Professional Documents

Culture Documents

Batching Plant Installation Schedule With Comment Rev 24september2017

Uploaded by

crys suryo prayogoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batching Plant Installation Schedule With Comment Rev 24september2017

Uploaded by

crys suryo prayogoCopyright:

Available Formats

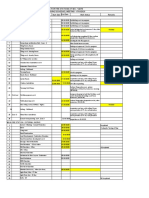

Batching Plant Setting Up Schedule

To make schedule at Site with following key point Start Concrete production shall

be after production test . It

1 Schedule for Foudation of BUMA meens that Production will

2 Schedule of USI to confirming with Project Manager Hendry (He will stay at site 2 weeks from Sep 12) start Dec.4 in eariest case

3 Check Material Availability supplied by USI and setting target receiving schedule(If not yet received)

4 Minimum Requirement for Production concrete:

(F)1Unit of Batching Plant, (G)Loading Ramp, (N)Labolatory, (C)Chiller, (J)Concrete Wash Pond

(H)Sediment Pond 1,(Q)Toilet, (R )Sewage, (T)Genset Shelter 1, Water Supply Line, Electrical Supply Line, Drainage

5 To dedicate water supply tie in point

6 Drainege must be planned at site and incorporating to This Schedule

Work Description Sep Oct Nov Dec

4 11 18 25 2 9 16 23 30 6 13 20 27 4 11 18 25

S/C Milestone 1st Concrete Casting

A WORK SHOP

Foundation USI

Container Installation USI

Roof Installation USI

B DAIRY SAND & AGGREGATE SHED

Foundation BUMA

Roof Colomn Materal Fab BUMA

Elecrion of Shed BUMA

C CHILLER & INSULATED TANK (3 ea)

Foundation USI to be confirmed BUMA on

Chiller Installation USI

25th Sep

Water Supply Line (Inside Area) USI

D CONCRETE WATER TANK

Foundation USI

Chiller Installation USI

Water Supply Line (Inside Area) USI

E West HOPPER, Mixer, Conveyor, Operation Room & 3Silos

Foudation with Anchor Bolt BUMA

Installation Hopper USI

Installation Conveyer USI

Installation Silo USI

installation Operation Room USI

Electrical Line from Generator USI

F East HOPPER, Mixer, Conveyer, Operation Room & 4 Silos

Foudation with Anchor Bolt BUMA

Installation Hopper USI Hopper Roof to be considered

Installation Conveyer USI

where necessary

Installation Silo USI

installation Operation Room USI

Electrical Line from Generator USI

G LOADING RAMP 1) Plan to Subcontract between USI & Baharu

ConcreteBund Wall BUMA will be 26th September.

Back Fill BUMA 2) Plan to start Erection work of 1st Batcing

Crushed Stone BUMA Palnt Unit from 28th September

H SEDIMENT POND 1

Size Information USI

Excavation USI

Concrete Lining w/WireMesh BUMA

I SEDIMENT POND 2 considering SIMOPS.

Size Information USI Buma will install scaffolding only one side.

Excavation USI (other than Hoppoer side).

Concrete Lining w/WireMesh BUMA to carry out Retaining Wall work.

J CONCRETE WASH POND

Size Information USI

Concrete Paving w/WireMesh BUMA

K CRUSHER MACHINE

Gravel Paving BUMA

L CONCRETE WASTE AREA

Gravel Paving BUMA

M CURING PONDSteel Pond)

Excavation USI

Installation USI

Back Fill USI

N LABORATORY DELIVERY CHECK

Foundation USI

Laboratory (Container) Installation USI

Air Conditioner USI

Water Supply Line (Inside Area) or Small Tank USI

Electrical Line from Generator (P)Office Area

O REST AREA

Installation w/o Fdn USI

P OFFICE AREA

Foundation USI

Office Installation USI

Generator Installation w/Steel Pan etc. USI

Q TOILET

Foundation USI

Toilet Installation USI

R SEWAGE (Septic Tank) 4nos of site toilet is under

Excavation USI operation in batching Plant Area. it

Septic Tank Installation USI can be utilized in initial stage.

Back Fill USI

S STOCK CEMENT SHELTER

Foundation BUMA

Roof Colomn Materal Fab BUMA

Elecrion of Shed BUMA

T GENSET SHELTER 1 Strat Concrete production shall be

Size Information USI after production test . It meens

Concrete Pave w/Dike BUMA that Production will start Dec.4

Generator/Panel Installtion USI in eariest case

U GENSET SHELTER 2

Size Information USI

Concrete Pave w/Dike BUMA

Generator/Panel Installtion USI

CARIBLATION USI

PRODUCTION TEST USI

USI will arrange Government Authorities and PT DDT

to get certificate & calibartion for Batching Plant

You might also like

- TBPP CON 01 CM MSM 0009 D Method Statement of Quay Deck ConstructionDocument522 pagesTBPP CON 01 CM MSM 0009 D Method Statement of Quay Deck ConstructionMr BanditNo ratings yet

- 04-MAIN-VILLA - (Stand Alone (Nargis) ) Final Price-11-12-2019Document22 pages04-MAIN-VILLA - (Stand Alone (Nargis) ) Final Price-11-12-2019jatinNo ratings yet

- Chapter 3 Pile Construction SequenceDocument22 pagesChapter 3 Pile Construction SequenceFitsumbirhan AmanuelNo ratings yet

- Naima GuideDocument36 pagesNaima GuideJebús Eduardo MenesesNo ratings yet

- U - Value Reference TableDocument4 pagesU - Value Reference Tableksa_hishamNo ratings yet

- Metro world mall 1st RA bill abstract sheetDocument15 pagesMetro world mall 1st RA bill abstract sheetpranjal malikNo ratings yet

- XD PDFDocument36 pagesXD PDFPudu MounikaNo ratings yet

- Villa - Interior B.O.Q. (Egypt)Document30 pagesVilla - Interior B.O.Q. (Egypt)Moustapha AlgoharyNo ratings yet

- eProcurement System Government of Uttar Pradesh Construction ProjectDocument4 pageseProcurement System Government of Uttar Pradesh Construction ProjectDeepak Sonkar100% (1)

- 4 Point Inspection FormDocument3 pages4 Point Inspection Formsendmattanemail4346No ratings yet

- GreenGlobes PresentationDocument28 pagesGreenGlobes PresentationAlexander CaicedoNo ratings yet

- WP 010813Document7 pagesWP 010813Mohammad Syourkam ZakariaNo ratings yet

- 374 Provisional Extension of Time (EOT) For Completion Under Article 10 Clause 10.5 of EPC Agriment 22-06-17 Executed Between The AuthorityDocument9 pages374 Provisional Extension of Time (EOT) For Completion Under Article 10 Clause 10.5 of EPC Agriment 22-06-17 Executed Between The AuthorityAjay GuptaNo ratings yet

- Circular On Calibration of Equipment For Pile Load TestDocument8 pagesCircular On Calibration of Equipment For Pile Load TestAnonymous hhdd4mOmOhNo ratings yet

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingDocument9 pages7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresNo ratings yet

- Weekly Lookhead and Weekly Progress ReportDocument2 pagesWeekly Lookhead and Weekly Progress ReportAnonymous Xb3zHioNo ratings yet

- 2.2.4 Construction Schedule For Mechanical WorkDocument2 pages2.2.4 Construction Schedule For Mechanical WorkĐình Nam100% (1)

- Lifting PlanDocument12 pagesLifting Plangeriaxavier2022No ratings yet

- Larsen and Toubro's Substructure Waterproofing MethodDocument6 pagesLarsen and Toubro's Substructure Waterproofing MethodGaneshNo ratings yet

- 40 Cubic Meter Concrete Batching PlantDocument11 pages40 Cubic Meter Concrete Batching PlantRanndolf JavierNo ratings yet

- Work Order for Culvert and Bridge ConstructionDocument5 pagesWork Order for Culvert and Bridge ConstructionLaxmipathi Rao LakkarajuNo ratings yet

- A-U00-C-Ms-2042-000-Crs-00c - Method Statement For Shoreline Protection - DaDocument14 pagesA-U00-C-Ms-2042-000-Crs-00c - Method Statement For Shoreline Protection - DaKurnia AryadiNo ratings yet

- EPC4 Weekly Report Highlights Progress and SafetyDocument7 pagesEPC4 Weekly Report Highlights Progress and SafetyMarkyNo ratings yet

- ZCC850H: 85 Ton CapacityDocument8 pagesZCC850H: 85 Ton CapacityYulianto JoeNo ratings yet

- Bar Bending Schedule of Box CulvertDocument8 pagesBar Bending Schedule of Box Culvertluchio correiaNo ratings yet

- EXW P006 0000 MQ SHC MS 00014 SubmittalDocument216 pagesEXW P006 0000 MQ SHC MS 00014 SubmittalRaheelHashmiNo ratings yet

- 2 - Detailed Project Recoveryrec Schedule As of May2014Document46 pages2 - Detailed Project Recoveryrec Schedule As of May2014raza.slietNo ratings yet

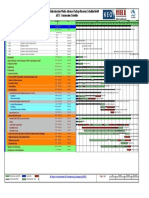

- North/South DEFA Water Injection Pipeline System Manpower HistogramDocument3 pagesNorth/South DEFA Water Injection Pipeline System Manpower HistogramMoaatazz Nouisri0% (1)

- Concrete Batching PlantDocument8 pagesConcrete Batching PlantJerry TomNo ratings yet

- CAST IN-SITU WORKSDocument30 pagesCAST IN-SITU WORKSBhargav BbvsNo ratings yet

- Car Park Shed Additional ScopeDocument12 pagesCar Park Shed Additional ScopeRupesh GenesisNo ratings yet

- RCC Piling MethodDocument21 pagesRCC Piling MethodArju AbedinNo ratings yet

- Bihar Urban Infrastructure Development Corporation Ltd. Drinking Water Supply SchemeDocument19 pagesBihar Urban Infrastructure Development Corporation Ltd. Drinking Water Supply Schemesumit249100% (1)

- Myanmar Aquarium Daily Construction ReportDocument3 pagesMyanmar Aquarium Daily Construction ReportNwe Oo100% (1)

- Scope of Work Dismantling and Installation Wall and Roof Cladding at Compressor House Unit 1520Document21 pagesScope of Work Dismantling and Installation Wall and Roof Cladding at Compressor House Unit 1520muhamadrafie1975No ratings yet

- CW Pump Station Rev01Document3 pagesCW Pump Station Rev01karna@No ratings yet

- Napsa Stars House Remodelling Mobilisation ScheduleDocument1 pageNapsa Stars House Remodelling Mobilisation ScheduleWoodlock Limited0% (1)

- Proposal For Maintenance of Iyana Ipaja Bridge (New Lagos - Abeokuta Dual Carriageway) in Lagos StateDocument9 pagesProposal For Maintenance of Iyana Ipaja Bridge (New Lagos - Abeokuta Dual Carriageway) in Lagos Stateadetokunbo fapuroNo ratings yet

- L9 - Construction Methodology - 1Document20 pagesL9 - Construction Methodology - 1J. Kumar Infraprojects LtdNo ratings yet

- MS 130 - Construction of P.S Manhole Rev 0Document9 pagesMS 130 - Construction of P.S Manhole Rev 0ahmed maherNo ratings yet

- 20.312 - D25 - Rev 01 Site Installation Method StatementDocument34 pages20.312 - D25 - Rev 01 Site Installation Method StatementLuz ArazolaNo ratings yet

- Lifting Permit Permit ASM4Document1 pageLifting Permit Permit ASM4HSE Health Safety EnvironmentNo ratings yet

- Construction Planning Reviewed May 2018Document8 pagesConstruction Planning Reviewed May 2018Bishan Shrestha100% (1)

- Site Works Scheduel Meeting - 17/10/2020: Epic For Fire Stations at Mic - 143/18Document2 pagesSite Works Scheduel Meeting - 17/10/2020: Epic For Fire Stations at Mic - 143/18HariKumar PNo ratings yet

- Quotation SupplyDocument6 pagesQuotation SupplyShaikhMazharAhmedNo ratings yet

- Building Construction Schedule 2Document8 pagesBuilding Construction Schedule 2Mohanad SulimanNo ratings yet

- Chimney Windshield OperationDocument19 pagesChimney Windshield Operationsimple_aniNo ratings yet

- Monthly Project Progress ReportDocument3 pagesMonthly Project Progress Reportm-ravNo ratings yet

- HZS75 Concrete Batching Plant 2Document20 pagesHZS75 Concrete Batching Plant 2zhenheng100% (1)

- KR Parco Ps6 Ms 0001 M.S For ConcreteDocument11 pagesKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeNo ratings yet

- Microsoft Office Project - STP Schedual Phase-IIDocument1 pageMicrosoft Office Project - STP Schedual Phase-IImumtaz796100% (1)

- Ready Mix Concrete EssentialsDocument3 pagesReady Mix Concrete EssentialsYoga Raj0% (1)

- Construction ScheduleDocument1 pageConstruction ScheduleAamir AwanNo ratings yet

- CMW 11113 D001 G P 5003 PDFDocument1 pageCMW 11113 D001 G P 5003 PDFaqueelengNo ratings yet

- PT. PAKUBUMI SEMESTA Bored Piling MethodDocument19 pagesPT. PAKUBUMI SEMESTA Bored Piling MethodjimdabrondNo ratings yet

- BOQ of Pipe Sleepers-SwccDocument2 pagesBOQ of Pipe Sleepers-SwccjatinNo ratings yet

- BCB Solutions Business ProfileDocument9 pagesBCB Solutions Business ProfileJacaranda FM NewsNo ratings yet

- Tools & Tackles Monthly InspectionDocument4 pagesTools & Tackles Monthly InspectionDeepu ChandranNo ratings yet

- Construction of Batinah Expressway Package.5 Revised Programme of Works - DD: 30 October 2016Document3 pagesConstruction of Batinah Expressway Package.5 Revised Programme of Works - DD: 30 October 2016Tahir YousafzaiNo ratings yet

- Tracked Program of WorksDocument2 pagesTracked Program of WorksEliphas Quabe IVNo ratings yet

- Tac Company Profile 2012Document33 pagesTac Company Profile 2012vista_serverNo ratings yet

- Bored Pile BBS (8m) - Jan 30, 2019Document2 pagesBored Pile BBS (8m) - Jan 30, 2019Jimmy PimentelNo ratings yet

- ITP LTS - v3Document2 pagesITP LTS - v3fargoNo ratings yet

- Speed Deck 508: Metal Roof & Wall Cladding SystemDocument6 pagesSpeed Deck 508: Metal Roof & Wall Cladding SystemMuraleedharanNo ratings yet

- Method Statement For Hume Pipe CulvertDocument6 pagesMethod Statement For Hume Pipe CulvertRabnawaz Imam0% (1)

- Resources Histogram, Planned VS ActualDocument6 pagesResources Histogram, Planned VS ActualburereyNo ratings yet

- July 31 Location Description Activity WHO Due Date Finish Date Remarks Materials Manpower StatusDocument7 pagesJuly 31 Location Description Activity WHO Due Date Finish Date Remarks Materials Manpower StatusPaooieNo ratings yet

- Material Take-Off List: Wbs-4 Expense (Demolition/Sec)Document135 pagesMaterial Take-Off List: Wbs-4 Expense (Demolition/Sec)Jonald DagsaNo ratings yet

- HSE - Safety Gas Welding & Cutting PDFDocument16 pagesHSE - Safety Gas Welding & Cutting PDFcrys suryo prayogoNo ratings yet

- Capture Remaining WorkDocument1 pageCapture Remaining Workcrys suryo prayogoNo ratings yet

- Recommended velocities or frictional ΔP / 100 ft (physical length) of pipelinesDocument2 pagesRecommended velocities or frictional ΔP / 100 ft (physical length) of pipelinescrys suryo prayogoNo ratings yet

- Rust DegreeDocument2 pagesRust Degreecrys suryo prayogoNo ratings yet

- DataNickelSilverRBCuZn DDocument1 pageDataNickelSilverRBCuZn Dcrys suryo prayogoNo ratings yet

- Font MapDocument3 pagesFont Mapapi-3824713No ratings yet

- Water & Waste TreatmentDocument225 pagesWater & Waste Treatmentcrys suryo prayogoNo ratings yet

- Read MeDocument2 pagesRead MeDessy AlvNo ratings yet

- Water & Waste Treatment PDFDocument225 pagesWater & Waste Treatment PDFcrys suryo prayogoNo ratings yet

- Font MapDocument3 pagesFont Mapapi-3824713No ratings yet

- DataNickelSilverRBCuZn DDocument1 pageDataNickelSilverRBCuZn Dcrys suryo prayogoNo ratings yet

- DataNickelSilverRBCuZn DDocument1 pageDataNickelSilverRBCuZn Dcrys suryo prayogoNo ratings yet

- Toeic Strategies PDFDocument58 pagesToeic Strategies PDFcrys suryo prayogoNo ratings yet

- Chonoco PDFDocument2 pagesChonoco PDFcrys suryo prayogoNo ratings yet

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizNo ratings yet

- Cover PDFDocument1 pageCover PDFcrys suryo prayogoNo ratings yet

- ChonocoDocument2 pagesChonococrys suryo prayogoNo ratings yet

- Flowchart - IRN Realease - 01Document1 pageFlowchart - IRN Realease - 01crys suryo prayogoNo ratings yet

- ASME B31.3 Interpretations No. 14: General Information BeenDocument10 pagesASME B31.3 Interpretations No. 14: General Information Beenchuck_sbNo ratings yet

- Lesson 10 - 1Document1 pageLesson 10 - 1crysNo ratings yet

- Camp/ Location Name of Modules Cluster Total of RoomDocument2 pagesCamp/ Location Name of Modules Cluster Total of Roomcrys suryo prayogoNo ratings yet

- Sno Q Wen Rfi 076Document9 pagesSno Q Wen Rfi 076crys suryo prayogoNo ratings yet

- RFI Inspection RequestDocument12 pagesRFI Inspection Requestcrys suryo prayogoNo ratings yet

- Final Inspection Check ListDocument16 pagesFinal Inspection Check Listcrys suryo prayogoNo ratings yet

- Manpower Daily Time Sheet (General) - Mech (1-15 Mar 2015)Document316 pagesManpower Daily Time Sheet (General) - Mech (1-15 Mar 2015)crys suryo prayogoNo ratings yet

- Request For Inspection: Tripatra-Samsung ConsortiumDocument11 pagesRequest For Inspection: Tripatra-Samsung Consortiumcrys suryo prayogoNo ratings yet

- Request For Inspection: (Client Name)Document19 pagesRequest For Inspection: (Client Name)crys suryo prayogoNo ratings yet

- Padding Inspection ReportsDocument80 pagesPadding Inspection Reportscrys suryo prayogoNo ratings yet

- Brosur Raised Floor DealerDocument13 pagesBrosur Raised Floor DealerMuchsin Mansyur100% (2)

- Rates Analysis for Building WorksDocument8 pagesRates Analysis for Building WorksyogeshNo ratings yet

- NSAI CertDocument24 pagesNSAI CertmdbeukelNo ratings yet

- Class A Loading (Two Lane) Deck SlabDocument8 pagesClass A Loading (Two Lane) Deck SlabSUPERINTENDING ENGINEERNo ratings yet

- Construction of New Storefront and InteriorsDocument1 pageConstruction of New Storefront and InteriorsconeyquNo ratings yet

- Shah Alam Bungalow DemolitionDocument4 pagesShah Alam Bungalow DemolitionteeyuanNo ratings yet

- Brick Masonry RateDocument3 pagesBrick Masonry RateSam Roger100% (1)

- Geogrid Spec GuidelinesDocument4 pagesGeogrid Spec GuidelineshahaerNo ratings yet

- Saudi Aramco Inspection Checklist: Battery Room HVAC Requirements SAIC-K-4046 HvacDocument2 pagesSaudi Aramco Inspection Checklist: Battery Room HVAC Requirements SAIC-K-4046 HvacshahzadaNo ratings yet

- Licensed To Arun Kumar Das: Amendment No. Se'Rimber ToDocument2 pagesLicensed To Arun Kumar Das: Amendment No. Se'Rimber ToOMEGA CONSULTANT SERVICESNo ratings yet

- New AVME EXPORT-20220530 - 090509Document4,936 pagesNew AVME EXPORT-20220530 - 090509Muthukumaran TNo ratings yet

- Review of Related Literature: TH TH THDocument4 pagesReview of Related Literature: TH TH THCheryl GetongoNo ratings yet

- Vertical Wall Earthbag HomesDocument4 pagesVertical Wall Earthbag Homesdanut_docNo ratings yet

- Utility Change OrderDocument6 pagesUtility Change Ordersimeon james villacrusisNo ratings yet

- SECTION 09 06 00 Schedule For FinishesDocument66 pagesSECTION 09 06 00 Schedule For FinishesRima Baz FadousNo ratings yet

- Group PPT BCDocument17 pagesGroup PPT BCNitesh KumarNo ratings yet

- Private Wing Building Project ScheduleDocument1 pagePrivate Wing Building Project SchedulehasanplanningNo ratings yet

- Recycled Aggregate Concrete Presentation SummaryDocument23 pagesRecycled Aggregate Concrete Presentation SummarynemsharuNo ratings yet

- Habitat 67's 354 Prefab Concrete Cubes Form Unique Montreal HousingDocument4 pagesHabitat 67's 354 Prefab Concrete Cubes Form Unique Montreal Housingsrividhya raghavan100% (1)

- Cooler Catalogue PDFDocument12 pagesCooler Catalogue PDFCărunta-Crista CristinaNo ratings yet

- Roof Ponding and Sprinkled Roof: Bs-IiiDocument8 pagesRoof Ponding and Sprinkled Roof: Bs-IiiPriya UdamaleNo ratings yet

- Building Construction WoodDocument30 pagesBuilding Construction WoodDaryl Gomez Timatim100% (1)

- Investor: Municipality of Devoll, Undp Object: Multifunctional Social Centre - Bilisht, Devoll Works Cost EstimateDocument6 pagesInvestor: Municipality of Devoll, Undp Object: Multifunctional Social Centre - Bilisht, Devoll Works Cost EstimateGezim GezimNo ratings yet