Professional Documents

Culture Documents

Sadev Classic Attaches en

Uploaded by

Gerald VlaseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sadev Classic Attaches en

Uploaded by

Gerald VlaseCopyright:

Available Formats

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:20 Page 1

SPIDERS ::

Casted stainless steel spider

Ref: S3000 > Page 3.05

Ref: S3001 > Page 3.07

SUMMARY Ref: S3006 > Page 3.09

Casted aluminium spider

Ref: S3007 > Page 3.11

SPIDERS

Laser cut spider

Ref: S3003 > Page 3.13

Casted stainless steel spider,

with plate

Ref: S3100 > Page 3.15

Ref: S3101 > Page 3.17

Accessories

Page 3.19

Suggested mounting instructions

Page 3.21

SPIDERS :: 4 steps to order your spiders

Page 3.23

Pages 3.03 >> 3.25 Order form

Page 3.25

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.02 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:20 Page 2

SPIDERS ::

Specification sheet spiders: Original texts from cahier 3574 du CSTB

The technique:

The spider plays the role of intermediary between the carrying structure and the fittings fixed onto the glass panel.

The fineness of its lines allows the construction to retain all its transparency.

3.1.4 Functional clearances

The anticipated functional clearances of the spiders as well as the point fittings have to allow the glass to move towards their fixing points

without creating any stress in the plane of the glass or embedding moments under:

- the effects of the wind or snow loads (shortening of the distance between glass holes and deformation of the structure)

- the differential thermal dilatations between the structure and the glasses

- the differential displacements of the spiders

SPIDERS

FIXED POINT SLOTTED POINT

17 mm The glass panels are either supported or suspended. Every glass

17 x 24 mm

is generally held by two carrying points (supporting the weight)

allowing horizontal movements due to dilatation

Whichever technical dispositions are

adopted for the realization of the functio-

nal clearances, those ones have to

remain operational with the time (no sei-

zing, buttressing, jamming or uncontrol-

led tightening). This can be obtained

for example by the use of spacers.

FREE POINT FREE POINT

24 mm 24 mm

The other fixing points have to allow movements in all

directions in the plane of the glass.

The fixing of the spiders on the faade:

In order to obtain a cor-

rect adjustment of the

spider, it is recommen-

ded to use an interme-

diary part, the Omega.

This part allows a bi-

directional adjustment. The central slotted hole has

to be imperatively oriented

horizontally, so that the supported

weight does not cause the spider

to slide down.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.03 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:20 Page 3

SPIDERS ::

The anti-rotation of the spider:

daN

3.1.3 To

(lb)avoid the risk of displacement of the spiders under the weight of the glasses during installation or in case of accidental glass breakage,

the spiders have to be locked in rotation by any appropriate means (for example: use of high resistance bolts under controlled tightening, elastic

and cotter pins etc.).

ULS

SLS

SPIDERS

0 0,1 mm 1 mm

1 - In case of glass breakage, the spider is drag- 2 - All spiders positioned at the border of the

ged in rotation by the remaining glass panel. faade are dragged in rotation by the glass

Its from this point that the pins maintain the panels. The pins maintain continuously the

spider in position. spiders in position.

The layout of the spiders on the faade:

Each SADEV spider is delivered in accordance to its position on the faade.

In order to facilitate the orientation of the different positions, weve classified them in several mounting instructions that cover all scenarios.

For all requests, its sufficient for you to give us the inventory of your different positions. For example: 56 specimens of S3000 5.

01-THE STUDY 02-THE IDENTIFICATION

S3000 POSITION 3

1 14 14 14 3

16 5 5 5 17

16 5 7 8 17

16 5 9 10 17

16 5 7 8 17

16 5 6 4 17

11 12 11 13 13

For more information please find the page How to order your spiders? at the end of this chapter.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.04 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 4

SPIDERS ::

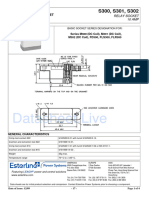

Reference: S3000 MONTI Designation : casted stainless steel spider.

TECH

NICAL

T

AS

SE

SME

RE

TE D

GIS

RE

Technical assessment

available online at

SPIDERS

www.sadev.com

Glass side view

Material: AISI 316 Surface finish: dull polished GR400

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.05 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 5

SPIDERS ::

Modle : S3000 MONTI

Mechanical performances:

daN

(lb) Load parallel to glass Load perpendicular

(per arm) to glass (per arm)

ULS

SLS

SLS* at 1 mm ULS* SLS* at 1 mm ULS*

434 daN 398 daN 238 daN 300 daN

(975 lb) (894 lb) (535 lb) (674 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

SPIDERS

0 0,1 mm 1 mm deformation of the spider of 0,1 mm).

Configuration:

Glass side view

2 arms 90

Weight: 1,41 kg

3 arms

Weight: 2 kg

2 arms 180

Weight: 1,1 kg

1 arm 180 1 arm 90

Weight: 0,71 kg Weight: 0,89 kg

4 arms

Weight: 2,6 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. speci-

fication sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.06 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 6

SPIDERS ::

Reference: S3001 Designation : casted stainless steel spider

TECH

NICAL

Technical assessment

T

AS

N

available online at SE

SME

www.sadev.com

SPIDERS

Glass side view

Material: AISI 316 Surface finish: electro polished

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.07 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 7

SPIDERS ::

Reference: S3001

Mechanical performances:

daN

(lb) Load parallel to glass Load perpendicular

(per arm) to glass (per arm)

ULS

SLS

SLS* at 1 mm ULS* SLS* at 1 mm ULS*

257 daN 241 daN 110 daN 155 daN

(577 lb) (541 lb) (247 lb) (348 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

SPIDERS

0 0,1 mm 1 mm deformation of the spider of 0,1 mm).

Configuration:

Glass side view

2 arms 90

Weight: 0,8 kg

3 arms

Weight: 1,06 kg

2 arms 180

Weight: 0,58 kg

1 arms 180 1 arm 90

Weight: 0,41 kg Weight: 0,49 kg

4 arms

Weight: 1,52 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. speci-

fication sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.08 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 8

SPIDERS ::

Reference: S3006 VERTECH Designation : casted stainless steel spider.

RE

TE D

GIS

RE

SPIDERS

Available in june 2010

Glass side view

Material: AISI 316 Surface finish: dull polished GR400

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.09 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 9

SPIDERS ::

Reference: S3006 VERTECH

Mechanical performances:

daN

(lb) Load parallel to glass Load perpendicular

(per arm) to glass (per arm)

ULS

SLS

SLS* at 1 mm ULS* SLS* at 1 mm ULS*

No tests No tests No tests No tests

available available available available

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

SPIDERS

0 0,1 mm 1 mm deformation of the spider of 0,1 mm).

Configuration:

Glass side view

2 arms 90

Weight: 1,20 kg 3 arms

Weight: 1,62 kg

2 arms 180

Weight: 0,94 kg

1 arm 180 1 arm 90

Weight: 0,62 kg Weight: 0,78 kg

4 arms

Weight: 2,14 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. speci-

fication sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.10 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 10

SPIDERS ::

Reference: S3007 Designation : casted aluminium spider.

TECH

NICAL

Technical assessment

T

AS

available online at

N

SE

SME

SPIDERS

www.sadev.com

Glass side view

Material: AI Si 5 Mg Surface finish: Sanded

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.11 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 11

SPIDERS ::

Reference: S3007

Mechanical performances:

daN

(lb) Load parallel to glass Load perpendicular

(per arm) to glass (per arm)

ULS

SLS

SLS* at 1 mm ULS* SLS* at 1 mm ULS*

235 daN 199 daN 182 daN 198 daN

(528 lb) (447 lb) (409 lb) (445 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

SPIDERS

0 0,1 mm 1 mm deformation of the spider of 0,1 mm).

Configuration:

Glass side view

2 arms 90

Weight: 0,68 kg

3 arms

Weight: 0,8 kg

2 arms 180

Weight: 0,58 kg

1 arm 180 1 arm 90

Weight: 0,38 kg Weight: 0,48 kg

4 arms

Weight: 1,1 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. speci-

fication sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.12 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 12

SPIDERS ::

Reference: S3003 Designation : laser cut spider.

TECH

NICAL

T

AS

SE

SME

Technical assessment

available online at

SPIDERS

www.sadev.com

Glass side view

Material: AISI 316L Surface finish: dull polished GR220

Material: E36 / Epoxy painting, polished zinc undercoat

Thickness: E= 8 mm, 10 mm, 12 mm, 14 mm, 16 mm.

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.13 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:21 Page 13

SPIDERS ::

Reference: S3003

Mechanical performances:

daN

(lb) Load parallel to glass Load perpendicular

(per arm Ep. 10 mm) to glass (per arm Ep. 10 mm)

ULS

SLS

SLS* at 1 mm ULS* SLS* at 1 mm ULS*

1077 daN 820 daN 85 daN 136 daN

(2421 lb) (1843 lb) (191 lb) (305 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

SPIDERS

0 0,1 mm 1 mm deformation of the spider of 0,1 mm).

Configuration:

Glass side view

2 arms 90

Ep. 10 mm = Weight: 1,4 kg 3 arms

Ep. 10 mm =

Weight: 1,86 kg

2 arms 180

Ep. 10 mm = Weight: 1,04 kg

1 arm 180

Ep. 10 mm = Weight: 0,76 kg 1 arm 90

Ep. 10 mm = Weight: 0,90 kg 4 arms

Ep. 10 mm =

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free Weight: 2,32 kg

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The drilling diameter for the pins is 6 mm. Do not drill the holes for the pins in your structure before mounting the spiders. To fix the spider on your structure the

Omega (see accessories) is highly recommended to adjust the spiders position. The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply).

This bolt shall not be fitted into a vertical slotted holes due to the risk of slipping (under the weight), the pins are not designed to hold any permanent loads (cf. speci-

fication sheet). The spider has to be positioned on a flat support. The slotted holes 17x24 mm and free holes 24 mm in the spider are not to be used to adjust

the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.The spiders are standardized for

M14 fittings (FXR, FXV); other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.14 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:22 Page 14

SPIDERS ::

Reference: S3100 MONTI Designation : casted stainless steel spider, with plate.

TECH

NICAL

T

AS

SE

SME

RE

Technical assessment TE D

GIS

available online at

RE

www.sadev.com

Glass side view

SPIDERS

Material: AISI 316 Surface finish: dull polished GR400

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.15 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:22 Page 15

SPIDERS ::

Reference: S3100 MONTI

Mechanical performances:

daN

(lb) Load parallel to glass Load perpendicular

(per arm) to glass (per arm)

ULS

SLS

SLS* at 1 mm ULS* SLS* at 1 mm ULS*

542 daN 410 daN 195 daN 184 daN

(1218 lb) (921 lb) (438 lb) (413 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

SPIDERS

0 0,1 mm 1 mm deformation of the spider of 0,1 mm).

Configuration:

Glass side view

1 arm 180

Weight: 1,06 kg

2 arms

Weight: 2,18 kg

1 arm 90 1 arm 90

left right

Weight: 1,59 kg Weight: 1,59 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply). The slotted holes 17 x 24 mm and free holes 24 mm in the spider are not to be

used to adjust the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.

The spiders are standardized for M14 fittings (FXR, FXV). Other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.16 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:22 Page 16

SPIDERS ::

Reference: S3101 Designation : casted stainless steel spider, with plate.

TECH

NICAL

T

AS

SE

SME

Glass side view

Technical assessment

available online at

SPIDERS

www.sadev.com

Material: AISI 316 Surface finish: electro polished

Dimensions:

Glass side view

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.17 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:22 Page 17

SPIDERS ::

Reference: S3101

Mechanical performances:

daN

(lb) Load parallel to glass Load perpendicular

(per arm) to glass (per arm)

ULS

SLS

SLS* at 1 mm ULS* SLS* at 1 mm ULS*

457 daN 497 daN 128 daN 128 daN

(1027 lb) (1117 lb) (287 lb) (287 lb)

*SLS: Serviceability Limit State (load causing a deformation of 1 mm)

ULS: Ultimate Limit State: Elastic limit Rp0.1 (maximal load causing a permanent

SPIDERS

0 0,1 mm 1 mm deformation of the spider of 0,1 mm).

Configuration:

Glass side view

1 arm 180

Weight: 0,79 kg

2 arms

Weight: 1,46 kg

1 arm 90 1 arm 90

left right

Weight: 1,1 kg Weight: 1,1 kg

Represents a fixed point 17 mm, a slotted point 17x24 mm, or a free

point 24 mm depending on the position of the spider on the faade (see

suggested mounting instructions at the end of the chapter).

Suggested mounting instruction:

The fixing of the spider is done with a M16 or a M12 bolt (out of Sadev supply). The slotted holes 17 x 24 mm and free holes 24 mm in the spider are not to be

used to adjust the spider! They are needed to absorb the manufacturing tolerances and the thermal deformation of the glass and of the structure.

The spiders are standardized for M14 fittings (FXR, FXV). Other diameters are available on request.

SADEV recommends using thread locking compound, except in case of specific mounting constraints.

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.18 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:22 Page 18

SPIDERS ::

Reference: BENDED OMEGA Designation: bended omega for vertical mounting:

Adjustment (1)

of +/- 5 mm horizontally

and vertically

SPIDERS

Vertical use COMPULSORY

Reference for spiders S3000, S3001, S3003, S3007:

OMGA-IN12V AISI 316L Stainless steel model dull polished

OMGA-IN12V-R Painted AISI 316L Stainless steel model with

your needed RAL-colour

Designation : fastenings kit for bended:

Kit for S3000 spiders. Kit for S3001, S3003 and S3007 spiders.

KIT-OM-VIS-S3000 KIT-OM-VIS-S300137

1 M12 bolt 1 M12 bolt

2 Washer for M12 2 Washer for M12

3 Insert (S3000 only) 4 Spring washer

4 Spring washer 5 M12 nut

5 M12 nut

Reference: CASTED STAINLESS Designation: casted omega kit for S3006 spider for

STEEL OMEGA vertical mounting:

RE

TE D

GIS

RE

Registered

Vertical use COMPULSORY

1 Omega

2 M12 H bolt

Reference 3 Anti-rotation plate

4 Washer for M12

S3000-OMEGA-R AISI 316 Stainless steel model for S3006 5 Spring washer

Vertech spider. Finish dull polished GR400 6 - M12 nut

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.19 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:22 Page 19

SPIDERS ::

Stainless steel spacer:

The spacer is compulsory in order to allow the free displacement of the fitting towards the spider.

One spacer per spiders arm (or per fitting) are needed.

Designation Diameter of the fitting Reference

spacer for S3000, S3001, S3006,

S3100, S3101, S3003 thickness 12 M12 ENT-12-16,5-12,5

spacer for S3003 thickness 8 M12 ENT-12-16,5-8,5

spacer for S3003 thickness 10 M12 ENT-12-16,5-10,5

spacer for S3003 thickness 15 M12 ENT-12-16,5-15,5

SPIDERS

spacer for S3007 M12 ENT-12-16,5-21,5

spacer for S3000, S3001, S3006,

S3100, S3101, S3003 thickness 12 M14 ENT-14-16,5-14,5

spacer for S3003 thickness 8 M14 ENT-14-16,5-8,5

spacer for S3003 thickness 10 M14 ENT-14-16,5-10,5

spacer for S3003 thickness 15 M14 ENT-14-16,5-15,5

spacer for S3007 M14 ENT-14-16,5-21,5

spacer for S3000, S3001, S3006,

S3100, S3101, S3003 thickness 12 M16 ENT-16-18,5-18,5

spacer for S3003 thickness 8 M16 ENT-16-18,5-8,5

spacer for S3003 thickness 10 M16 ENT-16-18,5-10,5

spacer for S3003 thickness 15 M16 ENT-16-18,5-15,5

spacer for S3007 M16 ENT-16-18,5-21,5

Stainless steel elastic pin:

The pin is compulsory in order to lock the spider in rotation towards the structure.

Two pins per spider are needed +5 %.

Designation: Reference:

Pin for S3000, S3001, S3006, S3003 D1481A2-6-36

Pin for S3007 D1481A2-6-60

Special drill for stainless steel:

Special drill for stainless steel. Diameter 6 mm.

Rfrence :

09 90 01 60

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.20 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 10/02/10 14:06 Page 20

SPIDERS ::

Suggested mounting instruction:

Montage - A Montage - B

1 14 14 14 3

1 2 2 2 3

4 5 5 5 6 16 5 5 5 17

SPIDERS

4 5 7 8 6 16 5 7 8 17

4 5 9 10 6 16 5 9 10 17

4 5 7 8 6 16 5 7 8 17

4 5 6 4 6 16 5 6 4 17

11 12 13 11 13

11 12 11 13 13

Montage - C Montage - D

19 20 19 20 19 20 19 20 19 24 24 24 25

23 26 26 26 23

21 22 21 22 21 22 21 22

19 24 24 24 25

23 26 26 26 23

21 22 21 22 23 23 21 22

19 24 25 19 25

23 26 23 23 23

21 22 21 22 21 22

19 20 19 24 24 24 25

23 26 26 26 23

21 22 21 22 23 23 21 22

19 24 25 19 25

23 26 23 23 23

21 22 21 22 21 22

19 24 25 19 25

23 26 23 23 23

23 23 23 23 23 23

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.21 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:22 Page 21

SPIDERS ::

Suggested mounting instructions for plate spiders:

Montage

daN -E Montage - F

1 3 1 3 1 3 1 3

ELS 1 2 2 2 3B

ELU

1sym 3 1 3 1 3 1 3sym

4 6 4 6 4 6 4 6

16 6 4 6 4 6 4 17

SPIDERS

4 0 6

0,1 mm 4 6 11 1 mm 13 4 6

16 6 4 6 11 13 4 17

4 6 4 6 1 3 4 6

16 6 4 6 1 3 4 17

4 6 4 6 11 13 4 6

16 6 4 6 11 13 4 17

4 6 4 6 4 6

16 6 4 6 4 17

11 13 11 13 11 13

13 13 11 13 11 11

12

12

Montage - G Montage - H

19 20 19 20 19 20 19 20

19 25 19 25 19 25 19 25

23 23 23 23 23 23 23 23

23 23 23 23 23 23 23 23

19 20 19 20 19 20 19 20

19 25 19 25 19 25 19 25

23 23 23 23 23 23 23 23

23 23 23 23 23 23 23 23

19 20 19 20 19 20

19 25 19 25 19 25

23 23 23 23 23 23

23 23 23 23 23 23

19 20 19 20 19 20 19 20

19 25 19 25 19 25 19 25

23 23 23 23 23 23 23 23

23 23 23 23 23 23 23 23

19 20 19 20 19 20

19 25 19 25 19 25

23 23 23 23 23 23

23 23 23 23 23 23

19 20 19 20 19 20

19 25 19 25 19 25

23 23 23 23 23 23

23 23 23 23 23 23

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.22 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:23 Page 22

SPIDERS ::

4 steps to order your spiders:

01-THE STUDY 02-THE IDENTIFICATION 03-THE ORDER 04-THE DELIVERY

3

x3

S3000 POSITION 3 S3000-3

01-THE STUDY

Considering the mechanical performances and the esthetical design youve chosen for example - the S3000 spider. With the

help of the spiders drawings available on SADEVs web site www.sadev.com, you design your faade. At this stage you place

the different spiders (4 arms, 2 arms etc.) using the symbol O. You can already get inspired by the mounting instructions availa-

SPIDERS

ble at the end of this chapter.

S3000

02-THE IDENTIFICATION

Once the faade is designed, you have to identify the position of the spider so that SADEV can deliver the right spider with the cor-

3 rect configuration of the holes 17 mm, 17 x 24 mm and 24 mm. Therefore, get the mounting proposition(s) corresponding to

your faade and mark the position numbers on your drawing.

POSITION 3

1 14 14 14 3

16 5 5 5 17

16 5 7 8 17

16 5 9 10 17

16 5 7 8 17

16 5 6 4 17

11 12 11 13 13

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.23 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:23 Page 23

SPIDERS ::

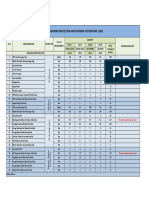

03-THE ORDER

All your spiders are now identified; sample the different spider quantities by position in the order form (end of the chapter).

x3

S3000-3 Mounting suggestions: A, B, C, D, E, F, G, H.

Fittings diameter (FXR, FXV) : M12, M14, M16, autre :

REFERENCE POSITION QTY PRICE

S3000 5 27

S3000 17 9

SPIDERS

S3000 16 9

S3000 14 9

S3000 1 3

S3000 3 3

Omga-in 12 v - 60

D1481 a2-6-36 - 120

ENT-14-16,5-14,5 - 168

04-THE DELIVERY

The spiders will be delivered packed in cardboard boxes and referenced by position. Do not forget to furnish

the montage team with the mounting drawings of your facade on which the mounting positions are indicated.

x3 x27 x9 x3 x9

x9

S3000-3 S3000-14 S3000-5 S3000-16 S3000-1 S3000-17

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.24 www.sadev.com - info@sadev.com

chap_03-ATTACHES-cat-classic-gb:Mise en page 1 25/11/09 21:23 Page 24

SPIDERS ::

Price request

Order

Order form for spider

Customer name: Interlocutor: Date:

Project name Your phone number: DISCOUNT

Your fax:

Mounting suggestions: A, B, C, D, E, F, G, H.

Fittings diameter (FXR, FXV): M12, M14, M16, Others :

REFERENCE POSITION QTY PRICE

SPIDERS

TOTAL

Tel. +33 (0)4 50 08 39 00 - Fax +33 (0)4 50 08 39 49 3.25 www.sadev.com - info@sadev.com

You might also like

- Spidere Pentru Fixarea Fatadelor Din Sticla Sadev Classic Eng Nou 52058Document24 pagesSpidere Pentru Fixarea Fatadelor Din Sticla Sadev Classic Eng Nou 52058Iulia PetrescuNo ratings yet

- Steel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDDocument12 pagesSteel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDmalikasalNo ratings yet

- Jackscrew Backshell Installation Instructions: 190-00313-11 October, 2017 Revision EDocument24 pagesJackscrew Backshell Installation Instructions: 190-00313-11 October, 2017 Revision EAlex AnishchykNo ratings yet

- Roofsafe Rail Bulb Type-Folded Standing Seam IIDocument13 pagesRoofsafe Rail Bulb Type-Folded Standing Seam IIJHON ESTEBAN TILANO REOMERONo ratings yet

- General Information: 2.1. ConcreteDocument4 pagesGeneral Information: 2.1. ConcreteWilliam ProvidoNo ratings yet

- Taco Brazed Plate HX Install ManualDocument11 pagesTaco Brazed Plate HX Install ManualTEMPNo ratings yet

- FBM03Document8 pagesFBM03Damsha NdahiNo ratings yet

- Tapcon: Storm Guard AnchorsDocument2 pagesTapcon: Storm Guard Anchorsblessed cccNo ratings yet

- Brakage Analysis in Alminium in DrawingDocument11 pagesBrakage Analysis in Alminium in DrawingWajeeh BitarNo ratings yet

- Instruction Manual for Ball Mill Lining Plate ErectionDocument23 pagesInstruction Manual for Ball Mill Lining Plate Erection96652529No ratings yet

- 4 - Column DesignDocument10 pages4 - Column Designlarry0lao0iiiNo ratings yet

- 9630 20 TSM HBQ 8439.autoDocument1 page9630 20 TSM HBQ 8439.autoIvan QuezadaNo ratings yet

- ETABS 2013 Beam-Column Connection AnalysisDocument2 pagesETABS 2013 Beam-Column Connection Analysisbenjamin diazNo ratings yet

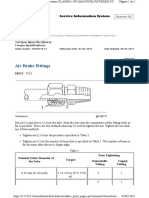

- Air Brake Fittings: Torque SpecificationsDocument2 pagesAir Brake Fittings: Torque SpecificationsCristian SNo ratings yet

- SPT I30 01 Failed ReportDocument10 pagesSPT I30 01 Failed ReportmalikasalNo ratings yet

- E11-S01 - 0 Low Resistance Grounding SysDocument6 pagesE11-S01 - 0 Low Resistance Grounding SysMuhammad IrfanNo ratings yet

- Art 28 Anode Inspection and Defect Definition Rev00Document3 pagesArt 28 Anode Inspection and Defect Definition Rev00soltani aliNo ratings yet

- Input Data - Design Summary: C E L L B E A M Ver. 10.3.1 (Build170)Document7 pagesInput Data - Design Summary: C E L L B E A M Ver. 10.3.1 (Build170)sloane01No ratings yet

- Interface Shear Check PDFDocument11 pagesInterface Shear Check PDFavikshit yNo ratings yet

- Torque Socket Square For Square NutDocument1 pageTorque Socket Square For Square NutArdian ArdianNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNo ratings yet

- NE01 119revbDocument24 pagesNE01 119revbMarlene Yuriserll Ruiz Muñoz100% (1)

- Mil STD 413Document105 pagesMil STD 413msraskinNo ratings yet

- BlumDocument21 pagesBlumproductNo ratings yet

- The Treatment of Below-The-Knee Arterial Stenosis: Focused Force Angioplasty ForDocument2 pagesThe Treatment of Below-The-Knee Arterial Stenosis: Focused Force Angioplasty ForAyu RukmanaNo ratings yet

- Diamond Turning: Xinquan Zhang Keng Soon WoonDocument21 pagesDiamond Turning: Xinquan Zhang Keng Soon Woonbhakti gumiraNo ratings yet

- Spiderbeam Construction Guide EnglishDocument30 pagesSpiderbeam Construction Guide EnglishAnonymous s3UY0d3H9No ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- CONNECTION: UB305X165X40BS5950 - Base Plate: AdminDocument3 pagesCONNECTION: UB305X165X40BS5950 - Base Plate: AdminPNo ratings yet

- FBM06Document4 pagesFBM06Damsha NdahiNo ratings yet

- ETABS 2016 Concrete Frame Design: IS 456:2000 Column Section Design (Envelope)Document1 pageETABS 2016 Concrete Frame Design: IS 456:2000 Column Section Design (Envelope)Abdullah MohamedNo ratings yet

- Datasheet - Live: Engineering Data SheetDocument4 pagesDatasheet - Live: Engineering Data Sheetgaetan.boehlyNo ratings yet

- Torque-Air Brake FittingsDocument2 pagesTorque-Air Brake Fittingsyoga_jpbmbmNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)Murthy GunaNo ratings yet

- AM2217 - Module - 3 - C Metallic ProfilesDocument33 pagesAM2217 - Module - 3 - C Metallic ProfilesMadalin NitaNo ratings yet

- FLBM13: Proposed Entrepreneurship Centre ADS 001 3 Page 1/2 ABF 14-Oct-23 CM 17-Sep-23 CM 17-Sep-23Document2 pagesFLBM13: Proposed Entrepreneurship Centre ADS 001 3 Page 1/2 ABF 14-Oct-23 CM 17-Sep-23 CM 17-Sep-23Damsha NdahiNo ratings yet

- NOV Lock Wiring Guide: Document No ASP00019Document9 pagesNOV Lock Wiring Guide: Document No ASP00019Mohammed JalalNo ratings yet

- Section 1 Section 1: General InformationDocument1 pageSection 1 Section 1: General InformationPalincas Alin FelixNo ratings yet

- WeldDocument4 pagesWeldmjohnNo ratings yet

- Coo Ele Cat CDC Ups 0012 0Document10 pagesCoo Ele Cat CDC Ups 0012 0Ricardo VerdugoNo ratings yet

- 19/33kV Cable Cross-Section DimensionsDocument1 page19/33kV Cable Cross-Section Dimensionsshivam dwivediNo ratings yet

- NIWI-2703.3 Guidelines For Removing Metal Flow From Insulated JointsDocument6 pagesNIWI-2703.3 Guidelines For Removing Metal Flow From Insulated JointsCK TangNo ratings yet

- J100.01.17.VEF REV 0 Geodesic Dome CalculationsDocument682 pagesJ100.01.17.VEF REV 0 Geodesic Dome CalculationsFranscois Van RooyenNo ratings yet

- Spcolumn V6.00 Computer Program For The Strength Design of Reinforced Concrete Sections All Rights ReservedDocument5 pagesSpcolumn V6.00 Computer Program For The Strength Design of Reinforced Concrete Sections All Rights ReservedKhandaker Khairul AlamNo ratings yet

- Design of Isolated Footing to BS-8110Document29 pagesDesign of Isolated Footing to BS-8110sundarNo ratings yet

- Mech-V-Design of Machine Elements I U7 PDFDocument45 pagesMech-V-Design of Machine Elements I U7 PDFHaniya FathimaNo ratings yet

- Td-011-Talang Datar - Rev 0Document1 pageTd-011-Talang Datar - Rev 0Fariz TefaNo ratings yet

- CNC Machining Technology GuideDocument64 pagesCNC Machining Technology GuidePraveena S.SundaramNo ratings yet

- Connection Design ReportDocument97 pagesConnection Design ReportTrungNguyenNo ratings yet

- Technical Data For Steel-Concrete Composite Beam: Type Approval 300/6221/2001Document20 pagesTechnical Data For Steel-Concrete Composite Beam: Type Approval 300/6221/2001Naveen RohiraNo ratings yet

- Diamond Turning: Xinquan Zhang Keng Soon WoonDocument21 pagesDiamond Turning: Xinquan Zhang Keng Soon WoonMaddy SultanNo ratings yet

- Brida Flexible VitaulicDocument3 pagesBrida Flexible VitaulicG Abigail MorenoNo ratings yet

- LPS & Es - 21033Document1 pageLPS & Es - 21033sabih344No ratings yet

- 93c87c1f827f986e15c7d0535587d989Document5 pages93c87c1f827f986e15c7d0535587d989Siphelele SimelaneNo ratings yet

- Mil Metal RemovalDocument20 pagesMil Metal Removalparimalam100% (2)

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)christi SNo ratings yet

- FSW of Aluminum MMC 6092-17.5%SiCpDocument22 pagesFSW of Aluminum MMC 6092-17.5%SiCpSanthosh Kumar KodhandapaniNo ratings yet

- Working X3T9.2 Draft Project 375D: Information Technology - Small Computer System Interface - 2Document502 pagesWorking X3T9.2 Draft Project 375D: Information Technology - Small Computer System Interface - 2XHieu NguyenNo ratings yet

- (Peter Polak (Auth.) ) Designing For Strength Prin PDFDocument323 pages(Peter Polak (Auth.) ) Designing For Strength Prin PDFChristopher Carrillo100% (1)

- Midas Rail-Structure InteractionDocument17 pagesMidas Rail-Structure Interactionteawater1977No ratings yet

- 087 Assessment of A Bridge Pier Pile PDFDocument8 pages087 Assessment of A Bridge Pier Pile PDFVardhanNo ratings yet

- Pavement Engineering 4300:565 Assignment #5 Spring 2014: Submitted by Mir Shahnewaz Arefin Student Id: 2824475Document8 pagesPavement Engineering 4300:565 Assignment #5 Spring 2014: Submitted by Mir Shahnewaz Arefin Student Id: 2824475Mir Shahnewaz ArefinNo ratings yet

- U-Shaped Reinforced Bellows (Austenitic Steel)Document10 pagesU-Shaped Reinforced Bellows (Austenitic Steel)met-calcNo ratings yet

- Analysis of A Reinforced Concrete BuildingDocument119 pagesAnalysis of A Reinforced Concrete Buildinghooty_OWLNo ratings yet

- Modeling wear in a pin-on-disc tribometerDocument10 pagesModeling wear in a pin-on-disc tribometerDanilo SouzaNo ratings yet

- Stability of Structures PDFDocument11 pagesStability of Structures PDFHari Krishna MoorthyNo ratings yet

- ISRM-Is-1978-019Three Practical Examples For The Interaction Between Concrete Dams and Foundation RockDocument26 pagesISRM-Is-1978-019Three Practical Examples For The Interaction Between Concrete Dams and Foundation Rockamy75No ratings yet

- Uplift Capacity T-Z MethodDocument5 pagesUplift Capacity T-Z MethodPalak ShivhareNo ratings yet

- Determination of Johnson HolmquistDocument4 pagesDetermination of Johnson Holmquistsime13No ratings yet

- BTech 1st Sem: Mechanical Science: Stress & StrainDocument10 pagesBTech 1st Sem: Mechanical Science: Stress & StrainTechno India Group100% (1)

- PMT and Dilatometer TestDocument34 pagesPMT and Dilatometer TestAshrethNo ratings yet

- Plaxis Advanced Course New Delhi 2014 (Print)Document448 pagesPlaxis Advanced Course New Delhi 2014 (Print)ladheedha100% (4)

- Materials Science and EngineeringDocument300 pagesMaterials Science and Engineeringhadj menNo ratings yet

- Crack Analysis of a Curved WallDocument21 pagesCrack Analysis of a Curved WallandreaNo ratings yet

- EfewfwefewfwefwefDocument14 pagesEfewfwefewfwefwefSuperHotRapperNo ratings yet

- ASCE 2004 Paquette Bruneau BrzevDocument10 pagesASCE 2004 Paquette Bruneau Brzevryan rakhmatNo ratings yet

- Design and Fluid Structural Interface Analysis of Marine PropellerDocument67 pagesDesign and Fluid Structural Interface Analysis of Marine PropellerPavaniNo ratings yet

- 4-CE523-Handout-Compression Members-1Document56 pages4-CE523-Handout-Compression Members-1ehabNo ratings yet

- Method of least work for statically indeterminate beams and framesDocument64 pagesMethod of least work for statically indeterminate beams and framesyellowpawpaw80% (5)

- Homework 3Document8 pagesHomework 3Alferid ShifaNo ratings yet

- Assem1-Static 1-1Document11 pagesAssem1-Static 1-1andre careraNo ratings yet

- Lecture 1 - Stress-Strain RelationshipDocument26 pagesLecture 1 - Stress-Strain RelationshipSri JaiandranNo ratings yet

- Construction and Building Materials Study on GFRP Reinforced Concrete ColumnsDocument11 pagesConstruction and Building Materials Study on GFRP Reinforced Concrete ColumnsAliNo ratings yet

- 19 - ZhongDocument8 pages19 - ZhongJasmina TodorovićNo ratings yet

- General Stress-Strain Behavior: Unit M3.2Document37 pagesGeneral Stress-Strain Behavior: Unit M3.2droessaert_stijnNo ratings yet

- A Seminar On Material-SelectionDocument39 pagesA Seminar On Material-SelectionThirukkumaranBalasubramanianNo ratings yet

- A New Standard For Radiographic Acceptance Criteria For Steel CastingsDocument13 pagesA New Standard For Radiographic Acceptance Criteria For Steel CastingsCarlos Ortega JonesNo ratings yet

- Design of Slab For Bending: Benchmark Example No. 1Document6 pagesDesign of Slab For Bending: Benchmark Example No. 1Sri RamNo ratings yet