Professional Documents

Culture Documents

Carbothane 134 HG PDS

Uploaded by

Khemaraj PathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbothane 134 HG PDS

Uploaded by

Khemaraj PathCopyright:

Available Formats

Carbothane 134 HG

Selection & Specification Data Substrates & Surface Preparation

Generic Type Aliphatic Acrylic Polyurethane General Surfaces must be clean and dry. Employ adequate

Description Thin film, high gloss finish with exceptional weathering methods to remove dirt, dust, oil and all other

performance characteristics. Used extensively in contaminants that could interfere with adhesion of the

virtually all industrial markets, 134 HG provides a coating. For all surfaces prime with specific Carboline

smooth, durable finish that has superior resistance to primer as recommended by your Carboline sales

corrosion, abrasion and chemical exposure. representative. Refer to the specific primers Product

Data Sheet for detailed requirements.

Features High solids, low VOC content

Excellent weatherability Galvanized Steel Prime with specific Carboline primer as recommended

Exceeds SSPC Paint 36 specification for a Level 3 by your Carboline Sales Representative. Refer to the

urethane specific primers Product Data Sheet for substrate

Available in all Carboline colors including metallic- preparation requirements.

pigmented colors Previously Painted Lightly sand to roughen and degloss the surface.

Excellent flow characteristics allow for application by Surfaces Existing paint must attain a minimum 3A rating in

spray or roller accordance with ASTM D3359 XScribe adhesion

Superior impact and abrasion resistance test.

Indefinite recoatability

VOC compliant to current AIM regulations

Suitable for use in USDA inspected facilities

Performance Data

Color Refer to Carboline Color Guide. Certain colors, Test Method System Results

particularly in non-leaded safety oranges, reds and ASTM B117 Salt Fog Blasted Steel 1 No rusting, blistering,

yellows may require multiple coats for adequate ct Org Zinc 1 ct. loss of bond or any

hiding. Check color suitability before use. Epoxy 1 ct 134 HG measurable creepage

from the scribe

Finish Gloss

after 3000 hours.

Primer Refer to Substrates & Surface Preparation. ASTM D2794 Blasted Steel 155 inch-pounds;

Dry Film Thickness 2 - 3 mils (51 - 76 microns) per coat Impact Resistance 1 ct 134 HG no visible cracking.

Gardner Impact Tester

Solids Content By Volume 70% +/- 2% ASTM D3359 Adhesion Blasted Steel 1 ct. 5A

Epoxy 1 ct 134 HG

Theoretical 2 2

1123 ft /gal at 1.0 mils (27.6 m /l at 25 microns) ASTM D3363 Hardness Blasted Steel 1 ct H

Coverage Rate 2 2 Epoxy 1 ct 134 HG

561 ft /gal at 2.0 mils (13.8 m /l at 50 microns)

2 2 ASTM D4060 Abrasion Blasted Steel 70 mg. loss after

374 ft /gal at 3.0 mils (9.2 m /l at 75 microns)

1 ct 134 HG 1000 cycles, CS17

wheel, 1000 gm. load

Allow for loss in mixing and application.

ASTM D4541 Adhesion Blasted Steel 1 ct. 2562 psi Pneumatic

VOC Values Thinner 214 25 oz/gal 2.9 lbs./gal (348 g/l) Epoxy 1 ct. 134 HG

Thinner 215 25 oz/gal 3.0 lbs./gal (362 g/l) ASTM D870 Blasted Steel 1 No rusting in the scribe;

Thinner 25 25 oz/gal 3.06 lbs./gal (366 g/l) Immersion Resistance ct. Org. Zinc 1 ct no blistering, softening

As Supplied 2.2 lbs./gal (264 g/l) Epoxy 1 ct 134 HG or discoloration either 30

These are nominal values and may vary slightly with color. days of soft water imm

Dry Temp. Continuous: 200 F (93 C) ASTM G26 Blasted Steel 1 ct. No blistering, rusting

Resistance Non-Continuous: 250 F (121 C) Weatherometer Epoxy 1 ct. 134 HG or cracking; gloss

retention of 85%;

Discoloration and loss of gloss is observed above 200F (93C).

color change of 1

Limitations *The alignment of aluminum flakes in aluminum- McAdam unit after 2000

filled finishes is very dependent on application ASTM G53 ASTM Blasted Steel 1 No rusting, blistering

conditions and techniques. Care must be taken to D4587 Accelerated ct. Org. Zinc 1 ct. or loss of adhesion;

keep conditions as constant as possible to reduce Weathering Epoxy 1 ct. 134 HG less than 5% gloss

variations in final appearance. It is also advisable to loss after 3000 hours

work from a single batch of material since variations Test reports and additional data available upon written request.

can occur from batch to batch. For more information

consult Carboline Technical Service Department.

Topcoats Carbothane 134 Clear Coat when required

Mixing & Thinning

Mixing Power mix Part A separately, then combine with Part

B and power mix. DO NOT MIX PARTIAL KITS.

September 2017 0859

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 1 of 2

Carbothane 134 HG

Mixing & Thinning Curing Schedule

Thinning Spray: Up to 25 oz/gal (20%) w/ Thinner 214 or 25 Surface Temp.

* Dry to Handle Dry to Recoat Final Cure

Brush: Up to 25 oz/gal (20%) w/ Thinner 215 & Topcoat w/ General

Roller: Up to 25 oz/gal (20%) w/ Thinner 215 other finishes

Use of thinners other than those supplied or 35 F (2 C) 36 Hours 36 Hours 14 Days

recommended by Carboline may adversely affect 50 F (10 C) 16 Hours 16 Hours 10 Days

product performance and void product warranty, 75 F (24 C) 8 Hours 8 Hours 7 Days

whether expressed or implied. Carboline Thinner

90 F (32 C) 4 Hours 4 Hours 5 Days

236E may also be used to minimize HAP and VOC

emissions. These times are based on a 2.0 mil (50 micron) dry film thickness. Higher film thickness, insufficient

ventilation or cooler temperatures will require longer cure times and could result in solvent

Ratio 4:1 Ratio (A to B) entrapment and premature failure.

*Maximum recoat times are indefinite. Surface must be clean and dry. As part of good painting

Pot Life 4 Hours at 75F (24C) and less at higher temps. Pot practice it is recommended to test for adhesion by wiping the surface with Thinner 214 or 215. If the

life ends when coating becomes too viscous to use. film shows a slight tack the surface is suitable for recoating without extensive surface preparation

such as abrading.

MOISTURE CONTAMINATION WILL SHORTEN POT Carboline Additive 101 can be used to accelerate the film forming process in this product for

LIFE AND CAUSE GELLATION. conditions outside of the parameters of this data sheet. Carboline Additive 101 is added at a rate

of 1.0-2.0 oz per mixed gallon or a maximum of 6 oz per mixed five gallons. At this addition rate,

Additive 101 will accelerate the cure rate of the urethane product between 25-40% depending on the

Application Equipment Guidelines substrate temperature range and reduce the pot life of the product by approximately 40-50% of that

stated on the product data sheet. With the use of Additive 101, this product will continue to cure at

Listed below are general equipment guidelines for the application of this product. Job site conditions temperatures as low as 20F (-7C).

may require modifications to these guidelines to achieve the desired results.

Spray Application This is a high solids coating and may require Cleanup & Safety

(General) adjustments in spray techniques. Wet film thickness

is easily and quickly achieved. Spray equipment is Cleanup Use Thinner 2 or Acetone. In case of spillage, dispose

available from manufacturers such as Binks, DeVilbiss of in accordance with local applicable regulations.

and Graco. Safety Read and follow all caution statements on this product

Conventional Pressure pot equipped with dual regulators, 3/8 data sheet and on the MSDS for this product and use

Spray I.D. minimum material hose, .070 I.D. fluid tip and personal protective equipment as directed.

appropriate air cap. Ventilation When used in enclosed areas, thorough air circulation

Airless Spray *Pump Ratio: 30:1 (min.) must be used during and after application until the

GPM Output: 3.0 (min.) coating is cured. The ventilation system should be

Material Hose: 3/8 I.D. (min.) capable of preventing the solvent vapor concentration

Tip Size: .015-.017 from reaching the lower explosion limit for the solvents

Output PSI: 2100-2400 used. User should test and monitor exposure levels

Filter Size: 60 mesh to insure all personnel are below guidelines. If not

*Teflon packings are recommended and available from able to monitor levels, use MSHA / NIOSH approved

the pump manufacturer. respirator.

Brush & Roller Multiple coats may be required to obtain desired

(General) appearance, recommended dry film thickness and Packaging, Handling & Storage

adequate hiding. Avoid excessive re-brushing or

Shelf Life Part A: Min. 36 months at 75F (24C)

rerolling. For best results, tie-in within 10 minutes at

Part B: Min. 24 months at 75F (24C)

75F (24C).

*Shelf Life: when kept at recommended storage conditions and in

Brush Recommended for touch-up only. Use a medium, original unopened containers.

natural bristle brush.

Shipping Weight 1 Gallon Kit - 13 lbs (5kg)

Roller Use a short-nap mohair roller cover with phenolic core. (Approximate) 5 Gallon Kit - 57 lbs (26 kg)

Storage 40 -110F (4-43C)

Application Conditions Temperature & 0-80% Relative Humidity

Condition Material Surface Ambient Humidity Humidity

Minimum 50 F (10 C) 35 F (2 C) 35 F (2 C) 0% Flash Point Carbothane 134 HG Part A: 50F (10C)

Maximum 100 F (38 C) 120 F (49 C) 95 F (35 C) 80% (Setaflash) Urethane Converter 811 Part B: 127F (53C)

Industry standards are for substrate temperatures to be above 5F (3C) the dew point. Storage Store Indoors.

Caution: This product is moisture sensitive in the liquid stage and until fully cured. Protect from

This product is solvent based and not affected by excursions below

high humidity, dew and moisture contact until fully cured. Application and/or curing in humidities

these published storage temperatures, down to 10F, for a duration of no

above maximum, or exposure to moisture from rain or dew may result in a loss of gloss and/or

more than 14 days. Always inspect the product prior to use to make sure

microbubbling of the product.

it is smooth and homogeneous when properly mixed.

September 2017 0859

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 2 of 2

You might also like

- Sigma Prime 200Document7 pagesSigma Prime 200Kue Nai NaiNo ratings yet

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- Jotun Penguard Midcoat MIO Application GuideDocument8 pagesJotun Penguard Midcoat MIO Application GuideSANKARAN.KNo ratings yet

- QUALITY AUDIT CHECKLIST FOR PAINTING AND BLASTINGDocument4 pagesQUALITY AUDIT CHECKLIST FOR PAINTING AND BLASTINGEyoh EffiongNo ratings yet

- Marathon XHBDocument4 pagesMarathon XHBeskim00No ratings yet

- Coating Personnel Id FormatDocument1 pageCoating Personnel Id FormatShabbar Abbas MalikNo ratings yet

- ASTM D4541 and ISO 4624: ?/sup InstrumentsDocument2 pagesASTM D4541 and ISO 4624: ?/sup InstrumentsTeguh SilaNo ratings yet

- Electrically Dissipating Mortar for Tiling and Brick LiningsDocument2 pagesElectrically Dissipating Mortar for Tiling and Brick Liningsshankarkl100% (1)

- Sheet Pile Wall: A Presentation OnDocument22 pagesSheet Pile Wall: A Presentation OnRajaNo ratings yet

- Chemtech GM Clear - English (Uk) - Issued.06.12.2007Document3 pagesChemtech GM Clear - English (Uk) - Issued.06.12.2007Mohamed Farag50% (2)

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- Inspection Check List 2Document34 pagesInspection Check List 2r.devendranNo ratings yet

- Revision Questions PA 10 Specific Page 23-12Document2 pagesRevision Questions PA 10 Specific Page 23-12Bayu Falen100% (2)

- Pts Ip Paint SystemDocument51 pagesPts Ip Paint SystemshiqinmkNo ratings yet

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFSohail Tisekar100% (1)

- ASTM D 714 - 87 r00Document6 pagesASTM D 714 - 87 r00Abi PutraNo ratings yet

- 6-Blasting and Painting Procedure - BP006Document14 pages6-Blasting and Painting Procedure - BP006mohd as shahiddin jafriNo ratings yet

- Surface Preparation and Painting ProcedureDocument25 pagesSurface Preparation and Painting ProcedureMarhadi Adi100% (1)

- SCM 400 Salt Contamination MeterDocument2 pagesSCM 400 Salt Contamination MeterJohn WatsonNo ratings yet

- Hempadur Quattro 17634 Product Data SheetDocument4 pagesHempadur Quattro 17634 Product Data Sheetulul100% (1)

- Epoxy Bedding SystemDocument2 pagesEpoxy Bedding Systempravi34340% (1)

- Powder Coating TrainingDocument22 pagesPowder Coating Trainingakash.vd.1603No ratings yet

- Painting ReportDocument1 pagePainting Reportbaidu1980No ratings yet

- Painting Procedure for Ship MaintenanceDocument7 pagesPainting Procedure for Ship MaintenanceSyaiful Arif WicaksonoNo ratings yet

- Surface Preparation & Paint Inspection ReportDocument2 pagesSurface Preparation & Paint Inspection ReportFatih DemircanNo ratings yet

- Surfacepreparation StandardDocument11 pagesSurfacepreparation StandardAri SupramonoNo ratings yet

- Subject: Method Statement For Shuttering WorksDocument5 pagesSubject: Method Statement For Shuttering WorksRounak MaheshwariNo ratings yet

- Masterprotect 190: A Two Component Solvent Free High Build Flexible Epoxy Polyurethane Resin Coating SystemDocument3 pagesMasterprotect 190: A Two Component Solvent Free High Build Flexible Epoxy Polyurethane Resin Coating SystemEngTamer100% (1)

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard Midcoatadeoye_okunoyeNo ratings yet

- High Build Epoxy Tank Lining CoatingDocument3 pagesHigh Build Epoxy Tank Lining CoatingSiDdu Kalashetti0% (1)

- Web Publish 2361972 1 A 1 Pintura DroDocument12 pagesWeb Publish 2361972 1 A 1 Pintura DroJuan Arturo Hernandez RamosNo ratings yet

- Paint ApplicationDocument4 pagesPaint ApplicationSteven FlynnNo ratings yet

- Painting Procedure For CondenceDocument26 pagesPainting Procedure For CondenceNamta GeorgeNo ratings yet

- Daily Painting Inspection Report 08Document2 pagesDaily Painting Inspection Report 08Oussama Ben AbbesNo ratings yet

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarNo ratings yet

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDocument2 pagesDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyNo ratings yet

- Jotafloor Coating: Technical Data SheetDocument5 pagesJotafloor Coating: Technical Data SheetBilher SihombingNo ratings yet

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDocument4 pagesDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanNo ratings yet

- GS-09 (Painting) PDFDocument22 pagesGS-09 (Painting) PDFSarbendu PaulNo ratings yet

- Data Sheet: Elcometer 142 ISO 8502-3 Dust Tape Test KitDocument2 pagesData Sheet: Elcometer 142 ISO 8502-3 Dust Tape Test KitDavid Frizt SiregarNo ratings yet

- 0079 - Asian Wall PuttyDocument5 pages0079 - Asian Wall Puttypravi3434No ratings yet

- D4758 Test de No VolatilesDocument2 pagesD4758 Test de No VolatilesMiguel Angel Lupaca BernalesNo ratings yet

- Zinc Plating Reports 01Document2 pagesZinc Plating Reports 01Amandeep Singh100% (1)

- 1 Insulation SupervisorDocument2 pages1 Insulation Supervisorrsamim0% (1)

- Coating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryDocument43 pagesCoating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryLarasanto Larasanto100% (1)

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Rubber Lining PrinciplesDocument5 pagesRubber Lining PrinciplesTushar MangratiNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- TDS Coat Saver Metal Primer - GeneralDocument1 pageTDS Coat Saver Metal Primer - GeneralMary Kristine0% (1)

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSfazeel mohammedNo ratings yet

- Carbothane 134 HG PDSDocument5 pagesCarbothane 134 HG PDSsanthoshkumarplNo ratings yet

- Carbothane 134 HG Polyurethane Coating MSDSDocument13 pagesCarbothane 134 HG Polyurethane Coating MSDSjgzlzNo ratings yet

- Carboline Carbothane 133 HBDocument5 pagesCarboline Carbothane 133 HBArturo SalinasNo ratings yet

- Carbothane 133 HB: Selection & Specification DataDocument5 pagesCarbothane 133 HB: Selection & Specification DatalavekushNo ratings yet

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- Carboguard 193: Selection & Specification DataDocument4 pagesCarboguard 193: Selection & Specification DataGraciele SantosNo ratings yet

- Carboguard 60: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboguard 60: Selection & Specification Data Substrates & Surface PreparationImran AhmadNo ratings yet

- F13 - Carboguard 893-Zn PDS 10-09Document2 pagesF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989No ratings yet

- FNo QualificationDocument1 pageFNo QualificationKhemaraj PathNo ratings yet

- BrochureDocument6 pagesBrochureKhemaraj PathNo ratings yet

- CWB Guide to Welding Certification RequirementsDocument8 pagesCWB Guide to Welding Certification RequirementsKhemaraj PathNo ratings yet

- BrouchureDocument8 pagesBrouchureKhemaraj PathNo ratings yet

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- Terms and ConditionsDocument10 pagesTerms and ConditionsKhemaraj PathNo ratings yet

- B31.3 2016 Acc TableDocument3 pagesB31.3 2016 Acc TablePrasan SJNo ratings yet

- Welder QualificationDocument1 pageWelder QualificationKhemaraj PathNo ratings yet

- Docslide - Us - Nace Level 1 Quiz PDFDocument5 pagesDocslide - Us - Nace Level 1 Quiz PDFKhemaraj PathNo ratings yet

- Thermaline 4900Document2 pagesThermaline 4900Khemaraj PathNo ratings yet

- Question & Answer - Module 1 NACEDocument6 pagesQuestion & Answer - Module 1 NACEraghuvarma0% (1)

- Thermaline Heat Shield PDSDocument2 pagesThermaline Heat Shield PDSKhemaraj Path100% (1)

- Carbothane 134 PDSDocument2 pagesCarbothane 134 PDSKhemaraj Path0% (1)

- Carbozinc 11Document2 pagesCarbozinc 11Khemaraj PathNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSKhemaraj PathNo ratings yet

- Carbothane 134 PDSDocument2 pagesCarbothane 134 PDSKhemaraj Path0% (1)

- CWB Guide to Welding Certification RequirementsDocument8 pagesCWB Guide to Welding Certification RequirementsKhemaraj PathNo ratings yet

- Phenoline 187 VOC PDSDocument2 pagesPhenoline 187 VOC PDSKhemaraj Path100% (1)

- Chemguard C306-MS-C 3% AFFF Concentrate: DescriptionDocument2 pagesChemguard C306-MS-C 3% AFFF Concentrate: DescriptionChyeAmshariYumanNo ratings yet

- Product Brands in Building ConstructionDocument5 pagesProduct Brands in Building Constructionfriendzel pengiNo ratings yet

- Guidelines For Specification, Welding and Inspection of Stainless Alloy Piping Craig Reid, P.EngDocument19 pagesGuidelines For Specification, Welding and Inspection of Stainless Alloy Piping Craig Reid, P.EngFinnFan8No ratings yet

- LOBP COR UPDATE MTG NOV 20 2019Document16 pagesLOBP COR UPDATE MTG NOV 20 2019MarieNo ratings yet

- Instruksi Penggunaan Webbing SlingDocument7 pagesInstruksi Penggunaan Webbing SlingRusdiana PertiwiNo ratings yet

- BondhusDocument52 pagesBondhusalphatoolsNo ratings yet

- Quality Improvement of Corn Husk As Raw Material For Textile ProductsDocument5 pagesQuality Improvement of Corn Husk As Raw Material For Textile ProductsSophie BaromanNo ratings yet

- Gasification Technology Option - Ronald Schoff, EPRIDocument34 pagesGasification Technology Option - Ronald Schoff, EPRIAnonymous 4PuFzARNo ratings yet

- Pre-PDI Form for 38-Storey Residential BlockDocument9 pagesPre-PDI Form for 38-Storey Residential BlockMohd Jamal Mohd MoktarNo ratings yet

- Project Report On Aac Block Manufacturing PlantDocument7 pagesProject Report On Aac Block Manufacturing PlantEIRI Board of Consultants and PublishersNo ratings yet

- Delhi Schedule RateDocument403 pagesDelhi Schedule RateJagdish GiriNo ratings yet

- TLE-FoodProcessing8 Q2M5Week8 OKDocument15 pagesTLE-FoodProcessing8 Q2M5Week8 OKAmelita Benignos OsorioNo ratings yet

- EM Complete NotesDocument191 pagesEM Complete NoteswsbwaqhpwpvcwuhajkNo ratings yet

- Linda - Review W CKI - 04mar20 - Increasing 10percent of Contract Unit RateDocument54 pagesLinda - Review W CKI - 04mar20 - Increasing 10percent of Contract Unit RateoktianaNo ratings yet

- BSR Imperial - RADocument179 pagesBSR Imperial - RAIccar ConstructionNo ratings yet

- BMW Center Show Room Final-01Document43 pagesBMW Center Show Room Final-01QC MEPNo ratings yet

- ABS - P430: Production-Grade Thermoplastic For Design Series 3D PrintersDocument2 pagesABS - P430: Production-Grade Thermoplastic For Design Series 3D PrintersqualityfreekNo ratings yet

- 5C1. Coal Ash Generation Process and Application FieldsDocument2 pages5C1. Coal Ash Generation Process and Application Fieldssrigirisetty208No ratings yet

- Electrical Basics: Presented By: Santosh Kumar GoudaDocument79 pagesElectrical Basics: Presented By: Santosh Kumar GoudaSantosh GoudaNo ratings yet

- CBSE Class 10 Chemistry Worksheet - Metals and Non-MetalsDocument2 pagesCBSE Class 10 Chemistry Worksheet - Metals and Non-MetalsNishant Singh100% (1)

- Wave-X HEAT Shrink Tube Solutions: Ultra Thin EMI Sheet SolutionsDocument10 pagesWave-X HEAT Shrink Tube Solutions: Ultra Thin EMI Sheet SolutionsstrubbelsNo ratings yet

- Chem Review CH 8, 9, 10, 11Document2 pagesChem Review CH 8, 9, 10, 11eherrerahghsNo ratings yet

- Timber Finish Wood SealerDocument3 pagesTimber Finish Wood SealerNippon Paint PakistanNo ratings yet

- B85B85M Inyeccion AluminioDocument10 pagesB85B85M Inyeccion AluminioAngel Vinicio Valencia RamosNo ratings yet

- Comparative Study On Ring, Rotor and Air-Jet Spun Yarn: Sharif AhmedDocument14 pagesComparative Study On Ring, Rotor and Air-Jet Spun Yarn: Sharif AhmedBithy PaulNo ratings yet

- Laying and Jointing Water PipesDocument15 pagesLaying and Jointing Water Pipesashish reddyNo ratings yet

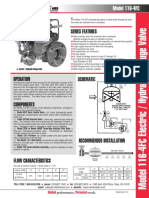

- Hoja de Datos - 116-4FCDocument2 pagesHoja de Datos - 116-4FCHenry Garavito RamirezNo ratings yet

- WWF Paper PDFDocument7 pagesWWF Paper PDFniharNo ratings yet

- Alathon L5840Document1 pageAlathon L5840mohamed1303No ratings yet

- Carbon FiberDocument4 pagesCarbon Fiberpeio.salvarreyNo ratings yet