Difference Between Node Values and Values: ElementDocument2 pagesDifference Between Node Values and Values: ElementAnonymous LeC3YexoBoNo ratings yet

- AVEVA Business Paper Bolting It All TogetherDocument8 pagesAVEVA Business Paper Bolting It All TogetherAnonymous LeC3YexoBoNo ratings yet

- Fuller CatalogueDocument72 pagesFuller CatalogueAnonymous LeC3YexoBoNo ratings yet

- The Buckling Behaviour of Thin-Walled Circular Steel SilosDocument11 pagesThe Buckling Behaviour of Thin-Walled Circular Steel SilosAnonymous LeC3YexoBoNo ratings yet

- Analysis of A Cylinder Shell Supported by Two Longitudinal BeamsDocument11 pagesAnalysis of A Cylinder Shell Supported by Two Longitudinal BeamsAnonymous LeC3YexoBoNo ratings yet

- 1995 - Naijie Shen - Stressstateinthesaddlezoneofpressurevesselsandpipi (Retrieved-2014!03!05)Document10 pages1995 - Naijie Shen - Stressstateinthesaddlezoneofpressurevesselsandpipi (Retrieved-2014!03!05)Anonymous LeC3YexoBoNo ratings yet

- The Behaviour of Locally-Supported Cylindrical Shells - Unstiffened ShellsDocument23 pagesThe Behaviour of Locally-Supported Cylindrical Shells - Unstiffened ShellsAnonymous LeC3YexoBoNo ratings yet

- Buckling of Steel Shells European RecommendationsDocument136 pagesBuckling of Steel Shells European RecommendationsAnonymous LeC3YexoBoNo ratings yet

- Buckling of Thin Shells, Recent Advances and TrendsDocument12 pagesBuckling of Thin Shells, Recent Advances and Trendschuckhsu1248No ratings yet

- WWW - Efm.leeds - Ac.uk CIVE CIVE2400 OpenChannelHydraulics2Document39 pagesWWW - Efm.leeds - Ac.uk CIVE CIVE2400 OpenChannelHydraulics2Prabu Rengarajan100% (1)

- 74Document8 pages74Samir MansurNo ratings yet

- Launder - Procedure PDFDocument10 pagesLaunder - Procedure PDFAnonymous LeC3YexoBoNo ratings yet

- Gravity Launder Flow ProcedureDocument10 pagesGravity Launder Flow ProcedureiranmortezaNo ratings yet

- FINALS REVIEWER ENVI ENGG Topic 1Document8 pagesFINALS REVIEWER ENVI ENGG Topic 1As ReNo ratings yet

- Endocrown Review 1Document9 pagesEndocrown Review 1Anjali SatsangiNo ratings yet

- Owners Manual Water Mist PDFDocument6 pagesOwners Manual Water Mist PDFZeeNo ratings yet

- ABSCESSDocument35 pagesABSCESSlax prajapatiNo ratings yet

- QRF HD785-7Document2 pagesQRF HD785-7Ralf MaurerNo ratings yet

- Formularium ApotekDocument12 pagesFormularium ApotekNurul Evi kurniatiNo ratings yet

- Nutrition During PregnancyDocument8 pagesNutrition During PregnancyHalliahNo ratings yet

- Model Fs CatalogDocument4 pagesModel Fs CatalogThomas StempienNo ratings yet

- BCM Continuous ImprovementDocument22 pagesBCM Continuous ImprovementnikoNo ratings yet

- 2 English Course BDocument8 pages2 English Course BAnjana27No ratings yet

- Chapter 4Document26 pagesChapter 4Lana AlakhrasNo ratings yet

- Marketing-Aspect 4Document10 pagesMarketing-Aspect 4Leiren RingorNo ratings yet

- Case Report on Right Knee FuruncleDocument47 pagesCase Report on Right Knee Furuncle馮宥忻No ratings yet

- Akshaya Trust NgoDocument24 pagesAkshaya Trust NgodushyantNo ratings yet

- Jairo Garzon 1016001932 G900003 1580 Task4Document12 pagesJairo Garzon 1016001932 G900003 1580 Task4Jairo Garzon santanaNo ratings yet

- Manual Masina de Spalat Slim SamsungDocument1,020 pagesManual Masina de Spalat Slim SamsungPerfectreviewNo ratings yet

- Chapter 3 - CT&VT - Part 1Document63 pagesChapter 3 - CT&VT - Part 1zhafran100% (1)

- Lesson Plan 7 Tabata TrainingDocument4 pagesLesson Plan 7 Tabata Trainingapi-392909015100% (1)

- Scaffolding Control & MeasuresDocument3 pagesScaffolding Control & Measuresviswamanoj100% (1)

- Fitness WalkingDocument192 pagesFitness Walkingjha.sofcon5941100% (1)

- 3-Step Mindset Reset: Overcome Self-Doubt with Mel Robbins' TrainingDocument11 pages3-Step Mindset Reset: Overcome Self-Doubt with Mel Robbins' TrainingBožana RadošNo ratings yet

- Sigma monitor relayDocument32 pagesSigma monitor relayEdwin Oria EspinozaNo ratings yet

- Montgomery County Ten Year Comprehensive Water Supply and Sewerage Systems Plan (2003)Document228 pagesMontgomery County Ten Year Comprehensive Water Supply and Sewerage Systems Plan (2003)rebolavNo ratings yet

- DVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in ElectronicsDocument1 pageDVAIO R3 PRO HD Sound Quality In-Ear Wired Earphone Amazon - in Electronicsdinple sharmaNo ratings yet

- Pet - WikipediaDocument12 pagesPet - Wikipediabdalcin5512No ratings yet