Professional Documents

Culture Documents

05 Eurammon Symposium 2017 Renz f3 v2

Uploaded by

hjduarteCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05 Eurammon Symposium 2017 Renz f3 v2

Uploaded by

hjduarteCopyright:

Available Formats

eurammon Symposium 2017

Commercial Refrigeration Systems

with R290 and R1270

Criteria for the Selection and Layout of

ComponentsTITLEand Pipe Work

HermannSPEAKER

Renz, BITZER GmbH

Schaffhausen, 22nd / 23rd June, 2017

Commercial Refrigeration Systems with R290 and R1270

Contents

R290 and R1270 properties and their impact

Resulting design and layout criteria

Influence of hydrocarbons on compressor lubrication

Required measures for reliable operation

Summary

Presentation does not include measures for safety provisions

Schaffhausen, 22nd / 23rd June, 2017 Page 2

R290 and R1270 Properties and Their Impact (1)

Moderate pressure levels, low

pressure ratio (p/po) due to flat

temperature/pressure characteristics

p/po far lower than with any HFC

or HFC/HFO alternative

Volumetric refrigerating capacity

+/-20% vs. R22 and R404A/507A

High evaporation enthalpy

@ -10/40C approx. 1.7 times vs.

R22 // 2.5 times vs. R404A/R507A

Schaffhausen, 22nd / 23rd June, 2017 Page 3

Volumetric Refrigerating Capacity / Suction Gas Volume Flow

tc 40C, Dtoh 20 K tc 40C, Dtoh 20 K

Volumetric refrigerating capacity of Suction gas volume flow of different

different refrigerants compared to R290 refrigerants compared to R290

Identical suction volume flow Identical refrigerating capacity

Schaffhausen, 22nd / 23rd June, 2017 Page 4

R290 and R1270 Properties and Their Impact (2)

Low refrigerant mass flow

@ identical Qo 55..60% vs. R22 // 40% vs. R404A/R507A

Very low vapour and liquid densities

Vapour (suction): 35..55% vs. R22 and HFCs

Liquid: 40..50% vs. R22 and HFCs

Low pressure drop in heat exchangers (HX) and pipe work

High superheat enthalpy in relation to volume change

Rising volumetric refr. capacity with increasing useful superheat

Increase of capacity and COP with liquid/suction line HX

Schaffhausen, 22nd / 23rd June, 2017 Page 5

Refrigerant Mass Flow / Liquid Volume Flow

tc 40C, Dtoh 20 K

tc 40C, Dtoh 20 K

Mass flow of different Liquid volume flow of different

refrigerants compared to R290 refrigerants compared to R290

Identical refrigerating capacity Identical refrigerating capacity

Schaffhausen, 22nd / 23rd June, 2017 Page 6

Relative Compressor COP R22, HFCs vs. R290 and R1270

Compressor type: Semi-hermetic Recip (isentropic efficiency includes motor losses)

150

140 to +5C, tc 50C Dtoh 20 K

to -10C, tc 45C hc (+5/-10C): 0.7

130 to -35C, tc 40C hc (-35C): 0.65

120

110

Relative COP [%]

100

90

80

70

60

50

40

COP does not reflect system bahaviour

30

20

R22 R404A/R507A R407F (Dew) R448A/R449A (Dew) R290 R1270

Schaffhausen, 22nd / 23rd June, 2017 Page 7

R290 and R1270 Properties and Their Impact (3)

Low discharge gas and oil temperatures (low cp/cv)

Moderate thermal load even with high pressure ratio (LT single stage)

High critical temperature (96.7 / 91.1C)

Favorable compressor and system COP also at high condensing

temperatures and lift conditions

Schaffhausen, 22nd / 23rd June, 2017 Page 8

R290 and R1270 Properties and Their Impact (4)

Good heat transfer due to intensive boiling and excellent solubility

and miscibility with oil

Single fluids no temperature glide

Good oil transport, low viscosity also in superheat section of

evaporators

Material compatibility similar to R22 and HFCs

Elastomers/plastics some stronger limitations with R1270

(see also Forschungsrat Kltetechnik Research Report FKT61_99)

Schaffhausen, 22nd / 23rd June, 2017 Page 9

Comparison of Discharge Gas Temperatures

with Single Stage Operation

Compressor type: Semi-hermetic Recip (isentropic efficiency includes motor losses)

200

to +5C, tc 50C Dtoh 20 K

180

to -10C, tc 45C hc (+5/-10C): 0.7

to -35C, tc 40C hc (-35C): 0.65

160

Discharge Gas Temperature [C]

140

120

100

80

60

40

20

0

R22 R404A/R507A R407F (Dew) R448A/R449A (Dew) R 290 R 1270

Schaffhausen, 22nd / 23rd June, 2017 Page 10

Resulting Design and Layout Criteria (1)

Reduced cross sections in HX, suction and discharge lines vs. R22 / HFC

Due to far lower vapour density / pressure drop

Identical dimensions of liquid line as with R22

Higher liquid volume flow but less pressure drop lower density

Potential for minimum refrigerant charge

mass 40..60% vs. R22 / HFCs

Schaffhausen, 22nd / 23rd June, 2017 Page 11

Resulting Design and Layout Criteria (2)

Select HX and line components according to mass and volume flow

Evaporator: e.g. injection distribution, pipe length and pipe geometry

Danger of uneven distribution and liquid overfeed in part load

TXV / EXV capacity* vs. R22 same nozzle (bulb charge adapted):

R290 HT / MT: 0..+5% // LT: -2..+2.5%

R1270 +13..18%

Higher numbers with lower condensing temperatures (15 K < reference tc)

* Source: Danfoss / Honeywell calculation methodology

Schaffhausen, 22nd / 23rd June, 2017 Page 12

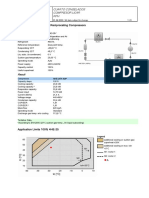

Resulting Design Criteria and Measures (3)

Preferred use of liquid/suction line HX target Dtoh 20 K (HT, MT)

Benefit in capacity, COP and reduced oil dilution higher oil temp

Examples of Cycle Configuration (R290)

71C 84C

10C

43.0C

-5C 43.0C

33.8C -5C

w/ IHX COP +5..6%

w/o IHX incl. higher isentropic eff. of compressor

Schaffhausen, 22nd / 23rd June, 2017 Page 13

R290 Cycle Diagram Capacity and COP Increase by IHX

Polytropic

IHX Compression

Schaffhausen, 22nd / 23rd June, 2017 Page 14

Influence of Hydrocarbons on Compressor Lubrication (1)

HCs have exceptionally good solubility/miscibility behaviour in oil

especially with lubricants of low polarity like MO

Strong oil dilution / reduced viscosity / solvent effect

Strong degassing and foaming with pressure fluctuation

Operating temperatures (discharge gas, oil) remarkably low

Increased amount of dissolved HC in oil especially at small pressure

ratios, high evaporating temperatures and low superheat

Schaffhausen, 22nd / 23rd June, 2017 Page 15

Influence of Hydrocarbons on Compressor Lubrication (2)

Solubility (oil/refrigerant) usually measured in mass %

With MO no severe difference in mass % vs. R22 or

HFCs w/ POE however

Low liquid density of HCs (40 45% vs. R22) leads to more than

double volume of dissolved refrigerant in oil

Far stronger oil dilution than with R22 and HFCs

Schaffhausen, 22nd / 23rd June, 2017 Page 16

Pressure / Temperature / Solubility Relation

Example MO Oil / R290 vs. R22

MO VG 68 cSt R290 MO VG 68 cSt R22

~ 16% R290

~ 8% R290

vapour pressure (bar)

vapour pressure (bar)

~ 17% R22

~ 7% R22

Temperature (C)

Standstill @ 20C Operation @ to +5C Temperature (C)

Oil temp R22 10 K higher than with R290 (55 vs. 45C)

Schaffhausen, 22nd / 23rd June, 2017 Page 17

Solubility / Viscosity Relation

Example MO Oil / R290 vs. R22

MO VG 68 cSt R290 MO VG 68 cSt R22

Far lower viscosities!

45C

Temperature (C)

Standstill @ 20C Operation @ to +5C 40C 55C

Oil temp 40C Oil temp R22 10 K higher than with R290 (55 vs. 45C) Temperature (C)

Schaffhausen, 22nd / 23rd June, 2017 Page 18

Lubricants: Required Measures for Reliable Operation (1)

Best suitable lubricant acc. to compressor manufacturer specification

Usually higher basic viscosity and/or lubricants with higher viscosity

index (Vi) or high polarity (lower solubility)

Minimum refrigerant charge

Generously sized crankcase heater

High suction pressure during standstill periods?

Pump down cycle may become necessary

Possible insulation of compressors in case of outdoor installation

Schaffhausen, 22nd / 23rd June, 2017 Page 19

Lubricants: Required Measures for Reliable Operation (2)

Superheat in MT & HT should be 20 K or higher, LT > 10 K

Liquid/suction line heat exchanger especially AC & Heat Pumps

Measures against wet operation during start and operation

Avoid refrigerant migration to suction side during standstill

Maintain sufficiently high suction gas superheat

Schaffhausen, 22nd / 23rd June, 2017 Page 20

Summary

The extended use of R290 and R1270 in commercial RAC systems

can be seen as one of the promising future solutions

High system efficiency and reliability can be reached with component and

system design precisely matched to the specific refrigerant properties

This as well includes to consider the necessary measures with regard to

lubricant related issues

Schaffhausen, 22nd / 23rd June, 2017 Page 21

Example of Chiller / Heat Pump Unit

Outdoor Units with a cooling

capacity range up to 190 kW

Reversing cycle

chiller / heat pump unit

3-pipe water loop

Refrigerant: R290/1270 blend

Source: Unichemie NL

Schaffhausen, 22nd / 23rd June, 2017 Page 22

Thank You for Your Attention!

Contact:

Hermann Renz

Eschenbruennlestr. 15, D-71065 Sindelfingen

Germany

+49 7031 932 240

+49 7031 932 5240

hermann.renz@bitzer.de

You might also like

- HGX34e R407C GBDocument8 pagesHGX34e R407C GBRodrigo GonçalvesNo ratings yet

- GEA - Bock - SemiHerm - Catalogue - GB 52Document1 pageGEA - Bock - SemiHerm - Catalogue - GB 52hadi mehrabiNo ratings yet

- Evaluation of performance of Heat pump system using R32 and HFO mDocument11 pagesEvaluation of performance of Heat pump system using R32 and HFO mHakan ÜçokNo ratings yet

- CO2 Presentation LAM 2003 06 PDFDocument81 pagesCO2 Presentation LAM 2003 06 PDFzikhail93No ratings yet

- R&T 2007 - CO2 Issues - HalseyDocument18 pagesR&T 2007 - CO2 Issues - Halseyheymaldo1No ratings yet

- GEA - Bock - SemiHerm - Catalogue - GB 44Document1 pageGEA - Bock - SemiHerm - Catalogue - GB 44hadi mehrabiNo ratings yet

- O.4.1.2 Thermodynamic Performance Assessment of R32 and R1234yfDocument8 pagesO.4.1.2 Thermodynamic Performance Assessment of R32 and R1234yfEsmeralda SouzaNo ratings yet

- Designing CO2 Evaporators for Refrigeration SystemsDocument29 pagesDesigning CO2 Evaporators for Refrigeration SystemsgamunozdNo ratings yet

- Hydrocracking Unit PDFDocument9 pagesHydrocracking Unit PDFcrili69No ratings yet

- R410A handling, design and installation guideDocument7 pagesR410A handling, design and installation guideEdward ChalloyNo ratings yet

- Ficha Técnica CompresorDocument4 pagesFicha Técnica CompresorPaulo Aparicio PortugalNo ratings yet

- Catalogue: Product Select Unit SettingsDocument3 pagesCatalogue: Product Select Unit Settingsأبو زينب المهندسNo ratings yet

- RS 50 R442A Bitzer CompressorsDocument5 pagesRS 50 R442A Bitzer CompressorsfarideNo ratings yet

- Distillation Column Design BasicsDocument24 pagesDistillation Column Design BasicsArjumand UroojNo ratings yet

- 4CES-9 R404A t0 - 7 TC 45Document4 pages4CES-9 R404A t0 - 7 TC 45Tedy ChriswandaNo ratings yet

- Fundamentals of Hydrocarbon Phase BehaviorDocument49 pagesFundamentals of Hydrocarbon Phase BehaviorabduNo ratings yet

- CO2 Refrigerant Guide for Industrial Refrigeration SystemsDocument81 pagesCO2 Refrigerant Guide for Industrial Refrigeration Systemsmirali74No ratings yet

- Columbus - Refrigerants Management Retrofits en Us 3663400 PDFDocument25 pagesColumbus - Refrigerants Management Retrofits en Us 3663400 PDFJefferson Emidio (je e fé)No ratings yet

- Bitzer Selection SoftwareDocument6 pagesBitzer Selection SoftwareAniol Coll AlarconNo ratings yet

- Evaluation of Performance of Heat Pump Using R32 and HFO-mixed ReDocument11 pagesEvaluation of Performance of Heat Pump Using R32 and HFO-mixed ReCypresDelaCruzSalvadorNo ratings yet

- R290 Propane: AJ AE HG VTCDocument16 pagesR290 Propane: AJ AE HG VTCengmec12188No ratings yet

- light commercial compressor技术交流资料20170702Document29 pageslight commercial compressor技术交流资料20170702Ali MoazzamNo ratings yet

- Fernández-Seara 2010 IJR R22 Substitutes Condensation CuNi Turbo CDocument10 pagesFernández-Seara 2010 IJR R22 Substitutes Condensation CuNi Turbo CJose Iglesias PradoNo ratings yet

- GEA - Bock - SemiHerm - Catalogue - GB 48Document1 pageGEA - Bock - SemiHerm - Catalogue - GB 48hadi mehrabiNo ratings yet

- FCC Fundamentals Workshop TitleDocument68 pagesFCC Fundamentals Workshop Titlevenkatraman1985100% (1)

- SCI Rotary Compressor PDFDocument13 pagesSCI Rotary Compressor PDFcalvin.bloodaxe4478100% (1)

- Selection: Semi-Hermetic Reciprocating Compressors: Input ValuesDocument5 pagesSelection: Semi-Hermetic Reciprocating Compressors: Input ValuesoozNo ratings yet

- AE1390YDocument1 pageAE1390YramaramadhanxvNo ratings yet

- Compresor 4he-25 R507a t0 - 28 TC 45 (1) CongeladoDocument5 pagesCompresor 4he-25 R507a t0 - 28 TC 45 (1) CongeladoArturo 1No ratings yet

- Compreso 4ves-10 R507a t0 - 8 TC 45 Cuarto 0cDocument5 pagesCompreso 4ves-10 R507a t0 - 8 TC 45 Cuarto 0cArturo 1No ratings yet

- Selection: Semi-Hermetic Screw Compressors HS: Input ValuesDocument5 pagesSelection: Semi-Hermetic Screw Compressors HS: Input ValuesTedy ChriswandaNo ratings yet

- LH135E-4JE-22 R134a t0 - 15 Tamb 30Document4 pagesLH135E-4JE-22 R134a t0 - 15 Tamb 30Caio CesarNo ratings yet

- A Natural Refrigeration System For Supermarkets Using CO2Document16 pagesA Natural Refrigeration System For Supermarkets Using CO2Behnam AshouriNo ratings yet

- Form 5-492 System Considerations For Refrig Blends PDFDocument24 pagesForm 5-492 System Considerations For Refrig Blends PDFDirt FilterNo ratings yet

- CO & CO2 ConsiderationsDocument5 pagesCO & CO2 Considerationsdhanasekaran19731945No ratings yet

- AE 2428ZK-SR Hermetic Compressor SpecsDocument1 pageAE 2428ZK-SR Hermetic Compressor Specsphuongtn1991No ratings yet

- Ae 2420ZK 301 A0Document1 pageAe 2420ZK 301 A0Adam NabawiNo ratings yet

- BITZER Software Analysis of Open Screw CompressorsDocument6 pagesBITZER Software Analysis of Open Screw CompressorsRajkumar GulatiNo ratings yet

- 新冷媒相关Document5 pages新冷媒相关ruoqi.chengNo ratings yet

- BITZER OS Compressor SimulationDocument6 pagesBITZER OS Compressor SimulationRajkumar GulatiNo ratings yet

- Simulation and Validation of A R404A - CO2 Cascade Refrigeration SyDocument9 pagesSimulation and Validation of A R404A - CO2 Cascade Refrigeration SyDan IonascuNo ratings yet

- Nominal Performance: Hermetic Compressor Model: La 5590exg BOM ID: 016-A0Document1 pageNominal Performance: Hermetic Compressor Model: La 5590exg BOM ID: 016-A0Zikko FirmansyahNo ratings yet

- LH135-4PES-15 R404A t0 - 25 Tamb 43Document4 pagesLH135-4PES-15 R404A t0 - 25 Tamb 43Bashir SalimNo ratings yet

- Refrigration SystemDocument32 pagesRefrigration Systemsachin0% (1)

- The Use of R-407CDocument6 pagesThe Use of R-407CdokundotNo ratings yet

- Lp-Gas Serviceman'S Manual: Now Available in The Rego App!Document56 pagesLp-Gas Serviceman'S Manual: Now Available in The Rego App!Shehab Abu AhmadNo ratings yet

- Hydrotreating Unit Operating VariablesDocument45 pagesHydrotreating Unit Operating VariablesAn Lê TrườngNo ratings yet

- TSB1380YGSDocument2 pagesTSB1380YGSlelopNo ratings yet

- (B) Industrial Hygiene May 2017Document23 pages(B) Industrial Hygiene May 2017scribideNo ratings yet

- Compressor BITZER Open TypeDocument6 pagesCompressor BITZER Open Typejorge castilloNo ratings yet

- Julabo F32 He 9212632 en UsDocument4 pagesJulabo F32 He 9212632 en UsShayane PereiraNo ratings yet

- Natural Refrigerant Based Airconditioning With Module On R290 SystemsDocument55 pagesNatural Refrigerant Based Airconditioning With Module On R290 SystemsÁlvaro ArangoNo ratings yet

- Heat Pumps Co2Document8 pagesHeat Pumps Co2Domagoj VulinNo ratings yet

- Application r290 11-2000 cn60f102Document12 pagesApplication r290 11-2000 cn60f102Giorgio OlianasNo ratings yet

- CO2 Refrigeration, Air Conditioning and Heat Pump TechnologyDocument13 pagesCO2 Refrigeration, Air Conditioning and Heat Pump TechnologyOnofreHalberNo ratings yet

- R410A Refrigerant Guide: Properties, Tools and Installation TipsDocument24 pagesR410A Refrigerant Guide: Properties, Tools and Installation TipsubndhnNo ratings yet

- GEA - Bock - SemiHerm - Catalogue - GB 25Document1 pageGEA - Bock - SemiHerm - Catalogue - GB 25hadi mehrabiNo ratings yet

- Aw2510z 9Document1 pageAw2510z 9Duong PhạmNo ratings yet

- Readin Writing2Document5 pagesReadin Writing2hjduarteNo ratings yet

- J GustavssonDocument24 pagesJ Gustavssonhjduarte100% (1)

- Hvac Long Form ChecklistDocument15 pagesHvac Long Form ChecklistPaul Garcia100% (4)

- I2 Fin RepDocument123 pagesI2 Fin RephjduarteNo ratings yet

- En 12101 344 Powered Smoke Exhaust SystemsDocument6 pagesEn 12101 344 Powered Smoke Exhaust SystemspsmanasseNo ratings yet

- Hvac Long Form ChecklistDocument15 pagesHvac Long Form ChecklistPaul Garcia100% (4)

- Hvac SHRTDocument4 pagesHvac SHRTHaroon GhaniNo ratings yet

- Pitotless Nozzle InstDocument1 pagePitotless Nozzle InsthjduarteNo ratings yet

- 0514 RtuDocument4 pages0514 RtuhjduarteNo ratings yet

- Scheduled Maintenance for HVAC and Refrigeration EquipmentDocument9 pagesScheduled Maintenance for HVAC and Refrigeration Equipmenthjduarte100% (1)

- DOE Technical Standards List IndexDocument127 pagesDOE Technical Standards List IndexhjduarteNo ratings yet

- Requirements For Seasonal Efficiency For Air-Conditioning UnitsDocument4 pagesRequirements For Seasonal Efficiency For Air-Conditioning UnitsmanchuricoNo ratings yet

- Eurovent 9 - 5 - 2002Document36 pagesEurovent 9 - 5 - 2002hjduarteNo ratings yet

- Approved - Guidance: GNB-CPDDocument3 pagesApproved - Guidance: GNB-CPDhjduarteNo ratings yet

- Brake L Specification Text Brake Leur ADocument3 pagesBrake L Specification Text Brake Leur AhjduarteNo ratings yet

- RFP 11 13 Amendment001 PDFDocument43 pagesRFP 11 13 Amendment001 PDFhjduarteNo ratings yet

- Datwiler Manual 2008 v3 enDocument57 pagesDatwiler Manual 2008 v3 enhjduarteNo ratings yet

- InformacioTecnica 02 SODECADocument10 pagesInformacioTecnica 02 SODECAbioarquitecturaNo ratings yet

- Catinternational E06 PDFDocument508 pagesCatinternational E06 PDFhjduarteNo ratings yet

- RS 6C007 2018 - RTDocument27 pagesRS 6C007 2018 - RThjduarteNo ratings yet

- Catinternational E06 PDFDocument508 pagesCatinternational E06 PDFhjduarteNo ratings yet

- 28 Ehps 2015 FX Ball v2fcDocument31 pages28 Ehps 2015 FX Ball v2fchjduarteNo ratings yet

- Eurammon 01 enDocument3 pagesEurammon 01 enhjduarteNo ratings yet

- AL-KO Prospekt Hygiene EnglDocument8 pagesAL-KO Prospekt Hygiene EnglLeed ENNo ratings yet

- Brakel Eura Excellent: Highly Insulated Louvred VentilatorDocument4 pagesBrakel Eura Excellent: Highly Insulated Louvred VentilatorhjduarteNo ratings yet

- Calculating SCOP for heat pumpsDocument10 pagesCalculating SCOP for heat pumpsRicardo FigueiraNo ratings yet

- Claraboias DesenfumagemDocument2 pagesClaraboias DesenfumagemPaulo CostaNo ratings yet

- Brakel Eura Excellent: Highly Insulated Louvred VentilatorDocument4 pagesBrakel Eura Excellent: Highly Insulated Louvred VentilatorhjduarteNo ratings yet

- Brakel Optima: Thermally Separated Louvred VentilatorDocument4 pagesBrakel Optima: Thermally Separated Louvred VentilatorhjduarteNo ratings yet

- Af521 (2012) - ManDocument22 pagesAf521 (2012) - ManNUCLEONIX SYSTEMS PVT LTDNo ratings yet

- P 2 TLDocument9 pagesP 2 TLgresyestepinaNo ratings yet

- Engineering Failures Case StudiesDocument3 pagesEngineering Failures Case Studiesamanpreet_ahujaNo ratings yet

- Boeing 747-400 White Cockpit TourDocument5 pagesBoeing 747-400 White Cockpit ToursakiNo ratings yet

- GS Ep Civ 501 enDocument22 pagesGS Ep Civ 501 enHuy Nguyễn Võ XuânNo ratings yet

- Road Signs and Pavement MarkingsDocument89 pagesRoad Signs and Pavement MarkingsBrian PaulNo ratings yet

- Man 1-87 Ing 3 Ed - BBVDocument24 pagesMan 1-87 Ing 3 Ed - BBVaironyxNo ratings yet

- The Naughty BusDocument2 pagesThe Naughty BusSITI ELINA BINTI MD ZIN MoeNo ratings yet

- 1561717115940-Revised June 2019 Ldce Question Bank HelpersDocument85 pages1561717115940-Revised June 2019 Ldce Question Bank HelpersJaikanthan DasarathaNo ratings yet

- Horizontal Curve Excel SheetDocument9 pagesHorizontal Curve Excel SheetTarunNo ratings yet

- BMW 7-Series Project Process ChangesDocument27 pagesBMW 7-Series Project Process ChangesSambit RoyNo ratings yet

- Nissan e-NV200 Evalia: Details of Tested CarDocument5 pagesNissan e-NV200 Evalia: Details of Tested CarJonatan Raya SánchezNo ratings yet

- 1 Medio Ruta de Aprendizaje 07 - 08 - 09Document32 pages1 Medio Ruta de Aprendizaje 07 - 08 - 09nanolakesNo ratings yet

- 737 Incident ReportDocument61 pages737 Incident ReportAbdul Qadeer Khan100% (1)

- Horizontal Airflow Carbonization MachineDocument3 pagesHorizontal Airflow Carbonization MachineTintin HaberNo ratings yet

- 287 HO 04 Vario Roof (CrullG) 08-17-04Document32 pages287 HO 04 Vario Roof (CrullG) 08-17-04arkhom167% (3)

- Scientific American Architects and Builders Edition 1890 Jan-JunDocument240 pagesScientific American Architects and Builders Edition 1890 Jan-JunNickiedeposieNo ratings yet

- Aws WJ 201409Document166 pagesAws WJ 201409spineyro1500No ratings yet

- SH1.RFP - P4 OTR - Ch1 General Description - 140530Document18 pagesSH1.RFP - P4 OTR - Ch1 General Description - 140530Minh Hoang NguyenNo ratings yet

- A City Break British English TeacherDocument5 pagesA City Break British English TeacherJuanitaGomezMorenoNo ratings yet

- TLIC107C - Drive Vehicle - Learner GuideDocument101 pagesTLIC107C - Drive Vehicle - Learner GuideromerofredNo ratings yet

- Radio and Player Wiring DiagramDocument4 pagesRadio and Player Wiring DiagramHerson EscobarNo ratings yet

- AR542/ Regulation & Law - Lecture 1Document21 pagesAR542/ Regulation & Law - Lecture 1Narden AshrafNo ratings yet

- copeland-stream-digital-compressors-4MFD-13x-to-4MKD-35x-6mmd-30x-to-6MKD-50x - DWMDocument31 pagescopeland-stream-digital-compressors-4MFD-13x-to-4MKD-35x-6mmd-30x-to-6MKD-50x - DWMdenilson carvalho guimaraesNo ratings yet

- Podgorica To Prishtina in 5 DaysDocument2 pagesPodgorica To Prishtina in 5 Daysapi-357009030No ratings yet

- VW Polo Sales PitchDocument10 pagesVW Polo Sales Pitchcool47guy09No ratings yet

- The circulatory system transports oxygen and nutrientsDocument2 pagesThe circulatory system transports oxygen and nutrientsAmarpreet Kaur100% (1)

- Bus Ticket TS4D43900748Document5 pagesBus Ticket TS4D43900748Shivam YadavNo ratings yet

- APSRTC Official Website For Online Bus Ticket Booking - APSRTConline1Document2 pagesAPSRTC Official Website For Online Bus Ticket Booking - APSRTConline1Shahbaz AlamNo ratings yet

- Handbooks NCDL EnglishDocument52 pagesHandbooks NCDL EnglishSaurabh SharmaNo ratings yet