Professional Documents

Culture Documents

ASSE Wind Turbine Safety 12

Uploaded by

AntonioCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASSE Wind Turbine Safety 12

Uploaded by

AntonioCopyright:

Available Formats

Worker Protections

Peer-Reviewed

Wind Turbine

Safety

Developing

a Technician

Training Course

By Isaac Slaven and Ed Dennis

T

he growth of the wind energy industry 2,000 were classified as contact with equipment;

in the U.S. has created the need for quali- falls; exposure to harmful substances or environ-

fied technicians to perform maintenance ments; and fires or explosions.

and operation activities. American Wind Energy This article describes how a course was adapted

Association (AWEA, 2010) has to be more specific to the high-risk nature of wind

IN BRIEF identified several wind turbine turbine work while covering OSHA-10 general in-

The wind turbine industry has grown technician training programs in dustry and OSHA-10 construction topics.

significantly in recent years, and pro- the U.S. The AWEA Seal of Ap- Specifically, the authors share the experience of

jections say it will continue to do so. proval for these programs looks developing a wind power course at Ivy Tech Com-

Many training programs for wind tur- to be an important step in their munity College in Lafayette, IN. The course serves

bine technicians have begun across standardization (Interstate Re- as an introduction to the wind industry and wind

the U.S. newable Energy Council, 2009). turbine safety. It was designed to ensure that the

This article examines the develop- The importance of training topics and activities presented are relevant to the

ment of a safety course for prospec- is mentioned more than 850 wind technician field and to increase student inter-

tive wind technicians. The goal was times in OSHA standards. The est in safety.

to increase student interest in safety agencys authority to enforce

topics related to the wind turbine safety regulations dates back to Wind Turbine Safety

industry and to maintain the material the 1970s, yet fatalities and cita- The four leading causes of death during construc-

within the OSHA-10 topics guidelines. tions occur every day due to fac- tion activities in the U.S. are falls, hit by/struck by,

tors such as failure to properly caught between and electrical injuries. These haz-

execute risk assessment and use ards account for 90% of workplace fatalities. As a

PPE. In 2010, 4,547 people died in the workplace result, OSHA has adopted a focused inspection ini-

(Bureau of Labor Statistics, 2011). Of these, nearly tiative. All four of these dangers are inherent to work

Isaac Slaven, Ph.D., is an assistant professor at Eastern Illinois Uni- Ed Dennis is the safety director at Wind Energy Services in Westfield,

versity (EIU) in the applied engineering technology program within IN. He currently holds OSHA 500, OSHA 501, OSHA 3150 (tower

the School of Technology. He holds a Ph.D. from Purdue University. safety), and cranes and rigging certifications. Dennis has worked in

Prior to joining the EIU faculty, Slaven developed the sustainable the tower industry for nearly 20 years and has worked with the wind

energy program at Ivy Tech Community College in Lafayette, IN. industry for approximately 5 years.

44 ProfessionalSafety FEBRUARY 2012 www.asse.org

Photo 1: A wind technician For example, scaffolds are not likely to be found on a

climbs into the single access wind turbine site and, therefore, the elective time for

location for the wind turbine hub. the construction training would be more effectively

Some models have access inside spent on a topic such as stairways and ladders.

the nacelle. Optional time presents another opportunity to

integrate wind turbine safety topics; generally, this

that wind turbine technicians

is the last 2 hours in the general industry course

perform each day.

and 4 hours in the construction course. Training for

As wind energy installa-

fall protection and electrical safety, respectively, in-

tions increase across the U.S.,

troduces ANSI Z359 and NPFA 70E as a necessary

so does the demand for tech-

point of reference. Further descriptions and exer-

nicians to maintain and op-

cises in these topics are applicable to wind turbine

erate the turbines. Although

work as well. During this optional time, additional

much turbine operation can

exercises can be developed to address and practice

be performed remotely using

activities related to these hazards.

supervisory control and data

acquisition technology, much

Barriers

of the work requires techni-

Although all barriers can be categorized as fi-

cians be in physical contact

nancial in some respect, key concerns include li-

with the turbines. Technicians

ability; appropriate and applicable equipment and

regularly climb towers that are

structures; facilities and space to house and handle

usually 197 to 328 ft (60 to 100

equipment and structures; competent/qualified in-

m) to the hub. They routinely

structors and instructor expense; time within cur-

place themselves at risk when

rent curriculum; and pressure to develop online

working at height in and on

curriculum.

these elevated structures.

Multiple activities require

Liability

work or travel on top of the na-

Since the school provides the opportunity for

celle and hub (see Key Terms

students to climb, it is exposing them to a known

sidebar on p. 46). Generators

hazard: gravity. Hold-harmless and release of li-

typically produce between 500

ability forms are essential to the training process.

and 700 V AC, and grid con-

Ivy Tech requires one hold-harmless and release of

nection at each tower is in the

liability for each semester, and a signed inspection

range of 36,000 V AC. Hydrau-

form for each activity on the towers. In addition,

lic tool pumps used in the tow-

job safety analysis (JSA) worksheets are filed for

er and nacelle can operate at pressures up to and

the group before each activity.

exceeding 650 bar (9,400 psi). Furthermore, the en-

tire structure, including the tower, nacelle and hub,

Equipment

falls under OSHAs definition of a confined space

Using the appropriate equipment is essential

[29 CFR 1910.146(a)].

to successful implementation of a wind-turbine-

Under the OSH Act, OSHA requires that em-

specific training program. In addition to correct

ployers provide a workplace free of known or

equipment that can pass competent inspection, old

recognized hazards that are causing or have the

equipment which has been retired adds value to

potential to cause injury or death. A typical OSHA-

the tactile experience. Table 2 (p. 47) outlines the

10 course for general industry or construction does

equipment used at Ivy Tech. A setup with required

not adequately address the specific topics techni-

PPE, indoor climbing apparatus and an outdoor

cians would need to know in order to better recog-

climbing tower that can reasonably accommodate

nize hazards applicable to wind turbine work. This

the variety of potential participants can easily cost

coincides with NIOSHs (2010) hierarchy of con-

more than $100,000. Since many PPE items are

trols, which contains five key elements: 1) hazard

small and often desirable for personal use, an ac-

elimination; 2) substitution; 3) engineering con-

counting system is needed for each item.

trols; 4) administrative controls; and 5) PPE.

Table 1 (p. 46) outlines the time requirements for

Facilities

each topic for standard OSHA-10 courses for gen-

To house climbing towers, the institution must

eral industry or construction. Because these times

dedicate adequate space for them. For example, the

are minimums, it is possible that only 2 hours are

indoor climbing apparatus at Ivy Tech requires a

spent on the Focus Four hazards. This means that

permanent footprint of approximately 6x6 ft. When

participants could receive an OSHA-10 certificate as

apparatus are used for climbing exercises, a larger

a part of a wind turbine technician training program

space is required. Therefore, any items stored under

with only 30 minutes exposure to fall protection.

the tower must not be permanently installed.

Mandatory times for each topic in the OSHA-10

In this case, the outdoor tower was custom de-

classes must be met regardless of any modification

signed for training purposes. It is a three-legged,

to the trainings emphasis. So, elective and optional

self-support tower of lattice construction. Each leg

times are the best opportunities for focused training.

has removable climbing pegs (to reduce the tower

www.asse.org FEBRUARY 2012 ProfessionalSafety 45

vertical trespassing potential as an attractive nui-

Key Terms sance) and wire rope safety climbs. Since the tower

is 80 ft above ground level,

Nacelle: The complete up-tower housing contain- Photo 2 a circular free space with

ing the gearbox, generator and other components 100-ft radius was chosen.

in a wind turbine (label 1 in Photo 2). In addition to removable

climbing pegs, a chain-link

Hub: The part of a wind turbine that connects the fence was installed to re-

blades to the nacelle (label 2 in Photo 2). duce trespassing.

As a self-support tower,

Tower: A vertical apparatus. In the wind energy a reinforced concrete foun-

industry, this term can be used to describe the dation was necessary. At

vertical support system for the wind turbine or the this site, the foundation is

entire wind turbine assembly (label 3 in Photo 2). a pad and pier design of

approximately 12126 ft

V AC: Volts of alternating current. (LWD) with engineered

reinforcement. The foun-

Wind turbine: Term that generally describes a dation design is dependent

utility-scale wind energy conversion system. on site-specific geotechni-

cal data.

Once the soil samples

have been collected from a

proposed site for geotechni-

Table 1 cal analysis, a qualified civil

OSHA-10 General Industry engineer can determine the

foundation design that best

& Construction Topics meets the desired level of

safety. Designers should also

Required time General industry topic Required time Construction topic know that the tower will be

2 hours Introduction to OSHA 2 hours Introduction to OSHA used to instruct nonprofes-

mandatory OSH Act mandatory OSH Act

sional climbers in climbing

Rights Rights

Inspections, citation, penalties Inspections, citation, penalties and rescue. Often, they will

General duty clause General duty clause increase the designs safety

OSHA website and phone number OSHA website and phone number factors to improve the tow-

Value of safety and health Value of safety and health ers rigidity.

1 hour Walking working surfaces/fall 2 hours Focus Four hazards

mandatory protection mandatory Fall protection Competent &

Electrical Qualified Instructors

Struck by

An OSHA-10 course must

Caught in/between

1 hour Emergency action plans, fire, exits 30 minutes PPE

be taught by trainers autho-

mandatory mandatory rized by DOLs Directorate

1 hour Electrical 30 minutes Health hazards in construction of Training and Education

mandatory mandatory (OSHA, 2010). To be an

1 hour PPE 2 hours elective Two of: instructor for general in-

mandatory Material handling dustry and construction, an

Tools individual must have 5 years

Scaffolds

verifiable experience in the

Cranes, derricks, etc.

Excavations

applicable training area, or

Stairways and ladders s/he must hold a CSP or CIH

1 hour Hazard communication 4 hours Teach any other construction designation, with 3 years

mandatory optional industry hazard or expand on the experience in the applicable

mandatory or electives safety field (OSH). In addi-

2 hours elective Two of: tion, continuing education

Hazardous materials is required every 4 years to

Materials handling keep instructors updated.

Machine guarding

Industrial hygiene

In addition to being au-

Bloodborne pathogens thorized by OSHA to teach

Ergonomics the classes, the instructor of

Safety and health programs a wind energy course must

Fall protection have experience with wind

2 hours optional Teach any other general industry turbines as s/he must have

hazards or policies and/or expand a thorough and complete

on the mandatory understanding of the conse-

quences of applicable work-

46 ProfessionalSafety FEBRUARY 2012 www.asse.org

place hazards. Beyond the

inherent believability of first- Table 2

hand knowledge, research

has shown that instructors Equipment List

who have practical experience

in the courses they teach are Item Standard Explanation

better received by students Indoorpracticetower Tower:Engineeredwith Climbablelattice.Height:18ft

stamp;safetyclimb

(Scott, 1996). Outdoortower Tower:Engineeredwith Climbablelatticewithcornerclimbingpegs.Height:80ft

Competent climber and stamp;safetyclimb

competent rescuer training is PPE:Fullbodyharness ANSIZ359(2007) DorsalDringminimum.SternalandhipDringsalso

generally operated through requiredonsite.Towerharnesswithattachedseat

specific manufacturers or preferredforexercises

training organizations. The PPE:Twinlegsafetylanyard ANSIZ359(2007) Usedforsafetytieoffexercises

training selected must be ap- PPE:Cablesleeve ANSIZ359(2007) Usedonthewireropesafetyclimbapparatus

plicable to wind turbines and PPE:Helmet ANSIZ89(2003)TypeI Chinstraprequiredforswingfallscenarios

PPE:Eyeprotection ANSIZ87.1(2003) Eyeinjuryprotectionfromfallingordeflectingobjects

wind turbine hazards.

PPE:Positioninglanyard 3,000lb.minimum Forontowerpositioning

OSHA defines a compe- breakingstrength

tent person as one who is PPE:Selfretractinglanyard ANSIZ359(2007) Backupfallprotectionforindoorexercises

capable of identifying existing PPE:Verticallifeline ANSIZ359(2007) Backupfallprotectionforoutdoorexercises

and predictable hazards in PPE:Ropegrab ANSIZ359(2007) Backupfallprotectionforoutdoorexercises

the surroundings or working Rescueequipment ANSIZ359(2007) Chosenrescuesystemis light,meetsstandard andis

conditions which are unsani- reusable

tary, hazardous or dangerous Miscellaneousconnectors ANSIZ359(2007) Carabiners,blocks/pulleys,chokerslings,etc.

to employees. Without wind

turbine experience, it would

be difficult for an instructor to

convey a working knowledge

related to the specific hazards Table 3

of a wind turbine.

General Industry Safety Course

Online Curriculum With Wind Turbine Emphasis

As institutions compete for Time Additional learning objectives for

student enrollment, accom- spent OSHA-10 general industry topic wind turbine emphasis

modations are being made to 2 hours Introduction to OSHA Research case studies specific to wind turbine accident

OSH Act investigation

make education more avail- Rights Investigate history and evolution of fall protection

able for students. Often, this Inspections, citation, penalties Explain the importance of the general duty clause with

includes the availability of on- General duty clause regards to wind turbine work

line or web-based instruction. OSHA website and phone number

Benefits of online courses or, Value of safety and health

2 hours Walking working surfaces/fall protection Identify the walking working surfaces in a wind turbine

at minimum, mixed-mode

Analyze certified anchor points on a ladder in a wind

(sometimes called blended turbine

learning or hybrid instruc- Evaluate a wind park fall protection plan

tion) courses include asyn- Create a fall protection plan for the training site

chronous group interaction, 2 hours Emergency action plans, fire, exits Describe the confined space hazards at various locations

location independence and in a wind turbine

Differentiate situations resulting in in-tower and outside-

multimedia interactions

tower exits

(Harasim, 2000). Evaluate a wind parks emergency action plan

However, research has Summarize heat/cold stress symptoms and prevention

shown that many students 2 hours Electrical Identify electrical locations in a wind turbine

feel courses suffer without Apply NFPA 70E guidelines for various electrical

real-time, face-to-face, class- applications in a wind turbine

2 hours PPE Identify the ANSI Z359.1-2007 components of a personal

room interaction (Flowers,

fall arrest system (PFAS)

2001; Schmidt & Gallegos, Inspect PFAS equipment for defects, nonconformities or

2001). In the case of a climb- other noncompliance.

ing safety and fall protection Demonstrate the safe use of PFAS in a tower-climbing

course, certain learning ob- exercise

jectives cannot be reasonably Evaluate noncomplaint PFAS PPE

1 hour Hazard communication Identify materials that are present in a wind turbine

met using online technolo-

Analyze MSDS for various fluids, cleaners or greases

gies exclusively. The effec- commonly found in wind turbines

tiveness of hands-on training 1 hour Confined spaces Identify confined spaces related to wind turbine work

on learning retention has Evaluate a permit-required confined space scenarios

been validated in many stud-

ies (Korwin & Jones, 1990).

www.asse.org FEBRUARY 2012 ProfessionalSafety 47

Opportunities evaluation, as functions of higher levels of cogni-

Although the OSHA-10 training courses are tion, can be achieved through exercises and activi-

designed to be classroom-based experiences, this ties. Among others, these can focus on NFPA 70E,

Photo 3: A student training is a good bridge into higher cognitive lev- JSA worksheets, and climbing and rescue activities.

performs a con- els of the learning dimensions. OSHA regulations As noted, research shows that hands-on activities

trolled descent on serve as the guideline, but they do not provide a increase the effectiveness of cognitive retention

the training tower. method for implementing practices. Analyzing and (Korwin & Jones, 1990).

One distinct difference between classroom

teaching and on-the-job training (OJT) is the im-

mediacy of application. Since OJT is typically per-

formed using the actual equipment that will be

used, the training is quickly applied. If it is the first

time that a student/new employee has seen the

concepts, the construction of knowledge (i.e., de-

velopment of cognitive, psychomotor and affective

knowledge) may be difficult. Additionally, due to

the expense of time, OJT is often specific to equip-

ment or a particular site, and its effectiveness relies

heavily on a trainees previous experience (van der

Klink & Streumer, 2002). In addition, it has been

shown that workplace tenure and career satisfac-

tion are positively influenced by focused training

(Wayne, Liden, Kraimer, et al., 1999).

Classroom learning is effective when students

have sufficient transfer of prior knowledge to the

new setting. However, without the foundations of

knowledge, construction of knowledge, such as

that through OJT, is more difficult, and long-term

retention is reduced (Halpern & Hakel, 2003). More

practice and group interaction in activities, such

as climbing, can yield further

cognitive development (Gla-

sersfeld, 1989). Skills resulting

Table 4 from higher levels of cognitive

Construction Safety Course development include differen-

With Wind Turbine Emphasis

tiation, investigating, critiqu-

ing and adapting (Gronlund,

Time Additional learning objectives for

2003).

spent OSHA-10 construction topic wind turbine emphasis

2 hours Introduction to OSHA Research case studies specific to wind turbine accident Liability as an Opportunity

OSH Act investigation Although liability may pres-

Rights Investigate history and evolution of fall protection ent a minor barrier to the de-

Inspections, citation, penalties Explain the importance of the general duty clause with regards

General duty clause to wind turbine work

velopment of a wind turbine

OSHA website and phone number safety curriculum, it is an ex-

Value of safety and health perience the instructor can

3.5 hours Focus Four hazards Determine locations on a wind turbine that are directly related use as a teaching mechanism.

Fall protection to the Focus Four hazards The importance of required

Electrical Identify features of crane and rigging equipment that requires documentation, such as a site-

Struck by a competent inspection

Caught in/between Apply NFPA 70E guidelines for various electrical applications in

specific fall plan, JSA, PPE

a wind turbine inspection logs, tower main-

Explain the importance of a prework JSA for safe tenance logs and postactivity

communication and actions worksheets can be shared with

3.5 hours PPE Identify the ANSI Z359.1-2007 components of a personal fall students. This helps students

arrest system (PFAS) understand that such docu-

Inspect PFAS equipment for defects, nonconformities or other

noncompliance.

mentation is a necessary com-

Demonstrate the safe use of PFAS in a tower-climbing exercise ponent of safety management

Evaluate noncomplaint PFAS PPE as required by OSHA, ANSI

1 hour Health hazards in construction Identify materials that are present in a wind turbine and manufacturers.

Analyze MSDS for various fluids, cleaners or greases commonly In the case of Ivy Tech, in

found in wind turbines

addition to the liability waiver

Summarize heat/cold stress symptoms and prevention

1 hour Confined spaces Identify confined spaces related to wind turbine work

students must complete be-

Evaluate a permit-required confined space scenarios fore each semester, they must

maintain inspection logs, JSA

worksheets and postactivity

48 ProfessionalSafety FEBRUARY 2012 www.asse.org

worksheets for their own records. This is an added

safety measure for the students and the school.

When students are asked to discuss an activity,

Green Job Hazards

such as climbing prior to the event through a JSA, OSHA has identified the wind energy industry as a major source of

they are more mentally prepared for the activity. green jobs. According to OSHA, A key concept for all industries,

When students perform their own inspections, but especially those that are just beginning to grow, is prevention

there is more certainty that the equipment is, in through design (PTD)designing the process/equipment in a way

fact, fit for use. Additionally, the students develop a that eliminates hazards to the workers who use them. Employers

tactile comfort in the condition of their equipment. should have a system in place where safety and health profession-

als work with design engineers in designing out hazards through-

Training Time out the design phase of their products. Read more from OSHA

As noted, the course developed covers safety in at www.osha.gov/dep/greenjobs/index.html. Learn more about

wind turbines while maintaining the time require- NIOSHs PTD efforts at www.cdc.gov/niosh/topics/PTD and its

ments for OSHA-10 general industry and con- green jobs initiatives at www.cdc.gov/niosh/topics/PtD/green

struction courses. Tables 3 (p. 47) and 4 list the jobs.html.

distribution of time for elective and optional topics.

Although these tables indicate minimum times

2012, from www.awea.org/newsroom/inthenews/

adjusted to meet OSHA time requirements, much

release_112210a.cfm.

more time is spent on many sections to accommo- Bureau of Labor Statistics. (2011). Census of fatal

date the time necessary for hands-on activities. For occupational injuries. Washington, DC: U.S. DOL,

example, a minimum of 3.5 hours must be spent on Author. Retrieved Sept. 1, 2011, from www.bls.gov/iif/

PPE. However, for supervised activities with PPE, oshwc/cfoi/cftb0250.pdf.

such as inspection and use on the tower, a more Flowers, J. (2001). Online learning needs in technol-

realistic amount of time would be 16 classroom ogy education. Journal of Technology Education, 13(1),

hours. 17-30.

Glasersfeld, E.V. (1989). Cognition, construction of

Increasing Student Interest knowledge and teaching. Synthese, 121-140.

Gronlund, N.E. (2003). Writing instructional objec-

The authors examined the effectiveness of this tives for teaching and assessment. Upper Saddle River, NJ:

training in increasing student interest in safety ex Prentice Hall.

post facto. As a result of the increased interest in Halpern, D.F. & Hakel, M.D. (2003). Applying the

the job-specific, hands-on approach to the train- science of learning. Change, 36-41.

ing, a new course (advanced wind turbine safety) Harasim, L. (2000). Shift happens: Online educa-

was developed. It opened for enrollment 2 weeks tion as a new paradigm in learning. Internet and Higher

before the first day of the semester, and was offered Education, 3, 41-61.

as a Saturday class (meeting eight consecutive Sat- Interstate Renewable Energy Council. (2009, Dec.

urdays for 8 hours each). The class had 13 enrolled 17). AWEAs Seal of Approval for wind technician

training programs. Retrieved Feb. 25, 2010, from http://

students, and many students have inquired about

irecusa.org/2009/12/aweas-seal-of-approval-for

the continuation of the course in future semesters. -wind-technician-training-programs.

Korwin, A.R. & Jones, R.E. (1990). Do hands-on ac-

Conclusion tivities, technology-based activities enhance learning by

Development of a safety course specific to wind reinforcing cognitive knowledge and retention. Journal

turbines is resource-consuming and intensive. Al- of Technology Education, 1(2), 14-20.

though issues such as liability, space and equip- NIOSH. (2010, June 25). Engineering controls:

ment present barriers, there are opportunities and NIOSH workplace safety and health topic. Washington,

teachable moments through the administrative DC: U.S. Department of Health and Human Services,

experience. Documentation of safety protocol, in- CDC, Author. Retrieved Sept. 1, 2011, from www.cdc

.gov/niosh/topics/engcontrols.

spection and incident reporting introduces students Schmidt, E.K. & Gallegos, A. (2001). Distance

to scenarios in which these documents are required. learning: Issues and concerns with distance learners.

An instructor or administrator should never sac- Journal of Industrial Technology, 17(3), 2-5.

rifice the quality of a safety course in order to inflate Scott, P.A. (1996). Attributes of high-quality intensive

numbers in a class or program; it is dangerous and course learning experiences: Student voices and experi-

can result in legal issues for the instructor and in- ences. College Student Journal, 30, 69-77.

stitution. In any case, completing a safety training OSHA. (2010, March 10). How to become an au-

course is not an end, it is a starting point. In wind thorized trainer. Washington, DC: U.S. DOL, Author.

energy, as in any industry, equipment and process- Retrieved July 28, 2010, from www.osha.gov/dte/out

reach/construction_generalindustry/authorized

es constantly evolve. With this, hazards change.

.html.

Worker training should adapt with it. PS van der Klink, M.R. & Streumer, J.N. (2002). Ef-

fectiveness of on-the-job training. Journal of European

References Industrial Training, 26, 196-199.

American Wind Energy Association. (2010, Nov. Wayne, S.J., Liden, R.C., Kraimer, M.L., et al.

22). Wind industry unveils Seal of Approval for job (1999). The role of human capital, motivation and

training for wind turbine service technicians [Press supervisor sponsorship in predicting career success.

release]. Washington, DC: Author. Retrieved Jan. 6, Journal of Organizational Behavior, 20(5), 577-595.

www.asse.org FEBRUARY 2012 ProfessionalSafety 49

You might also like

- Toolbox Talk Register (Yard)Document14 pagesToolbox Talk Register (Yard)jumansyahamid1988No ratings yet

- 2.1 - Machine GuardingDocument6 pages2.1 - Machine Guardingkumar100% (1)

- Structural Risk Assessment & Method StatementDocument19 pagesStructural Risk Assessment & Method StatementNaresh DharmaNo ratings yet

- 10 Frequently Asked Questions About The Machinery DirectiveDocument5 pages10 Frequently Asked Questions About The Machinery Directivesujal_aminNo ratings yet

- Lifting ChecklistDocument13 pagesLifting ChecklistEric T100% (1)

- LIFTING OPERATIONS DIRECTIVEDocument93 pagesLIFTING OPERATIONS DIRECTIVEjoeybaffNo ratings yet

- ER-MO - 02 Preparing and Installing Components1Document17 pagesER-MO - 02 Preparing and Installing Components1Alex IgnatNo ratings yet

- Factories and Machinery Act 1967 (FMA 1967) - Safety Related RegulationsDocument59 pagesFactories and Machinery Act 1967 (FMA 1967) - Safety Related RegulationsZainorin Ali87% (31)

- G1 - General Site Requirements - GD351766 R5 CNDocument79 pagesG1 - General Site Requirements - GD351766 R5 CNpthuyNo ratings yet

- Site Conditions: Technical TrainingDocument16 pagesSite Conditions: Technical TrainingadrianNo ratings yet

- Mechanical Hazards and Machine SafeguardingDocument19 pagesMechanical Hazards and Machine Safeguardingm_alodat6144No ratings yet

- SIT Modul 4Document31 pagesSIT Modul 4adrianNo ratings yet

- EI TR Performance StandardDocument44 pagesEI TR Performance StandardgiampieroNo ratings yet

- QPV-CV-PRM-PMP-016 - VB Transportation Management Plan During ConstructionDocument22 pagesQPV-CV-PRM-PMP-016 - VB Transportation Management Plan During ConstructionMehwish Rehman Alvi100% (1)

- Fitcher CSPDocument53 pagesFitcher CSPMansoor Awan100% (1)

- Mns Ecp Self Audit Wet ProcessingDocument5 pagesMns Ecp Self Audit Wet ProcessingShahab Ud Din Shakeel0% (1)

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Document6 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Khaled RaafatNo ratings yet

- Eis 28Document4 pagesEis 28Ab AUNo ratings yet

- Appendix 4 - SSR - SG6.2-170-135mHH (1) Cel Mai ImportantDocument56 pagesAppendix 4 - SSR - SG6.2-170-135mHH (1) Cel Mai ImportantDaniel StefanNo ratings yet

- OHS-PR-02-07 Document ControlDocument14 pagesOHS-PR-02-07 Document ControlSn Ahsan100% (1)

- Safe Operation of Overhead CranesDocument16 pagesSafe Operation of Overhead CranesviniciusgdelimaNo ratings yet

- G+ Safe by Design Workshop Report Update: WTG Service Lifts - Follow-Up On Workshop ConclusionsDocument52 pagesG+ Safe by Design Workshop Report Update: WTG Service Lifts - Follow-Up On Workshop Conclusionsromedic36No ratings yet

- 22 Hand Tool SafetyDocument8 pages22 Hand Tool SafetyAlma Tomas-CafeNo ratings yet

- Working at Heights, Fire Safety & Confined Spaces TrainingDocument22 pagesWorking at Heights, Fire Safety & Confined Spaces Trainingadrian100% (1)

- Employee Handbook Aug 2017 - Final Version - 0Document67 pagesEmployee Handbook Aug 2017 - Final Version - 0maroof afsar100% (2)

- SIT Modul 2Document26 pagesSIT Modul 2adrianNo ratings yet

- V19 General SpecificationDocument22 pagesV19 General SpecificationVan Hung DoNo ratings yet

- SIT 2016 Safety Introduction for TechniciansDocument3 pagesSIT 2016 Safety Introduction for TechniciansadrianNo ratings yet

- Wind Turbine Fire PDFDocument24 pagesWind Turbine Fire PDFSheraz Qamer100% (1)

- Safety Manual for Construction SitesDocument99 pagesSafety Manual for Construction SitesNguyễnTiếnĐạtNo ratings yet

- Turbine SpecificationsDocument7 pagesTurbine SpecificationsFaouzi TlemcenNo ratings yet

- NGC GuideDocument69 pagesNGC GuideNasim AkhtarNo ratings yet

- Bread and Pastry TG PDFDocument19 pagesBread and Pastry TG PDFAmpolitoz86% (7)

- NASCDocument2 pagesNASCGia Minh Tieu TuNo ratings yet

- Section A G Safe Helicopter Operations in Support of The Global Offshore Wind IndustryDocument23 pagesSection A G Safe Helicopter Operations in Support of The Global Offshore Wind Industryromedic36No ratings yet

- 2.5.34 Training For Assela Wind FarmDocument42 pages2.5.34 Training For Assela Wind FarmWeldayNo ratings yet

- Wind Turbines As Confined SpacesDocument2 pagesWind Turbines As Confined SpacesPerwez21No ratings yet

- Power AscenderDocument6 pagesPower AscenderApriliando KurniawanNo ratings yet

- CE Marking For Wind TurbinesDocument2 pagesCE Marking For Wind TurbinesRamon GutierrezNo ratings yet

- Work at HeightDocument11 pagesWork at HeightEhsanNo ratings yet

- 400SS Field Glazed Installation ManualDocument75 pages400SS Field Glazed Installation ManualAmin SalahNo ratings yet

- BOOK (21st Century Skills Library - Cool STEM Careers) Wil Mara - Wind Turbine Service Technician-Cherry Lake Publishing (2013) PDFDocument36 pagesBOOK (21st Century Skills Library - Cool STEM Careers) Wil Mara - Wind Turbine Service Technician-Cherry Lake Publishing (2013) PDFfernandochinas2253No ratings yet

- Section B G Safe Helicopter Operations in Support of The Global Offshore Wind IndustryDocument115 pagesSection B G Safe Helicopter Operations in Support of The Global Offshore Wind Industryromedic36No ratings yet

- Turbine Inspection Checklist - SafetyCultureDocument21 pagesTurbine Inspection Checklist - SafetyCultureromedic36No ratings yet

- Presentation For RiggingDocument18 pagesPresentation For RiggingRameese MuhammedNo ratings yet

- NS165 NsaDocument35 pagesNS165 NsaNaif AlNo ratings yet

- Isolation and Lockout - IEDocument25 pagesIsolation and Lockout - IEyuwantoniNo ratings yet

- Crane Safety: Factors Reducing Lifting Capacity Below Rated ValuesDocument1 pageCrane Safety: Factors Reducing Lifting Capacity Below Rated ValuesvishnuNo ratings yet

- Combined Fall and Rescue Plan TemplatesDocument14 pagesCombined Fall and Rescue Plan TemplatesOsama ShaalanNo ratings yet

- 32.crane Inspection Monthly Checklist Isgecimsspocp-20f-32Document1 page32.crane Inspection Monthly Checklist Isgecimsspocp-20f-32MD AbdullahNo ratings yet

- CV For All ProfessionDocument3 pagesCV For All ProfessionArman RajuNo ratings yet

- Lock Out Tag Out SafetyDocument2 pagesLock Out Tag Out SafetyAhmed IbrahimNo ratings yet

- Dhaka Garment Factory CollapseDocument10 pagesDhaka Garment Factory CollapseMuhammad Hazim NazwiNo ratings yet

- Code of Practive For Safe Use and Operation of Suspended Working PlatformDocument62 pagesCode of Practive For Safe Use and Operation of Suspended Working PlatformthowchinNo ratings yet

- Keeline Operation & Maintenance Manual: Safety at The Highest LevelDocument24 pagesKeeline Operation & Maintenance Manual: Safety at The Highest LevelEddy Cuellar MartinezNo ratings yet

- Informatie Over Wegen en Transport Bij de Realisatie V112Document18 pagesInformatie Over Wegen en Transport Bij de Realisatie V112micnunNo ratings yet

- Lifts and Lifting Equipment Policy and Best Practice NoteDocument30 pagesLifts and Lifting Equipment Policy and Best Practice NoteAnsara Pasir TumbohNo ratings yet

- LO Procedure SampleDocument6 pagesLO Procedure SampleNenad Spiki VukomanovicNo ratings yet

- EEMUA Publications Catalogue May 2016Document5 pagesEEMUA Publications Catalogue May 2016malkaniravinderNo ratings yet

- Wire Rope Cutting ChartDocument8 pagesWire Rope Cutting ChartAkash SharmaNo ratings yet

- Hot Work at Height and From Scaffolding Presents Special Hazards. Additional Requirements Are NeededDocument2 pagesHot Work at Height and From Scaffolding Presents Special Hazards. Additional Requirements Are Neededテレブリコ ジェファーソンNo ratings yet

- Wind Turbine Nacelle Datasheet Pack ENGDocument16 pagesWind Turbine Nacelle Datasheet Pack ENGMamelucoNo ratings yet

- SRC3000UXI - APC Smart-UPS RC 3000VA 230V No Batteries - Schneider ElectricDocument10 pagesSRC3000UXI - APC Smart-UPS RC 3000VA 230V No Batteries - Schneider ElectricilkinNo ratings yet

- Project Proposal Wind MillDocument8 pagesProject Proposal Wind MillAbdul BasitNo ratings yet

- Special Report Electrical System SafetyDocument14 pagesSpecial Report Electrical System SafetyBuelvas NicanorNo ratings yet

- Dim Kingsley Chima - 00807044Document15 pagesDim Kingsley Chima - 00807044Kingsley DimNo ratings yet

- Tas s4 s5 Electronics Power Hungry ProgramDocument21 pagesTas s4 s5 Electronics Power Hungry ProgramAji ECNo ratings yet

- An Approach To Grid Control Engineer Training Using National Occupational StandardsDocument6 pagesAn Approach To Grid Control Engineer Training Using National Occupational StandardsHamlyn HolderNo ratings yet

- Sustainability at LT Jun2021Document23 pagesSustainability at LT Jun2021Pushpa LathaNo ratings yet

- Hira of ElectricalDocument14 pagesHira of ElectricaltarendraNo ratings yet

- Code of Ethics Print Ver FinalDocument1 pageCode of Ethics Print Ver FinalTruman CANo ratings yet

- OH&SMS Data Sheet-IRCA 2020Document1 pageOH&SMS Data Sheet-IRCA 2020Cesar ReyNo ratings yet

- Philippine College of Occupational Medicine, Inc.: Phil M. Pangilinan, MD, Mha, FPSMS, Dpcom, PafpDocument3 pagesPhilippine College of Occupational Medicine, Inc.: Phil M. Pangilinan, MD, Mha, FPSMS, Dpcom, PafpANNLNo ratings yet

- Cleantrol Lemon Wall Wash - MsdsDocument6 pagesCleantrol Lemon Wall Wash - MsdsVishnu NNo ratings yet

- P527M (R4) SdsDocument10 pagesP527M (R4) Sdsnursyazwani6494No ratings yet

- JSL Jajpur-1975Document3 pagesJSL Jajpur-1975Roshan JhaNo ratings yet

- Method Statement and Risk Assessment GeneralDocument16 pagesMethod Statement and Risk Assessment GeneralDwi Windi AjiNo ratings yet

- Awareness of Occupational Hazards and Use of Safety Measures Among Welders: A Cross-Sectional Study From Eastern NepalDocument6 pagesAwareness of Occupational Hazards and Use of Safety Measures Among Welders: A Cross-Sectional Study From Eastern NepalJustine BuenoStitchNo ratings yet

- GRAPHITE SAFETYDocument7 pagesGRAPHITE SAFETYakbar macheteNo ratings yet

- OMHEC Competence and Skills Requirements For An Enterprise of Competence (EOC) of Offshore CranesDocument22 pagesOMHEC Competence and Skills Requirements For An Enterprise of Competence (EOC) of Offshore CranesLasse WelleNo ratings yet

- MSDS Duct SealantDocument6 pagesMSDS Duct SealantbuddhikasatNo ratings yet

- LPG MSDS-liquid-petroleum-gas-lpgDocument10 pagesLPG MSDS-liquid-petroleum-gas-lpgJumco OPS WarriNo ratings yet

- Msds - Manganese Octoate 10Document5 pagesMsds - Manganese Octoate 10Future InnovationsNo ratings yet

- Method Statement - Lafarge SandwashDocument14 pagesMethod Statement - Lafarge SandwashfatinNo ratings yet

- Sulfuric Acid 93-Pct WT-SA15 SDSDocument6 pagesSulfuric Acid 93-Pct WT-SA15 SDSnitroxx7No ratings yet

- ENGG5103 Week 2 Lecture Notes 2021: 1. What Types of "Incidents or Accidents" Can You List?Document4 pagesENGG5103 Week 2 Lecture Notes 2021: 1. What Types of "Incidents or Accidents" Can You List?Xuyan ZhuNo ratings yet

- Final - LNG PDFDocument19 pagesFinal - LNG PDFMahdiNo ratings yet

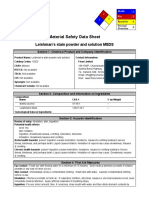

- Material Safety Data Sheet: Leishman's Stain Powder and Solution MSDSDocument5 pagesMaterial Safety Data Sheet: Leishman's Stain Powder and Solution MSDSmaha muhammedNo ratings yet

- Cookery NC II CGDocument47 pagesCookery NC II CGVanessa NaveraNo ratings yet