Professional Documents

Culture Documents

A

Uploaded by

akranganOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A

Uploaded by

akranganCopyright:

Available Formats

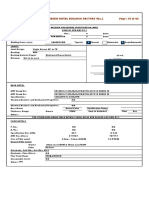

Prepared by: WELDING PROCEDURE Identification # DEMO-FCAW

WPSAmerica.com

SPECIFICATION (WPS) Ref. Code AWS D1.3

Company Name: www.WPSAmerica.com

PQR No. PREQUALIFIED

Address: info@WPSAmerica.com, Toll Free: 1 (877) WPS-WELD

Process FCAW Process Type Semi-Automatic Positions F, H, V (up), OH

Base Metals Steels in Groups I and II of Table 1.2 of AWS D1.3

Filler Metals AWS A5.20: E71T-11, E71T-11 H16 (FCAW-S)

Shielding Gas Flow Rate N/A

Self-Shielded (FCAW-S)

Flux (SAW) Nozzle Dia. 5/8 in

Weld Type Partial Joint Penetration Groove Weld Current/ Polarity DCEN

Electrical Stick Out Preheat / 0 °C (32 °F), Clause 5.1-AWS D1.3

1/2 to 3/4

Interpass Temp., Min Surfaces free from moisture

ESO (in)

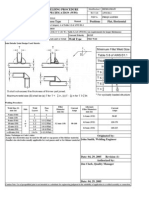

Joint Details/ Joint Design Used/ Sketch:

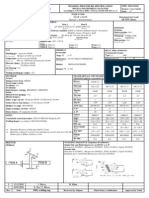

Welding Procedure:

Thickness (T) Weld Size Weld Pass Filler Metal Current Wire Feed Speed Travel Speed

mm (in) ETT (E) Side Layers No. Diameter Amps Volts (IPM) (IPM)

mm (in)

From 18 Ga. Min. 120 15 70

to range shown in

Sketch As shown 1.1/ 1.2 mm 140 16 90

1 1 to 2 1 to 2 10 to 25

in Sketch (0.045) 160 17 110

170 18 130

Notes, Technique or Code’s rules: Originated by:

-Depending upon welding position, weld type, surface condition or other factors,

voltage and/or wire feed speed may need to be adjusted. John Smith, Welding Engineer

-Thicker sheets may need more than 1 layer and pass.

Date: 04, 29, 2005 Revision (1)

Authorized by:

Jim Clark, Quality Manager

Date: 04, 29, 2005

Caution Note: Use of prequalified joint is not intended as a substitute for engineering judgment in the suitability of application to a welded assembly or connection.

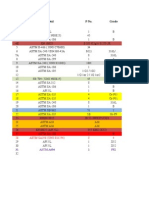

You might also like

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 pageWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- Welder Test Param19!03!201211Document151 pagesWelder Test Param19!03!201211VapaVapaNo ratings yet

- General Format For Girder Fabrication Check ListDocument4 pagesGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNo ratings yet

- Fit Up Inspection Report-10Document57 pagesFit Up Inspection Report-10rizky youlandaNo ratings yet

- POSCO SS VN - Inspection Testing Plan - ITPDocument4 pagesPOSCO SS VN - Inspection Testing Plan - ITPNguyen Anh Tuan100% (1)

- MATERIAL TRACKING LISTDocument2 pagesMATERIAL TRACKING LISTgopaltryNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Welder Qualification Register 01Document3 pagesWelder Qualification Register 01Andrei UrsacheNo ratings yet

- WPS MCC 001 PDFDocument1 pageWPS MCC 001 PDFNuwan RanaweeraNo ratings yet

- Welder and Welder Operator Qualification Record FormDocument1 pageWelder and Welder Operator Qualification Record FormNanaba Nanayaw DwomohNo ratings yet

- List Welder PT - InstrucomDocument4 pagesList Welder PT - InstrucomHerlan HutabaratNo ratings yet

- Company Logo Added to QAP DocumentDocument4 pagesCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- Asirusa WPS-P-002 1FDocument5 pagesAsirusa WPS-P-002 1FWalter RuedaNo ratings yet

- INSPECTION REPORT TITLEDocument7 pagesINSPECTION REPORT TITLEABEC Trombay siteNo ratings yet

- Base Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4Document3 pagesBase Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4MAT-LIONNo ratings yet

- 03 Fish Bone DiagramDocument1 page03 Fish Bone DiagramShannon MacDonaldNo ratings yet

- QCF113 Structural Steel Pre-Fabrication CertificateDocument1 pageQCF113 Structural Steel Pre-Fabrication CertificateminhnnNo ratings yet

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Monitoring & MeasurementsDocument158 pagesMonitoring & MeasurementsaszlizaNo ratings yet

- Welding ReportDocument52 pagesWelding ReportalidadNo ratings yet

- Itp GRPDocument4 pagesItp GRPJo FrancescNo ratings yet

- Record of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014Document2 pagesRecord of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014cisar0007No ratings yet

- Back Weld Repair Procedure QualificationDocument15 pagesBack Weld Repair Procedure QualificationFelipe Vásquez ArribasplataNo ratings yet

- QF Qa 30 Visual Dimension Final Inspection ReportDocument8 pagesQF Qa 30 Visual Dimension Final Inspection ReportVikas Mani TripathiNo ratings yet

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- Standard QAPDocument9 pagesStandard QAPsivaNo ratings yet

- Poster Welding P VoxXa PDFDocument1 pagePoster Welding P VoxXa PDFAd Man GeTigNo ratings yet

- KBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3Document4 pagesKBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3kamlNo ratings yet

- Approved Weld Procedure SpecificationsDocument38 pagesApproved Weld Procedure SpecificationsJohan0001No ratings yet

- Inspection and Test Plan for TEA Product CoolerDocument7 pagesInspection and Test Plan for TEA Product CoolerJamal Mohamed Rahamathullah100% (1)

- MTH - Spec Cross-Ref Chartr1Document1 pageMTH - Spec Cross-Ref Chartr1RamuAlagappanNo ratings yet

- Thermal Power Project Weld Inspection ReportDocument1 pageThermal Power Project Weld Inspection ReportAshwani DograNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Is 7215 Tolerances For Fabrication of Steel Structures R0.183135154Document24 pagesIs 7215 Tolerances For Fabrication of Steel Structures R0.183135154rikumohan100% (1)

- Pipe Sizes and DimensionsDocument10 pagesPipe Sizes and DimensionsAbuAhmedQuaziNo ratings yet

- Weld Map # of (Total Quantity) : NotesDocument29 pagesWeld Map # of (Total Quantity) : NotesAbrahamNo ratings yet

- Saudi Aramco Dow Arabia (MFC) Project As Run Data Sheet: Sub-Contractor Welding Inspector DAELIM Welding InspectorDocument1 pageSaudi Aramco Dow Arabia (MFC) Project As Run Data Sheet: Sub-Contractor Welding Inspector DAELIM Welding InspectorSiddiqui Abdul Khaliq100% (1)

- 30 - Painting ProcedureDocument12 pages30 - Painting ProcedureNguyen Anh TuanNo ratings yet

- WPS TemplateDocument3 pagesWPS TemplateAldin MemidzanNo ratings yet

- WPS FormatDocument2 pagesWPS FormatHarshit AdwaniNo ratings yet

- Fit-Up Inspection ReportDocument27 pagesFit-Up Inspection ReportAlfian ImaduddinNo ratings yet

- Steel Material Table PDFDocument1 pageSteel Material Table PDFNathanNo ratings yet

- Welding & NDE Summary Sheet (BE)Document12 pagesWelding & NDE Summary Sheet (BE)MulPXNo ratings yet

- IS 2062 Structural Steel GuideDocument10 pagesIS 2062 Structural Steel GuideJagjeet SinghNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNo ratings yet

- Welder's Master ListDocument8 pagesWelder's Master ListAnonymous rYZyQQot55No ratings yet

- Welding Procedure Specification (WPS) : Demo-SmawDocument1 pageWelding Procedure Specification (WPS) : Demo-SmawakranganNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Welding Procedure Specification PresentasiDocument3 pagesWelding Procedure Specification PresentasiHASIM HASIMNo ratings yet

- 07 SMAW 332 18 532 332 E7018 Prequalified WPSsDocument82 pages07 SMAW 332 18 532 332 E7018 Prequalified WPSsErick VazquezNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Field Welding Procedure (HOIST CYLINDER BALL AND LIFT ARM BALL)Document33 pagesField Welding Procedure (HOIST CYLINDER BALL AND LIFT ARM BALL)Aamir AshinNo ratings yet

- Onshore Offshore Construction WPSDocument2 pagesOnshore Offshore Construction WPSeliskal bahar100% (1)

- Medium and high-strength ferritic weld deposits tensile properties challengeDocument11 pagesMedium and high-strength ferritic weld deposits tensile properties challengebiancogallazziNo ratings yet

- Welding Procedure Specification (WPS) : Demo-SmawDocument1 pageWelding Procedure Specification (WPS) : Demo-SmawakranganNo ratings yet

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- AWS WPQR WPS FormularioDocument1 pageAWS WPQR WPS FormularioAntonio RuscittoNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Solda DorNo ratings yet

- ADocument1 pageAakranganNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Solda DorNo ratings yet

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Welding Procedure Specification (WPS) : Demo-SmawDocument1 pageWelding Procedure Specification (WPS) : Demo-SmawakranganNo ratings yet

- By J. Chandler, C. Clasper, S. Liu, and G. Edwards Colorado School of MinesDocument2 pagesBy J. Chandler, C. Clasper, S. Liu, and G. Edwards Colorado School of MinesakranganNo ratings yet

- AWS WPQR WPS FormularioDocument1 pageAWS WPQR WPS FormularioAntonio RuscittoNo ratings yet

- Pipe Sizing for Hot and Cold Water SystemsDocument2 pagesPipe Sizing for Hot and Cold Water SystemsdosandosanNo ratings yet

- Pages From EPRI EL-6800Document6 pagesPages From EPRI EL-6800981002No ratings yet

- IS 8196-2004 (RA 2019) - Steel Cylinder For Compressed GasDocument18 pagesIS 8196-2004 (RA 2019) - Steel Cylinder For Compressed GasA N MadhavanNo ratings yet

- ATC-115+Roadmap Final 022715Document197 pagesATC-115+Roadmap Final 022715Nestor Walter Barrera RomeroNo ratings yet

- Chemistry Test Chapter 7 ElectrolysisDocument3 pagesChemistry Test Chapter 7 ElectrolysisamirNo ratings yet

- Welding ProcedureDocument1 pageWelding Procedurewseekell100% (1)

- Stress TransformationDocument22 pagesStress TransformationTran Manh HuyNo ratings yet

- Rhodes Solutions Ch14Document7 pagesRhodes Solutions Ch14Joson ChaiNo ratings yet

- Class 6 Science: Shah SeriesDocument16 pagesClass 6 Science: Shah SeriesAgha Khan DurraniNo ratings yet

- Integrated Reservoir ModelingDocument24 pagesIntegrated Reservoir Modelingc_b_umashankarNo ratings yet

- 10th MG Cup 2022 Physics English ProblemsDocument12 pages10th MG Cup 2022 Physics English Problemsmilos9444No ratings yet

- Casting Defects 6Document36 pagesCasting Defects 6AnuskaNo ratings yet

- Experiment 2: Brinell Hardness TestDocument5 pagesExperiment 2: Brinell Hardness TestseifNo ratings yet

- NHC Report On Hurricane IanDocument72 pagesNHC Report On Hurricane IanABC Action NewsNo ratings yet

- Force of FrictionDocument30 pagesForce of FrictiongearnhaleNo ratings yet

- Tugas 09 MEH - Pembahasan MAT FEMDocument157 pagesTugas 09 MEH - Pembahasan MAT FEMEristra ErnawanNo ratings yet

- Air Ejector Selection PDFDocument9 pagesAir Ejector Selection PDFmyungkwan haNo ratings yet

- 01 High Expansion Foam SystemsDocument4 pages01 High Expansion Foam SystemsDenys Castañeda TerrazosNo ratings yet

- Science Year 10 Exam Paper ReviewDocument11 pagesScience Year 10 Exam Paper ReviewGaayathri PancharatnamNo ratings yet

- Tutorial Answers Only 2002Document7 pagesTutorial Answers Only 2002Ahmed MoustafaNo ratings yet

- Lab02 Pressure WorksheetDocument3 pagesLab02 Pressure WorksheetFawadAkhtar100% (1)

- Introduction To Molecular Spectros PDFDocument333 pagesIntroduction To Molecular Spectros PDFmekoki86% (7)

- Rev11 en Manual Piclassic CutDocument12 pagesRev11 en Manual Piclassic Cutmausanchezmej.ingenieriaNo ratings yet

- WPS PQR Checklist 2021 by WeldassistantDocument2 pagesWPS PQR Checklist 2021 by WeldassistantŞhallaw R. QadirNo ratings yet

- CMM MQCDocument36 pagesCMM MQCThanigaivel ANo ratings yet

- Solar Radiation Measuring InstrumentsDocument14 pagesSolar Radiation Measuring InstrumentsadityapalsinghNo ratings yet

- HANDRAILDocument3 pagesHANDRAILGaneshalingam Ramprasanna2No ratings yet

- 2nd Training SessionDocument37 pages2nd Training SessionHimanshu SharmaNo ratings yet

- Pet Engineering College Department of Mechanical EngineeringDocument3 pagesPet Engineering College Department of Mechanical EngineeringAHAMED SULBIHAR MNo ratings yet

- SKIE MEGA COMBAT TEST SERIESDocument4 pagesSKIE MEGA COMBAT TEST SERIEScharsi anjumNo ratings yet