Professional Documents

Culture Documents

3412e PDF

Uploaded by

On OffOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3412e PDF

Uploaded by

On OffCopyright:

Available Formats

SAFETY.CAT.

COM

3412E and C30

MARINE ENGINES

Engine Safety

Excerpted from Operation & Maintenance Manual (SEBU7178-06)

2009 Caterpillar

All Rights Reserved

Downloaded from www.Manualslib.com manuals search engine

i03602780

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to observe

basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous

situations before an accident occurs. A person must be alert to potential hazards. This person should also

have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings

are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the Safety Alert Symbol and followed by a Signal Word such as

DANGER, WARNING or CAUTION. The Safety Alert WARNING label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or pictorially

presented.

A non-exhaustive list of operations that may cause product damage are identified by NOTICE labels

on the product and in this publication.

Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard.

The warnings in this publication and on the product are, therefore, not all inclusive. You must

not use this product in any manner different from that considered by this manual without first

satisfying yourself that you have considered all safety rules and precautions applicable to the

operation of the product in the location of use, including site-specific rules and precautions

applicable to the worksite. If a tool, procedure, work method or operating technique that is not

specifically recommended by Caterpillar is used, you must satisfy yourself that it is safe for you

and for others. You should also ensure that the product will not be damaged or become unsafe by

the operation, lubrication, maintenance or repair procedures that you intend to use.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before you

start any job. Caterpillar dealers have the most current information available.

When replacement parts are required for this

product Caterpillar recommends using Caterpil-

lar replacement parts or parts with equivalent

specifications including, but not limited to, phys-

ical dimensions, type, strength and material.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

Downloaded from www.Manualslib.com manuals search engine

6 SEBU7178-06

Safety Section

Safety Messages

Safety Section

i02553902

Safety Messages

SMCS Code: 1000; 7405

There are several specific safety messages on

this engine. The exact location of the hazards and

the description of the hazards are reviewed in this

section. Please become familiarized with all safety

messages.

Make sure that all of the safety messages are legible.

Clean the safety messages or replace the safety

messages if you cannot read the words. Replace

the illustrations if the illustrations are not visible.

When you clean the safety messages, use a cloth,

water and soap. Do not use solvent, gasoline, or

other harsh chemicals to clean the safety messages.

Solvents, gasoline, or harsh chemicals could loosen

the adhesive that secures the safety message. Loose

adhesive will allow the safety message to fall.

Replace any safety message that is damaged, or

missing. If a safety message is attached to a part

that is replaced, install a safety message on the

replacement part. Any Caterpillar dealer can provide

new safety messages.

The safety messages that may be found on the

engine are illustrated and described below.

Downloaded from www.Manualslib.com manuals search engine

SEBU7178-06 7

Safety Section

Safety Messages

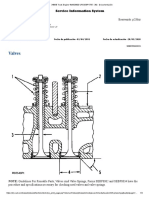

g01278236

Illustration 1

Downloaded from www.Manualslib.com manuals search engine

8 SEBU7178-06

Safety Section

Safety Messages

Universal Warning (1) Hot Fluid Under Pressure (2)

The universal safety message is located on each The safety message for hot fluid under pressure is

side of the valve covers. located on the expansion tank in front of the filler

neck.

g00934493

g00930639

Do not operate or work on this equipment unless

you have read and understand the instructions Pressurized system! Hot coolant can cause seri-

and warnings in the Operation and Maintenance ous burns, injury or death. To open the cooling

Manuals. Failure to follow the instructions or system filler cap, stop the engine and wait until

heed the warnings could result in serious injury the cooling system components are cool. Loosen

or death. the cooling system pressure cap slowly in order to

relieve the pressure. Read and understand the Op-

eration and Maintenance Manual before perform-

ing any cooling system maintenance.

Downloaded from www.Manualslib.com manuals search engine

SEBU7178-06 9

Safety Section

General Hazard Information

Clutch (If Equipped) Engine Lifting

g00367054

Illustration 3

Typical Example

The safety message for lifting the engine with a fuel

tank is located on the fuel tank (if equipped).

g00107406

Illustration 2

Typical Example

The safety message for the clutch is located on the

clutch housing (if equipped).

g00100728

Lift eyes or tank can fail when lifting tank con-

taining fluids resulting in possible personal injury.

g00107407 Drain tank of all fluids before lifting.

Rotating gears can cause entanglement of fingers

or entanglement of hands. Do not service this i02965953

component without first reading the operator manual.

General Hazard Information

SMCS Code: 1000; 7405

Attach a Do Not Operate warning tag or a similar

warning tag to the start switch or to the controls

before the engine is serviced or before the engine is

repaired. These warning tags (Special Instruction,

SEHS7332) are available from your Caterpillar

dealer. Attach the warning tags to the engine and to

each operator control station. When it is appropriate,

disconnect the starting controls.

Downloaded from www.Manualslib.com manuals search engine

10 SEBU7178-06

Safety Section

General Hazard Information

Ensure that all protective guards and all covers are

secured in place on the engine.

Never put maintenance fluids into glass containers.

Glass containers can break.

Use all cleaning solutions with care.

Report all necessary repairs.

Unless other instructions are provided, perform

the maintenance under the following conditions:

The engine is stopped. Ensure that the engine

g00104545

cannot be started.

Illustration 4

The protective locks or the controls are in the

Do not allow unauthorized personnel on the engine applied position.

or around the engine when the engine is serviced.

Disconnect the batteries when maintenance

Engine exhaust contains products of combustion is performed or when the electrical system is

which may be harmful to your health. Always start the serviced. Disconnect the battery ground leads.

engine and operate the engine in a well ventilated Tape the leads in order to help prevent sparks.

area. If the engine is in an enclosed area, vent the

engine exhaust to the outside. For initial start-up of a new engine or for starting an

engine that has been serviced, make provisions to

Cautiously remove the following parts: stop the engine if an overspeed occurs. This may

be accomplished by shutting off the fuel supply

Note: To help prevent spraying or splashing of and/or the air supply to the engine.

pressurized fluids, hold a rag over the part that is

being removed. Start the engine with the operator controls. Never

short across the starting motor terminals or the

Filler caps batteries. This could bypass the engine neutral

start system and/or the electrical system could be

Grease fittings damaged.

Pressure taps

Pressurized Air and Water

Breathers

Pressurized air and/or water can cause debris

Drain plugs and/or hot water to be blown out. This could result in

personal injury.

Use caution when cover plates are removed.

Gradually loosen but do not remove the last two bolts When pressurized air and/or pressurized water is

or nuts that are located at opposite ends of the cover used for cleaning, wear protective clothing, protective

plate or the device. Before removing the last two shoes, and eye protection. Eye protection includes

bolts or nuts, pry the cover loose in order to relieve goggles or a protective face shield.

any spring pressure or other pressure.

The maximum air pressure for cleaning purposes

Wear a hard hat, protective glasses, and other must be reduced to 205 kPa (30 psi) when the air

protective equipment, as required. nozzle is deadheaded and used with effective chip

guarding (if applicable) and personal protective

Do not attempt any repairs that are not understood. equipment. The maximum water pressure for

Use the proper tools. Replace any equipment that cleaning purposes must be below 275 kPa (40 psi).

is damaged or repair the equipment. Always wear eye protection for cleaning the cooling

system.

When work is performed around an engine that is

operating, wear protective devices for ears in order

to help prevent damage to hearing.

Do not wear loose clothing or jewelry that can snag

on controls or on other parts of the engine.

Downloaded from www.Manualslib.com manuals search engine

SEBU7178-06 11

Safety Section

General Hazard Information

Fluid Penetration Use caution. Avoid inhaling dust that might be

generated when you handle components that contain

Always use a board or cardboard when the engine asbestos fibers. Inhaling this dust can be hazardous

components are checked for leaks. Leaking fluid to your health. The components that may contain

that is under pressure can cause serious injury or asbestos fibers are brake pads, brake bands, lining

possible death. This includes leaks that are the size material, clutch plates, and some gaskets. The

of a pin hole. asbestos that is used in these components is usually

bound in a resin or sealed in some way. Normal

If fluid is injected into the skin, seek treatment handling is not hazardous unless airborne dust that

immediately. Seek treatment from a doctor that is contains asbestos is generated.

familiar with this type of injury.

If dust that may contain asbestos is present, there

are several guidelines that should be followed:

Containing Fluid Spillage

Care must be used in order to ensure that the fluids Never use compressed air for cleaning.

are contained during the inspection, the maintenance,

the testing, the adjusting, and the repair of the engine. Avoid brushing materials that contain asbestos.

Prepare to collect the fluid with suitable containers

before any compartment is opened or before any Avoid grinding materials that contain asbestos.

component is disassembled.

Use a wet method in order to clean up asbestos

materials.

Refer to Catalog, NENG2500, Caterpillar Dealer

Service Tool Catalog for the following items:

A vacuum cleaner that is equipped with a high

efficiency particulate air filter (HEPA) can also be

Tools that are suitable for collecting fluids and used.

equipment that is suitable for collecting fluids

Obey all local regulations for the disposal of liquids. Use exhaust ventilation on permanent machining

jobs.

Asbestos Information Wear an approved respirator if there is no other

way to control the dust.

Comply with applicable rules and regulations

for the work place. In the United States, use

Occupational Safety and Health Administration

(OSHA) requirements. These OSHA requirements

can be found in 29 CFR 1910.1001.

Obey environmental regulations for the disposal

of asbestos.

Stay away from areas that might have asbestos

particles in the air.

Illustration 5

g00702022 Lines, Tubes, and Hoses

Caterpillar equipment and replacement parts that are Do not bend or strike high pressure lines. Do not

shipped from Caterpillar are asbestos free. Caterpillar install lines, tubes, or hoses that are damaged.

recommends the use of only genuine Caterpillar

replacement parts. Use the following guidelines Repair any fuel lines, oil lines, tubes, or hoses that

when you handle any replacement parts that contain are loose or damaged. Leaks can cause fires.

asbestos or when you handle asbestos debris.

Inspect all lines, tubes and hoses carefully. Do

not use bare hands to check for leaks. Always

use a board or cardboard for checking engine

components for leaks. Tighten all connections to the

recommended torque.

Check for the following conditions:

Downloaded from www.Manualslib.com manuals search engine

12 SEBU7178-06

Safety Section

Burn Prevention

End fittings that are damaged or leaking Cooling system conditioner contains alkali. Alkali can

cause personal injury. Do not allow alkali to contact

Outer covering that is chafed or cut the skin, the eyes, or the mouth.

Wire that is exposed in reinforced hose Oils

Outer covering that is ballooning locally Hot oil and hot lubricating components can cause

personal injury. Do not allow hot oil to contact the

Flexible part of the hose that is kinked or crushed skin. Also, do not allow hot components to contact

the skin.

Armoring that is embedded in the outer covering

Ensure that all of the clamps, the guards, and the Batteries

heat shields are installed correctly. This will help to

prevent these effects: vibration, rubbing against other Electrolyte is an acid. Electrolyte can cause personal

parts, and excessive heat during operation. injury. Do not allow electrolyte to contact the skin or

the eyes. Always wear protective glasses for servicing

batteries. Wash hands after touching the batteries

Dispose of Waste Properly and connectors. Use of gloves is recommended.

Improperly disposing of waste can threaten the

environment. Potentially harmful fluids should be i01028355

disposed of according to local regulations.

Fire Prevention and Explosion

Always use leakproof containers when you drain

fluids. Do not pour waste onto the ground, down a

Prevention

drain, or into any source of water. SMCS Code: 1000; 7405

i01480768 Fire may result from lubricating oil or from fuel that

is sprayed on hot surfaces. Fire may cause personal

Burn Prevention injury and property damage. Inspect all lines and

tubes for wear or for deterioration. The lines must

SMCS Code: 1000; 7405 be properly routed. The lines must have adequate

support and secure clamps. Tighten all connections

Do not touch any part of an operating engine. to the recommended torque. Leaks can cause fires.

Allow the engine to cool before any maintenance

is performed on the engine. Relieve all pressure Determine whether the engine will be operated in an

in the air system, in the hydraulic system, in the environment that allows combustible gases to be

lubrication system, in the fuel system, or in the drawn in through the air inlet system. These gases

cooling system before any lines, fittings or related could cause the engine to overspeed. This could

items are disconnected. result in bodily injury, property damage, or damage

to the engine.

Coolant If the application involves the presence of combustible

gases, consult your Caterpillar dealer in order to

When the engine is at operating temperature, the

obtain additional information concerning suitable

engine coolant is hot. The coolant is also under

pressure. The radiator and all lines to the heaters or protection devices.

to the engine contain hot coolant.

Leaking fuel or fuel that is spilled onto hot surfaces or

Any contact with hot coolant or with steam can cause onto electrical components can cause a fire.

severe burns. Allow cooling system components to

All fuels, most lubricants, and some coolant mixtures

cool before the cooling system is drained.

are flammable. Diesel fuel is flammable. Gasoline is

flammable. The mixture of diesel fumes and gasoline

Check the coolant level after the engine has stopped

fumes is extremely explosive.

and the engine has been allowed to cool.

Do not smoke while the engine is refueled. Do not

Ensure that the filler cap is cool before removing the

smoke in the refueling area.

filler cap. The filler cap must be cool enough to touch

with a bare hand. Remove the filler cap slowly in

Store all fuels and all lubricants in properly marked

order to relieve pressure.

containers. Store the protective containers in a safe

place.

Downloaded from www.Manualslib.com manuals search engine

SEBU7178-06 13

Safety Section

Crushing Prevention and Cutting Prevention

Do not smoke in battery charging areas. Batteries Wiring must be kept in good condition. Wires must

give off flammable fumes which can explode. be properly routed and securely attached. Routinely

inspect the wiring for wear or for deterioration. Loose

Do not smoke in areas that contain flammable wiring, unattached wiring, or unnecessary wiring

material. must be eliminated. All wires and all cables must be

of the recommended gauge. The wires and cables

Store oily rags and other flammable material in must be connected to a fuse or to a circuit breaker, as

protective containers. required. Do not bypass fuses and/or circuit breakers.

Do not use a wire of a smaller gauge. Arcing or

Do not weld on pipes or tubes that contain flammable sparking could cause a fire. Secure connections,

fluids. Do not flame cut pipes or tubes that contain recommended wiring, and properly maintained

flammable fluids. Before pipes or tubes are welded battery cables will help to prevent arcing or sparking.

or flame cut, clean the inside and clean the outside

of the pipes or tubes thoroughly with nonflammable

solvent.

Fire Extinguisher

Ensure that a fire extinguisher is available. Be familiar

Do not allow flammable materials to accumulate on

with the operation of the fire extinguisher. Inspect

the engine.

the fire extinguisher and service the fire extinguisher

regularly. Service the fire extinguisher according to

Do not expose the engine to flames.

the recommendations on the instruction plate.

Exhaust shields (if equipped) protect hot exhaust

components from oil or fuel spray in case of a line, i01359666

a tube, or a seal failure. Exhaust shields must be

installed correctly. Crushing Prevention and

Dispose of oil according to local regulations. Oil

Cutting Prevention

filters and fuel filters must be properly installed. The SMCS Code: 1000; 7405

housing covers must be tightened to the proper

torque when the housing covers are reinstalled. Support the component properly when work beneath

the component is performed.

Batteries must be kept clean. The covers (if equipped)

must be kept on the cells. Use the recommended Unless other maintenance instructions are provided,

cables, connections, and battery box covers when never attempt adjustments while the engine is

the engine is operated. running.

When the engine is started from an external source, Stay clear of all rotating parts and of all moving

always connect the positive + jump start cable to parts. Leave the guards in place until maintenance

the positive + terminal of the battery of the engine is performed. After the maintenance is performed,

that is being started. Make this connection before the reinstall the guards.

negative jump start cable is connected.

Keep objects away from moving fan blades. The fan

To help prevent sparks from igniting combustible blades will throw objects or cut objects.

gases that are produced by some batteries, the

negative jump start cable should be connected When objects are struck, wear protective glasses in

last from the external power source to the negative order to avoid injury to the eyes.

terminal of the starting motor. If the starting motor

is not equipped with a negative terminal, connect Chips or other debris may fly off objects when objects

the jump start cable to the engine block. are struck. Before objects are struck, ensure that no

one will be injured by flying debris.

Check the electrical wires daily for wires that are

loose or frayed. Before the engine is operated,

tighten all loose electrical wires. Repair all frayed i01372247

electrical wires.

Mounting and Dismounting

SMCS Code: 1000; 7405

Inspect the steps, the handholds, and the work area

before mounting the engine. Keep these items clean

and keep these items in good repair.

Downloaded from www.Manualslib.com manuals search engine

14 SEBU7178-06

Safety Section

Before Starting Engine

Mount the engine and dismount the engine only at All protective guards and all protective covers must

locations that have steps and/or handholds. Do not be installed if the engine must be started in order

climb on the engine, and do not jump off the engine. to perform service procedures. To help prevent an

accident that is caused by parts in rotation, work

Face the engine in order to mount the engine or around the parts carefully.

dismount the engine. Maintain a three-point contact

with the steps and handholds. Use two feet and one Do not bypass the automatic shutoff circuits. Do not

hand or use one foot and two hands. Do not use any disable the automatic shutoff circuits. The circuits are

controls as handholds. provided in order to help prevent personal injury. The

circuits are also provided in order to help prevent

Do not stand on components which cannot support engine damage.

your weight. Use an adequate ladder or use a work

platform. Secure the climbing equipment so that the See the Service Manual for repairs and for

equipment will not move. adjustments.

Do not carry tools or supplies when you mount the

i01103904

engine or when you dismount the engine. Use a hand

line to raise and lower tools or supplies. Engine Starting

i03560601 SMCS Code: 1000

Before Starting Engine If a warning tag is attached to the engine start switch

or to the controls, DO NOT start the engine or move

SMCS Code: 1000 the controls. Consult with the person that attached

the warning tag before the engine is started.

NOTICE

For initial start-up of a new or rebuilt engine, and for All protective guards and all protective covers must

start-up of an engine that has been serviced, make be installed if the engine must be started in order

provision to shut the engine off should an overspeed to perform service procedures. To help prevent an

occur. This may be accomplished by shutting off the accident that is caused by parts in rotation, work

air and/or fuel supply to the engine. around the parts carefully.

Start the engine from the operator's compartment or

from the engine start switch.

Engine exhaust contains products of combustion Always start the engine according to the procedure

which may be harmful to your health. Always start that is described in this Operation and Maintenance

and operate the engine in a well ventilated area Manual, Engine Starting topic (Operation Section).

and, if in an enclosed area, vent the exhaust to the Knowing the correct procedure will help to prevent

outside. major damage to the engine components. Knowing

the procedure will also help to prevent personal injury.

Inspect the engine for potential hazards. To ensure that the jacket water heater (if equipped)

and/or the lube oil heater (if equipped) is working

Do not start the engine or move any of the controls properly, check the water temperature gauge and the

if there is a DO NOT OPERATE warning tag or oil temperature gauge during the heater operation.

similar warning tag attached to the start switch or to

the controls. Engine exhaust contains products of combustion

that can be harmful to your health. Always start the

Before starting the engine, ensure that no one is on, engine and operate the engine in a well ventilated

underneath, or close to the engine. Ensure that the area. If the engine is started in an enclosed area,

area is free of personnel. vent the engine exhaust to the outside.

If equipped, ensure that the lighting system for the

engine is suitable for the conditions. Ensure that all Ether

lights work properly, if equipped.

Ether is poisonous and flammable.

Do not inhale ether, and do not allow ether to contact

the skin. Personal injury could result.

Do not smoke while ether cylinders are changed.

Downloaded from www.Manualslib.com manuals search engine

SEBU7178-06 15

Safety Section

Engine Stopping

Use ether in well ventilated areas. To help prevent sparks from igniting combustible

gases that are produced by some batteries, the

Use ether with care in order to avoid fires. negative jump start cable should be connected

last from the external power source to the negative

Keep ether cylinders out of the reach of unauthorized terminal of the starting motor. If the starting motor

persons. is not equipped with a negative terminal, connect

the jump start cable to the engine block.

Store ether cylinders in authorized storage areas

only. Check the electrical wires daily for wires that are

loose or frayed. Tighten all loose electrical wires

Do not store ether cylinders in direct sunlight or at before the engine is operated. Repair all frayed

temperatures above 49 C (120 F). electrical wires before the engine is started. See

the Operation and Maintenance Manual, Engine

Discard the ether cylinders in a safe place. Do not Starting for specific starting instructions.

puncture the ether cylinders. Do not burn the ether

cylinders. Grounding Practices

i01462046 The electrical system for the vessel and the engine

must be properly grounded. Proper grounding

Engine Stopping is necessary for optimum engine performance

and reliability. Improper grounding will result in

SMCS Code: 1000 uncontrolled electrical circuit paths and in unreliable

electrical circuit paths.

Stop the engine according to the procedure in

the Operation and Maintenance Manual, Engine Uncontrolled electrical circuit paths can result in

Stopping (Operation Section) in order to avoid damage to main bearings, to crankshaft bearing

overheating of the engine and accelerated wear of journal surfaces, and to aluminum components.

the engine components. Uncontrolled electrical circuit paths can also cause

electrical noise. Electrical noise may degrade the

Use the Emergency Stop Button (if equipped) ONLY performance of the vessel and of the radio.

in an emergency situation. Do not use the Emergency

Stop Button for normal engine stopping. After an The alternator, the starting motor, and all of the

emergency stop, DO NOT start the engine until the electrical systems MUST be grounded to the negative

problem that caused the emergency stop has been battery terminal. The alternator must meet marine

corrected. isolation requirements. The starting motor must also

meet marine isolation requirements.

Stop the engine if an overspeed condition occurs

during the initial start-up of a new engine or an engine For engines which have an alternator that is grounded

that has been overhauled. This may be accomplished to an engine component, a ground strap MUST

by shutting off the fuel supply to the engine and/or connect that component to the negative battery

shutting off the air supply to the engine. terminal and the component MUST be electrically

isolated from the engine.

To stop an electronically controlled engine, cut the

power to the engine. A bus bar with a direct path to the negative - battery

terminal is permissible and recommended for use

for all components that require a negative - battery

i02456933

connection. The bus bar should be directly connected

Electrical System to the negative - battery terminal. A bonding cable

should also be connected from the cylinder block to

SMCS Code: 1000; 1400 the bus bar on the negative - battery connection.

Never disconnect any charging unit circuit or battery Use of a bus bar ensures that the Electronic Control

circuit cable from the battery when the charging unit Module (ECM) and all of the components that are

is operating. A spark can cause the combustible connected to the ECM have a common reference

gases that are produced by some batteries to ignite. point.

Refer to Special Instruction, REHS1187, Marine

Engine Electronic Installation Guide for additional

information on grounding procedures.

Downloaded from www.Manualslib.com manuals search engine

You might also like

- C-15 Petroleum EnginesDocument64 pagesC-15 Petroleum Enginesmohammad hazbehzad100% (1)

- Cylinder Head - InstallDocument4 pagesCylinder Head - InstallGeorge GuerreroNo ratings yet

- CAT 3412 Lubrication SystemDocument5 pagesCAT 3412 Lubrication SystemCEVegaO100% (1)

- 3408 Automatic Timing Advance PDFDocument6 pages3408 Automatic Timing Advance PDFmanu luvungaNo ratings yet

- Caterpillar 3508, 3508B, 3508CDocument11 pagesCaterpillar 3508, 3508B, 3508CGazNo ratings yet

- Senr3130 19 00 - Manuals Service Modules - SpecificationsDocument24 pagesSenr3130 19 00 - Manuals Service Modules - Specificationsmostafa aliNo ratings yet

- SS815Document24 pagesSS815Adel Ahmed100% (1)

- Assembling C32Document24 pagesAssembling C32Muhammad Ramadhan100% (2)

- Systems Operation Testing Adjusting 3500 Generator Set Engine AttachmentsDocument34 pagesSystems Operation Testing Adjusting 3500 Generator Set Engine Attachmentsale alvarezNo ratings yet

- ShutoffDocument27 pagesShutoffSergio Andrés ArizaNo ratings yet

- Quick guide to piston ring inspection and measurementDocument7 pagesQuick guide to piston ring inspection and measurementshashirajNo ratings yet

- Analysis Report: Marginal NormalDocument2 pagesAnalysis Report: Marginal NormalJohn Choquemaque MendozaNo ratings yet

- Marine Engine: SpecificationsDocument4 pagesMarine Engine: SpecificationsSiding BarroNo ratings yet

- D399 Operation SystemDocument64 pagesD399 Operation SystemNOUR ZAINNo ratings yet

- Manual de Operacion - Side Boom CaterpillarDocument84 pagesManual de Operacion - Side Boom CaterpillarJaime Sua100% (1)

- Caterpillar C15 FTH000001Document3 pagesCaterpillar C15 FTH000001Hendra MechanicNo ratings yet

- Detonation SensorDocument1 pageDetonation Sensormiguel oswaldo gonzalez benitezNo ratings yet

- Cat 3304b Disassimble BearingDocument8 pagesCat 3304b Disassimble BearingMahmoud KhattabNo ratings yet

- Cat 3512 1280HP A RatingDocument4 pagesCat 3512 1280HP A RatingingjoseosunaNo ratings yet

- Sistema de Operacion Testing y Adjusting Renr5078!07!00-AllDocument80 pagesSistema de Operacion Testing y Adjusting Renr5078!07!00-AllMartin Franco100% (2)

- Manual de Mantenimiento Caterpillar 3412Document203 pagesManual de Mantenimiento Caterpillar 3412Crespo JorgeNo ratings yet

- Disassembly and Assembly: C27 and C32 Generator Sets EnginesDocument108 pagesDisassembly and Assembly: C27 and C32 Generator Sets Engineskariem noweerNo ratings yet

- C15C18T4IDocument108 pagesC15C18T4IDefinal ChaniagoNo ratings yet

- Overhaul Considerations: Operation and Maintenance ManualDocument6 pagesOverhaul Considerations: Operation and Maintenance ManualCamilo Andres Cardozo FajardoNo ratings yet

- 3512 Techdoc - Print - PageDocument4 pages3512 Techdoc - Print - Pagefromgod83100% (1)

- Caterpillar 3500b Disassembly Assembly Manual 558 PagesDocument558 pagesCaterpillar 3500b Disassembly Assembly Manual 558 Pagesroland100% (1)

- Eliminator™ FilterDocument35 pagesEliminator™ FiltertstkupdhNo ratings yet

- E362 Engine OverspeedDocument2 pagesE362 Engine OverspeedTeo Sil CasNo ratings yet

- 6 Cyl Cummins 6 CTA83 GSDSmaintDocument761 pages6 Cyl Cummins 6 CTA83 GSDSmaintukrdiselNo ratings yet

- C15 and C18 Electrical System Industrial and Petroleum EngineDocument4 pagesC15 and C18 Electrical System Industrial and Petroleum EngineLhsan Rajawi0% (1)

- 3406B TruckDocument4 pages3406B Truckvictor franco gallegosNo ratings yet

- Manual Partes 3516Document100 pagesManual Partes 3516Jorge Enrique Fuentes Marin100% (1)

- Refill CapacitiesDocument4 pagesRefill CapacitieslisahunNo ratings yet

- Testing For Excessive Cylinder Blowby in 3500 EnginesDocument10 pagesTesting For Excessive Cylinder Blowby in 3500 EnginesPILAR MARTINEZNo ratings yet

- Caterpillar R448 Voltage Regulator Setup, Troubleshooting, and Correct Part Identification Guide (4450, 4467)Document7 pagesCaterpillar R448 Voltage Regulator Setup, Troubleshooting, and Correct Part Identification Guide (4450, 4467)CEVegaO100% (1)

- QSK60 Over Head Valve Setting PerformaDocument2 pagesQSK60 Over Head Valve Setting PerformaMuhammad Ishfaq100% (1)

- 3512B Marine Engine S2L00001-UP (SEBP3916 - 57) - Systems & Components PDFDocument173 pages3512B Marine Engine S2L00001-UP (SEBP3916 - 57) - Systems & Components PDFnauta007No ratings yet

- Sebu8224-08-00-3500c Omm-2014 PDFDocument160 pagesSebu8224-08-00-3500c Omm-2014 PDFMartin Franco100% (2)

- 3500 Series Engines Hydramechanical Protective SystemDocument18 pages3500 Series Engines Hydramechanical Protective SystemEbied Yousif AlyNo ratings yet

- SEBU7843-3408C&3412C Aux OMMDocument140 pagesSEBU7843-3408C&3412C Aux OMMHải Lưu Minh100% (1)

- Maintenance Bintang Diesel 3516Document635 pagesMaintenance Bintang Diesel 3516bintang Diesel100% (1)

- Volvo Penta 200 KW TAD753GE EPA Tier 3 Emissions Engine Spec SheetDocument13 pagesVolvo Penta 200 KW TAD753GE EPA Tier 3 Emissions Engine Spec SheetJoanne CordesNo ratings yet

- Manual Operacion y Maqntto R1600G SEBU7331-01Document196 pagesManual Operacion y Maqntto R1600G SEBU7331-01Ricky Vil100% (1)

- 3412 Gen Set Product DescriptionDocument28 pages3412 Gen Set Product DescriptionFabricio Delgado100% (1)

- 3512C Oil Well Servicing EngineDocument16 pages3512C Oil Well Servicing EngineMaxiNo ratings yet

- Manual C18 PDFDocument42 pagesManual C18 PDFRannier CazagrandeNo ratings yet

- Power Gri P: Installation & Maintenance ManualDocument36 pagesPower Gri P: Installation & Maintenance ManualDina BihaqqiNo ratings yet

- Cummins QSK60 Engine Spare Parts CatalogDocument22 pagesCummins QSK60 Engine Spare Parts CatalogBillNo ratings yet

- Finding The Top Center Position For The No. 1 PistonDocument3 pagesFinding The Top Center Position For The No. 1 PistonHugo CiprianiNo ratings yet

- 3412E FlywheelDocument4 pages3412E Flywheelmohammed mostafaNo ratings yet

- Cat 3400 AdjustingDocument7 pagesCat 3400 AdjustingaliNo ratings yet

- C15 Genset SchematicDocument8 pagesC15 Genset SchematicdubimouNo ratings yet

- DATA BOOSTER 3412C Marine Engine High Performance 3JK00146-UP (SEBP2969 - 54) - Sistemas y ComponentesDocument8 pagesDATA BOOSTER 3412C Marine Engine High Performance 3JK00146-UP (SEBP2969 - 54) - Sistemas y ComponentesmanuelNo ratings yet

- CatDocument36 pagesCatnagananda_ar100% (1)

- Piston Cooling Jets - Remove and InstallDocument4 pagesPiston Cooling Jets - Remove and Installeshopmanual limaNo ratings yet

- C15, C18 and C27 Engines LEHR8068-01Document4 pagesC15, C18 and C27 Engines LEHR8068-01costy_trans100% (1)

- Caterpillar 3412D MARINE ENGINE Workshop Repair Service Manual PDF DownloadDocument405 pagesCaterpillar 3412D MARINE ENGINE Workshop Repair Service Manual PDF Downloadben threadwell75% (4)

- Cylinder Pressure TestDocument4 pagesCylinder Pressure TestPILAR MARTINEZNo ratings yet

- Safety: Operation and Maintenance Manual ExcerptDocument22 pagesSafety: Operation and Maintenance Manual Excerptivan_hadi_prawiraNo ratings yet

- 3015 PDFDocument24 pages3015 PDFO ParNo ratings yet

- The Calculation For Hospital Piping System:-: Chapter FIVEDocument4 pagesThe Calculation For Hospital Piping System:-: Chapter FIVEOn OffNo ratings yet

- BSS Instructor Course Dates 2017Document2 pagesBSS Instructor Course Dates 2017On OffNo ratings yet

- J. Kowalski, J. Pstruś, S. Pawlak, M. Kostrzewa, R. Martynowski, W. WołczyńskiDocument15 pagesJ. Kowalski, J. Pstruś, S. Pawlak, M. Kostrzewa, R. Martynowski, W. WołczyńskiOn OffNo ratings yet

- R 0659 eDocument28 pagesR 0659 eOn OffNo ratings yet

- VIBRATION ANALYSIS TITLEDocument153 pagesVIBRATION ANALYSIS TITLEAnonymous ffje1rpa100% (1)

- D. Infrared ThermographyDocument28 pagesD. Infrared ThermographyOn OffNo ratings yet

- TC 680Document16 pagesTC 680On OffNo ratings yet

- December - Cost of Goods Sold (Journal)Document14 pagesDecember - Cost of Goods Sold (Journal)kuro hanabusaNo ratings yet

- AAR Maintenance 001Document3 pagesAAR Maintenance 001prakash reddyNo ratings yet

- Business Startup Practical Plan PDFDocument70 pagesBusiness Startup Practical Plan PDFShaji Viswanathan. Mcom, MBA (U.K)No ratings yet

- Philippines implements external quality assessment for clinical labsDocument2 pagesPhilippines implements external quality assessment for clinical labsKimberly PeranteNo ratings yet

- 2.assessment of Dental Crowding in Mandibular Anterior Region by Three Different MethodsDocument3 pages2.assessment of Dental Crowding in Mandibular Anterior Region by Three Different MethodsJennifer Abella Brown0% (1)

- NLOG GS PUB 1580 VGEXP-INT3-GG-RPT-0001.00 P11-06 Geological FWRDocument296 pagesNLOG GS PUB 1580 VGEXP-INT3-GG-RPT-0001.00 P11-06 Geological FWRAhmed GharbiNo ratings yet

- Job Satisfaction RRLDocument39 pagesJob Satisfaction RRLMarie Tiffany100% (1)

- Natural Resources in PakistanDocument5 pagesNatural Resources in PakistanSohaib ENo ratings yet

- Lease Practice QuestionsDocument4 pagesLease Practice QuestionsAbdul SamiNo ratings yet

- Manual Masina de Spalat Slim SamsungDocument1,020 pagesManual Masina de Spalat Slim SamsungPerfectreviewNo ratings yet

- Urban Drainage Modelling Guide IUD - 1Document196 pagesUrban Drainage Modelling Guide IUD - 1Helmer Edgardo Monroy GonzálezNo ratings yet

- BS 5911-120Document33 pagesBS 5911-120Niranjan GargNo ratings yet

- C. Drug Action 1Document28 pagesC. Drug Action 1Jay Eamon Reyes MendrosNo ratings yet

- How To Become A Coffee Aficionado: Tips & Tricks: Kate Macdonnell Brewing Updated: Feb 06 2023Document17 pagesHow To Become A Coffee Aficionado: Tips & Tricks: Kate Macdonnell Brewing Updated: Feb 06 2023sadenaikeNo ratings yet

- Insects, Stings and BitesDocument5 pagesInsects, Stings and BitesHans Alfonso ThioritzNo ratings yet

- Abortion and UtilitarianismDocument4 pagesAbortion and UtilitarianismBrent Harvey Soriano JimenezNo ratings yet

- Solution Manual of Physics by Arthur BeiserDocument145 pagesSolution Manual of Physics by Arthur BeiserManuull71% (49)

- PERSONS Finals Reviewer Chi 0809Document153 pagesPERSONS Finals Reviewer Chi 0809Erika Angela GalceranNo ratings yet

- QRF HD785-7Document2 pagesQRF HD785-7Ralf MaurerNo ratings yet

- Neurons and Nerve Impulses: Nandika Arora and Risa Gaikwad (11 G2)Document17 pagesNeurons and Nerve Impulses: Nandika Arora and Risa Gaikwad (11 G2)RisaNo ratings yet

- The Impact of StressDocument3 pagesThe Impact of StressACabalIronedKryptonNo ratings yet

- BCM Continuous ImprovementDocument22 pagesBCM Continuous ImprovementnikoNo ratings yet

- BOF, LF & CasterDocument14 pagesBOF, LF & CastermaklesurrahmanNo ratings yet

- Pulsar2 User Manual - ENDocument83 pagesPulsar2 User Manual - ENJanette SouzaNo ratings yet

- Tutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)Document3 pagesTutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)NOR SYAZLIANA ROS AZAHARNo ratings yet

- Clinical Case Report No 2Document11 pagesClinical Case Report No 2ملک محمد صابرشہزاد50% (2)

- Antenna LecDocument31 pagesAntenna Lecjosesag518No ratings yet

- FinalsDocument8 pagesFinalsDumpNo ratings yet

- 2 English Course BDocument8 pages2 English Course BAnjana27No ratings yet

- Wastewater Treatment Plant Design PDFDocument68 pagesWastewater Treatment Plant Design PDFmostafa1alaahobaNo ratings yet