Professional Documents

Culture Documents

Notes Structural Design 1-2

Uploaded by

Athiyo MartinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes Structural Design 1-2

Uploaded by

Athiyo MartinCopyright:

Available Formats

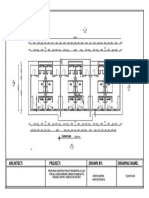

KYAMBOGO UNIVERSITY

FACULTY OF ENGINEERING

Department of Civil & Building Engineering

BACHELOR OF ENGINEERING IN CIVIL AND BUILDING ENGINEERING

YEAR III, SEMESTER I

LECTURE NOTES

TCBE 3101: STRUCTURAL DESIGN I

By

OLENG MORRIS

(Course Lecturer)

0703688747 or 0772285215

wotamuko@gmail.com

Edition, August 2016

Table of Contents

Preamble

Brief Description

Bridges the transition from Analysis to design, by explaining how forces used in analysis are

obtained from people and other objects and the materials of the structure.

Explains the properties of materials that make up reinforced concrete.

Reviews analysis using a method that can be used with an electronic calculator and computer

to obtain applied internal actions / forces

Explains the concept of design of all the major components of a reinforced concrete building

where the strength of these components must be greater than the applied forces by a

reasonable margin, and where each component must be checked for each of the possible

modes of failure.

Objectives

By the end of the course the student should be able to:

Calculate the forces applied to the structure arising from its weight, expected usage and

external loads;

Demonstrate understanding of the behaviour of reinforced concrete and its constituent

materials and be able to predict its behaviour under all the expected loading and

environmental conditions;

Analyze; i.e. determine all internal actions (Axial load, shear force, bending and torsion

moments) on each member of the structure using a calculator and computer;

Identify all possible causes and modes of failure;

Design all the major components of a reinforced concrete building to prevent any mode of

failure occurring.

Detailed Course Description

Introduction to Limit State Design (5 hours)

Ultimate limit state: considering Strength, stability and robustness

Serviceability limit state: Deflection, Durability (fire and corrosion resistance), Vibration

Material properties for steel and concrete and partial safety factor for materials.

Design Standards: Historical review, Elastic Analysis; CP114, Limit state Design; CP110 and BS

8110, EC2

Loading: dead, wind , imposed and notional loads , load combinations and Partial safety factors

for loads

Robustness & Design of ties, Importance of robustness in explosions and terrorists attack.

Analysis of framed structures using moment distribution and computer applications

Shear, Bond & Torsion (5 hours)

Shear strength of a reinforced concrete beam without links

Shear resistance of links

Shear resistance of Bent up bars

Shear in slabs

Local bond, Anchorage bond and length

OLENG Morris (+256703688747) Page i Edition 2016

Preamble

Hooks, bends, laps, joints

Torsion analysis, Torsion shear stress & reinforcement

Design of Beams (15 hours)

Simply supported & continuous beams; (loading, analysis, moment redistribution)

Analysis of beams : Assumptions, parabolic & Rectangular Stress blocks

Singly reinforced beams: Moments of resistance, balanced, under and over reinforced section,

Design of section using analytical & design charts.

Design of Doubly Reinforced beams

Design of Flanged beams; with Neutral axis in the in web or flange

Design of slabs (10 hours)

Classification of slabs based on: Nature of support (simply supported, continuous, flat slabs),

Direction of support (One way and two way supporting), Type of section (solid, hollow blocks,

ribbed slabs),

Design of main and secondary slab reinforcement in one way (solid & ribbed/hollow block) slab,

and two way slab

Checking for Shear control in slabs

Checking for Deflection control in slabs

Checking for Cracking control in slabs

Anchorage and detailing

Introduction to Yield line method

Design of Staircases; A special type of slopping slabs (5 hours)

Classification of stairs into transverse and longitudinal spanning,

Relevant Building regulations ,determination of staircase loading and analysis of staircases,

Design of main and provision of distribution steel, checking for shear, deflection, cracking.

Detailing of and anchorage.

Design of Columns (8 hours)

Classification: (short & slender columns, Braced & unbraced columns)

Section analysis

Design of short Columns subjected to only to axial loads

Design of short column subjected to axial loads & uniaxial bending using charts.

Design of short columns subjected to axial loads & biaxial Bending; (Analytical use of charts)

Design of slender columns

Checking columns for shear strength.

Design of Walls (2 hours)

Functions Types & loads on walls

Design of Reinforced concrete walls

Design of plane concrete walls

Design of foundations (6 hours)

Design of axially loaded pad bases; determination of pad size and depth, Design for moment

steel, checking for Vertical and punching shear.

Discussion of Eccentrically loaded pad bases

Discussion of Design of Raft, strip and combined foundations

Discussion of Pile foundations

OLENG Morris (+256703688747) Page ii Edition 2016

Preamble

Retaining wall structures (5 hours)

Earth Pressure and Types of retaining walls

Discussion of design of cantilever walls

Discussion of design of Counterfort retaining walls

Introduction to Prestressed Concrete (8 hours)

Advantages prestressed concrete

Pretensioning and Postensioning

Design of prestressed beams for Serviceability limit state and ultimate limit state.

Stress loss at transfer for beams

Detailing (2 hours)

Bar Bending Schedules

Detailing and curtailment of bars

Evaluation of Concrete (4 hours)

Defects in Concrete

Field evaluation of concrete defects

Repair of defects

Modes of Course Delivery

The course will be taught using lecturers, tutorials; assignments and field visits.

Assessment

The course will be assessed through assignments, tests, practical reports, field visit reports and course

examination. Their relative contribution to the final grade is shown below:

Requirements Contribution

Assignments 15%

Tests 25%

Final course examination 60%

Total 100%

OLENG Morris (+256703688747) Page iii Edition 2016

Table of Contents

Table of Contents

Preamble .............................................................................................................................................. i

Brief Description ............................................................................................................................. i

Objectives ........................................................................................................................................ i

Detailed Course Description ............................................................................................................ i

Modes of Course Delivery ............................................................................................................. iii

Assessment .................................................................................................................................... iii

Table of Contents ............................................................................................................................... iv

CHAPTER I. INTRODUCTION.........................................................................................................1

1.0 General ..................................................................................................................................1

Assumptions made in structural design .......................................................................................1

Structural design procedure .........................................................................................................1

1.1 Historical Perspective ...........................................................................................................1

1.1.1 General ...........................................................................................................................1

1.1.2 The Elastic Design. ........................................................................................................2

1.1.2 CP 114 ...........................................................................................................................2

1.3 Introduction to limit state design. .........................................................................................2

1.4 Introduction to Eurocode 2 ...................................................................................................2

1.5 Why change to Euro code II from BS8110 ...........................................................................3

CHAPTER II. PROPERTIES OF REINFORCED CONCRETE........................................................4

2.0 Introduction ...........................................................................................................................4

2.1 Composite action...................................................................................................................4

2.2 Stress strain relations .........................................................................................................5

2.2.1 Stress Strain relationship of concrete .........................................................................5

2.2.2 Stress- Strain relationship of steel .................................................................................7

2.3 Shrinkage and thermal movement.........................................................................................8

2.3.1 Causes of shrinkage .......................................................................................................8

2.3.2 Calculation of stresses induced by shrinkage ................................................................8

2.3.2 Factors affecting shrinkage ..........................................................................................11

2.4 Creep ................................................................................................................................11

2.4.1 General .........................................................................................................................11

2.4.2 Characteristic of Creep ................................................................................................11

2.4.3 Effects of Creep ...........................................................................................................12

CHAPTER III. LIMIT STATE DESIGN ..........................................................................................13

3.0 Introduction .........................................................................................................................13

3.0.1 The permissible stress method. ....................................................................................13

OLENG Morris (+256703688747) Page iv Edition 2016

Table of Contents

3.0.2 The Load factor Method. .............................................................................................13

3.0.3 Limit State Method ......................................................................................................13

3.1 Limit states ..........................................................................................................................13

3.1.1 The Ultimate Limit State. ............................................................................................14

3.1.2 Serviceability Limit State ............................................................................................19

3.2 Characteristic material strength ..........................................................................................22

3.2.1 General .........................................................................................................................22

3.2.2 Concrete (Cl. 3.1, EC 2) ..............................................................................................23

3.2.3 Reinforcement of steel. (Cl. 3.2, EC 2) .......................................................................24

3.3 Partial factors of safety .......................................................................................................26

3.4 Combination of actions .......................................................................................................30

3.4.1 Action (Load) arrangements ........................................................................................30

3.4.2 Combination of actions (Loads) ..................................................................................30

3.4.3 Combination expressions .............................................................................................33

3.5 Wind Loads .........................................................................................................................34

CHAPTER IV. ANALYSIS OF THE STRUCTURE AT THE ULTIMATE LIMIT STATE .........37

4.0 Introduction .........................................................................................................................37

4.1 Actions ................................................................................................................................37

4.1.1 Permanent actions ........................................................................................................37

4.1.2 Variable actions ...........................................................................................................37

4.2 Load combinations and patterns for ultimate limit state .....................................................37

4.3 Analysis of beams ...............................................................................................................38

4.3.1 Non continuous beams ..............................................................................................39

4.3.2 Continuous beams ........................................................................................................40

4.4 Analysis of frames ..............................................................................................................44

4.4.1 Braced frames supporting vertical loads only .............................................................45

4.4.2 Lateral loads on frames ................................................................................................50

4.5 Redistribution of moments ..................................................................................................54

CHAPTER V. ANALYSIS OF THE SECTION ...............................................................................56

5.1 Stress Strain Relations .....................................................................................................56

5.1.1 Concrete .......................................................................................................................56

5.1.2 Reinforcing steel ..........................................................................................................56

5.2 Distribution of strains and stress across a section in bending .............................................57

5.3 Bending and the equivalent rectangular stress block ..........................................................59

5.4 Singly reinforced rectangular section in bending at the ultimate limit state .......................59

5.4.1 Design equations for bending ......................................................................................59

5.4.2 The balanced section....................................................................................................60

OLENG Morris (+256703688747) Page v Edition 2016

Table of Contents

5.4.3 Analysis equation for a singly reinforced section ........................................................61

5.5 Rectangular section in bending with compression reinforcement at the ultimate limit state

.63

5.5.1 Derivation of basic equations ......................................................................................63

5.5.2 Numerical Examples ....................................................................................................65

5.6 Flanged section in bending at the ultimate limit state .........................................................66

5.6.1 Flanged section- the depth of the stress block lies within the flange, s h f ..............67

s hf

5.6.2 Flanged section- the depth of the stress block extends below the flange, ........68

5.7 Moment redistribution and the design equations ................................................................72

CHAPTER VI. SHEAR AND BOND ...............................................................................................76

6.1 Shear....................................................................................................................................76

6.1.1 The variable strut inclination method for sections that do require shear reinforcement

..76

6.1.2 Bent-up bars .................................................................................................................79

6.2 Anchorage bond ..................................................................................................................81

6.2.1 General .........................................................................................................................81

6.2.2 Basic anchorage length ................................................................................................81

6.2.3 Design anchorage length..............................................................................................82

CHAPTER VII. DESIGN OF REINFORCED CONCRETE BEAMS .............................................86

7.0 Introduction .........................................................................................................................86

7.1 Preliminary analysis and member sizing ............................................................................86

7.1.1 Overview......................................................................................................................86

7.1.2 Span-effective depth ratios ..........................................................................................90

7.2 Design for bending of a rectangular section with no moment redistribution......................94

7.2.1 Requirements ...............................................................................................................94

7.2.2 Singly reinforced rectangular sections, no moment redistribution ..............................95

7.2.3 Rectangular sections with tension and compression reinforcement, no moment

redistribution ..............................................................................................................................96

7.3 Design for bending of a rectangular section with moment redistribution...........................98

7.3.1 Singly reinforced rectangular sections with moment redistribution ............................98

7.3.2 Rectangular sections with tension and compression reinforcement with moment

redistribution applied (based on the UK Annex to EC2) ...........................................................98

7.4 Flanged beams...................................................................................................................100

7.4.1 Overview....................................................................................................................100

7.4.2 Design procedure for a flanged beam subject to a sagging moment .........................102

7.4.3 Shear between the web and flange of a flanged section ............................................102

7.5 One span beams .............................................................................................................106

7.6 Design for shear ................................................................................................................107

OLENG Morris (+256703688747) Page vi Edition 2016

Table of Contents

7.6.1 General Overview ......................................................................................................107

7.6.2 Vertical stirrups or links ............................................................................................108

7.6.3 Bent-up bars to resist shear ........................................................................................111

7.7 Continuous beams .............................................................................................................111

7.8 Curtailment and anchorage of reinforcing bars.................................................................116

CHAPTER VIII. DESIGN OF REINFORCED CONCRETE SLABS ...........................................119

8.0 Introduction .......................................................................................................................119

8.0.1 Classification of Slabs ...............................................................................................119

8.0.2 Concrete sections that do not require design shear reinforcement ............................119

8.1 Shear in slabs ....................................................................................................................120

8.1.1 Introduction................................................................................................................120

8.1.2 Punching shear analysis .............................................................................................120

8.1.3 Punching shear reinforcement design ........................................................................122

8.2 Span effective depth ratios .............................................................................................125

8.3 Reinforcement details .......................................................................................................125

8.4 One Way Spanning Solid Slabs .....................................................................................125

8.4.1 Single-span solid slabs ...............................................................................................126

8.4.2 Continuous solid slab spanning in one direction .......................................................128

8.5 Two Way Spanning Solid Slabs.....................................................................................131

8.5.1 Simply supported slab spanning in two directions ....................................................131

8.5.2 Restrained slab spanning in two directions ...............................................................133

8.6 Ribbed and Hollow Block Slabs .......................................................................................136

8.6.1 Classification; ............................................................................................................136

8.6.2 Advantages of Ribbed and hollow block slabs: .........................................................136

8.6.3 Design ........................................................................................................................136

8.7 Stair slabs ..........................................................................................................................144

8.7.1 General .......................................................................................................................144

8.7.2 Stairs spanning horizontally ......................................................................................144

8.7.3 Stair slab spanning longitudinally .............................................................................145

CHAPTER IX. DESIGN OF COLUMNS.......................................................................................147

9.0 Introduction .......................................................................................................................147

9.1 Classification of Columns .................................................................................................147

9.2 Slenderness ratio, Effective height and Limiting slenderness ratio of column .................148

9.2.1 Slenderness ratio of a column ....................................................................................148

l0

9.2.2 Effective height of a column .................................................................................148

9.2.3 Limiting slenderness ratio-short or slender columns .................................................149

9.3 Reinforcement details .......................................................................................................152

OLENG Morris (+256703688747) Page vii Edition 2016

Table of Contents

9.3.1 Longitudinal steel ......................................................................................................152

9.3.2 Links ..........................................................................................................................152

9.4 Short columns resisting moments and axial forces ...........................................................152

9.5 Design equations for a non-symmetrical section ..............................................................158

9.6 Design of slender columns ................................................................................................161

CHAPTER X. DESIGN OF FOUNDATIONS ...............................................................................165

10.1 Introduction ...................................................................................................................165

10.1.1 General .......................................................................................................................165

10.1.2 Foundation types ........................................................................................................165

10.1.3 Foundation design ......................................................................................................166

10.2 Pad footings ...................................................................................................................167

10.2.1 Overview....................................................................................................................167

10.2.2 Requirements .............................................................................................................168

10.2.3 Design Procedure .......................................................................................................169

OLENG Morris (+256703688747) Page viii Edition 2016

Chapter I: Introduction

CHAPTER I. INTRODUCTION

1.0 General

A structure is any load bearing construction; in other words it is an organized assembly of connected

parts designed to provide mechanical resistance and stability.

Assumptions made in structural design

a) Structures are designed by appropriately qualified and experienced personnel.

b) Adequate supervision and quality control is provided in factories, plants and site.

c) Construction is carried out by personnel with appropriate skills and experience.

d) The construction materials and products are used as specified in euro code II or in the relevant

materials or product specifications.

e) The structure will be adequately maintained.

Structural design procedure

The architect determines arrangement of elements to meet the clients requirements. This is availed

to the structural engineer as architectural plants. The structural engineer determines the best structural

system to fit the architects concept. There are two structural systems are

framed

framed with shear walls

After completing the structure arrangement/ structure lay out, the design process consists of the

following steps.

i) Idealization of the structure into load bearing frames and elements for analysis and design.

ii) Estimation of loads based on materials and use of structure.

iii) Analysis to determine the maximum moments, axial forces, shear and torsional forces, and

deflection for design.

iv) Design of concrete sections and reinforcement areas and layout for slabs, beams, columns,

walls and foundations.

v) Production of detailed drawings and bar bending schedules.

1.1 Historical Perspective

1.1.1 General

The Eurocodes are a family of ten European codes of practice for the design of building and civil

engineering structures in concrete, steel, timber and masonry, amongst other materials. Table 7.1 lists

the reference numbers and titles of the ten Eurocodes. Like the present UK codes of practice,

Eurocodes will come in a number of parts, each containing rules relevant to the design of a range of

structures including buildings, bridges, water retaining structures, silos and tanks. EN 1991 provides

characteristic values of loads (termed actions in Eurocode-speak) needed for design. EN 1990, the

head Eurocode, is the worlds first materialindependent design code and provides guidance on

determining the design value of actions and combination of actions, including partial safety factors

for actions. EN 1997 covers the geotechnical aspect of foundation design. EN 1998 is devoted to

earthquake design and provides guidance on achieving earthquake resistance of buildings, bridges,

towers, geotechnical structures, amongst others.

Uganda being a former British protectorate has followed the British system of design. Upto 1972, the

British system was designing structures using the elastic design/ Modular ratio method of designing.

OLENG Morris (+256703688747) Page 1 of 173 Edition 2016

Chapter I: Introduction

Table 1-1 The Structural Eurocodes

EuroNorm reference Title

EN1990 Eurocode 0: Basis of design

EN1991 Eurocode 1: Actions on structures

EN1992 Eurocode 2: Design of concrete structures

EN1993 Eurocode 3: Design of steel structures

EN1994 Eurocode 4: Design of composite steel and concrete structures

EN1995 Eurocode 5: Design of timber structures

EN1996 Eurocode 6: Design of masonry structures

EN1997 Eurocode 7: Geotechnical design

EN1998 Eurocode 8: Design of structures for earthquake resistance

EN1999 Eurocode 9: Design of aluminium structures

1.1.2 The Elastic Design.

It is based on the assumption that the stress strain behavior of both steel and concrete remain elastic

i.e. stress is proportional to strain.

Force , change in length , and Stress

Stress Strain Modulus of Elasticty

Area original length Strain

Both the concrete and steel have a constant modulus of elasticity; E s Ec , and therefore there is

Es

a fixed ratio of moduli that n .

Ec

It further implies that the stresses are limited to permissible values.

The code of practice in use was CP 114.

1.1.2 CP 114

Multiplies a factor of a third (1 / 3) by the cube stress to obtain the permissible stress of concrete

under bending/flexure.

If divides the yield stress by factor of 1.8 to get the permissible stress in steel.

The permissible stress of steel was limited to 230N / mm 2 whatever the grade of steel. This

limitation aimed at controlling the crack width since at the permissible stress of steel in tension,

the surrounding concrete has cracked.

1.3 Introduction to limit state design.

In 1972, a limit state design code CP110 was introduced but it was not until 1986 that Engineers in

Uganda switched to limit state design. In 1985. CP110 was withdrawn. A new limit state design code

BS 8110 was introduced. This has undergone a series of amendment until it was withdrawn in 2010.

Euro code II was introduced in 2000 and has been working hand in hand with BS8110. Euro code II

applies to normal weight concrete. The design rules of Eurocode II is based only on the f ck of

cylinders at 28days. Cube strength is mentioned only as an alternative to prove compliance.

1.4 Introduction to Eurocode 2

Eurocode 2 applies to the design of buildings and civil engineering works in concrete. It is based on

limit state principles and comes in four parts as shown in Table 1-2 below.

Part 1.1 of Eurocode 2 gives a general basis for the design of structures in plain, reinforced,

lightweight, pre-cast and prestressed concrete. In addition, it gives some detailing rules which are

OLENG Morris (+256703688747) Page 2 of 173 Edition 2016

Chapter I: Introduction

mainly applicable to ordinary buildings. It is largely similar in scope to BS 8110 which it will replace

by about 2010. Design of building structures cannot wholly be undertaken using Part 1.1 of Eurocode

2, however. Reference will have to be made to a number of other documents, notably EN 1990

(Eurocode 0) and Eurocode 1 to determine the design values of actions (section 8.5), BS 4449 for

mechanical properties of reinforcing steel (section 8.4.1), Part 1.2 of Eurocode 2 for fire design

(section 8.7.1), BS 8500 and EN 206 for durability design (section 8.7.2) and Eurocode 7 for

foundation design (Fig. 8.1).

Table 1-2 Scope of Eurocode 2: Design of Concrete Structures

Part Subject

1.1 General rules and rules for buildings

1.2 Structural fire design

2 Reinforced and prestressed concrete bridges

3 Liquid retaining and containment structures

The main reason cited for structuring the information in this way is to avoid repetition and make the

design guidance in Part 1.1 more concise than BS 8110. Part 1.1 of Eurocode 2, hereafter referred to

as EC 2, was issued as a preliminary standard or ENV in 1992 and in final form as BS EN 1992-1-1

in 2004. The following subjects are covered in EC 2:

Section 1: General

Section 2: Basis of design

Section 3: Materials

Section 4: Durability and cover to reinforcement

Section 5: Structural analysis

Section 6: Ultimate limit states

Section 7: Serviceability limit states

Section 8: Detailing of reinforcement and prestressing tendons General

Section 9: Detailing of members and particular rules

Section 10: Additional rules for precast concrete elements and structures

Section 11: Lightweight aggregate concrete structures

Section 12: Plain and lightly reinforced concrete structures

Also included are ten annexes which provide supplementary information on a range of topics

including creep and shrinkage, reinforcing steel, durability design and analysis of flat slabs and shear

walls.

1.5 Why change to Euro code II from BS8110

(a) Euro code II results in more economic structures.

(b) Euro code II is less restrictive than British standards.

(c) Euro code II is extensive and comprehensive.

(d) The new Euro codes are claimed to be the most technically advanced codes in the world.

(e) Europe, all public works must follow Euro codes for structural design, implying that KYU

graduates would be able to work in Europe and probably the whole of Africa.

(f) Euro codes are logical and organized to avoid repetition.

OLENG Morris (+256703688747) Page 3 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

CHAPTER II. PROPERTIES OF REINFORCED CONCRETE

2.0 Introduction

Reinforced concrete consists of both concrete and steel. It is a strong durable building material that

can be formed into many varied shapes and ranging from a simple rectangular column, to a slender

curved dome or shell, its utility and versatility are achieved by combining the best features of concrete

and steel.

Table 2-1: properties of steel and concrete

Property concrete steel

Strength in tension Poor Very good

Strength in compression Good Very good but slender bars will

Strength in shear Fair buckle

Durability Good Very good

Fire resistance Good Poor, corrodes if unprotected

Poor-suffers rapid loss of strength at

high temperature

As seen from table 2-1, concrete is poor in tension, good in compression, and fair in shear. On the

other hand, steel is very good in tension, compression and shear. Thus, when they are combined, the

steel is able to provide the tensile strength and probably some of the shear strength while the concrete,

strong in compression, protects the steel to give durability and fire resistance.

i) In beams, slabs, and stair cases, where there is tension, the concrete must be reinforced by steel.

ii) In areas where the compression forces are very high such as columns, concrete must be

reinforced by steel and the steel must be tied and surrounded by concrete in order not to buckle.

Steel is poor in durability and fire resistance while concrete is good, therefore concrete must provide

cover to protect the steel.

2.1 Composite action

The tensile strength of concrete is only about 10 per cent of the compressive strength. Because of

this, nearly all reinforced concrete structures are designed on the assumption that the concrete does

not resist any tensile forces. Reinforcement is designed to carry these tensile forces, which are

transferred from concrete to steel by bond which is achieved by;

i) Using concrete with f ck 20N / mm2

ii) Well compacted concrete around reinforcement bars.

iii) Ribbed and twisted bars to give an extra mechanical grip

If this bond is not adequate, the reinforcing bars will just slip within the concrete and there will not

be a composite action. Composite action is achieved when there is perfect bond such that the strain

in steel equals to that in the adjacent concrete.

The coefficients of thermal expansion for steel and for concrete are nearly the same; therefore

differential expansion does not affect bond over normal temperature ranges.

Coefficients of Thermal Expansion,

for steel 10 106 per C

for concrete (7 ~ 12) 106 per C

OLENG Morris (+256703688747) Page 4 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

Figure 2-1 illustrates the behavior of a simply supported beam subject to bending and shows the

position of steel reinforcement to resist the tensile forces, while the compression forces in the top of

the beam are carried by the concrete.

Load A

Compression

Tension Strain Section A-A

Distribution

Cracking

Reinforcement A

Fig.2-1 Composite action

Since concrete is poor in tension, the bottom concrete will crack.

However, this cracking does not detract from the safety of the structure provided there is good

reinforcement bonding to ensure that the cracks are restrained from opening so that the embedded

steel continues to be protected from corrosion.

2.2 Stress strain relations

The loads on a structure cause distortion of its members with resulting stresses and strains in the

concrete and the steel reinforcement. To carry out the analysis and design of a member it is necessary

to have a knowledge of the relationship between these stresses and strains. This knowledge is

particularly important when dealing with reinforced concrete which is a composite material; for in

this case the analysis of the stresses on a cross-section of a member must consider the equilibrium of

the forces in the concrete and steel.

2.2.1 Stress Strain relationship of concrete

Concrete is a very variable material, having a wide range of strengths and stress-strain curves. A

typical curve for concrete in compression is shown in figure 2.2. As the load is applied, the ratio

between the stresses and strains is approximately linear at first and the concrete behaves almost as

an elastic material with virtually a full recovery of displacement if the load is removed. Eventually,

the curve is no longer linear and the concrete behaves more and more as a plastic material. If the load

were removed during the plastic range the recovery would no longer be complete and a permanent

deformation would remain. The ultimate strain for most structural concretes tends to be a constant

value of approximately 0.0035, irrespective of the strength of the concrete. The precise shape of the

curve is very dependent on the length of time the load is applied. Figure 2.2 is typical for a short-

term loading.

The stress/strain diagram for concrete subject to uniaxial compression is shown in the figure below.

OLENG Morris (+256703688747) Page 5 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

c <0

simplification

fc actual

cu fc peak stress

0.4f c cl strain at the peak stress fc

Ec cu ultimate stress

Ecm

c <0

cl cu

Fig.2-2 Stress-strain diagram for uniaxial compression

CL 0.0022 , CU 0.0035 and Ecm mean value of the secant modulus

a) Strength classes of concrete

The design shall be based on the strength classes of concrete which correspond to characteristic

strength values given in table 3.1 of euro code II. Table 3.1 gives the f ck of concrete and the

corresponding tensile strength.

The quality of concrete are described by characteristic cylinder strength/ characteristic cube

strength, e.g. C30/37.

In the U.K and consequently in Uganda, compressive stress has been measured and expressed

in terms of 150mm cube crushing strength at an age of 28days. Most other countries use

150mm diameter cylinders which are 300mm long. For normal strength concrete, the cylinder

strength is equal to 0.8 of the cube strength.

All design calculations to Euro code II are based on the characteristic cylinder strength f ck .

b) Modulus of Elasticity

The modulus of elasticity depends on;

i) Strength class of concrete,

ii) Properties of aggregates used,

iii) The mean value of the secant modulus Ecm for a particular class is obtained from table 3.2 of

the code.

Table 2.2 Values of the secant modulus of elasticity E cm (in kN/mm 2 ) (based on table 3.2 EC II)

Strength

C12/15 C16/20 C20/25 C25/30 C30/37 C35/45 C40/50 C45/55 C50/60

class C

E cm 26 27.5 29 30.5 32 33.5 35 36 37

The values in table 3.2 are based on the equation.

Ecm 9.5 f ck 8

1// 3

where Ecm is in KN / mm 2

f ck is in N / mm 2 , f ck is strength at 28days

Thus Ecm is also for 28days.

The modulus of elasticity is required.

(i) When investigating deflection of a structure.

(ii) When investigating cracking of a structure.

(iii)When considering both short term and long term effects of creep and shrinkage.

OLENG Morris (+256703688747) Page 6 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

c) Poissons Ratio

For design purpose; the Poissons ratio for elastic strain is 0.2

2.2.2 Stress- Strain relationship of steel

Figure 2.3 shows typical stress strain curves for (a) hot rolled yield steel, and (b) cold-worked high

yield steel. Mild steel behaves as an elastic material, with the strain proportional to the stress up to

the yield, at which point there is a sudden increase in train with no change in stress.

After the yield point, mild steel becomes a plastic material and the strain increases rapidly up to the

ultimate value. High yield steel, which is most commonly used for reinforcement, may behave in a

similar manner or may, on the other hand, not have such a definite yield point but may show a more

gradual change from an elastic to a plastic behaviour and reduced ductility depending on the

manufacturing process.

All materials have a similar slope of the elastic region with elastic modulus E 200kN / mm 2

approximately.

0.2% proof

Yield stress

stress

stress

stress

Strain 0.002 Strain

(a) Hot rolled steel (b) Cold worked steel

Fig.2.3 Stress-strain curves for high yield reinforcing steel

The specified strength used in design is based on either the yield stress or a specified proof stress. A

0.2 per cent proof stress is defined in figure 2.4 by the broken line drawn parallel to the linear part of

the stress-strain curve.

Removal of the load within the plastic range would result in the stress-strain diagram following a line

approximately parallel to the loading portion - see line BC in figure 2.4. The steel will be left with a

permanent strain AC, which is known as slip. If the steel is again loaded, the stress-strain diagram

will follow the unloading curve until it almost reaches the original stress at B and then it will curve

in the direction of the first loading. Thus, the proportional limit for the second loading is higher than

for the initial loading. This action is referred to as strain hardening or work hardening.

B

stress

A C

Fig.2.4 Strain hardening

OLENG Morris (+256703688747) Page 7 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

2.3 Shrinkage and thermal movement

This is the reduction in volume as concrete hardens. This shrinkage is liable to cause cracking of the

concrete, but it also has beneficial effect of strengthening the bond between the concrete and the

steel reinforcement. Shrinkage begins to take place as soon as the concrete is mixed.

2.3.1 Causes of shrinkage

It is caused by;

a) Initial absorption of the water by the concrete and the aggregate.

b) Evaporation of the water which rises to the concrete surface.

c) During the hydration of cement, a great deal of heat is generated and as concrete cools, the

thermal contraction results in further shrinkage.

d) The hardened concrete continuous drying resulting in further shrinkage.

How it can be controlled;

Thermal shrinkage may be reduced by restricting temperature rise during hydration, and can be

achieved by;

a) Use a mix design with a low cement content or suitable cement replacement.

b) Avoid rapid hardening and finely ground cement if possible.

c) Keep aggregate and mixing water cool.

d) Use steel shuttering and cool with a water spray.

e) Strike the shuttering early to allow the heat of hydration to dissipate.

A low water-cement ratio will help to reduce drying shrinkage by keeping to a minimum the volume

of moisture that can be lost.

If the change in volume of the concrete is allowed to take place freely and without restraint, there

will be no stress change within the concrete. Restraint of the shrinkage, on the other hand, will cause

tensile strains and stresses. The restraint may be caused externally by fixity with adjoining members

or friction against an earth surface, and internally by the action of the steel reinforcement. For a long

wall or floor slab, the restraint from adjoining concrete may be reduced by constructing successive

bays instead of alternate bays. This allows the free end of every bay to contract before the next bay

is cast.

When tensile stresses caused by shrinkage or thermal movement exceed the strength of concrete,

cracking will occur. To control cracking, steel reinforcement must be provided close to the concrete

surface.

2.3.2 Calculation of stresses induced by shrinkage

(a) Shrinkage restrained by the reinforcement

The shrinkage stresses caused by reinforcement in an otherwise unrestrained member may be

calculated quite simply. The member shown in figure 2.5 has a free shrinkage strain of cs if made

of plain concrete, but this overall movement is reduced by the inclusion of reinforcement, giving a

compressive strain sc in the steel and causing an effective tensile strain ct the concrete.

OLENG Morris (+256703688747) Page 8 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

Original member -

as cast

cs

Plain concrete -

unrestrained

ct

Reinforced concrete -

unrestrained

sc

ct

Reinforced concrete -

fully restrained

Fig.2.5 Shrinkage strains

The free shrinkage strain in concrete Ecs is given by;

cs ct sc

where ct tensile strain in concrete.

sc compressive strain in steel.

but we know, strain( ) stress f

Young' s Modulus E

f ct f

cs ct sc sc (1)

Ecm Es

where f ct is the tensile stress in concrete area Ac and f sc is the compressive stress in steel area As .

Equating forces in the concrete and steel for equilibrium gives

Ac f ct As f sc (2)

As

therefore f ct f sc

Ac

Substituting for f ct in equation (1)

As f sc f

cs sc

Ac Ecm Es

A 1

cs f sc s

Ac Ecm Es

E

Thus if n s

Ecm

nA 1

cs f sc s

Ac Es Es

f sc nAs

1

Es Ac

Therefore the steel stress

cs E s

f sc (3)

1 nAs / Ac

OLENG Morris (+256703688747) Page 9 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

Worked Example 2.1: Calculation of shrinkage stresses in concrete that is restrained by

reinforcement only.

A member contains 1.0 per cent reinforcement, and the free shrinkage strain cs of the concrete is

200 106 . For steel, Es 200KN / mm2 and for concrete Ecm 15KN / mm2 . Determine the stresses in

steel and concrete given that the member is restrained by reinforcement only.

Solution.

As A

1% 100 s 0.01

Ac Ac

From equation (3)

cs E s

stress in reinforcement f sc

1 nAs / Ac

Es 200

where Ecs 200106 , Ecm 15KN / mm2 , Es 200KN / mm2 and n

Ecm 15

200 106 200 103

f sc

1 200 / 15 0.01

f sc 35.3 N / mm2 ( compression)

As

stress in reinforcement f ct f sc

Ac

0.01 35.3

0.35 N / mm 2 (tension)

Note: The stresses produced in members free from external restraint are generally small as example

1.1, and can be easily withstood both by the steel and the concrete.

(b) Shrinkage fully restrained

If the member is fully restrained, then the steel cannot be in compression since sc 0 and hence

f sc 0 (figure 1.7). In this case the tensile strain induced in the concrete ct must be equal to the free

shrinkage strain cs , and the corresponding stress will probably be high enough to cause cracking in

immature concrete.

Worked Example 2.2: Calculation of fully restrained shrinkage stresses

If the member in example 2.1 above was fully restrained, determine the tensile stress in concrete.

Solution.

If the member in example 1.1 was fully restrained, the stress in the concrete would be given by

f ct ct Ecm ;

where ct cs 200106

then

f ct 200 106 15 103

3.0 N / mm 2

OLENG Morris (+256703688747) Page 10 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

2.3.2 Factors affecting shrinkage

Shrinkage of concrete depends on;

a) Ambient humidity.

b) Dimensions of the elements.

c) Compressive of concrete.

Table 2-3 (Table 3.4 of euro code II) gives the final shrinkage strain of a normal weight concrete

subject to a compressive stress not exceeding 0.45 f ck at the time of first loading.

i) For values in table 3.4 variation in temperature between 20C and 40C are acceptable.

ii) Variations in humidity between relative humidity (RH 20% 100%) are acceptable.

iii) Linear interpolation between the values in the table are acceptable.

Table 2.3- Final shrinkage strain cs of normal weight concrete (Table 3.4 of euro code II)

Location of the Relative humidity Notional size 2 Ac / u (mm)

member (%) 150 600

Inside 50 -0.60 -0.50

Outside 80 -0.33 -0.28

where Ac cross-sectional area of concrete

u perimeter of that area

2.4 Creep

2.4.1 General

Creep is the continuous deformation of a member under sustained load. It is a phenomenon associated

with many materials, but it is particularly evident with concrete. It depends on;

i) The aggregates and the mix design (Composition of concrete).

ii) Ambient humidity

iii) Member cross-section.

iv) Age at first loading.

v) Duration of loading.

vi) Magnitude of loading.

2.4.2 Characteristic of Creep

a) The final deformation of the member can be three to four times the short-term elastic deformation.

b) The deformation is roughly proportional to the intensity of loading and to the inverse of the

concrete strength.

c) If the load is removed, only the instantaneous elastic deformation will recover; the plastic

deformation will not.

d) There is a redistribution of the load between the concrete and any steel present.

e) The redistribution of load is caused by the changes in compressive strains being transferred to the

reinforcing steel. Thus the compressive stresses in the steel are increased so that the steel takes a

larger proportion of the load.

OLENG Morris (+256703688747) Page 11 of 173 Edition 2016

Chapter II: Properties of Reinforced Concrete

2.4.3 Effects of Creep

The effects of creep are particularly important in beams, where the increased deflections may cause;

a) Opening of cracks.

b) Damage to finishes.

c) Non-alignment of mechanical equipment.

Redistribution of stress between concrete and steel occurs primarily in the uncracked compressive

areas and has little effect on the tension reinforcement other than reducing shrinkage stresses in some

instances. The provision of reinforcement in the compression zone of a flexural member, however,

often helps to restrain the deflections due to creep.

Values in table 2-4 (Table 3.3 of euro code II) can be considered as the final creep coefficient (, t o )

of a normal weight concrete subjected to a compressive stress not exceeding 0.45 f ck .

Table 2.4- Final creep coefficient (, t o ) of normal weight concrete

Notional size 2 Ac / u (in mm)

Age at 50 150 600 50 150 600

loading to Humid atmospheric conditions

Dry atmospheric conditions (inside)

(days) (outside)

(RH=50%)

(RH=80%)

1 5.5 4.6 3.7 3.6 3.2 2.9

7 3.9 3.1 2.6 2.6 2.3 2.0

28 3.0 2.5 2.0 1.9 1.7 1.5

90 2.4 2.0 1.6 1.5 1.4 1.2

365 1.8 1.5 1.2 1.1 1.0 1.0

Linear interpolation between the values in table is permitted.

OLENG Morris (+256703688747) Page 12 of 173 Edition 2016

Chapter III: Limit State Design

CHAPTER III. LIMIT STATE DESIGN

3.0 Introduction

Limit state design of an engineering structure must ensure that under the worst loadings the structure

is safe, and that during normal working conditions the deformation of the members does not detract

from the appearance, durability or performance of the structure. Three methods have been developed

for design of structures.

3.0.1 The permissible stress method.

The ultimate strengths of the materials are divided by a factor of safety to provide permissible design

stresses which are usually within the elastic range (It can also be called Elastic design method or the

modular ratio method).

Limitation;

i) It is not really applicable to a semi-plastic material such as concrete since it is based on an elastic

stress distribution.

ii) It is not suitable when displacement are not proportional to the loads such as in slender columns.

3.0.2 The Load factor Method.

The working loads are multiplied by a factor of safety.

Limitations;

i) It does not apply a factor of safety to material stresses. Therefore it does not consider variability

of materials.

ii) It cannot be used to calculate the deflection and cracking at service loads.

In the load factor method the ultimate strength of the materials should be used in the calculations. As

this method does not apply factors of safety to the material stresses, it cannot directly take account

of the variability of the materials, and also it cannot be used to calculate the deflections or cracking

at working loads. Again, this is a design method that has now been effectively superseded by modern

limit state design methods.

3.0.3 Limit State Method

The limit state method of design, now widely adopted across Europe and many other parts of the

world, overcomes many of the disadvantages of the previous two methods. It multiplies the service

loads by partial factor of safety and also divides the materials ultimate strengths by further partial

factors of safety.

3.1 Limit states

A limit state is a situation beyond which the structure becomes unfit for its intended use. The purpose

of design is to achieve acceptable probabilities that a structure will not become unfit for its intended

use that is, that it will not reach a limit state. Thus, any way in which a structure may cease to be

fit for use will constitute a limit state and the design aim is to avoid any condition being reached

during the expected life of the structure. There are two limit states.

i) The ultimate limit state.

ii) The serviceability limit state.

OLENG Morris (+256703688747) Page 13 of 173 Edition 2016

Chapter III: Limit State Design

3.1.1 The Ultimate Limit State.

This requires that the structure must be able to withstand, with an adequate factor of safety against

collapse, the loads for which it is designed to ensure the safety of the building occupants and/or the

safety of the structure itself. The possibility of buckling or overturning must also be taken into

account, as must the possibility of accidental damage as caused, for example, by an internal

explosion. The structure or its elements should not collapse, overturn or buckle, or become unfit for

use due to accidental damage.

The Ultimate Limit State considers;

i) Robustness.

ii) Stability.

iii) Strength.

i) Robustness

To be robust means that the layout of the structure should be such that damage to a small area or

failure of a single element will not lead to progressive collapse.

To achieve robustness;

i) The structure must be able to resist a minimum horizontal load.

ii) The elements of the structure must be provided with ties.

Minimum Horizontal Load: (Clause 2.5.1.3) and figure 3.1

The minimum horizontal load is given by

a) The design horizontal load assumed to act at any floor level should not be less than H min .

Horizontal loads are as a result of wind, earthquake and traffic where H min is given by

H min Vi n

where Vi total design vertical load above the level considered.

notational (assumed) out of plumbed angle in radians given by

1 1

(100 L ) 200

where L is the overall height of the structure in meters.

n is an allowance for causes where n vertically continuous elements act

together.

1 1/ n

n

2

b) In a braced structure, the horizontal elements connecting the vertical elements to the bracing

structure should be designed to carry an additional horizontal load H fd

v

H fd ( N ba N bc )

2

where N ba design vertical load in the vertical elements above the horizontal member

considered.

N bc design vertical load in the vertical elements below the horizontal member

considered.

Details of N ba and N bc are given in figure 2.1 of the code.

OLENG Morris (+256703688747) Page 14 of 173 Edition 2016

Chapter III: Limit State Design

Vc1 Vc2 Vcn Vc1 Vc2 Vcn

a) c b) c) c

Hc Hc

Vb1 Vbn Vb1 Vb2 Vbn

b Nbc lcol b

Hb H fd Hb

Va1 Van Va1 Va2 Van

l floor a l floor a

v Ha v/2 Nba lcol Ha

v v v

n

H j = Vji v H fd = ( Nbc + Nba ) v/2 H j as in fig. a)

Fig.3.1 Application of the effective geometrical imperfections

Design of Ties

Detailed design information for ties is not given in Euro code II.

NAD National Application Document recommends that the design method for BS8110 should

be used.

The design of ties is given in clause 3.12.3 of BS8110.

The general stability and robustness of a building structure can be increased by providing

reinforcement acting as ties. These ties should act both vertically between roof and foundations, and

horizontally around and across each floor (figure 3.2), and all external vertical load-bearing members

should be anchored to the floors and beams.

The types of ties

Fig.3.2 Tie forces

Vertical ties

Vertical ties are not generally necessary in structures of less than five storeys but in higher buildings

should be provided by reinforcement, effectively continuous from roof to foundation by means of

proper laps, running through all vertical load-bearing members. This steel should be capable of

resisting a tensile force equal to the maximum design ultimate load carried by the column or wall

from any one storey or the roof.

OLENG Morris (+256703688747) Page 15 of 173 Edition 2016

Chapter III: Limit State Design

Horizontal ties

Horizontal ties should be provided for all buildings, irrespective of height, in three ways:

1. Peripheral ties.

2. Internal ties.

3. Column and Wall ties.

a) Peripheral ties.

Peripheral tie must be provided by reinforcement at each floor or roof level.

Peripheral tie must be continuous.

This reinforcement must lie within 1.2m from the edge of building or within the perimeter wall.

It should be capable of resisting a force of at least Ft .

Ft (20 4no ) or 60KN whichever is less.

no number of storeys in structure.

b) Internal Ties

Internal ties should be provided at each floor in two perpendicular directions.

They should be continuous throughout their length.

They should be anchored at each end, either to the peripheral tie or to the continuous column or

wall ties.

They may be located as follows;

a) Spread evenly in slabs

b) Grouped in beams

c) Grouped in walls. Where walls are used, the tie reinforcement must be within 0.5m

of the top or bottom of the floor slab.

Internal ties should be able to resist a tensile force T.

F (G Qk ) Lr

T t k or 1.0 Ft whichever is greater.

7.5 5

where (Gk Qk ) the characteristic load per m 2 of the floor considered.

Lr the greatest horizontal distance in the direction of the tie between the centres of

vertical load-bearing members.

If the ties are grouped in walls or beams, their maximum spacing should be limited to 1.5Lr .

Spacing 1.5Lr

c) Column and Wall Ties

Column and Wall Ties must be able to resist a force of 3% of the total vertical ultimate load

carried by columns or walls.

L

The resistance provided must not be less than the smaller of 2 Ft or s Ft kN where L s is the

2 .5

floor to ceiling height in members.

Wall ties are assessed on the basis of the above forces acting per metre length of the wall.

Column ties are concentrated within 1m of either side of the column center line.

OLENG Morris (+256703688747) Page 16 of 173 Edition 2016

Chapter III: Limit State Design

Worked Example 3.1: Stability ties

Calculate the stability ties required in an eight-storey building of plan area shown in figure 3.3:

Clear storey height under beams 2.9m

Floor to ceiling height (l s ) 3.4m

Characteristic permanent load ( g k ) 6KN / m 2

Characteristic variable load (qk ) 3KN / m 2

Characteristic steel strength ( f yk ) 500N / mm 2

Precast floor slab Longitudinal beam

7m

Transverse beams

4 bays @ 6.5m=26m

Fig.3.3 Structure layout

Ft (20 4 number of storeys)

20 4 8 52KN 60KN

(a) Peripheral ties

Force to be resisted Ft 52KN

52 103

Bar area required 104mm 2

500

This could be provided by one H12 bar.

(b) Internal ties

Ft ( g k q k ) l r

Force to be resisted kN per metre

7.5 5

(1) Transverse direction

52(6 3) 7

Force 87.4 KN / m Ft

7.5 5

Force per bay 87.4 6.5 568.1KN

Therefore, bar area required in each transverse interior beam is

568.1 103

1136mm 2

500

This could be provided by 4 H20 bars.

(2) Longitudinal direction

52(6 3) 6.5

Force 81.1KN / m Ft

7.5 5

OLENG Morris (+256703688747) Page 17 of 173 Edition 2016

Chapter III: Limit State Design

Therefore force along length of building 81.1 7 567.7KN , hence bar area required in each

567.7 103

longitudinal beam is 567mm 2

2 500

This could be provided by 2 H20 bars.

(3) Column ties

Force to be designed for is

ls 3.4

Ft 52 70.7 KN 2 Ft

2.5 2.5

or 3 per cent of ultimate floor load on a column is

3 7

8 (1.35 6 1.5 3) 6.5 69KN at ground floor level

100 2

To allow for 3 per cent of column self-weight, take design force to be 72KN, say, at ground level.

72 103

Area of ties required 144mm 2

500

This would be provided by 1 H20 bar and incorporated with the internal ties. At higher floor levels a

design force of 70.7KN would be used giving a similar practical reinforcement requirement.

(c) Vertical ties

Assume quasi-permanent loading with 2 0.6 .

Thus the ultimate design load 1.0 6 0.6 3 7.8KN / m 2 .

Maximum column load from one storey is approximately equal to

7.8 3.5 6.5 177.5KN

Therefore bar area required throughout each column is equal to

177.5 103

355mm 2

500

This would be provided by 4 H12 bars.

ii) Stability

Building structures are classified into two types.

a) Braced, and

b) Unbraced

A braced structure is one that resists lateral loads by means of bracing. Lateral loads include;

wind loads, and

seismic loads (earthquake loads)

Bracing in RC structures include;

Shear walls

RC lift shafts

RC stair wells

The bracing must be able to transmit the horizontal loads down to foundation.

* Unbraced structures dont have bracing elements.

Lateral loads are resisted by action of rigidly connected columns, beams and slabs.

OLENG Morris (+256703688747) Page 18 of 173 Edition 2016

Chapter III: Limit State Design

Structures can also be describes as sway or non sway structures.

Non sway structures are those where there is less than 10% increase in the normal design

moment due to the displacement of the structure.

Sway structures are those where the secondary moment due to displacement are greater than

10% of the normal design moment.

iii) Strength

The structure should be adequately strong to carry all applied loads without collapse.

3.1.2 Serviceability Limit State

Generally the most important serviceability limit states are:

i) Deflection:

The appearance or efficiency of any part of the structure must not be adversely affected by deflections

nor should the comfort of the building users be adversely affected.

ii) Cracking:

Local damage due to cracking and spalling must not affect the appearance, efficiency or durability

of structure.

iii) Durability:

This must be considered in terms of the proposed life of the structure and its conditions of exposure.

This is the resistance to wear, tear and environmental effects with time. Any reinforced concrete

structure must be designed to protect the embedded steel.

Thus the durability of concrete is influenced by;

a) Exposure conditions

b) Concrete quality and workmanship

c) Cover to reinforcement

d) Width of any crack

If durability is neglected, it will lead to increased expenditures on;

i) Inspection

ii) maintenance

iii) repair

Durability in R.C concerns the selection of the appropriate concrete grade and cover, for the

conditions of;

a) Environmental exposure

b) Protection of reinforcement against a rapid rise in temperature and resultant loss of strength.

Exposure conditions are given in table 4.1 of the code and Minimum cover requirements for exposure

conditions are given in table 4.2.

OLENG Morris (+256703688747) Page 19 of 173 Edition 2016

Chapter III: Limit State Design

Table 3-1 (Table 4.1 of Euro code II) Exposure classes related to environmental conditions

Exposure class Example of environmental conditions

1 interior of buildings for normal habitation or offices a

dry environment

2 a - interior of buildings where humidity is high (e.g. laundries)

without - exterior components

humid frost - components in non-aggressive soil and/or water

environment b - exterior components exposed to frost

With - components in non-aggressive soil and/or water and exposed

frost to frost

- interior components when the humidity is high and exposed

to frost

3

humid environment with frost Interior and exterior components to frost and de-icing agents

and

de-icing salts

4 a - components completely or partially submerged in seawater,

without or in the splash

frost - components in saturated salt air (coastal area)

seawater environment b - components partially submerged in seawater or in the splash

With zone and exposed to frost

frost - components in saturated salt air and exposed to frost

The following classes may occur alone or in combination with the above classes:

5 a - slightly aggressive chemical environment (gas, liquid or

aggressive chemical solid)

b

environment - aggressive industrial atmosphere

b moderately aggressive chemical environment (gas, liquid or

solid)

c highly aggressive chemical environment (gas, liquid or solid)

a

This exposure class is valid only as long as during construction the structure or some of its

components is not exposed to more severe conditions over a prolonged period of time.

b

Chemically aggressive environments are classified in ISO/DP 9690. The following equivalent

exposure conditions may be assumed:

Exposure class 5a: ISO classification A1G,A1L,A1S

Exposure class 5b: ISO classification A2G,A2L,A2S

Exposure class 5c: ISO classification A3G,A3L,A3S

OLENG Morris (+256703688747) Page 20 of 173 Edition 2016

Chapter III: Limit State Design

Table 3-2 (Table 4.2 of Euro code II) Minimum cover requirement for normal weight concrete 1)

Exposure class, according to Table 4.1

1 2a 2b 3 4a 4b 5a 5b 5c

2) Reinforcement 15 20 25 40 40 40 25 30 40

Minimum cover

(mm)

Prestressing 25 30 35 50 50 50 35 40 50

steel

NOTES

1. In order to satisfy the provisions of 4.1.3.3 P(3), these minimum values for cover should be associated

with particular concrete qualities, to be determined from Table 3 in ENV 206.

2. For slab elements, a reduction of 5mm may be made for exposure classes 2-5.

3. A reduction of 5mm may be made where concrete of strength class C40/50 and above is used for

reinforced concrete in exposure classes 2a-5b, and for prestressed concrete in exposure classes 1-5b.

However, the minimum cover should be less than that for Exposure Class 1 in Table 4.2.

4. For exposure class 5c, the use of a protective barrier, to prevent direct contact with the aggressive media,

should be provided.

Concrete cover (clause 4.1.3.3)

The concrete cover is the distance between the outer surface of the reinforcement (including links

and stirrups) and the nearest concrete surface.

cover

cover

bundle

A minimum concrete cover shall be provided in order to ensure;

i) the safe transmission of bond forces;

ii) that spalling will not occur;

iii) an adequate fire resistance;

iv) the protection of the steel against corrosion;

The protection of reinforcement against corrosion depends upon the continuing presence of a

surrounding alkaline environment provided by an adequate thickness of good quality, well-cured

concrete.

The thickness of cover required depends both upon;

The exposure conditions as shown in table 4.2

The concrete quality.

Minimum Concrete Cover

5mm

i) cover min if d g 32mm

n 5mm

OLENG Morris (+256703688747) Page 21 of 173 Edition 2016

Chapter III: Limit State Design

ii) cover min d 32mm

n g

where the diameter of the bar

n the equivalent diameter for a bundle

d g the largest nominal maximum aggregate size.

The minimum concrete cover to all reinforcement including links and stirrups should not be less than

the appropriate values of given in Table 4.2, for the relevant exposure class defined in Table 4.1.

Nominal Cover

This is the cover used in design and specify on drawing and nominal cover is given by nominal cover

which is equal to minimum cover + h .

where h is Tolerance on cover to reinforcement and given by; 5mm h 10mm .

h depends on;

i) Type and size of structural element/member.

ii) Type of construction.

iii) Standards of workmanship.

iv) Quality control

v) Detailing practice.

Other limit states that may be reached include:

iv) Excessive vibration: which may cause discomfort or alarm as well as damage.

v) Fatigue: must be considered if cyclic loading is likely.

vi) Fire resistance: this must be considered in terms of resistance to collapse, flame penetration

and heat transfer.

Fire resistance depends on;

o amount of cover

o member thickness

o type and quality of materials

o workmanship

vii) Special circumstance: any special requirements of the structure which are not covered by

any of the more common limit states, such as earthquake resistance, must be taken into

account.

3.2 Characteristic material strength

3.2.1 General

The strengths of materials upon which a design is based, normally, those strengths below which

results are unlikely to fall. These are called characteristic strength. It is assumed that for a given

material, the distribution of strength will be approximately normal, so that a frequency distribution

curve of a large number of sample results would be of the form shown in figure 3-4. The characteristic

strength is taken as that value below which it is unlikely that more than 5 per cent of the results will

fall.

This is given by

f k f m 1.64

OLENG Morris (+256703688747) Page 22 of 173 Edition 2016

Chapter III: Limit State Design

where f k characteristic strength

f m mean strength, f m

f

n

f =values of cube strength

n = number of cubes tested.

standard deviation, is a measure of quality control

( f fm )2

1/ 2

n

The relationship between characteristic and mean values accounts for variations in results of test

specimens and will, therefore, reflect the method and control of manufacture, quality of

constructions, and nature of the material.

Mean strength ( fm )

Characteristic

strength ( f k )

number of

test specimens

1.64

strength

Fig.3-4 Normal frequency distribution of strengths

3.2.2 Concrete (Cl. 3.1, EC 2)

a) Compressive strength of concrete

Unlike BS 8110, the design rules in EC 2 are based on the characteristic (5 per cent) compressive

cylinder strength of concrete at 28 days ( f ck ). Equivalent cube strengths ( f ck ,cube ) are included in EC

2 but they are only regarded as an alternative method to prove compliance. Generally, the cylinder

strength is approximately 0.8 the cube strength of concrete i.e. f ck 0.8 f ck ,cube .

b) Tensile strength of concrete

The tensile strength of concrete is the maximum stress the concrete can withstand when subjected to

uniaxial tension (tensile force applies in one axis).

The mean tensile strength f ct .k of concrete may be derived from equations 3.1, 3.2 and 3.3.

f ctm 0.3 f ck( 2 / 3) Nmm 2 (3.1)