Professional Documents

Culture Documents

16 Amrutam

Uploaded by

Nikita KadamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16 Amrutam

Uploaded by

Nikita KadamCopyright:

Available Formats

Underground Water Tanks

... A hygienic way of water storage

The Supreme Industries Ltd., is an acknowledged leader of India's plastic industry. The innovative product portfolio

offered by the company is extensive in range and application and comprises a variety of pipes and a vast spectrum of

fittings totaling around 7000 diverse products. Together these constitute the most comprehensive range in the industry

that caters almost every conceivable need and application. Company has been a torch bearer in transition from

conventional products to advance plastics piping products in the country and has been termed as "Trend Setters of

Plastic Piping Products".

After successfully introducing many innovative plastic piping products for different application segments including

overhead water tanks, we are now proud to introduce yet another innovative, useful and superior product i.e.

Underground Water Tanks. These ready to use tanks in plastics are introduced under the brand name of Amrutam. The

Supreme Amrutam underground water storage tanks are designed to provide a better substitute to existing

conventional concrete and masonry tanks. Conventional tanks are associated with multiple problems like crack

formation, seepage, root penetration etc. Besides cumbersome and time consuming construction and repeated

maintenance requirement, the life span of these tanks is short and uncertain. On the other hand, Supreme Amrutam

underground tanks are free from above problems and has many outstanding features.

Unique Features

Rotationally Molded, One-Piece Construction Hygienic and Safe- Free from root penetration,

Unique single piece patented design corrosion and biological growth.

Great Strength- Robustly designed with unique rib Minimum space requirement

structure. Minimal Maintenance requirements

Simple and Quick Installation Long Life-Minimum 50 years of service life.

Provided with air tight threaded cover Eco-friendly

100% Watertight

Available Range : We offer underground water tanks in different sizes from 1000 to 30,000 liters capacity. Underground water

tanks up to 3000 liters are made available in vertical design whereas the tank sizes above 6000 liters have modular horizontal design.

Different modular units can be connected with each other for increased capacity up to 30,000 liters.

Jeevan bhar ka saath...

Underground Water Tanks

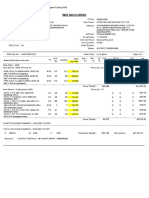

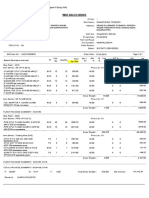

Product Details of Vertical Design Product Details of Modular Design

Capacity Diameter Height Capacity Combinations Length Diameter/Height

(Liters) (m) (m) (Liters) (m) (m)

1000 1.2 1.321 6000 Stand alone 2.4 2.2

1500 1.2 1.692 10000 2 domed ends coupled 3.8 2.2

1800 1.2 2.052 14000 2 domed ends + 1 Intermediate section 5.2 2.2

2000 1.7 1.301 18000 2 domed ends + 2 Intermediate sections 6.6 2.2

3000 1.7 1.748 22000 2 domed ends + 3 Intermediate sections 8.0 2.2

All the tanks are supplied with threaded lid, in case of modular 26000 2 domed ends + 4 Intermediate sections 9.4 2.2

tanks they are supplied with connecting pipes and rubber seals for

connection of adjoining modular units. 30000 2 domed ends + 5 Intermediate sections 10.8 2.2

Installation Procedure

1. Excavate a pit approximately 600 mm larger than the 5. When the level of the backfill reaches the underside of the

diameter of the tank. inlet pipe invert, inlet and outlet connections should be

2. Prepare a 150 mm (6) thick bed of granular material and made.

compact it properly. Ensure that the base of the pit is smooth, 6. Select the appropriate cover as per the site loading

flat and sufficiently hard to form a solid foundation for the conditions and place it on the top of tank. In case of

tank and no sharp object/stone etc. should protrude which pedestrian movement where vehicular loads are not

can puncture the tank. expected, plastic light weight cover is recommended. This

3. Lower the tank into position in the pit ensuring that it is plastic cover should filled with concrete after placing it on the

vertical, centrally positioned, correctly aligned and leveled tank. For vehicular traffic movement GRP

using spirit level. cover of appropriate load class is

4. Fill the tank with a tap water up to 1/3rd capacity. Then start recommended. For GRP covers 150 mm Light Weight Plastic Cover

the backfilling, backfilling and water filling should be carried thick PCC (min. M150 grade) beneath the

out simultaneously ensuring that the backfilling level never cover frame for full width of tank is

GRP Cover

exceed the rising level of water within the tank until the water recommended.

reaches maximum level. The width of the backfilling should 7. In case of modular tanks, a firm and stable base or a flat cast-

be minimum 300 mm (12) around the tank. Only selected in-situ150 mm thick concrete slab that will facilitate the

inert granular material i.e. sand/stone dust/ gravels (max. size assembly of the modular tank on a flat surface and will

10 mm) should be used as backfill material and should be 'bridge' the soil and distribute the weight of the full tank like a

placed in 250 mm layers and compacted to 90% proctor raft foundation is necessary.

density. It is particularly important to note that excavated (For more details please refer to Users Guide of Safegard

material consisting of rock, peat or clay is not used as backfill septic tank.)

material.

1 2 3 4

Note: Where abnormal soil conditions occur such as vehicular traffic, rock, black cotton soil or high water table is anticipated or when the backfill above the lid

exceeds 1000 mm, detailed guidelines should be referred and the final design rests with the engineer or architect on the project.

All the dimensions unless otherwise specified are in mm All information contained in this literature is given in good faith and believed to be accurate and reliable. But because of many factors which are outside our

knowledge and control and affect the use of product, no warranty is given or is to be implied with respect to such information, nor we offer any warranty of immunity against patent infringement. No

responsibility can be accepted for any error, omissions or incorrect assumptions. Any specifications can change without prior notice.

The Supreme Industries Ltd. (Plastic Piping Division)

1161/1162, Solitair Corporate Park, Building No. 11,167, Andheri Ghatkopar Link Road, Andheri (East) Mumbai - 400 093. India

Tel: 91-22-6771 0000, 4043 0000 Fax: 6771 0099 / 4043 0099. E-mail pvc-pipes@supreme.co.in Website www.supreme.co.in

Overseas Office : Sharjah, U.A.E. Tel # + 971 6 557 4484; Fax # + 97165574485

I & T SIL Gadegaon, Dist-Jalgaon=PC/AUWT-SP/MKG/87=REV.02-12/2016

www.supreme.co.in

You might also like

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Design of Overhead RCC Rectangular WaterDocument4 pagesDesign of Overhead RCC Rectangular WaterAhmed AwadNo ratings yet

- The Total Gym Ball Workout - Steve BarrettDocument19 pagesThe Total Gym Ball Workout - Steve BarrettFreddy ÁlvarezNo ratings yet

- Reaction Types 2Document2 pagesReaction Types 2jefferson33% (3)

- Numerology and The Property CycleDocument147 pagesNumerology and The Property CycleRAKESH KUMAR RAI100% (2)

- IEEE STD C135.3Document15 pagesIEEE STD C135.3ronald salvatierra100% (1)

- Penstocks: Figure: Typical Installaion of PenstocksDocument6 pagesPenstocks: Figure: Typical Installaion of PenstocksTharindu Nuwan JayakodyNo ratings yet

- Piles: Pile FoundationDocument22 pagesPiles: Pile Foundationmalik1950No ratings yet

- Appendix - Ii: Principles of Construction, Material and Design of Ferrocement TankDocument5 pagesAppendix - Ii: Principles of Construction, Material and Design of Ferrocement TankbenzzenhdNo ratings yet

- Piles DesignDocument15 pagesPiles Designvenkatesh19701No ratings yet

- Construction of BridgesDocument104 pagesConstruction of BridgesV Venkata Narayana89% (9)

- Design and Pressure Analysis of Steel Silo 8000 TonsDocument4 pagesDesign and Pressure Analysis of Steel Silo 8000 TonsEditor IJTSRD0% (1)

- Box Culvert Design As Per AASHTO LRFDDocument18 pagesBox Culvert Design As Per AASHTO LRFDshish0iitr0% (1)

- Salt Cavern Critical ElementsDocument170 pagesSalt Cavern Critical ElementsNurcahyo Djati W100% (4)

- WaterproofingDocument12 pagesWaterproofingJason GillespieNo ratings yet

- Jis G3101-2010Document14 pagesJis G3101-2010Prabath Madusanka100% (3)

- Law of Succession 3rd EditionDocument343 pagesLaw of Succession 3rd EditionEllie Beeken100% (1)

- Under Reamed Pile FoundationDocument8 pagesUnder Reamed Pile Foundationlprose33% (3)

- UNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNDocument7 pagesUNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNAnonymous nwByj9LNo ratings yet

- Types of Rigid Pavements: Jointed Plain Concrete Pavement (JPCP), Jointed Reinforced Concrete Pavement (JRCP), Continuously Reinforced Concrete Pavement (CRCPDocument48 pagesTypes of Rigid Pavements: Jointed Plain Concrete Pavement (JPCP), Jointed Reinforced Concrete Pavement (JRCP), Continuously Reinforced Concrete Pavement (CRCPashoknrNo ratings yet

- How Selegiline (Deprenyl) Slows BrainDocument162 pagesHow Selegiline (Deprenyl) Slows Brainglaucoac9No ratings yet

- Chapter 1+Casing+12Feb18Document47 pagesChapter 1+Casing+12Feb18Mohamad ZakwanNo ratings yet

- Aluminium Alloy AMS 4050 T7451 Plate 223Document2 pagesAluminium Alloy AMS 4050 T7451 Plate 223raoz810% (1)

- Fire Hydrant Flow Test - NFPA 291 & AWWA M17Document21 pagesFire Hydrant Flow Test - NFPA 291 & AWWA M17Nikita KadamNo ratings yet

- Pile Work Presentation at IITK Summer Camp 08Document82 pagesPile Work Presentation at IITK Summer Camp 08praxie0% (1)

- Pile DesignDocument15 pagesPile Designmohanty_anantakumar6332100% (1)

- Ingles AvanzadoDocument248 pagesIngles AvanzadoStepia Rodriguez100% (1)

- Underground Water Tanks: A Hygienic Storage SolutionDocument2 pagesUnderground Water Tanks: A Hygienic Storage Solutionarjun 11No ratings yet

- Underground Water StorageDocument2 pagesUnderground Water StorageManohar AttiliNo ratings yet

- Comparative Study For Overead and Intze TankDocument6 pagesComparative Study For Overead and Intze TankASHOK ARJUNRAO TAYADENo ratings yet

- Impact of Varying Height To Diameter Ratio of Intze Tank On Different Components and Cost of TankDocument6 pagesImpact of Varying Height To Diameter Ratio of Intze Tank On Different Components and Cost of TankEditor IJTSRDNo ratings yet

- Case Study On Water Tank Resting On GroundDocument3 pagesCase Study On Water Tank Resting On GroundSaifAldeenAbdulmotaalSulimanNo ratings yet

- 3484-5000sqft-nvph-a-frameDocument9 pages3484-5000sqft-nvph-a-framegotoyex612No ratings yet

- Wa0007Document34 pagesWa0007Dipesh PatilNo ratings yet

- Schedule of Rates - 1-FinalDocument28 pagesSchedule of Rates - 1-FinalAnonymous UUw70xirblNo ratings yet

- Well Foundations NotesDocument11 pagesWell Foundations NotesK.manojNo ratings yet

- Scope of Work:: Gail (India) LimitedDocument8 pagesScope of Work:: Gail (India) LimitedAnonymous sdMq4MSNo ratings yet

- Tank Design Class Notes 009Document68 pagesTank Design Class Notes 009Abdullah SahlyNo ratings yet

- Precast Ferrocement Water Tanks Upto Ioooolitres Capacity-SpecificationDocument12 pagesPrecast Ferrocement Water Tanks Upto Ioooolitres Capacity-SpecificationRomani Noel S. Chavez Jr.No ratings yet

- CED - QB Unit 1-2Document2 pagesCED - QB Unit 1-2Shivam JagtapNo ratings yet

- Bill of Quantities Riyadh - An Nakheel General Requirements Item No. Description Unit QTY Unit Price Amount SRDocument34 pagesBill of Quantities Riyadh - An Nakheel General Requirements Item No. Description Unit QTY Unit Price Amount SRmahmoud sayedNo ratings yet

- Pile DesignDocument16 pagesPile DesignVinod KrishnaNo ratings yet

- Cap MicrocreteDocument2 pagesCap MicrocreteSayed Diab AlsayedNo ratings yet

- ALDEC 700 Series High Performance Decanter Optimizes Sludge DewateringDocument2 pagesALDEC 700 Series High Performance Decanter Optimizes Sludge DewateringCaio NunesNo ratings yet

- Seminar Report FinalDocument34 pagesSeminar Report FinalSanthosh PrabuNo ratings yet

- Specification of 12KL Water Tanker with Firefighting PumpDocument7 pagesSpecification of 12KL Water Tanker with Firefighting PumpRajesh KumarNo ratings yet

- Shipping Container OfficeDocument9 pagesShipping Container OfficeAbrarNo ratings yet

- Construcion PiqueDocument7 pagesConstrucion PiqueYery SantanderNo ratings yet

- Long-Span Structural Systems OverviewDocument46 pagesLong-Span Structural Systems OverviewAdil ImtiazNo ratings yet

- Galvanized Brochure Final - 2016Document6 pagesGalvanized Brochure Final - 2016Majdi JerbiNo ratings yet

- Steel Water Storage Tanks: Design Guidelines and Cost FactorsDocument5 pagesSteel Water Storage Tanks: Design Guidelines and Cost FactorsSumit KulkarniNo ratings yet

- Intzetankdesign 170211222454Document43 pagesIntzetankdesign 170211222454Vishwanath KrNo ratings yet

- Hydrant ReportDocument12 pagesHydrant ReportMuhammadNo ratings yet

- Geotextile Tubes in Environmental Applications: or orDocument14 pagesGeotextile Tubes in Environmental Applications: or orEric ChanNo ratings yet

- Design of Caustic Recovery Tank For Bottle Washer Machine: Jaimin PandyaDocument6 pagesDesign of Caustic Recovery Tank For Bottle Washer Machine: Jaimin PandyaMark Daniel BaduaNo ratings yet

- Pile Foundations As Settlement Reducer For Large Ms Storage TanksDocument4 pagesPile Foundations As Settlement Reducer For Large Ms Storage Tanksrtwueee fcbcNo ratings yet

- Project - Sport CityDocument30 pagesProject - Sport CityAdmin DepartmentNo ratings yet

- Aqueduct at KM 41.535 of Gnss Main Canal Across MogamureruDocument5 pagesAqueduct at KM 41.535 of Gnss Main Canal Across MogamureruSn SatyanarayanaNo ratings yet

- How To Make A Solar Still PDFDocument15 pagesHow To Make A Solar Still PDFLuis MartinezNo ratings yet

- Hybrid Wall Systems ExplainedDocument27 pagesHybrid Wall Systems ExplainedElizaNabilahNo ratings yet

- Report1 X 2 X 2 (F 7)Document38 pagesReport1 X 2 X 2 (F 7)Divakar NaniNo ratings yet

- Interim Report (Block C)Document23 pagesInterim Report (Block C)Kiran JoshiNo ratings yet

- IS 2911 (Part 1/Sec 2) : 2010 Standards for Bored Cast In-Situ PilesDocument6 pagesIS 2911 (Part 1/Sec 2) : 2010 Standards for Bored Cast In-Situ PilesDixit JariwalaNo ratings yet

- Box Culvert NotesDocument3 pagesBox Culvert NotesraghuNo ratings yet

- Floor Drains Tech DataDocument3 pagesFloor Drains Tech DataMohammed RishadNo ratings yet

- Ausdrain Drainage Cell BrochureDocument4 pagesAusdrain Drainage Cell BrochurejigsNo ratings yet

- PppDocument33 pagesPppYuvaraju CherukuriNo ratings yet

- U Boot BetonDocument23 pagesU Boot BetonMegha KallihalNo ratings yet

- HS - 2 - CH - 2 (Part II)Document41 pagesHS - 2 - CH - 2 (Part II)Mikiyas AkliluNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- 515 - ADD ORDER FOR PANJRAPOLE 12 02 18Document1 page515 - ADD ORDER FOR PANJRAPOLE 12 02 18Nikita KadamNo ratings yet

- Subject - Offer For Supreme Flameguard CPVC Pipes and Fittings For Your ProjectDocument2 pagesSubject - Offer For Supreme Flameguard CPVC Pipes and Fittings For Your ProjectNikita KadamNo ratings yet

- Mahindra Order 4200323341Document1 pageMahindra Order 4200323341Nikita KadamNo ratings yet

- Web Sales Order: The Supreme Industries Limited (Gadegaon Piping Unit)Document1 pageWeb Sales Order: The Supreme Industries Limited (Gadegaon Piping Unit)Nikita KadamNo ratings yet

- Sr. No. Item Size Rate Per MTR (RS)Document1 pageSr. No. Item Size Rate Per MTR (RS)Nikita KadamNo ratings yet

- Hiranandani Castle RockDocument1 pageHiranandani Castle RockNikita KadamNo ratings yet

- Sr. No Item Unit Lobby Flat 1 (2 BHK) Flat 2 (2 BHK) Flat 3 (3 BHK)Document2 pagesSr. No Item Unit Lobby Flat 1 (2 BHK) Flat 2 (2 BHK) Flat 3 (3 BHK)Nikita KadamNo ratings yet

- Ajmera - Treon - FF - R4 - 13-11-17 FinalDocument45 pagesAjmera - Treon - FF - R4 - 13-11-17 FinalNikita KadamNo ratings yet

- Measurement Sample FlatDocument5 pagesMeasurement Sample FlatNikita KadamNo ratings yet

- Flameguard Item Qty. Unit ERP Code Item Code RateDocument1 pageFlameguard Item Qty. Unit ERP Code Item Code RateNikita KadamNo ratings yet

- Mahindra Order 4200323341Document1 pageMahindra Order 4200323341Nikita KadamNo ratings yet

- Hilti 2016 price list with 40% discount on toolsDocument89 pagesHilti 2016 price list with 40% discount on toolsMYGMINo ratings yet

- Web Sales Order: The Supreme Industries Limited (Gadegaon Piping Unit)Document1 pageWeb Sales Order: The Supreme Industries Limited (Gadegaon Piping Unit)Nikita KadamNo ratings yet

- Directorate of Maharashtra Fire Services: List of 588 Approved Licensed Agencies As 31.10.2017Document77 pagesDirectorate of Maharashtra Fire Services: List of 588 Approved Licensed Agencies As 31.10.2017Nikita KadamNo ratings yet

- Tabela - CPVC Chemical Compatibility Resistance ChartDocument11 pagesTabela - CPVC Chemical Compatibility Resistance ChartHimozaesNo ratings yet

- How To Read The Metric Vernier CaliperDocument2 pagesHow To Read The Metric Vernier CaliperNikita KadamNo ratings yet

- Mahindra Order 4200323341Document1 pageMahindra Order 4200323341Nikita KadamNo ratings yet

- VS Price ListDocument2 pagesVS Price ListNikita KadamNo ratings yet

- Supreme Industries Piping Unit Sales Order for CPVC PipesDocument1 pageSupreme Industries Piping Unit Sales Order for CPVC PipesNikita KadamNo ratings yet

- Geberit Pluvia BrochureDocument20 pagesGeberit Pluvia BrochureNikita KadamNo ratings yet

- Fire Hydrants - Loop TestingDocument9 pagesFire Hydrants - Loop TestingNikita KadamNo ratings yet

- NFPA 25 - ITM-TaggingDocument10 pagesNFPA 25 - ITM-TaggingMEHBOOB SHAIKHNo ratings yet

- Pump Test RequirementsDocument1 pagePump Test RequirementsNikita KadamNo ratings yet

- Fire Prevention Checklist For Storage WarehouseDocument2 pagesFire Prevention Checklist For Storage WarehouseNikita KadamNo ratings yet

- FLS - Fire Flow CalculationsDocument4 pagesFLS - Fire Flow CalculationsNikita KadamNo ratings yet

- Spacing and Location - Part ADocument23 pagesSpacing and Location - Part ANikita KadamNo ratings yet

- Point of Use Accessories: Turnkey Solutions For End-To-End EfficiencyDocument4 pagesPoint of Use Accessories: Turnkey Solutions For End-To-End EfficiencyNikita KadamNo ratings yet

- Convective HT For SprinklerDocument4 pagesConvective HT For SprinklerShabin ShabiNo ratings yet

- Welding Document & WPQDocument1 pageWelding Document & WPQNikita KadamNo ratings yet

- Anne Green Gables Main Idea PDFDocument2 pagesAnne Green Gables Main Idea PDFKATHERINE TOLENTINONo ratings yet

- Brand FailureDocument6 pagesBrand FailureOwais ShiekhNo ratings yet

- 346-Installing and Maintaining Tubing and Hose SystemsDocument80 pages346-Installing and Maintaining Tubing and Hose SystemsatagucaNo ratings yet

- Mapa de Colombia PraDocument3 pagesMapa de Colombia PraISRAEL HERNANDEZNo ratings yet

- History of Communication TechnologyDocument11 pagesHistory of Communication TechnologyNasrullah KhanNo ratings yet

- NEWProunoun Agreement Practice IndefiniteDocument4 pagesNEWProunoun Agreement Practice Indefinitere7abNo ratings yet

- Language Disorders From Infancy Through Adolescence E Book: Listening, Speaking, Reading, Writing, and Communicating 5th Edition, (Ebook PDFDocument36 pagesLanguage Disorders From Infancy Through Adolescence E Book: Listening, Speaking, Reading, Writing, and Communicating 5th Edition, (Ebook PDFlisa.gomez339100% (24)

- The Worl of Dance India Qualifiers: Sponsorship ProposalDocument8 pagesThe Worl of Dance India Qualifiers: Sponsorship ProposalCourse HeroNo ratings yet

- Who Invented Lollipops Reading-ComprehensionDocument3 pagesWho Invented Lollipops Reading-Comprehensionslavica_volkan100% (1)

- Popular Inventions - Quiz Questions & Answers: Author: Administrator Saved FromDocument2 pagesPopular Inventions - Quiz Questions & Answers: Author: Administrator Saved FromPradnya JoshiNo ratings yet

- Cocaine For TropinoneDocument8 pagesCocaine For TropinoneJi ChemNo ratings yet

- Is 638 - 1979Document7 pagesIs 638 - 1979Nandkishor G MhatreNo ratings yet

- Manual de Billetero ArgusDocument174 pagesManual de Billetero ArgusJulio QuispeNo ratings yet

- Restate Key Words - Answer All Parts: All Questions Have Specific KEYWORDS. Some Questions Have Multiple PartsDocument3 pagesRestate Key Words - Answer All Parts: All Questions Have Specific KEYWORDS. Some Questions Have Multiple PartsFelicia DavisNo ratings yet

- Giving Tree 50th Event Kit Activity BookletDocument12 pagesGiving Tree 50th Event Kit Activity BookletLavinia CucuNo ratings yet

- Case Name: Copyright Over ScriptDocument9 pagesCase Name: Copyright Over ScriptmeghaNo ratings yet

- Moore 1966Document234 pagesMoore 1966splut99100% (1)

- Yorkshire Dialect Poems (1673-1915) and Traditional Poems by Moorman, Frederic William, 1872-1919Document96 pagesYorkshire Dialect Poems (1673-1915) and Traditional Poems by Moorman, Frederic William, 1872-1919Gutenberg.org100% (1)

- FCA Awards Helm Wear Mopar Branded Merchandising ProgramDocument3 pagesFCA Awards Helm Wear Mopar Branded Merchandising ProgramPR.comNo ratings yet

- Rainforest WorksheetsDocument6 pagesRainforest WorksheetsChit Myatnoe KhinNo ratings yet