Professional Documents

Culture Documents

44compressed Air Dryers - HDD

Uploaded by

Lê Anh ChiếnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

44compressed Air Dryers - HDD

Uploaded by

Lê Anh ChiếnCopyright:

Available Formats

HEATLESS COMPRESSED AIR

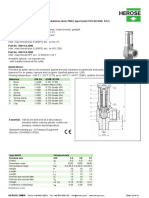

ADSORPTION DRYER HDD-SERIES DATA

HDD SERIES DESICCANT DRYERS - SPECIFICATIONS

Model Volume Flow Rate 1 Dimensions (mm) Connection Weight

Number l/s m3/min m3/hr cfm A (D) B (W) C (H) inch kg

HDD0039 39 2.33 140 82 605 960 1915 1 204

HDD0053 53 3.17 190 111 570 990 1925 1 274

HDD0067 67 4.00 240 141 570 990 1925 1 274

HDD0106 106 6.33 380 223 630 990 1965 1 370

HDD0150 150 9.00 540 317 610 1090 2125 1 481

HDD0181 181 10.83 650 382 655 1100 2140 1 553

HDD0236 236 14.67 850 500 650 1245 2180 1 643

HDD0292 292 17.50 1050 617 700 1320 2240 2 765

HDD0389 389 23.33 1400 823 735 1510 2130 DN80/3 956

HDD0472 472 28.33 1700 1000 750 1610 2150 DN80/3 1136

HDD0569 569 34.17 2050 1206 780 1660 2155 DN80/3 1272

HDD0667 667 40.00 2400 1412 850 1710 2270 DN80/3 1404

HDD0778 778 46.67 2800 1647 905 1760 2200 DN80/3 1547

HDD0889 889 53.33 3200 1882 915 2080 2370 DN100/4 1739

HDD1028 1028 61.67 3799 2176 970 2155 2410 DN100/4 1903

HDD1167 1167 70.00 4200 2470 1020 2270 2430 DN100/4 2074

1. Based on -40C pressure dew point with inlet conditions of 7 barg and 35C.

Systems with higher flow rates and/or lower pressure dew points are available upon request.

HEATLESS

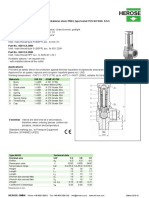

Correction Factors for Sizing of HDD Dryers for Different Operating Temperatures and Pressures Example:

Pressure Temperature (C) Flow rate 550 m3/h

(barg)

25 30 35 40 45 50

COMPRESSED

Pressure 9 bar

4 0.66 0.64 0.62 0.59 0.55 0.50 Inlet temp 35C

5 0.80 0.77 0.75 0.71 0.67 0.63

Pressure dew point -40C

AIR ADSORPTION

6 0.94 0.90 0.87 0.84 0.79 0.76

7 1.07 1.03 1.00 0.96 0.92 0.87 Dryer capacity: 550/1.18 = 437 m3

8 1.16 1.14 1.11 1.08 1.04 1.00 Therefore, selected dryer

DRYERS

9 1.23 1.21 1.18 1.14 1.10 1.07 model = HDD 0150

10 1.32 1.30 1.27 1.24 1.20 1.16

HDD SERIES

Airfilter Engineering reserves the right to change

specifications without prior notice.(Rev 02/08/13)

HEATLESS COMPRESSED AIR ADSORPTION

DRYERS HDD-SERIES

The Simple Philosophy AFE HDD Dryer Control Systems AFE manufactured desiccant

of Heatless Desiccant Dryers for Heatless Desiccant Dryers dryers are fully tested and are

for Compressed Air AFE offers two control systems for the HDD desiccant produced in accordance to the

dryers: ISO 9001 quality system.

Drying compressed air through adsorption represents a purely

1. PLC (Programmable Logic Controller System)

physical process in the course of which water vapour is bound

The HDD dryer is available with a time based PLC Control as

to the drying medium (desiccant) through binding forces of

standard. The standard cycle times are 5 minutes of adsorp-

molecular adhesion. For adsorption to take place, moist air is

tion followed by 4 minutes of regeneration and 1 minute for

directed through the adsorber at various operating pressures.

pressure build up.

During this process, the moist compressed air comes into

contact with the hydrophilic desiccant molecules when it flows 2. LCS (Load Control System)

from the bottom to the top of the vessel. The desiccant The LCS is a more economical system with energy saving

molecules will retain the moisture which results in dry features. Instead of re-generating every 5 minutes in a time

compressed air leaving the vessel. controlled PLC system, the LCS uses a dew point sensor

which detects the moisture load of the compressed air at the

outlet. The system then re-generates only when the dew

point is higher than the set level. This saves purge flow and

therefore energy.

How Does AFE HDD Desiccant

Dryer Works?

Two vessels connected in parallel are required for the continuous operation of drying via the adsorption process. Each vessel is

filled with desiccants which act as the drying medium. AFE desiccant dryers use high performance molecular sieve which have a The HDD Series of Desiccant Dryers manufactured by AFE

long service life at high input temperatures, resulting in very low pressure dew points. benefit from a simple but effective design which has been

Stage 1: The drying of compressed air takes place in vessel A and simultaneously, desorption (re-generation of the desiccant) studied and improved with many years of experience in the

occurs in vessel B. The desorption process in vessel B occurs in a counter flow direction by using a small flow of dry compressed Features and Advantages of the compressed air industry. AFE dryers are manufactured to

air channeled from the outlet of vessel A. The mode of operation of pressure change desorption corresponds to almost isothermal HDD Series Dessicant Dryers cater to a wide range of applications and the main benefits

desorption through partial pressure drop in the adsorbing component by means of pure purge gas.

are:

Welded vessels designed according

Stage 2: Upon completion of the re-generation cycle, - proven technology

to ASME VIII Div1. Standards. (other

re-pressurization takes place in vessel B until both vessels - robust construction

equalize in pressure. At this stage, the vessels are ready to designs and approvals on request)

switch over. Usage of self cleaning stainless steel - reliable performance

wedge wire in the wet area allows an - easy maintenance

Stage 3: The air from vessel A will purge out and the drying cycle even distribution of air flow with low

switches to vessel B. Vessel A will now undergo the desorption differential pressure across the

cycle to re-generate the desiccants.

system.

The entire process will repeat itself to continuously dry the Indication lights for dryer ON/OFF mode, adsorption, re-generation and LED display available

compressed air. for the dew point (if dew point meter is installed).

Usage of high performance molecular sieve which are suitable for application in a wide range

All AFE dryers are installed with coalescing pre-filters and

particle after-filters to provide clean and dry compressed air of operating conditions.

(CDA). Usage of standard industrial valves which are readily available and easily maintained.

Load Control System (LCS) display available as an economical and energy saving option.

Customized dryers according to OEMs requirements are available upon request.

Diagram 1: Schematic diagram for

HDD Adsorption Dryer

You might also like

- HWCF_170227_Wall MountDocument2 pagesHWCF_170227_Wall MountAkilaJosephNo ratings yet

- Emergency Relief Vent: MODEL 2000ADocument8 pagesEmergency Relief Vent: MODEL 2000ASantiago PeñuelaNo ratings yet

- Type 06205: Safety ValvesDocument2 pagesType 06205: Safety ValvesJim JonesjrNo ratings yet

- HidraulicaDocument42 pagesHidraulicaJuan Camilo Muñoz CarmonaNo ratings yet

- Type 06383: Safety ValvesDocument2 pagesType 06383: Safety ValvesJoan ReigNo ratings yet

- RCD IADECDocument4 pagesRCD IADECWesam UTECNo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- Data Sheet: Steam Condenser Protection Type HOV-SCDocument2 pagesData Sheet: Steam Condenser Protection Type HOV-SCRonak PatelNo ratings yet

- Ashley Power Disc Springs CatalogueDocument14 pagesAshley Power Disc Springs Cataloguesugali140270No ratings yet

- Typ 06388 1 enDocument2 pagesTyp 06388 1 enVikas PatelNo ratings yet

- RESEARCH PROJECT: Ac 4079 / A9 - 2.3.1. Resistance and Propulsion TestsDocument4 pagesRESEARCH PROJECT: Ac 4079 / A9 - 2.3.1. Resistance and Propulsion TestsTudor ChirilaNo ratings yet

- Project: Plot 68 Amghara SITE: Kuwait Ac Unit: Pacu 01 General DataDocument1 pageProject: Plot 68 Amghara SITE: Kuwait Ac Unit: Pacu 01 General DataMujtabaNo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- STRENGTH OF ANGLE SECTIONDocument7 pagesSTRENGTH OF ANGLE SECTIONkrunalNo ratings yet

- Copper Cable Tech. DetailsDocument8 pagesCopper Cable Tech. DetailsDaya CheluvaNo ratings yet

- Heated Compressed Air Adsorption Dryer Vehdd-Series DataDocument2 pagesHeated Compressed Air Adsorption Dryer Vehdd-Series DataRaphael212219No ratings yet

- Air CoolerDocument4 pagesAir Coolerprasad GabbitaNo ratings yet

- 2017 CWS THA Applied 12-48 MBH 50 HZDocument2 pages2017 CWS THA Applied 12-48 MBH 50 HZtuiNo ratings yet

- Lecture Notes05 Casing DesignDocument12 pagesLecture Notes05 Casing Designmohammad teimuriNo ratings yet

- IS800-2007 d/t ratiosDocument4 pagesIS800-2007 d/t ratios4geniecivilNo ratings yet

- CV10 CV15 Brochure 09.01.2021Document4 pagesCV10 CV15 Brochure 09.01.2021hamadaNo ratings yet

- SMD Power Coil: FerrocoreDocument2 pagesSMD Power Coil: FerrocorePuiu BercioiuNo ratings yet

- SHOABA PROJECT DUCT PRESSURE DROP ANALYSISDocument6 pagesSHOABA PROJECT DUCT PRESSURE DROP ANALYSISmohamedNo ratings yet

- Bearing CalalougeDocument9 pagesBearing CalalougeRakesh GairolaNo ratings yet

- Types of Free PointDocument19 pagesTypes of Free Pointphucbm bmNo ratings yet

- Victaulic Wye Type Vic-Strainer Series 732: 1.0 Product DescriptionDocument7 pagesVictaulic Wye Type Vic-Strainer Series 732: 1.0 Product DescriptionBayu NugrohoNo ratings yet

- KV Flow ChartDocument1 pageKV Flow ChartalexNo ratings yet

- Process Datasheet For Relief ValveDocument3 pagesProcess Datasheet For Relief Valvemadhu8087No ratings yet

- Data Sheet - DHDA Test PumpDocument2 pagesData Sheet - DHDA Test PumpDeepak DeepuNo ratings yet

- Steam Condenser Protection Bursting Discs TitleDocument1 pageSteam Condenser Protection Bursting Discs TitleMasood AlamNo ratings yet

- LIGHTWEIGHT, NON-SAGGING BUILDING INSULATIONDocument8 pagesLIGHTWEIGHT, NON-SAGGING BUILDING INSULATIONPhan LongNo ratings yet

- Major Civil Engineering: A3 Hindhead Determination of Particle Size Distribution: BS EN 933-1: 1997Document2 pagesMajor Civil Engineering: A3 Hindhead Determination of Particle Size Distribution: BS EN 933-1: 1997Andrew TorranceNo ratings yet

- Dsi-Usa Dywidag Tie Rods Us 02Document12 pagesDsi-Usa Dywidag Tie Rods Us 02Hery Mardiono HeryNo ratings yet

- 1 Core Copper Xlpe Armoured & Unarmoured Power CablesDocument1 page1 Core Copper Xlpe Armoured & Unarmoured Power CablesSikandar MirzaNo ratings yet

- Butterfly Valve B7GDocument3 pagesButterfly Valve B7GJorgeCabreraCoronelNo ratings yet

- Three Core Cable Three & Half Core Cable Four Core Cable: Reactance and Impedance of Xlpe PowerDocument10 pagesThree Core Cable Three & Half Core Cable Four Core Cable: Reactance and Impedance of Xlpe Powerarunpandey1686No ratings yet

- Final Correct Isolated FootingDocument20 pagesFinal Correct Isolated FootingK. S. Design GroupNo ratings yet

- En Ag2100marinesmoothDocument2 pagesEn Ag2100marinesmootheloy marroquinNo ratings yet

- Allowable Stress and Limit State Design ParametersDocument2 pagesAllowable Stress and Limit State Design Parameterssivaraju1No ratings yet

- Fahu - 1A: Fresh Air Fan Discharge SideDocument45 pagesFahu - 1A: Fresh Air Fan Discharge SideMUBASHIRNo ratings yet

- Catalogue Mondea 2023 Fix (2) XDocument38 pagesCatalogue Mondea 2023 Fix (2) XyanurulNo ratings yet

- Gas Absorption Treatment of DataDocument14 pagesGas Absorption Treatment of DataKharl De MesaNo ratings yet

- AZ0413YS - Curva de PerformaceDocument4 pagesAZ0413YS - Curva de PerformaceGeise Debiasi BiancoNo ratings yet

- Deep Groove Ball Bearings PDFDocument11 pagesDeep Groove Ball Bearings PDFArpit VermaNo ratings yet

- DPS Calculation SheetDocument133 pagesDPS Calculation SheetKraiwan AranyawatNo ratings yet

- Typ 06011 1 enDocument2 pagesTyp 06011 1 enMohamed RaafatNo ratings yet

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed RaafatNo ratings yet

- Folder Airless Auto Serie AlDocument2 pagesFolder Airless Auto Serie AlErika MaraNo ratings yet

- Percobaan V Kel 5Document3 pagesPercobaan V Kel 5FajliNo ratings yet

- Nyy - Iec PDFDocument5 pagesNyy - Iec PDFbenryNo ratings yet

- KabelmetaDocument1 pageKabelmetaLinda Soraya SeptianaNo ratings yet

- Model BVBS Vertical In-Line Strainers: DescriptionDocument4 pagesModel BVBS Vertical In-Line Strainers: Descriptionwalter ruizNo ratings yet

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Comparison Between Passengers Aircrafts (260-300 Seater)Document5 pagesComparison Between Passengers Aircrafts (260-300 Seater)B SandeepNo ratings yet

- HP Piping SystemDocument1 pageHP Piping SystemNicolás Cuevas SandovalNo ratings yet

- NYY 1 X (1.5-500) MM 0.6/1 KVDocument5 pagesNYY 1 X (1.5-500) MM 0.6/1 KVFebi HerdianaNo ratings yet

- De1207 220Document2 pagesDe1207 220Stoica VictorNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- ICCP Hull Corrosion Protection SystemsDocument12 pagesICCP Hull Corrosion Protection SystemsLê Anh ChiếnNo ratings yet

- GRASSMARLIN User GuideDocument55 pagesGRASSMARLIN User Guide김정미100% (1)

- IOGP Report # 459 Life-Saving RulesDocument22 pagesIOGP Report # 459 Life-Saving Rulesamra_410% (1)

- Swagelok-Thread and End Connection Identification Guide-MS-13-77 PDFDocument56 pagesSwagelok-Thread and End Connection Identification Guide-MS-13-77 PDFmac9papNo ratings yet

- Felcom - 15 Installation ManualDocument51 pagesFelcom - 15 Installation ManualLê Anh ChiếnNo ratings yet

- ABC of Cyber Security For ICS SystemDocument17 pagesABC of Cyber Security For ICS SystemLê Anh ChiếnNo ratings yet

- 2018.10.IEC ABC of Cyber SecurityDocument12 pages2018.10.IEC ABC of Cyber Securityclaudio.jc.limaNo ratings yet

- CL LMT ManualDocument296 pagesCL LMT Manualmarcosgran100% (1)

- Parker Fittings IomDocument120 pagesParker Fittings IomAgustin CesanNo ratings yet

- 44compressed Air Dryers - HDDDocument2 pages44compressed Air Dryers - HDDLê Anh Chiến100% (1)

- List of Rules - Codes - StandardDocument11 pagesList of Rules - Codes - StandardLê Anh ChiếnNo ratings yet

- ID5002P Ultranonic NIPS DatasheetDocument2 pagesID5002P Ultranonic NIPS DatasheetLê Anh ChiếnNo ratings yet

- Ex Sumary PDFDocument1 pageEx Sumary PDFLê Anh ChiếnNo ratings yet

- Sample For UpworkDocument6 pagesSample For UpworkMarlon AbellanaNo ratings yet

- Chris DeArmitt PHD ThesisDocument160 pagesChris DeArmitt PHD Thesisalinbu2007No ratings yet

- Air Quality Guidelines For EuropeDocument288 pagesAir Quality Guidelines For EuropeAlex OliveiraNo ratings yet

- Factors Affecting Solubility and Rate of Solution NotesDocument3 pagesFactors Affecting Solubility and Rate of Solution Notesscribduser0811972No ratings yet

- Salkowski Test ConclusionDocument3 pagesSalkowski Test Conclusionclint xavier odangoNo ratings yet

- Relationship Between Polarity and PropertiesDocument12 pagesRelationship Between Polarity and PropertiesJustine KylaNo ratings yet

- Rumen MicrobiologyDocument15 pagesRumen MicrobiologyJ Jesus Bustamante GroNo ratings yet

- Advanced Fluid Mechanics - Chapter 04 - Very Slow MotionDocument15 pagesAdvanced Fluid Mechanics - Chapter 04 - Very Slow Motionsunil481No ratings yet

- GTPL e BrochureDocument5 pagesGTPL e BrochuremishtinilNo ratings yet

- Chemical EquilibriumDocument2 pagesChemical EquilibriumDaniel Loh100% (1)

- Water/Cement Ratio LawDocument16 pagesWater/Cement Ratio LawNArendra REddyNo ratings yet

- Mid-Term Test 2012Document9 pagesMid-Term Test 2012Muhammad FauzanNo ratings yet

- Current, Resistance and DC Circuits: Physics 112NDocument27 pagesCurrent, Resistance and DC Circuits: Physics 112NgiyonoNo ratings yet

- Novaliches High School: 2. Dots in LEDS Represent A. Valence Electrons. B. Protons. C. Neutrons. D. ElectronsDocument4 pagesNovaliches High School: 2. Dots in LEDS Represent A. Valence Electrons. B. Protons. C. Neutrons. D. ElectronsExtremelydarknessNo ratings yet

- Engine Oil Volatility Noack Evaporation MethodDocument5 pagesEngine Oil Volatility Noack Evaporation MethodAvinash Gamit100% (1)

- Lab Exercise 6 SIMPLE STAININGDocument5 pagesLab Exercise 6 SIMPLE STAININGArianne Jans MunarNo ratings yet

- Ion ExchangeDocument25 pagesIon ExchangeArie Ikhwan SaputraNo ratings yet

- Oxford Quantum Theory Lecture NotesDocument92 pagesOxford Quantum Theory Lecture Notest ElderNo ratings yet

- Foodpharma MaterialoverviewpdfDocument2 pagesFoodpharma MaterialoverviewpdfJai BhandariNo ratings yet

- J. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideDocument3 pagesJ. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideFernandaIbarraVázquezNo ratings yet

- DSSC PresentationDocument50 pagesDSSC PresentationWisaruth MaethasithNo ratings yet

- To-GE KC-7 Methyl Salicylate 15% Menthol 7% Hydro Alcoholic Clear GelDocument1 pageTo-GE KC-7 Methyl Salicylate 15% Menthol 7% Hydro Alcoholic Clear GelAnand Rao100% (1)

- Microencapsulation of Cinnamon and Garlic Oils in Beta-CyclodextrinDocument10 pagesMicroencapsulation of Cinnamon and Garlic Oils in Beta-CyclodextrinErman ÇutukNo ratings yet

- Foundation Ch.61Document45 pagesFoundation Ch.61nelsonsainzNo ratings yet

- Kalibrasi Mesin DialDocument78 pagesKalibrasi Mesin DialMrQmonkNo ratings yet

- Lecture 02 Chemical Reactions COURSE II STUDENTS MI GC DJEDIDocument6 pagesLecture 02 Chemical Reactions COURSE II STUDENTS MI GC DJEDIIkram KhedimNo ratings yet

- Solution Manual To Options, Futures and Other Derivatives, 5th, by John Hull, John C. HullDocument3 pagesSolution Manual To Options, Futures and Other Derivatives, 5th, by John Hull, John C. HullSaumya SharmaNo ratings yet

- NASA SP36 ExtractoDocument82 pagesNASA SP36 ExtractoDiego Guerrero VelozNo ratings yet

- Evidence and Processes of EvolutionDocument14 pagesEvidence and Processes of EvolutionMiralen EndozoNo ratings yet

- Ugrad CurriculumDocument1 pageUgrad Curriculumapi-212407625No ratings yet